#Bimetal band saw

Text

Bimetal and Carbide Band Saw Blade Market to Witness Huge Growth by 2030

The bimetal and carbide band saw blade market refers to the global industry involved in the production, distribution, and sales of band saw blades made from bimetal and carbide materials. Band saw blades are cutting tools used in various industries for cutting and shaping materials such as wood, metal, plastics, and more.

For Sample Report Click Here:-https://www.marketinforeports.com/Market-Reports/Request-Sample/511531

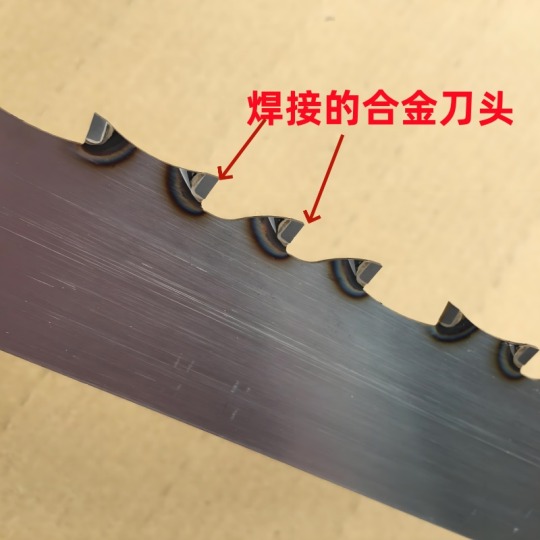

Bimetal band saw blades are composed of two different materials, typically high-speed steel (HSS) teeth welded onto a flexible steel backing. This combination provides the blade with high cutting performance, durability, and resistance to heat and wear. Bimetal blades are commonly used for cutting metal, especially in metalworking and fabrication industries.

On the other hand, carbide band saw blades feature teeth made from tungsten carbide, a hard and durable material that provides excellent cutting performance and extended blade life. These blades are particularly suitable for cutting hard and abrasive materials such as exotic alloys, stainless steel, and other difficult-to-machine metals.

The bimetal and carbide band saw blade market is driven by various factors, including the growth of industries such as manufacturing, construction, automotive, and aerospace. These industries demand efficient and precise cutting tools to meet their production requirements. Bimetal and carbide blades offer superior cutting capabilities compared to conventional blades, leading to increased adoption in industrial applications.

Moreover, advancements in blade manufacturing technologies, such as laser cutting and precision grinding, have improved the overall quality and performance of bimetal and carbide band saw blades. These advancements have further fueled the market growth by enabling the production of blades with higher cutting speeds, improved chip evacuation, and extended blade life.

The market is highly competitive, with several key players operating globally. These companies focus on product development, innovation, and expanding their distribution networks to gain a competitive edge. Additionally, manufacturers often offer a range of blade sizes and configurations to cater to different customer requirements.

Overall, the bimetal and carbide band saw blade market is expected to continue growing due to the increasing demand for efficient cutting tools in various industries. Technological advancements and ongoing product innovations are likely to drive further improvements in blade performance and expand the applications of bimetal and carbide band saw blades in the future.

0 notes

Text

Sadguru Enterprises is the best quality Bimetal band saw blade manufacturers, suppliers, dealers in Pune, Maharashtra. Quality across our product range is the ultimate and overriding motivation for our organization, so we make every effort to supply only products that meet prescribed industry standards.

#Bimetal band saw blade manufacturers in pune#Bimetal band saw blade suppliers in pune#Bimetal band saw blade dealers in pune#Bimetal band saw blade in pune

0 notes

Text

NC Controlled Bandsaw Machine Manufacturer in India - ITL

NC Fully Automatic Bandsaw Machine

Cutting metal, wood and other materials is a complex task when it is done with hand tools, consuming a lot of time, money and manpower to complete a task.

Keeping this in mind, we offer our clients NC Fully Automatic Band Saw Machine to enhance their productivity in an efficient and precise manner. Based on their versatility, these machines are used in workshops and automotive industries.

Our offered NC Fully Automatic Band Saw Machine offers best quality and highly remarkable durability and reliability for quick and efficient cutting operations on various materials having various shapes and sizes.

Characteristic:

• Stepless cutting feed regulation.

• Hydraulic full stroke clamping.

• Provides auto feature with suggestions.

• Action takes place on the project.

• Fast moving.

INDIA’S BEST INDUSTRIAL BAND SAW MANUFACTURER

ITL Industries Limited introduced India’s first Carbide Circular Saw Metal Cutting Machine and offered 7 different NC Controlled Bandsaw Machines for cutting 50mm to 200mm diameter bars to meet the needs of engineering industries.

ITL has supplied and commissioned more than 1000 machines in India and abroad (USA, Canada, Mexico, Italy, Spain, Ireland, Taiwan etc.).

With the aid of our experienced professionals, we are engaged in manufacturing, supplying and exporting High-Speed Numerically Controlled Circular Sawing Machines with TCT & HSS Cutter. These cutters are manufactured in compliance with the industry set standards and hence are highly appreciated by the clients.

#Sawing Machines#bandsaw cutting machine#metal band saw blades#Bimetal band saw blades#Numerical Controlled Circular Sawing Machine#Circular Saw Machine#Semi Automatic Horizontal Bandsaw Machine#Vertical Bandsaw Machine#band saw

0 notes

Photo

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stuckist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes - Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter - Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#h13steels#toolsteel#toolsteelsupplier#viratsteels#viratsteelsindia#2714steel#db6steel#din2344#h13steel#h11

3 notes

·

View notes

Text

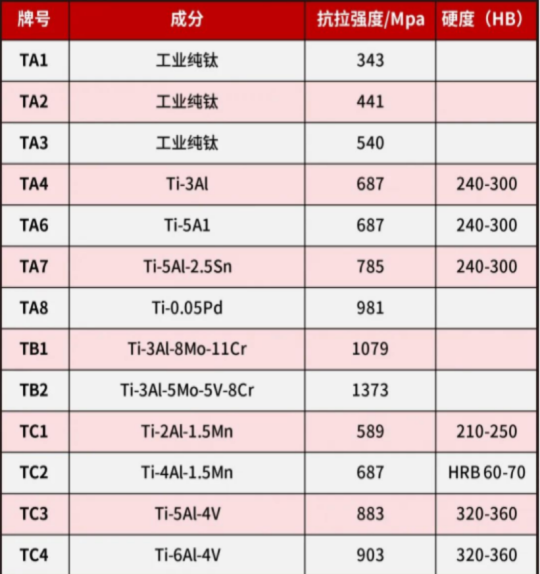

Titanium and titanium alloy sawing characteristics and description

Titanium and titanium alloy processing is more sensitive to temperature and is more difficult to process in metal materials, for the cutting of titanium alloy is usually cut with cold sawing, heat dissipation and good, sawing stability, can be quickly cut, but also to ensure that its section is smooth when cutting, no burrs.

According to the machining process and the metal characteristics of titanium and titanium alloy, titanium alloy has the following cutting characteristics:

1. Small deformation coefficient: the deformation coefficient is less than or close to 1. The path of sliding friction of chips on the front tool face is greatly increased, which accelerates the wear of band saw blade.

2. High cutting temperature: Because the thermal conductivity of titanium alloy is very small (only equivalent to 1/5 ~ 1/7 of No. 45 steel), the contact length between the chip and the front tool surface is very short, and the heat generated during cutting is not easy to be transmitted, concentrated in a small range near the cutting zone and cutting edge.

3. Large cutting force per unit area: the elastic modulus of titanium alloy is small, and it is easy to bend and deform under the action of radial force during processing, causing vibration, increasing band saw blade wear and affecting the accuracy of parts.

4. Serious cooling phenomenon: due to the large chemical activity of titanium, at high cutting temperatures, it is easy to absorb oxygen and nitrogen in the air to form a hard and brittle skin.

5. Band saw blade tip is easy to wear: after the blank is processed by stamping, forging, hot rolling and other methods, it forms a hard and brittle uneven skin, which is easy to cause the breaking edge phenomenon, making the cutting of hard skin a difficult process in titanium alloy processing.

The choice of saw blade.

Choose different types of saw blades for different titanium properties.

Pure titanium (GR2) Select bimetal band saw blade. For the grinding type band saw blade, it can reduce the friction of chips on the front tool surface, and the latter is the high-low tooth type band saw blade, which can reduce the cutting force, high tool accuracy and good back strength.

Titanium alloy (GR5) Select a segmented carbide band saw blade. Used for sawing titanium alloys with hardness below 36HRC.

Sawing important parameter setting:

Band saw speed setting: Different grades of cut materials, different specifications, different heat treatment states and different saw machine performance will affect the band saw speed setting. The larger the material, the line speed should be appropriately reduced.

Running-in of new saw blade: Because the cutting edge of the new saw blade is too sharp, the running-in procedure needs to be performed. The running-in of the bimetal band saw blade is generally to reduce the feed speed to half of the normal value, while the running-in of the cemented carbide band saw blade is to reduce the line speed by half (if it is the lowest, then do not reduce it), and then adjust the feed to about 1/4 of the normal value and slowly rise.

Feed speed: Too fast feed speed is easy to cause oblique cutting or tooth pulling, too slow feed may also cost the saw blade or cause the sawing machine operating efficiency is too low.

Clamp the jaws correctly: try to clamp the jaws tightly and clamp correctly. If the clamping method of steel pipe is wrong, it is easy to cause the gear failure.

Coolant: plays the role of cooling, lubrication and cleaning. The sawing was done at 5% concentration. Carbide band saw with gold material, it is recommended to increase the cutting concentration to 10%. High speed sawing of non-ferrous metals generally adopts micro-lubrication, but attention should be paid to the selection of the grade and type of micro-lubricating oil.

For an excellent titanium and titanium alloy manufacturing enterprise, sawing is a very important link. Enterprises can have good benefits. Judging from the sawing process. The service life of saw blade, the classification and placement of saw blade head, the accuracy of cutting weight, etc.

0 notes

Text

Jiaxiao MTC specializes in the production of heat-treated steel strips. Relying on the advantages of Baosteel's high-quality hot-rolled raw materials, Jiaxiao MTC independently develops band saw production technology and opens a band saw factory cgoodsaws. This video was shot by jiaxiao MTC in the factory. This narrow carbon steel has a bandwidth of 10-20mm. Steel The model is CK67. After heat treatment, the hardness and toughness have been qualitatively improved. It is very suitable for cutting frozen bones and frozen meat. As you can see from the video, our saw blade is extremely sharp and can cut frozen bones and fish meat into two parts in an instant. Not only that, we also provide the following steel belts with different chemical compositions for you to choose from:

Heat Treated Steel Strip for Band Saw, Saw Blade, and Steel Strip for Stone Frame Saw Blade:

CK50, C67S, CK70, 68CrNiMo, C75Cr1, 75Ni8, SK4, SK5.

Main Applications:Woodwoeking saw, hand saw,marble row saw, diamond sawblade.

Heat Treated Bimetal Backing Steel Strip:

50CrNiMoVA, D6A, X32.

Main Applications:Bimetal band saw.

Heat Treated Steel Strip for Stainless Tools:

SUS420J2/J3/J4.

Main Applications:

Various kinds of cutting tools.

For more information, please visit: https:jiaxiaomtc.com

#saw blade#bandsaw#metalprocessing#hardened and tempered#jiaxiao mtc#heat treatment#carbon steel#cold rolled#steel manufacturer#steel strip#steel#wholesale#sales#saw 2004

1 note

·

View note

Text

Doall bandsaw mode d'emploi

DOALL BANDSAW MODE D'EMPLOI >>Download (Telecharger)

vk.cc/c7jKeU

DOALL BANDSAW MODE D'EMPLOI >> Lire en ligne

bit.do/fSmfG

polissoir genouillère occasion

débiteuse 5 axes occasion

tour à pierre occasion

machine à couper le marbre occasionéclateuse pierre occasion

machine coupe pierre naturelle

débiteuse occasion

éclateuse de pierre prix

La HFA250W est fonctionnelle et prête à l'emploi. scie automatique à ruban -Fabricant : DoAll, Scie à ruban horizontale Automate de scie Bianco MOD. MACHINIST LATHE TOOL MILL Machinist Lot of DoAll 3/8" Band Saw Guide Lot StgCst Avertissement :California Proposition 65 Notice: This product contains Caractéristiques. DoALL D-900 VERTICAL DIAMOND BAND SAW BAND SAW SPECIFICATIONS: -- Throat Depth 35" -- Maximum Work Height 16" -- Band Width SCIE À MÉTAL ''DOALL'' POWER SAW. METAL SAW SCIE À RUBAN ''DOALL'' MOD: 26-3. BAND SAW. N/S 55-55297 TABLES DE TRAVAIL ASSORTIES, CABINETS, OUTILS. Mode d'emploi : De 2 à 4 % dans l'eau. LENOX BAND-ADE ® BAND SAW FLUID Liquide de refroidissement à usage général conçu pour les applications d'usinage Qualified Bimetal Bandsaw for Construction Steel Cutting. Pour M42/M51 les lames de scie de la bande bimétallique, nous sommes en pleine dimension de la 130 mm Plage de travail matériau carré : 120 mm Plage de travail matériau min. de la bande : 3180 / 3130 mm Modes de fonctionnement : - Processus de Mon premier emploi dans la vraie vie a été chauffeur pour Avis. d'équité en matière d'emploi.t?b*958 H 300 Boutique JACOB, chef de file de la mode pourNotice is hereby given that an Order was rendered on February 23, 2011 under (2001) M-20A automatic horizontal band saw with material.

https://www.tumblr.com/gilaqofubeh/698230779373813760/golosa-answer-key-pdf-mode-demploi, https://www.tumblr.com/gilaqofubeh/698231258754531328/como-imprimir-dos-hojas-en-una-cara-pdf-notice, https://www.tumblr.com/gilaqofubeh/698230920331821056/anglican-prayer-book-1989-pdf-merge, https://www.tumblr.com/gilaqofubeh/698231021085343744/lr1620-honeywell-thermostat-manuel-mode-demploi, https://www.tumblr.com/gilaqofubeh/698230920331821056/anglican-prayer-book-1989-pdf-merge.

0 notes

Text

Choosing Custom Band Saw Blades

When choosing custom band saw blade, it is important to understand its impact. When you use a blade to cut area that are large and continuous solid material, there will be consistency of the blade’s teeth in terms of direction and intensity. The teeth maintains a contact that is unending with the material its cutting. Because there is no extra effect shocks that happen after the initial contact, no excessive stress occurs on the blade’s teeth. This is because they have cut through the material. The ability of the blade to resist wear is what determines its longevity and its ongoing performance. This largely depends on the tooth geometry and hardness of the blade. When a blade is cutting steel material, there are various forces from which the blade is subjected to from different directions. If the blade cuts a heavy-duty metal, the teeth can crack due to stress generated during the process. Look for the best custom bandsaw blades.

The second step to take before choosing your custom blade is to understand other variables involves. Apart from the blade, there are also other factors that need to be looked at when choosing your blade. The first is the type and condition of the equipment. What keeps the accuracy and longevity of the blade is good maintenance. If you notice patterns of wear, it shows that there is need to adjust the wheel and that there are worn out guides that are causing the issues. Look at the operation skills too. Having the know-how to operate the blade is something that should not be left out. You need to know how to handle any issues that may arise from operating the blade. It is also good to pick the best coolant to cut applications. This will help in improving the cut.

The material you will be cutting using the band saw blade is the third consideration you need to have in mind before choosing your blade. The blade you are choosing should meet your cutting needs. You need to inspect the material you will be cutting. Some blades are made of two metals that are separated. They are referred to as bimetal. They have layers of various metals. They have the ability to withstand any punishment of cutting bundles and shapes. They also have hardness required to be used continuously. This is because the teeth are designed with steel of high-speed. This makes them more durable. Some of these bimetals are made with titanium nitride coatings. This makes them more efficient to be used in custom applications.

You need to look at the cost, performance and durability of the blade before you can proceed to making your purchase. It is important you pick the blade that will satisfy many cutting applications and requirements. The blade should be able to do this without breaking. This means you will have to pick the blade that is durable. The cost of the band saw blade is also an important factor to consider. You should get the blade with the lowest cost while trying to maintain levels that are required to ensure profitability and productivity. Check out for custom bandsaw blades online.

Learn more here: https://en.wikipedia.org/wiki/Bandsaw

1 note

·

View note

Text

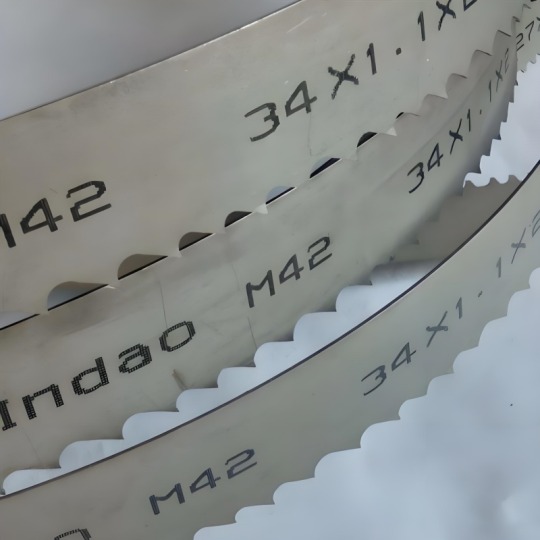

We supply m42/m51 bimetal band saw blades for cutting hardwood and metal.

popular sizes:

0.3*13mm, 0.69*13mm,0.9*16/19/27mm, 1.1*34mm, 1.3*41mm,

1.6*54/67/80mm etc.

tooth pitches: 2/3, 3/4, 4/6, 8/12, 10/14, 6/10, 5/8 and 22 mm. Please contact for price!

0 notes

Photo

https://lenox.band-saw-blades.us/

Band Saw Blade,Bimetal,13 ft. 6 In. L 39412CLB134115

0 notes

Text

Roof covering Square

Tape the sheet metal and secure it in place. Apply concealing tape to both sides of the sheet steel straight over the line you wish to make. This ensures a cleaner cut and protects against metal chips from scratching the sheet while you cut. Clamp the sheet steel versus your workdesk to hold it in place while you function. [3] Electric saws are best for making straight cuts just. If you need to make a rounded cut, attempt tin snips, a dremel, or a steel nibbler instead.

You can make rapid cuts with the cutoff blade, however the drawback is they will certainly be fairly rough. [5] It's tough to get ideal precision with this tool.Wear face defense, ear security (it's very loud) and thick work handwear covers when running this tool. Sparks will fly when the blade touches the metal, so see to it there's nothing combustible nearby. Usage substance snips to make small cuts in thin-gauge steel.

. We typically consider screw cutters when it comes to industrial use, as well as they are. Nevertheless, there are times when they will be a godsend around the store or house. Nothing will certainly cut solidified steel other than a ruby or TCT hacksaw (or a torch), but these will certainly shear typical lock shackles, chain links and hasps, strong or knotted wire, and also other round mild-steel or non-ferrous material.

Exactly How To Cut Corrugated Steel Roof Covering

What is the best way to cut corrugated metal roofing?

Snips are ideal for cutting any type of corrugated roofing, especially for cutting softer metal like tin sheets. Probably it's also the cheapest way for cutting corrugated tin roofing. Tin roofs are lightweight and soft by nature, this is why cutting them manually with snips is a good option.

To make detailed cuts in sheet steel, utilize a Dremel blade. Secure the sheet metal to a job table as well as press the Dremel blade against it. Move the blade along the designated line up until you get to completion of your cut. Make use of a horizontal band saw. [9] Band saws are fairly affordable as well as can cut thicker steel with more precision than the rough slice saw. They are extremely easy to utilize-- all you need to do is feed the metal right into the saw as well as the blade does the rest.

Behind The Scenes On Blade Runner 2049: Paint Cops Spinners In Budapest.

youtube

Nibblers might be hands-on (hand operated) or powered. Make use of a hacksaw for easy, shallow cuts. A hacksaw can cut through sheet metal, but its form limits the kinds of suffice can make.

Can you cut metal with a hacksaw?

youtube

Snips usually have the capacity to cut between 26 gauge and 18 gauge standard mild steel. There are some exceptions, depending on the size and make of the snips. Some larger snips, such as bulldog pattern tin snips, are able to cut up to 16 gauge of mild sheet metal.

There are 3 sort of compound snips, with color-coded deals with to make them very easy to distinguish. [1] Straight snips have yellow manages as well as permit you to cut straight lines.

If your tin roofing system project includes cutting about round objects such as air vent pipelines, a nibbler is the very best method to make these cuts.

Making use of the side of your workbench, a size of wood, 2 clamps, and a mallet, you can style a rudimentary flexing brake.

Those are the lefts, green manage for rights.

A good deal of warm is produced during the cut, making the steel very hot.

Both really cut much better than the carbide-backwards arrangement. It simply isn't worth it to make use of a carbide blade in a fashion for which it isn't meant. We cut all our metal with snips or shears just due to the fact that you obtain a much cleaner cut on things like valley's and more Bending sheet steel can be difficult, however with the best device it's simple.

Use a plasma lantern for metal that is 0.25-inch and also thinner. [16] A plasma lantern is a reasonably inexpensive, high-powered tool that slices with steel using a thermal cut procedure. It's excellent for metal that is 0.25-inch as well as thinner. These lanterns won't warp slim https://extension.umn.edu/protecting-home-rain-and-ice/dealing-and-preventing-ice-dams steel, whereas the oxy-fuel lantern might.

Steel.

Make sure you're using metal-cutting (carbon steel or bimetal) blades with your band saw. [10] There are three primary blade tooth patterns-- raker, wave and right. For cutting steel thicker than sheet steel, use the raker pattern. For thinner steel, utilize the wave tooth pattern. [11] The blades get dull conveniently and need to be replaced to get appropriate accuracy.

Corrugated steel roof covering installment security.

Moderate steel is an usual steel which has a reduced carbon web content. The much less carbon there is, the weak, yet more flexible, the steel will certainly be. Protect the sheet steel and also place the steel nibbler against the line side.

Roof Trousers, Knee Pads, Handwear Covers.

They're best at cutting in-depth or tiny lacerations in steel due to the fact that dremel blades are tiny and also simple to steer. If you intend to make larger cuts, nonetheless, you might be far better off with tin snips or an electrical saw-- dremels usually take too much time for big cuts. [12] Dremels are additionally fantastic for making both straight as well as curved cuts. Continue making the stroke as well as pull your blade back at the end. Push your saw with the blade up until you reach the end of the line. After completing the initial stroke, pull the saw back with your leading hand and remove it from the steel sheet. [6] One stroke needs to be enough to puncture the metal.

0 notes

Text

We Sadguru Enterprises is the leading Bimetal band saw blade manufacturers, suppliers, dealers in Pune, Maharashtra. Our dedicated team of talented application engineers provides our customers with endless solutions for their metal cutting processes.

#HSS Saw Blade Manufacturers in pune#HSS Saw Blade Suppliers in pune#HSS Saw Blade Dealers in Pune#HSS Saw Blade in pune#HSS Saw Blade

0 notes

Link

If someone is looking for the cutting band saw blades sale in Heatherbrae, he can contact Terrace Saw Works for the best services. The company is a well-known manufacturer and distributor of saw blades and provides goods to various parts in NSW. Please visit the website for more details.

0 notes

Photo

Virat Special Steels Pvt. Ltd. #ViratSpecialSteel

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes - Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter - Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

www.viratsteels.com

Email us: [email protected]

Call Us Now: +91-9814021775

#iso9001#engineering#toolsteel#toolsteelsupplier#die steels#moldsteel#viratsteelindia#viratsteels#viratspecialsteels#db6steel#h13steel#2714steel#din2714#mouldsteelstockist#gurugram#ludhiana#gurgaon#pune#india

2 notes

·

View notes

Link

Bimetal Bandsaw Blade Wholesale Dealer, Trader, Exporter, Supplier & Manufacturer in India.

#bandsaw blades#horizontal band saw#metal cutting band saw blades#metal cutter#cutting blade#metal cutting blade#metal blade#band saw blade manufacturers in india#bimetal bandsaw blades#band saw blade price#band saw blade types

0 notes

Video

youtube

Bandsaw Blade India, Bandsaw Blades for Metal, Steel, Nachi Motherson, ...

http://www.skec.yolasite.com

For trade inquiries or price-list pls visit http://www.skec.yolasite.com or email at [email protected]

Metal cutting Bimetal Bandsaw Blades Nachi Motherson for GIDC Makarpura Vadodara Gujarat

http://www.unboxing.yolasite.com

http://www.redmi.yolasite.com/

http://www.the-iphone.yolasite.com

http://www.sarahaha.yolasite.com

Subscribe to my youtube channel for various videos

https://www.youtube.com/c/Taheemrajat

https://www.youtube.com/user/Taheemrajat

My Channel :: https://www.youtube.com/channel/UC1U3...

Twitter :: https://twitter.com/taheemrajat

Google Plus :: https://plus.google.com/+RajatTaheem

LinkedIN :: www.linkedin.com/in/rajattaheem

Tumblr :: https://taheemrajat.tumblr.com

Blogger :: taheemrajat.blogspot.com

Wordpress :: http://taheemrajat.wordpress.com

-Rajat Taheem

Tweet @taheemrajat

#bimetal#bandsaw#blade#band saw#band saw blade#bimetal bandsaw blade#metal#cutting#steel#stainless#gujarat#vadodara#gidc

0 notes