#Polyester Film manufacturer

Text

A few years ago, I noticed that a number of factories in China had started opening TikTok accounts and posting footage from their assembly lines. The videos offered a rare glimpse into global supply chains, and millions of Western TikTok users marveled at teddy bears being stuffed with polyester fiberfill, machines dipping gardening gloves into hot liquified nitrile rubber, and quality assurance testers seeing whether cheap cigarette lighters worked. (My friend and former colleague Andrew Deck wrote a great story about factory TikTok for Rest of World in 2021.)

Since then, hundreds of other Chinese factories have joined TikTok. Some of them produce industrial equipment that would never be bought by normal people, like dump trucks or bottle labeling machines. And while the older factory accounts were often created by marketing agencies, these newer ones seem to largely be the work of earnest salespeople trying to find new customers. Many of them are relying on AI translation and text-to-speech tools, making the videos unintentionally sound very funny.

One of these manufacturers is a company called Donghua Jinlong, which is headquartered in Hebei province about 200 miles from Beijing. It sells “high quality industrial grade glycine,” a type of nutritional additive that evidently sounds silly and abstract to people who never need to think about how processed food is made. Donghua Jinglong and its glycine have become a relatively big meme on TikTok, Instagram, and X over the last few days, and some of the company’s videos are getting over 100,000 views (even though its official account only has roughly 4,400 followers).

Donghua Jinlong itself, however, doesn’t seem to have any idea what’s going on. People in the comments keep begging it to make official merch, but the company doesn’t understand why anyone would want a sweatshirt or t-shirt with the name of an industrial manufacturer on it. Shitposters have also started referencing the Donghua Jinlong meme in the comments of videos from other Chinese factories.

A company called HengYuan, for example, posted a video of what can only be described as a machine for filling Tide Pods, and one of the top comments is someone asking “Could you pack food grade glycine in this?”

Clearly baffled, HengYuan responded, “No. This is used to pack detergent in PVA Film.”

The Donghua Jinlong meme is a great microcosm of what’s actually happening on TikTok when it comes to content from China. Some people might argue that Chinese manufacturers are choosing to post on the app because its parent company, ByteDance, is also from China. In other words, these factories could be held up as an example of TikTok allowing Chinese influence to grow in the US (albeit a bizarre one).

But Donghua Jinlong also has a Facebook page with even more followers, it’s just that no one is engaging with its posts there. That’s because there are likely very few people searching social media for a new glycine supplier at any given time. TikTok, however, doesn’t rely on users to actively seek out content, it serves videos to them via an algorithm. So now tons of random people are coming across glycine manufacturers and Tide Pod machines by accident, and they’re happily turning the whole thing into a joke.

I personally find these videos to be fascinating, both because It’s cool to learn how things are made, and because they provide the opportunity to watch in real time what happens when random Chinese companies come into contact with American social media users. I don’t think this is the type of Chinese influence lawmakers are imagining when they worry about TikTok, but it’s arguably much more interesting and human.

353 notes

·

View notes

Text

All that glitters isn't always gold...

..sometimes it's just gold lame. Or Lurex. Or Mylar.

OK - so what the heck is lame? (pronounced 'lah-MAY') It was traditionally fabric made from metal fibers wrapped around other fibers, like silk or rayon. It was designed to create a metallic shine to clothing, so clothes were typically gold, silver, or copper colored. Besides style, lame was used in fencing uniforms which allowed the electrified sabers to register a 'hit' against an opponent.

Lurex is a close cousin to lame. In fact, you could claim they're in the same household since Lurex vaporized metal onto other fibers.

Today most manufacturers use Mylar, a polyester film that creates a metallic look, like with the one piece bathing suit I'm wearing. The trouble with Mylar is, after a while, it starts to peel off the backing fabric. Which makes clothing unappealing.

But, on the good side of things, a mylar swimsuit like this one is just fine for passing through airport metal detectors.

437 notes

·

View notes

Text

Christian Bale on "Batman Begins" (2005): "At first, I was somewhat hesitant to do the role. I mean, after all, Batman is an icon. But I remember, as clear as day, being at the grocery store the day the movie opened, and this little boy saw me. He couldn't have been more than five years old. He just walked right up to me and hugged me. He hugged me, and I was so moved by it that I hugged him back. Then he looked up at me and said, 'You're my hero.' And in that moment, I knew that not only as an actor that I had done my job, but that I had made the right decision to play Batman. And I've never looked back on my the decision to play Batman since."

Bale decided early on in the audition process that he didn't want to play Batman straight, but to play him as a rage-filled monster, figuring that it might polarize writer and director Christopher Nolan. To his delight, Nolan was thrilled with his off-kilter interpretation.

Heath Ledger was considered for the role of Bruce Wayne/Batman during this movie's early development before Ledger and Nolan agreed he was not right for the role. After this, he was cast as The Joker in "The Dark Knight" (2008), a role that won him an Academy Award for Best Actor in a Supporting Role.

The infamous growl performed by Bale was much rougher in "The Dark Knight" than "Batman Begins," and has been parodied countless times due to its extreme nature. However, the common misconception is that Bale was fully responsible for this voice. The real voice, during filming, was more toned down, and then heightened to a rougher, grittier vibe during post-production under the decision of writer, producer, and director Nolan.

Bruce Wayne wears a new Batsuit in "The Dark Knight." This Batsuit was an improvement on the outfit from "Batman Begins", and made Bale more comfortable and agile in his performance. It was constructed from two hundred unique pieces of rubber, fiberglass, metallic mesh, and nylon (producing an impression of sophisticated technology), with elastic banding added for tightening the costume to fit Bale. The gauntlets had their razors made retractable and able to be fired. The suit's cowl was based on a motorcycle helmet and separated from the neck piece, allowing Bale to move his head left/right/up/down, and comes equipped with white eye lenses for when Batman turns on Bat-sonar. Bale got to keep the Batman mask from the movie after filming.

For "The Dark Knight Rises" (2012), The Batsuit consisted of one hundred ten separate pieces. The base layer was made of a polyester mesh, utilized by the military and high-tech sports manufacturers due to its breathability and moisture-retaining properties. Molded pieces of flexible urethane were then attached to the mesh to form the overall body armor plating. Carbon fiberpanels were placed inside the sections on the legs, chest, and abdomen. The new owl was sculpted from a cast of Bale's face and head to become a perfect fit for Bale. (IMDb)

Happy Birthday, Christian Bale! 🦇

#dc#dcu#batman#bruce wayne#christan bale#batman dark knight#dark knight trilogy#christopher nolan#heath ledger#batman fandom#dc fandome

27 notes

·

View notes

Text

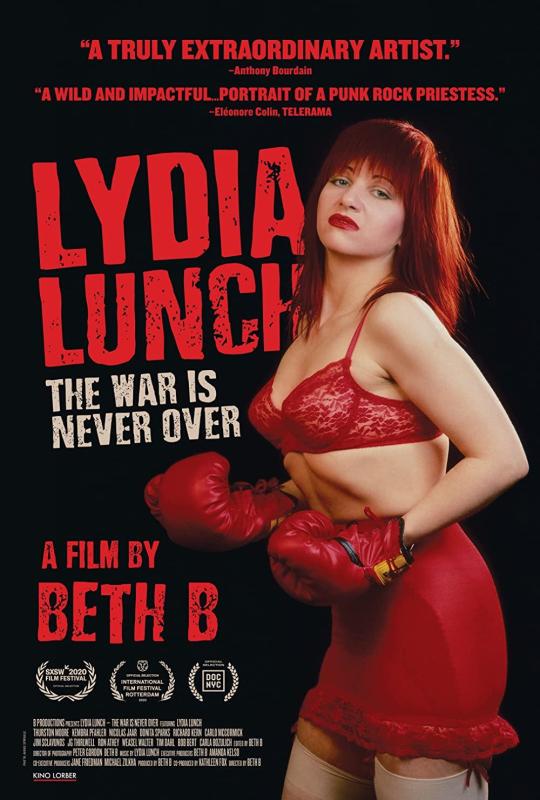

FILM INSPECTION: THE EARLY FILMS OF BETH B

by Emily Jenne, Institute of Fine Arts Conservation Center graduate student

Beth B, one of the most influential filmmakers to emerge from the generative chaos of the 1980s downtown scene, is known for her transgressive head-on confrontation of power structures and sexual politics. She formed the independent film production company B Movies (a play on low-budget films) with her partner Scott B, with whom she has worked over the years along with a panoply of collaborators, downtown luminaries such as Jack Smith, Arto Lindsay, Pat Place, John Lurie, Bill Rice, Gary Indiana, James Nares, Kiki Smith, Tom Otterness, Richard Edson, Vivienne Dick, James Russo, Richard Prince, Ann Magnuson, Jenny Holzer, Richard Kern, Kembra Pfahler, James Habacker, Dirty Martini, Thurston Moore, and Kai Eric (the list goes on). She is still active today, and her recent documentaries zero in on burlesque, no-wave provocateur Lydia Lunch, and the painter Ida Applebroog (who also happens to be Beth B’s mother).

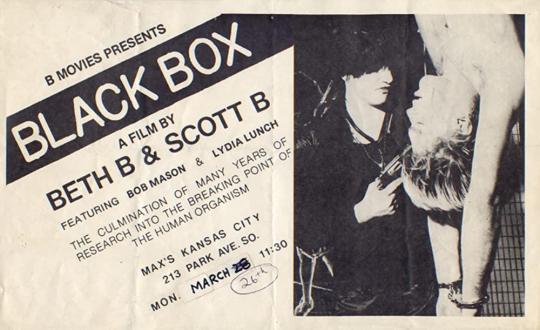

Flyer for ‘Black Box’

As a longtime Beth B fan myself, I was thrilled to have the opportunity to work on several of her early films as they entered NYU’s Special Collection (Beth B Papers, MSS.614; Scott and Beth B (B Movies) Records, MSS.622). This included: G Man (1978), Black Box (1979), The Trap Door (1981), Salvation (1987), Belladonna (1989), and Visiting Desire (1996), as well as a copy of Un Chant d’Amour (1950) the first and last film by French writer Jean Genet, famously banned for its explicit content. As a graduate student specializing in both time-based media and paper conservation at the Institute of Fine Arts NYU, I am often asked where these two seemingly disparate fields overlap. The work I’ve done at the Barbara Goldsmith Preservation & Conservation Department is an excellent example of the two working in tandem. The Beth B collection, for example, has both a media component (the films) and an accompanying paper element (posters and other ephemera).

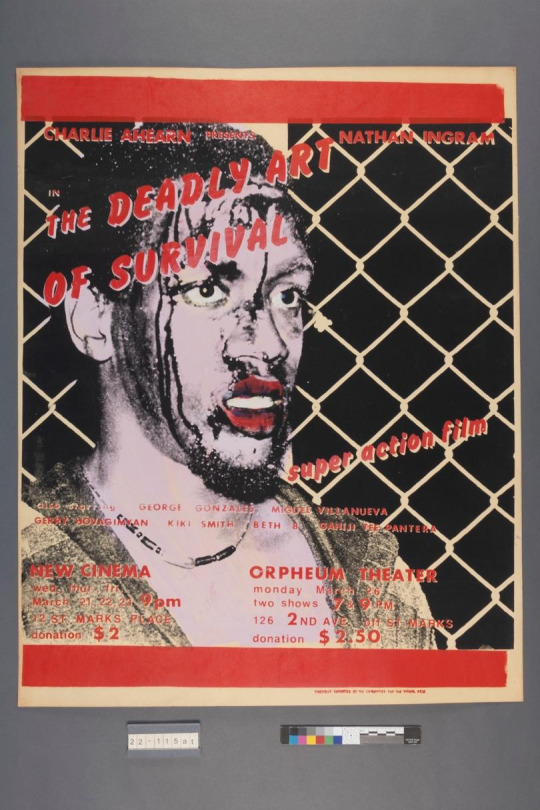

‘The Deadly Art of Survival’ poster, photograph by Dawn Manokowski

Film preservation begins with an assessment logging current conditions and identifying the media, which will determine the best practices for storage. The first order of business is identifying the film base as cellulose nitrate, acetate, or polyester. The film gauges present in the Beth B collection, 16mm and Super 8mm, ruled out one possibility, cellulose nitrate which was never used as an 8mm or 16mm substrate in the West. From there, acetate and polyester could be distinguished using a very high-tech piece of equipment, 3D movie glasses. A pair of polarized 3D glasses folded in half at the nose can be used for a polarization test. When slid between the lenses, a polyester base will birefringe, acetate will not (birefringence is a phenomenon of optical anisotropy in certain materials that causes distinctive visual undulations at changing angles). In the end, all of the films were found to have an acetate base.

The film inspection bench in the Barbara Goldsmith Preservation & Conservation Department.

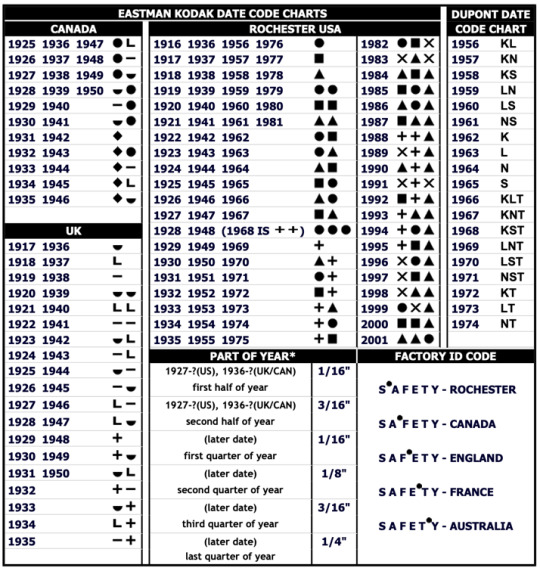

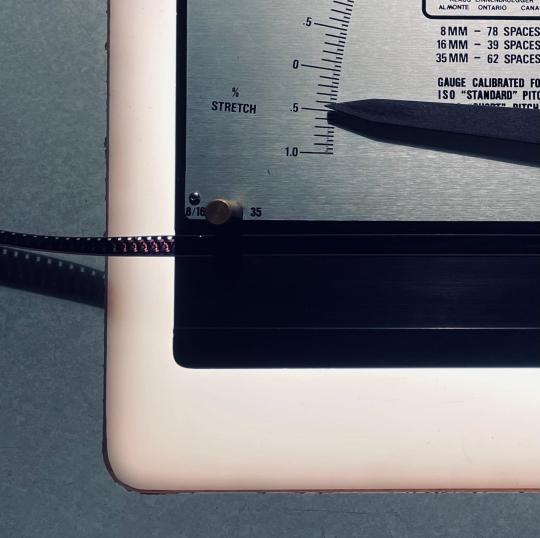

Further information about the film stock can be determined from clues in the edge code. Using a loupe and cross-referencing with an edge code chart, the year and even the location of manufacture can be established. The placement of a dot within the word ‘safety’ notes the location (acetate film base is known as ‘safety film’ in contrast to its highly reactive and flammable predecessor, cellulose nitrate). The film stock in the Beth B collection was manufactured in Rochester, NY.

Kodak edge code identifying Rochester, NY as the manufacturing location.

Eastman Kodak Date Code Chart

Information on the soundtrack format was also noted, the Super 8mm reversal films had a magnetic soundtrack, and the 16mm reversal films had a variable density optical track. Other relevant information was also recorded such as instances of surface abrasion, broken sprocket holes, number and character of splices, and any annotations on the head or tail leader (often instructions for the projectionist).

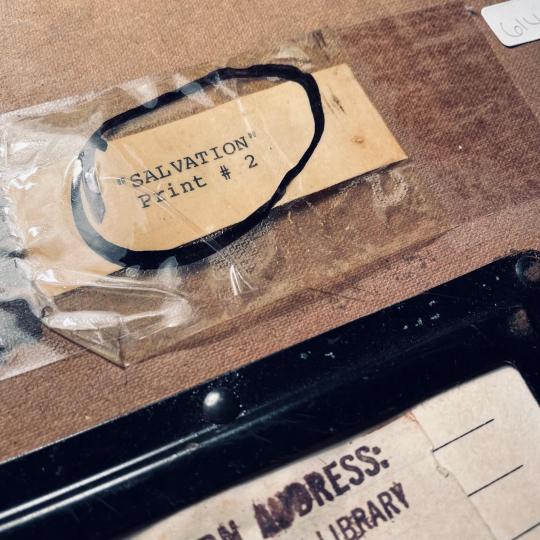

‘Salvation’ Print # 2

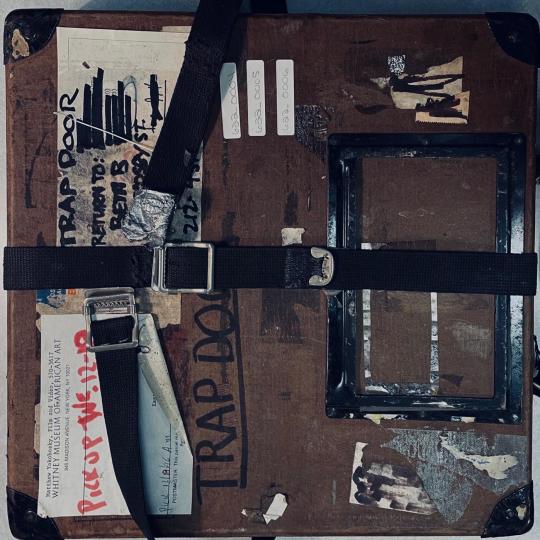

‘The Trap Door’ 8mm reel.

The major concern with acetate film base is deacetylation, an irreversible form of deterioration colloquially known as ‘vinegar syndrome’ for its distinctive acidic odor which can be detected at concentrations as low as 1 ppm. Deacetylation is essentially a reversal of the synthesis steps used to make the acetate base, and the reaction produces acetic acid which can also have a detrimental effect on the other component layers of the film. Acetic acid can soften the gelatin emulsion layer and accelerate fading of color dyes in color film. Deacetylation also leads to warpage, embrittlement, channeling, and shrinkage of the film base by as much as 10%. Shrinkage beyond 0.8% makes it dangerous to project the film.

Film shrinkage gauge.

Deacetylation is exacerbated by high humidity and fluctuations in temperature, but further damage can be mitigated with correct storage conditions. The industry standard for measuring the extent of deacetylation is with AD strips, a type of targeted litmus test, which measures acidity on a scale of 0 (blue, indicating no deterioration) to 3 (yellow, which indicates critical condition). In conjunction, multiple readings taken with a film shrinkage gauge can be used to determine the average shrinkage level of the film.

An 8mm film splicer in action.

‘Trap Door’ film reel storage case.

The films in the Beth B collection were found to be in generally good condition, and minor preservation interventions included the removal of tape residue and splicing of new labeled extensions onto the existing head and tail leader. The copy of Un Chant d’Amour, now upwards of 70 years old and suffering more from the effects of deacetylation in contrast the Beth B films, is a good reminder of the importance of consistent low humidity, low-temperature storage in prolonging the life of acetate-based films, just the kind that these films will receive in their new home at NYU.

Film Poster for ‘Lydia Lunch: The War is Never Over’

9 notes

·

View notes

Text

The thing about French medieval cinema is, I was listening to a video on yt about the reason costumes in rings of power use gold appliques instead of brocade fabric is that the textile industry is dying

Manufacturing of natural fabric has become a lot more rare, as in everyday clothes

If you are working for a film production, you'd go to the garment district and just buy fabric and then start from there

But most of the fabric on the market are some sort of polyester cotton blend

So the next possible step would be to produce your own fabric, which is both expensive and it's not like that doesn't require raw material and a whole lot of machinery, order from who knows where, again expensive and time consuming, or make due with whachya got and just stick gold leafs to fabric

Now that hot me thinking about Europe, and many Ministries of Culture, and publicly financed production of ethno garments, you see, in Europe governments have a vested interest in preserving culture, idea of history and continuity from then till now, so there's some money being spent on manufacturing authentic medieval costumes, but most importantly preserving technology, which is why French and British productions tend to pull of medieval with that itchy feeling of seeing raw wool on screen

6 notes

·

View notes

Video

Working Toray por David Blazejewski

Por Flickr:

With the first snow of the season finally sticking I went out trackside close to home to shoot the Seaview Transportation working down in Quonset-Davisville. After digging out cars at Ocean State Yard over on the Davisville Branch half of the railroad they headed over to the Quonset side and assembled their train in the new Mill Creek Yard before continuing east down the line to work mainstay customer, Toray Plastics. After crossing Roger Williams Ave. they are now inside the plant that features five stub ended tracks. As described by their own web site: 'Founded in 1985, Toray Plastics (America), Inc., is a leading innovator in polypropylene, polyester, and polyolefin technology and operates three state-of-the-art facilities. Our headquarters in North Kingstown, Rhode Island, is home to two facilities. There we manufacture cast and mono- and biaxially-oriented polypropylene film, biaxially-oriented polyester film, and bio-based films, and conduct in-house metallizing and coating. Our films are used for industrial, packaging, lidding, graphic, optical, and electronic applications.' Parent company Toray Industries is headquartered in Tokyo and was founded in 1926 as a Rayon Yarn Production Company. Today, it operates in 29 countries and has over 48, 000 employees globally and is the world's largest producer of carbon fiber among a vast array of other modern industrial products. SVTX GP10 1855 was built as a GP9 in Aug. 1956 for the Baltimore and Ohio as their #6467. Later rebuilt by ICG's Paducah Shop she bounced around on different shortlines until coming to Rhode Island in 2006 where she was given this snappy paint job. To learn more about this railroad check out the longer caption with this shot: flic.kr/p/2nNXfxP North Kingstown, Rhode Island Monday December 12, 2022

4 notes

·

View notes

Text

How do rubber rollers benefit manufacturing?

In this blog, we are going to highlight about industrial rubber rollers, how the device is transforming the manufacturing industry, and how industrial roller company is making use of the latest technology.

Learning about the manufacturing industry-centric rubber roller

An industrial rubber roller is a technology-driven device designed for manufacturing industries. The product comprises an inner shaft made up of metal, for instance, aluminum, steel, or carbon fiber. This metallic shaft is covered by a sturdy coating of elastomer compounds, including silicone, EPDM, neoprene, and natural rubber.

The device is ideal for sanding, grinding, etc. in the ensuing sections, we will discuss the applications.

Unique features of a rubber roller

The unique features of a premium quality rubber roller manufactured by a prominent industrial roller company in Ahmedabad, India makes it ideal for numerous manufacturing companies. While planning to purchase a roller for your manufacturing plant, you can match the roller with the following features:

Resistant to inclement weather

Sturdy design

Returns to its original shape, if distorted during application

Resistant to chemicals

Resistant to scratching and bumping

High coefficient of friction

Swiftly compensates for small changes that occur in machines precision

Durability

High tensile strength

Resistant to wear and tear

Unless the product matches these types of features, don't make the final decision. There are plenty of industrial roller companies in Ahmedabad, India. Why settle for less.

Applications of industrial rubber rolls

The manufacturing industry-centric rollers are substantially affecting the production process of various types of industries. Some of their industrial applications consist of:

Tape line / Woven sack (Silicon rollers)

Gravure printing (Printing)

Solvent-based lamination (Lamination)

Extrusion lamination (Hard chrome plated rollers)

Adhesive coating (Hard chrome plated rollers)

Blown film line (Silicon rollers)

Bopp/polyester line (Palletizer rollers)

Pelletize machine (Palletizer rollers)

Flexo graphic printing (Printing)

Solventless lamination (Lamination)

A reputed industrial roller company holds expertise in delivering custom-made solutions. If you are looking for a specific type of manufacturing industry-centric rubber rollers, you can connect with an established roller manufacturing company.

Industrial applications

The quality-driven roller is used in a wide range of industries, including:

Packaging

Paper

Plywood

Tyre

Steel

For further information, you can get in touch with a leading industrial roller company.

Latest technology

Over the years, the advent of technology has redefined the mechanism of industrial rubber rollers. Most reputed companies are drawing benefits from modern technology. And rightly so. Cutting-edge technology has helped in the development of modern rubber rollers.

Let’s connect for a mutually beneficial partnership

Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credit.

"Excellence means setting benchmarks, without telling others", this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product ranges and a presence in 52+ countries!

Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

9 notes

·

View notes

Text

Your Guide To Mylar Bags: A Must-Have for Food Storage

Do you have a food business and are worried about the preservation and storage of your food items? Mylar bags are the best solution for you!

These bags provide the ultimate protection to avoid the content that can degrade food quality. The middle aluminium layer of these bags serves as a barrier to air, moisture, and other external factors.

This way, the food particles can not come in contact with food. Hence, they play a crucial role in preserving the freshness of your food. Let’s get a bit deeper to get to know more about food storage mylar bags. Keep reading!

What Are Mylar Bags?

Mylar Bags are specifically designed bags used for storing different items. They are most popular in the food and cosmetic industry. A specific type of polyester film is used to manufacture these bags. This film makes these bags durable and strong enough to make a barrier.

When you store food items in these bags, this will automatically prevent the oxygen, light and moisture. All these factors contribute to affecting the quality of the food. Ultimately, this will extend the shelf life of the food item inside.

What Type Of Mylar Bags Are Best For Food Storage?

When it comes to the storage of food items, ensuring quality and freshness is paramount. It is essential to choose the right type of bag for food storage. Specifically, consider factors like the size, shape and closure mechanism of the bag according to the food type. Here are different types of bags that are useful for storing various food items.

Ziplock Mylar Bags

Ziplocak printed mylar bags are best fit for storing food items requiring frequent access. These bags have an easy opening and closing mechanism. This feature makes these bags useful for storing snacks and small food items.

Vacuum-Sealed Mylar Bags

Vacuum bags have a specific design to ensure there is no air inside while storing food items. Such bags are best for storing dairy products. You can use them for storing milk, cheese, or meat products. They are useful for the long-term storage of food products.

Stand-Up Mylar Pouches

Stand-up bags feature a unique gusseted bottom. With the help of this bottom, you can place the bag upright on countertops. These kinds of bags are best for storing bulky items. You can store food items like beans, pasta, grains or other items in stand-up bags.

Flat Mylar Bags

Stand-up mylar pouches come in custom sizes and shapes. They are best for storing products like bread and pastries. These bags can accommodate large-size food items. You can pick the size and design that aligns most with your requirements.

Mylar Bag Rolls For Custom Sizing

Mylar bag rolls are custom-sized bags with specific designs to store food items. When you’re preparing larger bags, you need to roll up bulky food items. This way, you can easily deliver the bulkier food items in an organised manner.

Buying Mylar Bags For Food Storage

There are certain things to look for while buying custom mylar bags for food storage. Keep these things in mind while choosing bags according to your needs:

Size And Capacity Considerations

Choose the bag size according to the quantity of food you intend to store. There are different types of bags for storing large and small-sized food items. First decide on the portion of your food, whether you need a small bag or large bag. Go through the guide before selecting the specific type of bag.

Thickness And Durability

Some products like dairy items require durable bags to ensure safety while shipping. Also, if you have to store bulky and heavy items, choose bags with extra thickness. Such bags have high wear and tear and don’t damage easily. You can store food items in them for longer periods.

Mistakes To Avoid While Using Mylar Bags

Using custom mylar bags for food storage requires appropriate attention. A minor mistake can result in the degradation of food quality. These are some pitfalls to watch out for while storing food items in bags:

Don’t overfill or underfill the bag with the food item. Choose the right custom size according to your product type. Seal the bag appropriately after filling in the item.

It is necessary to properly airtight the bag to prevent air contact with food. If you don’t seal the bag properly, it can affect the food's freshness.

Don’t keep food storage bags in extreme external conditions. Prefer to avoid high temperatures, moisture and sunlight to protect food items.

These following practices are best kept in mind to avoid any mistakes while storing food.

Summing Up!

In conclusion, mylar bags are the most important thing for storing food items. It is best to choose the right type of bag according to the product type. Use these bags effectively and avoid common mistakes to preserve food freshness.

If you’re in search of the best quality mylar bags in the UK, explore OXO Packaging's versatile range. Contact them to get the best quote for your order!

FAQs

How Long Can Food Stay Fresh in Mylar Bags?

A properly packed food item can remain fresh for a longer period. However, it also depends on the type of food. It is advisable to use the food according to their “Best before” date.

Can Mylar Bags Be Reused?

Yes, you can reuse mylar bags many times. However, it also depends on the strength and durability of the bag. You can easily reuse some types of bags, like zip lock bags because of their unique design. Be careful while storing food items while reusing a bag, keeping in mind the content interaction for safety concerns.

Are Mylar Bags Safe for Food Storage?

Yes, food-grade mylar bags are best for food storage. There is a wide use of different types of bags in the food industry. The best of them are FDA-approved bags that are safest for food items.

#mylar bags#custom mylar bags#Mylar bags UK#Printed Mylar bags#Food Storage Mylar bags#packaging#packagingindustry

1 note

·

View note

Text

Exploring the Art and Process of Silk Screen Printing

Silk screen printing, also known as screen printing or serigraphy, is a versatile and popular printing method that has been used for centuries to produce high-quality prints on various surfaces. This article explores the process, applications, benefits, and considerations of silk screen printing.

What is Silk Screen Printing?

Silk screen printing is a printing technique that involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface. The stencil is usually made of fine mesh, traditionally silk (hence the name), but now commonly polyester or nylon. The areas of the mesh that are not part of the stencil are blocked off, allowing the ink to pass through only the open areas onto the substrate.

The Process of Silk Screen Printing

Preparing the Screen: The first step in silk screen printing is creating the stencil. This involves coating the screen with a light-sensitive emulsion and exposing it to UV light through a film positive of the desired design.

Creating the Stencil: After exposure, the screen is washed with water, which removes the emulsion from the areas not exposed to light, leaving a stencil of the design on the mesh.

Setup and Registration: The screen is mounted on a printing press, and the substrate (such as fabric, paper, or plastic) is placed underneath. Proper registration ensures accurate alignment of the screen and substrate.

Applying Ink: Ink is applied to the top of the screen, and a squeegee is used to pull the ink across the screen, forcing it through the open areas of the stencil onto the substrate.

Curing the Ink: After printing, the substrate is passed through a dryer or oven to cure (or set) the ink. This step ensures durability and permanence of the print.

Repeating the Process: For multi-color designs, each color requires a separate screen and printing pass, with precise registration to ensure alignment of the colors.

Applications of Silk Screen Printing

Silk screen printing is widely used across various industries for a range of applications:

Textile Printing: Silk screen printing is extensively used in the textile industry to print designs on fabrics, including apparel, accessories, and home textiles.

Graphic Art: It is popular for producing posters, fine art prints, signage, and promotional materials.

Packaging: Silk screen printing is used on packaging materials such as boxes, bags, and labels.

Electronics: It is employed in the manufacturing of electronic components and printed circuit boards.

Industrial Applications: Silk screen printing is used for printing on glass, ceramics, plastics, and other industrial materials.

Benefits of Silk Screen Printing

Versatility: Silk screen printing can be applied to various substrates, including flat and curved surfaces.

Durability: The ink used in silk screen printing is durable and resistant to fading, making it suitable for outdoor applications.

High Quality: Silk screen printing produces vibrant colors and sharp details, ideal for intricate designs.

Cost-Effective: It is cost-effective for medium to large print runs, offering competitive pricing per unit.

Considerations for Silk Screen Printing

Setup Time: Creating screens and setting up equipment can be time-consuming for small print runs.

Color Limitations: Each color requires a separate screen, increasing complexity and cost for multi-color designs.

Not Suitable for Complex Gradients: Silk screen printing is best suited for solid colors and spot color designs rather than complex gradients.

Silk screen printing continues to be a popular choice for businesses and artists seeking high-quality, durable prints. Its versatility, durability, and vibrant results make it a preferred printing method across various industries.

0 notes

Text

The Role of Emulsion Polymers in the Textile Industry

In the ever-evolving textile industry, innovation drives progress, and one of the most significant advancements in recent years has been the utilization of emulsion polymers. These versatile materials have revolutionized fabric treatments, enhancing functionality, durability, and sustainability. As the demand for high-performance and environmentally friendly textiles continues to grow, emulsion polymers play a pivotal role in meeting these industry challenges.

Understanding Emulsion Polymers

Emulsion polymers are produced by the polymerization of monomers dispersed in water, forming a colloidal suspension. This method is environmentally favorable as it typically requires fewer organic solvents than other polymerization techniques. The resulting polymers are versatile and can be engineered with specific properties to suit various applications within the textile sector, ranging from fabric finishing to fiber manufacturing.

Enhancing Fabric Finishes

One of the primary applications of emulsion polymers in textiles is in the finishing process, where they are used to impart desirable characteristics to fabrics such as softness, wrinkle resistance, and water repellency. For instance, acrylic emulsion polymers are extensively used to create soft yet durable finishes on fabrics. These polymers form films on the fabric surface, providing a protective layer that enhances wear resistance and longevity.

Water repellency is another critical feature highly sought in textiles, especially in outdoor and sportswear. Emulsion polymers such as fluoropolymers offer exceptional water and stain-resistant properties without significantly affecting the fabric's breathability. This technology not only improves the consumer's wearing experience but also extends the garment's life by protecting it from the elements.

Improving Flame Retardancy and Strength

Safety is paramount in the textile industry, particularly in applications requiring fire-resistant clothing, such as in the military, firefighting, and certain industrial environments. Emulsion polymers are integral in the production of flame-retardant fabrics. These polymers can be formulated to form a char barrier on the fabric when exposed to heat, thus slowing down the spread of fire and providing crucial extra seconds for the wearer to escape danger.

Additionally, emulsion polymers are employed to enhance the mechanical strength of fibers. In the manufacturing of synthetic fibers, such as nylon and polyester, emulsion polymers are added to improve tensile strength and elasticity. This is particularly important in the production of high-performance textiles used in sportswear and automotive industries, where durability and performance under stress are essential.

Sustainability and Environmental Impact

The textile industry is increasingly under scrutiny for its environmental impact, particularly concerning water pollution and the use of toxic chemicals. Emulsion polymers offer a more sustainable alternative to traditional treatments that rely heavily on solvents. Water-based emulsions significantly reduce the need for volatile organic compounds (VOCs), which are harmful to both the environment and human health.

Furthermore, the development of biodegradable emulsion polymers is on the rise, which represents a significant step forward in reducing the ecological footprint of textile production. These innovative materials degrade more quickly and safely in the environment, helping to address the issue of textile waste and pollution.

Future Prospects

Looking ahead, the role of emulsion polymers in the textile industry is set to expand further. Advances in polymer chemistry are expected to produce even more specialized emulsions that could unlock new functionalities in textiles. For instance, there is ongoing research into emulsion polymers that can enable textiles to conduct electricity or change color in response to environmental stimuli, opening up possibilities for smart and interactive garments.

In conclusion, emulsion polymers are crucial in pushing the boundaries of what's possible in textile production. Their ability to enhance fabric properties, coupled with their environmental benefits, positions them as key components in the future of textile manufacturing. As the industry continues to innovate and move towards more sustainable practices, emulsion polymers will undoubtedly play a central role in its evolution, offering solutions that meet the needs of modern consumers and the planet alike.

0 notes

Text

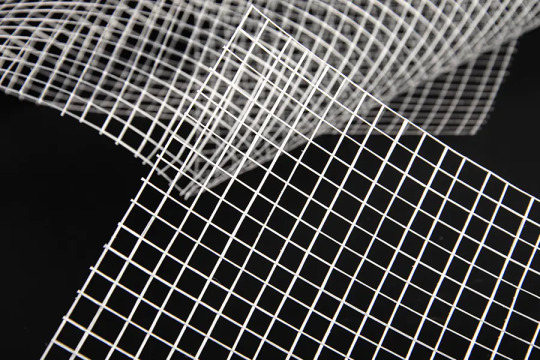

1100D 11 SBR PES laid scrim

Zhejiang Shengdannu New Materials Technology Co.,Ltd. is a professional manufacturer specializing in technical textile field. With 20 years export experience and researches on the new material field for all textile field. We started research on textile for industry on 2018. Based on a group of 10 technical people with 2 years research, we are now aimed on reinforcing textile materials for films and boards. Company imported Laid Scrim machine from German which can produce more than 60000 square-meter scrim every day with single or double layer lamination optionally.

As 1100D 11 SBR PES laid scrim Suppliers and custom Company, our main products include glass fiber and high strength polyester fiber laid scrim with 1*1 -3*3 /cm mesh. Single and double sides lamination with PVC tarpaulin, aluminium foil, PET foil, polyester non-woven fabric and glass fiber non-woven fabric. Those product widely used for indoor and outdoor waterproof system, thermal isolation system, road construction, agricultural shed, PVC flooring, cement board reinforcement and etc.,

0 notes

Text

The Importance of Dye Fixing Agents in the Textile Industry

The textile industry is a colorful world where the vibrancy and durability of fabrics play a crucial role in the marketability of products. In this context, dye fixing agents emerge as indispensable allies in the quest for long-lasting and vibrant textiles. These specialized chemicals not only ensure that colors adhere firmly to the fibers but also play a significant role in enhancing the overall quality and appeal of textile products.

What are Dye Fixing Agents

During the dyeing process lies the challenge of colour fastness—ensuring that dyes remain vivid and steadfast through washes and exposure to environmental elements. Dye fixing agents tackle this challenge head-on by forming strong chemical bonds between dye molecules and textile fibers. This bond significantly reduces the likelihood of fading, bleeding, or colour loss, thereby preserving the fabric’s aesthetic appeal over time.

Types of Dye Fixing Agents

Dye Fixing Agent Manufacturers use a variety of dye fixing agents, each suited to specific types of fibers and dyes, to achieve the desired level of colour fastness. Find the below mentioned types:

Tannic Acid-Based Fixing Agents: Derived from tannin-rich plants, these agents are effective for improving the colour fastness of natural dyes on cellulosic fibers, such as cotton and linen. They work by forming complexes with metal ions, facilitating a stronger bond between the dye and the fiber.

Metal Chelating Agents: These agents form stable complexes with metal ions present in the dye or water, preventing these ions from interfering with the dye-fiber bonding process. This enhances the dye fixation and overall colour retention.

Cationic Dye Fixing Agents: Primarily used for synthetic fibers like polyester and nylon, cationic agents work by forming electrostatic attractions with negatively charged dye molecules, thereby increasing the affinity between the dye and the fiber and enhancing colour fastness.

Crosslinking Fixing Agents: By creating strong covalent bonds between the dye molecules and textile fibers, crosslinking agents ensure excellent wash-fastness and resistance to fading. These agents are preferred for their durability, especially in harsh environmental conditions.

Anionic Dye Fixing Agents: Best suited for dyeing wool and silk, which carry a net positive charge, anionic agents form ionic bonds with positively charged dye molecules, ensuring effective dye fixation and vibrant colour retention.

Reactive and Non-reactive Fixing Agents: Reactive agents introduce reactive groups into the fixing agent molecules, forming covalent bonds with dye molecules and the fiber, improving dye fastness. Non-reactive agents, on the other hand, may work by film-forming on the fabric or blocking water-soluble groups on the fiber surface to improve colour fastness.

Each type plays a crucial role in ensuring that textiles retain their colour vibrancy and resist fading over time, underscoring the vital role dye fixing agents play in the textile industry.

The Role and Benefits of Dye Fixing Agents

1. Enhancing Colour Fastness

One of the paramount achievements of dye fixing agents is their role in bolstering colour fastness. This characteristic is crucial, as it determines how well a fabric can retain its colour through various conditions, such as exposure to sunlight, repeated washing, or mechanical wear.

By establishing a chemical fortress around the dye molecules, these agents effectively secure the dye to the fiber, minimizing the risk of fading. This process is not just about preserving the visual appeal of textiles but also about ensuring their longevity and durability. For manufacturers and consumers alike, this translates to textiles that maintain their vibrant hues and aesthetic appeal over time, even after multiple laundering cycles.

2. Preventing Dye Bleeding

Dye bleeding is a common challenge in the textile industry, especially when dealing with fabrics that feature multiple colors or intricate patterns. Dye fixing agents address this issue head-on by locking the dye molecules within the fabric’s fibers. This preventive measure ensures that colors do not migrate beyond their intended boundaries, preserving the sharpness and clarity of designs.

The significance of this function cannot be overstated, as it not only enhances the product’s overall quality but also boosts consumer satisfaction. Textiles treated with efficient dye fixing agents are more likely to hold their ground against the common pitfalls of colour blending or bleeding, ensuring that every wash leaves the design as intended.

3. Ensuring Uniform Colour Distribution

Achieving a uniform distribution of colour across a textile surface poses a significant challenge, particularly in large-scale production settings. Here, dye fixing agents play a pivotal role by facilitating an even attachment of dye molecules to the fabric fibers. This uniformity is critical for several reasons.

First, it ensures that every inch of the fabric reflects the intended shade and intensity, eliminating patches or variations that can detract from the textile’s overall appearance. Secondly, uniform colour distribution contributes to the consistency of product quality, a factor that is particularly important for brands that pride themselves on delivering exceptional and reliable merchandise.

In essence, dye fixing agents serve as the guardians of colour integrity, ensuring that from the first dye bath to the final product, the fabric remains a true representation of the designer’s vision.

4. Environmentally Friendly Solutions

The shift towards sustainability has ushered in an era where the environmental impact of textile production is under scrutiny. In this context, the role of dye fixing agents extends beyond just improving fabric quality to encompass environmentally friendly practices. Effective dye fixation minimizes the need for repeated washing and re-dyeing processes, which in turn reduces water consumption and the discharge of dye pollutants into water systems.

Furthermore, advancements in dye fixing agent formulations are increasingly focusing on biodegradable and eco-friendly components. These innovations aim to maintain or even enhance the efficacy of dye fixation while ensuring that the agents themselves do not contribute to environmental degradation.

The use of such agents aligns with the broader industry goal of reducing the ecological footprint of textile production, paving the way for a more sustainable fashion and fabric manufacturing sector.

Conclusion: ColourInn’s Commitment to Quality and Sustainability

In conclusion, the role of dye fixing agents in the textile industry cannot be overstated. Their contribution to enhancing colour fastness, preventing dye bleed, and ensuring uniform colour distribution is invaluable. As one of the leading dye fixing agent suppliers and manufacturers, ColourInn stands at the forefront of this essential aspect of textile production.

Our commitment to quality and sustainability is reflected in our innovative product range and eco-friendly practices, ensuring that our clients receive only the best in textile auxiliaries and chemicals. At ColourInn, we understand that the beauty of textiles lies not just in their colors but in their ability to endure and inspire.

#Dyeing Printing Auxiliaries Manufacturer#Dyeing Printing Auxiliaries Manufacturer in India#Textile Finishing Chemicals Manufacturers#Textile Finishing Chemicals Manufacturers in India#Textile Finishing Chemicals Suppliers#Dyes Manufacturers#Textile Dyes Manufacturers#dyes manufacturers in india#textile finishing chemicals#textile dyes manufacturers#dyeing auxiliaries#Finishing Chemical Manufacturers#Printing Dyes Suppliers#Textile Auxiliaries#Textile Auxiliary Manufacturer#Pretreatment Textile Manufacturer#Textile Pretreatment Chemicals#textile dyes auxiliaries#textile chemicals manufacturer

0 notes

Text

India Carbon Black Market Size, Growth Report 2031

Indian Carbon Black Market size was valued at USD 1.75 billion in FY2023 which is expected to reach USD 3.33 billion in FY2031 with a CAGR of 8.36% for the forecast period between FY2024 and FY2031. Recent years have seen a significant increase in the carbon black market in India due to factors like growing industrialization, improved infrastructure, and rising consumer demand for carbon black. Because it is widely used in tire manufacturing to improve performance and durability, the automotive industry is a significant consumer of carbon black. Given that India is one of the biggest markets for automobiles in the world, demand for carbon black is anticipated to rise further.

Further, the demand for carbon black is also influenced by the construction industry, which is fuelled by urbanization and government infrastructure projects. It is used to increase the strength, UV resistance, and other desirable properties of materials like asphalt, concrete, coatings, and adhesives. The demand for carbon black is also further driven by the packaging sector, as it is used in plastic packaging due to its durability and aesthetic appeal.

Additionally, manufacturers have the chance to reach markets outside of their home countries owing to the export potential of Indian carbon black products. Indian carbon black producers are working hard to meet global quality standards and take advantage of the expanding carbon black market in surrounding nations and regions.

Download Free Sample Report@ https://www.marketsandata.com/industry-reports/india-carbon-black-market/sample-request

A boom in Packaging Sector

The demand for packaging materials has increased due to the rapid expansion of e-commerce to guarantee the safe and secure delivery of goods to consumers. Plastic packaging products like bags, containers, and films are typically made using carbon black. These packaging materials can now be used for a variety of products and are guaranteed to remain intact during storage and transportation as carbon black is known for its strength, durability, and UV resistance.

One of India's fastest-growing industries is packaging, which currently has an annual growth rate of 25%. Carbon black is widely used in the packaging sector to achieve the desired colors and aesthetics in product packaging. It is a popular option in the industry because of its capacity to deliver a deep black color and consistent dispersion. The demand for packaged goods and carbon black in the packaging industry both rise along with the expansion of e-commerce.

Growing Automotive Sector

The high rate of urbanization, the average disposable income, and aggressive government initiatives to support domestic manufacturing and the use of electric vehicles in India are all factors driving the growth of the automotive industry. All these factors help to increase the production of vehicles, and as more cars are being produced.

According to the data published by MARKLINES, Indian passenger vehicle sales increased by 12.9% in April 2023. The increase in sales continues throughout India's first quarter of 2023, supporting the country's expanding automotive market demand. The market for Carbon black in India is heavily influenced by the automotive industry. Tire manufacturing involves the extensive use of carbon black, which improves the rubber's performance and strength. The demand for carbon black to produce tires has significantly increased with the expansion of the automotive industry in India.

Strong Growth in Textile Sector

Carbon black is used in the textile industry to create fibres, fabrics, and textiles for a variety of uses. Carbon black is used as a colorant or pigment in textiles. To produce dark-coloured textiles or achieve black shades in textile products, carbon black offers a deep and intense black coloration. During the manufacturing process, carbon black is frequently added to synthetic fibres like polyester, nylon, and acrylic. These fibres’ color fastness, UV resistance, and durability are all enhanced by the addition of carbon black. It aids in minimizing fading or discoloration brought on by sunlight exposure or other environmental elements.

According to a press release by The Textile Magazine, Cotton dominates the Indian textile market with a share of 60% compared to 40% globally. However, the situation is rapidly shifting. Manufacturers and brands are turning toward alternative fibre options, primarily polyester. There are currently 30 businesses with annual revenues exceeding USD 200 million, and many of them are expanding by double digits. The shift from Cotton to fibre along with the increasing textile sector will likely drive up the Carbon Black market in India.

Huge Construction Hikes

The demand for carbon black in India is driven by projects for infrastructure development and rapid urbanization. Carbon black is needed in the building industry for uses such as flooring, adhesives, sealants, and roofing materials in residential, commercial, and industrial construction. Carbon black is widely used in the infrastructure and construction industries. It is used to make asphalt, which is widely used in the construction of roads. Increased carbon black strength, resilience, and UV resistance are advantageous for asphalt.

Additionally, the Indian central government committed nearly USD 10 trillion in direct infrastructure investment as part of the Budget 2023. The Outlay of Pradhan Mantri Awas Yojana-Urban (PMAY-U) has increased by 66%, also, the Urban Infrastructure Development fund is increasing its focus on Tier-2 and Tier-3 cities to build bigger and better infrastructure. All such construction developments abet the rise in Carbon Black market in India.

The carbon black market in India is strongly tied to the country's automotive industry, which heavily relies on carbon black as a reinforcing filler in tire manufacturing and other rubber products. As India's automotive sector continues to grow, so does the demand for carbon black. Additionally, industrial applications such as plastics, coatings, and printing inks contribute to the demand for carbon black in the country.

Factors influencing the dynamics of the Indian carbon black market include the pace of industrialization, regulatory policies on emissions and pollution control, global market trends, availability and cost of raw materials, and the competitive landscape with both domestic and international players.

Carbon black is extensively used as a reinforcing filler in tires and other rubber products, as well as in various other applications such as plastics, inks, and coatings. In India, the demand for carbon black is largely driven by the automotive industry due to the significant presence of automobile manufacturing units.

The market dynamics for carbon black in India are influenced by factors such as:

Automotive Industry: The growth of the automotive sector directly impacts the demand for carbon black, particularly in tire manufacturing. As India's automotive industry continues to expand, so does the demand for carbon black.

Industrialization: Carbon black is also used in various industrial applications such as plastics, coatings, and printing inks. The pace of industrialization in India plays a crucial role in determining the demand for carbon black.

Regulatory Environment: Environmental regulations regarding emissions and pollution control can impact the production and usage of carbon black. Compliance with environmental standards can influence the manufacturing processes and costs associated with carbon black production.

Global Market Trends: Global trends in the carbon black market, such as supply-demand dynamics, pricing trends, and technological advancements, also have an impact on the Indian market.

Raw Material Availability: The availability and cost of raw materials, such as feedstock like coal tar and petroleum derivatives, influence the production cost of carbon black in India.

Competitive Landscape: The presence of key players in the carbon black market, both domestic and international, affects market dynamics, including pricing, product innovation, and distribution channels.

Impact of COVID-19

The global supply chains were disrupted by the pandemic, which also affected the availability of the chemicals and raw materials needed to produce carbon black in the Indian market. Transportation restrictions, logistics issues, and a temporary shutdown of manufacturing facilities impacted the ability of carbon black producers to produce their products. The pandemic's associated travel restrictions, lockdown measures, and economic unpredictability reduced India's overall demand for carbon black. Reduced activity in sectors namely automotive, building, and manufacturing led to a decline in the demand for products containing carbon black in the Indian market. For Instance, Maruti Suzuki reported a 47.4% decline in sales during March 2020.

The Indian carbon black market has shown resiliency and has begun to recover despite the initial difficulties as economic activity gradually picked up. A gradual increase in demand for carbon black has been observed across several industries, including the automotive and construction sectors, because of the relaxation of lockdown regulations and the implementation of government stimulus packages.

Indian Carbon Black Market: Report Scope

Indian Carbon Black Market Assessment, Opportunities and Forecast, FY2017-FY2031”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the carbon black market in India, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between FY2024 and FY2031. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120,

VA beach, VA,

USA 23462

Tel: +1 (757) 343-3258

Email: [email protected]

Website: https://www.marketsandata.com/

#Indian Carbon Black Market Size#Indian Carbon Black Market Share#Indian Carbon Black Market Industry#Indian Carbon Black Market Analysis#Indian Carbon Black Market Price#Indian Carbon Black Market Trends#Indian Carbon Black Market Growth#Indian Carbon Black Market Forecast#Indian Carbon Black Market Report#Indian Carbon Black Market Outlook#Indian Carbon Black Market Opportunity

0 notes

Text

Protecting Your Roof Box from Fading: A Comprehensive Guide

In the quest to safeguard your roof box from the detrimental effects of fading caused by UV exposure, delve into this comprehensive guide. Roof boxes serve as indispensable companions during family vacations, offering ample storage space for luggage and essential gear. However, the persistent issue of fading can mar their appearance, detracting from the overall aesthetics of both the box and the vehicle.

Understanding the Roof Box:

A roof box serves as a valuable addition to your vehicle, providing additional storage space for camping equipment, sports gear, and other essentials. Crafted from versatile materials such as fiberglass, aluminum, and plastic, roof boxes come in various shapes and sizes to cater to diverse needs. Despite their utility, roof boxes are susceptible to fading, primarily when exposed to direct sunlight, particularly during the scorching summer months.

Here you can explore the reasons that made the roof boxes to fade. Generally, gelcoat, a type of roof box and pigmented polyester can be used to manufacture the roof box. When the material surface is directly exposed to the UV rays, especially in summer months, then sure its color and shine will start to fade and dull.

Causes of Fading:

The fading of roof boxes can be attributed to their composition, typically comprising gelcoat and pigmented polyester. Direct exposure to UV rays accelerates the process of fading, diminishing the vibrancy and luster of the box's surface. Manufacturers are compelled to adhere to stringent environmental regulations, necessitating the reduction of certain substances in their products, such as cobalt, to mitigate environmental impact.

Preventing Fading:

While it may be challenging to entirely shield the roof box from sunlight due to its fixed position atop the vehicle, several preventive measures can effectively combat fading. One such method involves minimizing direct exposure to the sun whenever possible. Additionally, employing products like Polytrol proves highly effective in restoring the color and shine of the roof box, offering a simple yet efficient solution.

Application of Polytrol:

To rejuvenate the appearance of a faded roof box using Polytrol, follow these steps:

Clean the surface of the roof box with warm, soapy water.

Allow the box to dry for approximately 12 hours.

Apply Polytrol evenly using a brush or cloth.

Let it sit for about 20 minutes before wiping away any excess product with a lint-free cloth.

Allow the roof box to dry thoroughly.

Regular application of Polytrol can effectively revive the color and shine of the roof box, combating the effects of fading over time.

Benefits of Polytrol:

Polytrol, characterized by its advanced formula, penetrates deep into the surface of the roof box, restoring its original color and vibrancy. Not only does it enhance the appearance of gelcoats, plastics, and metals, but it also offers protection against corrosion, ensuring the longevity of the roof box. Unlike conventional coatings, Polytrol leaves no film residue, guaranteeing a durable and flexible finish that withstands the rigors of UV exposure.

Additional Preventive Measures:

In addition to using Polytrol, adopting regular maintenance practices such as cleaning the roof box with a soft brush can help remove dust and contaminants, preserving its appearance. Applying protective coatings like sealant, wax, or ceramic coating offers an added layer of defense against fading. When the vehicle is not in use for an extended period, consider removing the roof box and storing it indoors or under cover to minimize exposure to sunlight.

Conclusion:

By implementing the strategies outlined above, you can effectively safeguard your roof box against fading, ensuring its longevity and maintaining its aesthetic appeal. Don't wait until fading becomes noticeable—take proactive steps to protect your roof box and enjoy worry-free travels with family and friends.

#benefits of roof box#roof box#Car Roof Box#roof boxes#car and roof box#type of roof box#Top Packing Blunders

0 notes

Text

All about Benefits Solar Panel for a home in Dehli

Solar panels in Delhi have become increasingly common as the city strives to embrace renewable energy solutions and combat air pollution. These photovoltaic (PV) panels are installed on rooftops, and open areas, and even integrated into buildings, harnessing the abundant sunlight that Delhi receives throughout the year. As the capital city of India, Delhi faces significant energy demands, and solar panels offer a sustainable alternative to traditional fossil fuel-based electricity generation. With initiatives such as the Delhi Solar Policy and various incentives and subsidies provided by the government, the adoption of solar panels in Delhi has been on the rise. Homeowners, businesses, and government institutions are investing in solar energy to reduce their carbon footprint, lower electricity bills, and contribute to a cleaner and greener environment. As Delhi continues to expand its solar infrastructure, solar panels are expected to play a crucial role in meeting the city's energy needs while addressing environmental challenges.

What are the types of solar panels?

Solar panels come in various types, each with its own set of advantages and characteristics. The main types of solar panels include:

Monocrystalline Solar Panels: Made from high-purity silicon, monocrystalline solar panels have a single crystal structure, giving them a uniform black appearance. They are known for their high efficiency and space efficiency, making them ideal for installations with limited space.

Polycrystalline Solar Panels: Polycrystalline solar panels are made from multiple silicon crystals melted together, resulting in a less uniform appearance compared to monocrystalline panels. While they typically have lower efficiency than monocrystalline panels, polycrystalline panels are more cost-effective and offer good performance in various conditions.

Thin-Film Solar Panels: Thin-film solar panels are made by depositing thin layers of photovoltaic material onto a substrate, such as glass, plastic, or metal. They are lightweight, flexible, and less expensive to manufacture compared to crystalline silicon panels. However, thin-film panels generally have lower efficiency and degrade faster over time.

What are the components of solar panels?

Solar panels are composed of several key components, each playing a crucial role in harnessing sunlight and converting it into electricity. The main components of a solar panel include:

Photovoltaic (PV) Cells: PV cells are the core component of solar panels. These cells are made from semiconductor materials, typically silicon, which absorb sunlight and generate an electric current through the photovoltaic effect.

Encapsulation Material: PV cells are encapsulated in a durable and weather-resistant material, such as ethylene-vinyl acetate (EVA) or tempered glass, to protect them from environmental factors and ensure long-term performance.

Frame: Solar panels are typically housed in a rigid frame made from aluminum or steel, which provides structural support and protects the panel from physical damage.

Backsheet: The backsheet is a protective layer on the back of the solar panel, typically made from a polymer material, such as Tedlar or polyester. It provides insulation and moisture resistance, helping to protect the internal components of the panel.

Junction Box: The junction box is located on the back of the solar panel and houses electrical connections, diodes, and bypass diodes. It serves as the interface between the solar panel and external electrical components, such as wires and inverters.

Busbars: Busbars are thin metal strips that collect the electric current generated by the PV cells and transfer it to the junction box. They are typically made from copper or aluminum and are arranged in a grid-like pattern on the front surface of the solar panel.

Frontsheet: The frontsheet is a protective layer on the front of the solar panel, typically made from tempered glass. It is designed to transmit sunlight to the PV cells while providing durability and resistance to environmental factors, such as UV radiation and hail.

What are the benefits of solar panels in Delhi?

Solar panels offer several benefits to residents of Delhi, India, particularly in addressing energy needs, environmental concerns, and economic considerations:

Energy Independence: With abundant sunlight throughout the year, solar panels allow residents of Delhi to generate their own electricity, reducing dependence on the grid and fossil fuels. This independence provides resilience against power outages and price fluctuations in the electricity market.

Cost Savings: Solar panels enable residents to significantly lower their electricity bills by generating their own clean energy. Over time, the savings from reduced electricity bills can offset the initial investment in solar panel installation, leading to long-term financial benefits.

Environmental Sustainability: By harnessing solar energy, residents of Delhi can reduce their carbon footprint and contribute to environmental sustainability. Solar panels produce electricity without emitting greenhouse gases or other pollutants, helping to mitigate air pollution and combat climate change.

Government Incentives: The government of Delhi and the central government of India offer various incentives, subsidies, and rebates to promote the adoption of solar energy. These incentives can help offset the upfront costs of solar panel installation, making it more affordable for residents.

Energy Security: Solar panels enhance energy security by diversifying the energy mix and reducing reliance on imported fossil fuels. With locally generated solar energy, residents are less vulnerable to disruptions in fuel supply chains and geopolitical tensions.

Job Creation: The deployment of solar panels in Delhi creates job opportunities in various sectors, including manufacturing, installation, maintenance, and research. This job creation contributes to economic growth and empowers local communities.

Urban Development: Solar panels can be integrated into buildings and infrastructure, contributing to the aesthetic appeal and functionality of urban spaces. Solar-powered streetlights, water heaters, and other applications enhance the livability and sustainability of Delhi's urban environment.

What is the price of a solar panel?

The price of solar panels can vary widely depending on several factors, including the type and quality of the panels, the size of the system, installation costs, and location. here are some general price ranges for solar panels:

Residential Systems: For residential solar panel systems, prices typically range from 60000 to 95000 for a system size of 3 to 10 kilowatts (kW). This price range includes the cost of solar panels, inverters, mounting hardware, electrical components, and installation.

Conclusion - solar panels represent a transformative technology that holds immense potential to revolutionize the way we generate and consume electricity. As a clean, renewable energy source, solar panels offer numerous benefits, including reducing carbon emissions, mitigating climate change, and enhancing energy security. Despite some initial costs, the long-term economic advantages, such as savings on electricity bills and potential incentives, make solar panels an attractive investment for individuals, businesses, and governments alike.

0 notes

Text

Ceramic Window Film Is Best For Your Car

Ceramic Window Film Is Best For Your Car

When it comes to upgrading your window tinting, you should be aware that ceramic films offer the highest performance in UV protection and IR rejection. They are also backed by a lifetime warranty.

Unlike dyed film or carbon, ceramic tint contains small particles of nano-ceramic technology. It offers a high level of UV rejection and IR protection, as well as glare reduction. AltaMere in Plano will help you get covered.

Blocks the Sun’s Rays

The best ceramic window tint absorbs radiant energy and turns it into a harmless form of heat. The film also blocks harmful UV rays, preventing your car’s interior and your skin from premature aging and sun damage.

Our films are metal-free, unlike metallized film, which often interferes with cell phone signals, GPS systems and radio reception. They are also scratch-resistant and offer a sleek, dark look that is more attractive than dyed or metallic films. They are also less reflective than most other types of window tint. This makes them ideal for European vehicles with their clean lines and classic looks. They also keep your vehicle cooler and more comfortable, reducing annoying and distracting glare while blocking 98% of UV rays.

It’s More Attractive

As opposed to cheap dyed window tint that will fade, crack, and peel over time – ceramic automotive film is extremely durable. The films also provide a sleek, professional appearance. They are available in a wide range of VLTs to match the unique style of your car.

Superior grade ceramic IR tint is nonmetallic and nonconductive, but it still has amazing heat rejection and UV protection abilities. This type of window tint also reduces glare and is shatterproof.

Ceramic window tint consists of layers of clear polyester, ceramic nano particles, and laminate adhesive. The ceramic nano particles are infused with titanium nitride to reflect solar energy and UV rays and keep the interior of your vehicle cool and comfortable. This will also help you save money on your energy bills and prevent fading of upholstery, hardwood floors, and leather. It will also protect your skin from harmful UV rays and help prevent skin cancer. It also helps to reduce the sun’s damaging effects on your dashboard, seats, and steering wheel.

It’s More Durable

In general, ceramic tints are more durable than other types of window film. This is because they are less prone to cracking, bubbling and peeling over time. This can save you a lot of money in the long run, as it will reduce your need to get your car tinted again.

A great example of a ceramic film is a metal-free, clear VLT film that uses nano-ceramic particles to deliver outstanding heat rejection and glare control. It also prevents ghosting and hazing. Additionally, it blocks 98% of UV light and can reduce glare by up to 91%.

Another excellent option is our Xpel line. This is a dye-free, carbon film that delivers excellent heat rejection and glare reduction without the need for a dark shade. It is also metal-free and won’t interfere with GPS, radio or cell phone signals. In addition, it’s color stable and will not fade over time.

It’s More Affordable

Ceramic tint is the best for your car when it comes to heat rejection, sun glare reduction, and protection against harmful UV rays. It also looks great and doesn’t fade with time, saving you from spending more on a new window tint in the future.

XPEL PRIME XR PLUS ceramic film, it is a dye-free product that won’t change in color or develop hazing or ghosting over time. Huper Optik’s Carbon IR and Ceramic IR tint are similar to the above in terms of performance, but offer more of a traditional dark privacy look. These films are backed by a comprehensive manufacturer’s warranty, too.

Read the full article

0 notes