#Steel Tube Manufacturer in USA

Text

Superior Quality Steel Tube Manufacturer in USA

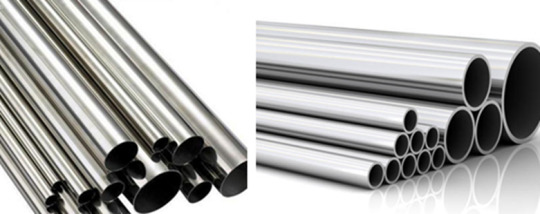

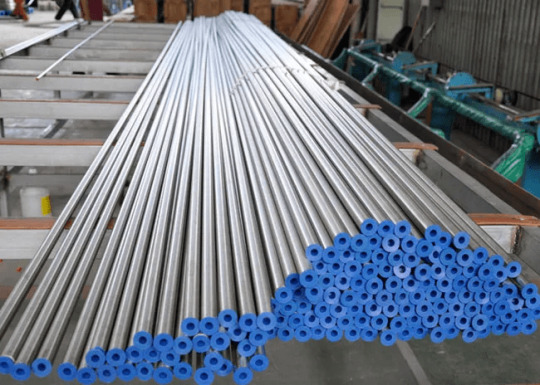

Piping projects is one of the leading Steel Tube Manufacturers in USA. We produce and distribute various steel tubes, including seamless, carbon, and welded tubes with OD ranges of 12.7 mm to 906 mm and wall thicknesses up to 40 mm. We use premium quality raw materials which enhance the durability and performance of Steel Tube.

We are a top-notch Steel Tube Manufacturers in USA. They can be varied in size, thickness, and length. Steel tubes can be made via electric resistance welding, seamless extrusion, or welding, depending on the application's needs. We are Also Leading Steel Pipe Manufacturers in USA.

The structural properties and production methods of seamless and welded steel tubes vary. A solid alloy is heated and punched to create Steel Tube Supplier, hollow tubes without weld joints. Strength and durability are increased by the constant and identical structure provided by this seamless design. We manufacture a wide range of Steel Tube Suppliers in USA.

Website: pipingprojects.us

0 notes

Text

Structure and Support | Goel Scientific | Canada

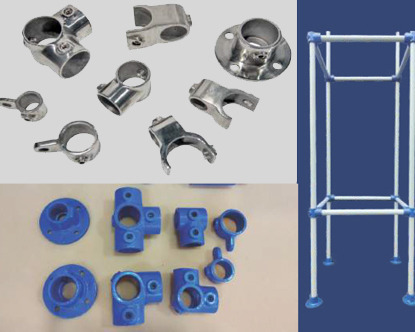

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-mods-for-a-800-hp-c7-z06-corvette/

Top 8 Best Mods for a 800+ HP C7 Z06 Corvette

If you’re looking to take your Corvette’s power and presence to the next level, you’ve come to the right place. In this guide, we’ll explore the top 8 best mods that can transform your Z06 into an 800+ horsepower beast, unleashing its full potential on the track or the street.

From enhancing exhaust notes to optimizing engine performance and improving traction, each of these mods plays a crucial role in elevating your driving experience. Whether you’re a seasoned enthusiast or just diving into the world of automotive upgrades, these carefully selected parts and accessories are sure to make a significant impact on your Corvette’s performance and aesthetics.

So buckle up, rev your engines, and let’s dive into the details of the Kooks Headers, Kooks X-Pipe, Borla ATAK Axleback exhaust, Cordes Performance upgrades including the 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank, the Low Side Fuel System for optimal fuel delivery, the traction-boosting Mickey Thompson Et Street SS Tires, and the stylish yet functional Forgestar D5 Drag Wheels. Get ready to experience the thrill of pushing your C7 Z06 Corvette to new heights!

youtube

https://www.vividracing.com/blog/wp-content/uploads/img-c7z06_forgestard5_mickeythompsonetstreet-3-scaled.jpg

1.) Kooks 1-7/8″ x 2″ x 3″ Stainless Steel Headers Chevrolet Corvette C7 2014-2019

When it comes to elevating your Corvette’s performance, few names carry as much weight as Kooks Headers and Exhaust. With a legacy spanning over 50 years, Kooks has solidified its position as a leader in the High Performance Exhaust Industry since 1962. What sets Kooks apart is not just their reputation but their unwavering commitment to delivering top-notch headers and exhaust systems for street, race, and off-road applications.

The accolades speak for themselves – Kooks has secured hundreds of championships and set numerous records across renowned racing organizations like NHRA, IHRA, NMCA, NMRA, NASCAR, NASA, SCCA, and many others. This level of success is a testament to the quality and performance of Kooks products.

What makes Kooks truly special is their dedication to craftsmanship and American manufacturing. With three generations of family leadership at the helm, every Kooks product is handcrafted right here in the USA. This commitment to quality control and precision ensures that every header and exhaust system that bears the Kooks name meets the highest standards of excellence.

The Kooks Headers and Exhaust kit for the C7 Corvette includes a 1-7/8″ x 2″ x 3″ Stainless Steel Long Tube Header, Cometic Multi-Layer Gaskets, Stage 8 Header Bolts, O2 Extensions, and Torca Clamps. Crafted from premium 304 Stainless Steel, these components not only offer exceptional durability but also add a touch of aesthetic appeal with their stainless steel finish.

Fitment is seamless for various Corvette models, including the Chevrolet Corvette C7 LT1 6.2L (2014-2019), Chevrolet Corvette C7 Z06/Z07 LT4 6.2L (2015-2019), and Chevrolet Corvette C7 ZR1 LT5 6.2L (2019).

So, if you’re ready to “Get Kookin with KOOKS!” and experience a performance boost like never before, the Kooks Headers and Exhaust system is a must-have addition to your C7 Corvette.

2.) Kooks OEM X 3 X 2 3/4 (OEM) C7 X Pipe Chevrolet Corvette C7 6.2L -All models 2014-2019

Upgrade your Chevrolet Corvette C7’s exhaust system with the high-performance Kooks X-Pipe. Crafted from T-304 Aircraft Quality Steel, this 3″ x 3″ X-Pipe optimizes exhaust gas flow for maximum power and a thrilling exhaust note.

Features:

OEM x 3″ Front connections to factory catalytic converter

3″ x 3″ X-Pipe

3″ x 2 3/4″ Mid-Pipes. Connects to 2 3/4″ OEM Style Exhaust.

Benefits:

Enhanced engine efficiency with reduced back pressure

Dyno and race-tested for optimal performance

Direct fitment for Chevrolet Corvette C7 6.2L models 2014-2019

Limited lifetime warranty to the original purchaser

Note: Designed for off-road use only and not CARB compliant for California.

Experience over fifty years of exhaust system craftsmanship with the Kooks X-Pipe, delivering power and performance for your Corvette C7.

3.) Borla ATAK Axleback Exhaust System Chevrolet 6.2L V8

The Borla ATAK Axleback exhaust system is the ideal companion to your Kooks X-Pipe and Headers upgrade for the Chevrolet Corvette C7, offering a seamless integration that results in a host of performance benefits. Together, these high-performance exhaust components optimize exhaust flow, reduce back pressure, and improve engine efficiency, translating into a noticeable increase in horsepower and torque for exhilarating acceleration. What truly sets this combination apart is the distinctive Borla Sound of Power, delivering an aggressive yet refined exhaust note that not only enhances driving excitement but also sets your Corvette apart from the crowd. Crafted from polished T-304 stainless steel, the Borla exhaust system not only ensures premium quality and durability but also adds a touch of visual appeal to your Corvette’s rear end. With precision CNC manufacturing and Borla’s Million-Mile Warranty backing, you can trust that your exhaust system will fit perfectly and be covered for the long haul. Together, the Kooks X-Pipe and Headers with the Borla ATAK Axleback exhaust unleash the full potential of your Corvette C7, offering an unmatched driving experience that’s as thrilling as it is refined.

4.) Cordes Performance 2.30″ LT4 Upper Pulley Kit Chevrolet Corvette 2014-2021

Upgrade your Chevrolet Corvette’s performance with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, designed specifically for models from 2014 to 2021. This kit offers a significant improvement by reducing the pulley size from the OEM 2.5 inches to a 2.3-inch diameter, resulting in a boost of 2-3 psi over stock levels. Included in the kit are essential components such as a press-on hub, 10 titanium torx bolts for secure installation, and the pulley itself featuring the newest griptec finish for enhanced traction and durability. Notably, the OEM belt can be reused if you have a stock-size lower, ensuring compatibility and ease of installation. This kit is compatible with all LT4 superchargers, making it a versatile and effective upgrade for unlocking additional power and performance from your Corvette’s engine. Experience improved boost levels and overall driving excitement with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, tailored to elevate your Corvette’s performance to new heights.

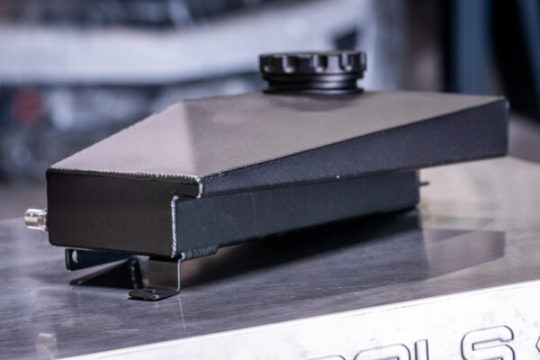

5.) Cordes Performance Engine Bay Ice Tank Chevrolet Corvette 2014-2021

Elevate your Chevrolet Corvette’s cooling capabilities with the Cordes Performance Engine Bay Ice Tank designed for models from 2014 to 2021. Cordes Performance Racing, renowned as the premier GM LTX/LTX motorsports company in Arizona, brings a wealth of expertise and passion to every product they offer. As a family-run business deeply committed to performance excellence, Cordes Performance Racing not only focuses on building high-level performing vehicles but also prioritizes the overall presentation, ensuring that you’re proud to showcase your Corvette. The Engine Bay Ice Tank is no exception, crafted using the highest-quality components to deliver optimal cooling efficiency and performance reliability. By maintaining lower engine temperatures, especially during high-performance driving or track sessions, this ice tank ensures that your Corvette operates at the peak of its performance, providing consistent power delivery and reliability. Trust Cordes Performance Racing to go above and beyond in enhancing your Corvette’s cooling system, enabling you to push the limits with confidence and enjoy an exhilarating driving experience every time you hit the road or track.

6.) Cordes Performance Low Side Fuel System Chevrolet Corvette 2014-2021

(Image may differ from actual product)

Enhance the fuel delivery and performance of your Chevrolet Corvette from 2014 to 2021 with the Cordes Performance Low Side Fuel System. Cordes Performance Racing stands as the premier GM LTX/LTX motorsports company in Arizona, driven by a deep passion for excellence in automotive performance. As a family-run business, Cordes Performance Racing not only focuses on building high-level performing vehicles but also emphasizes an overall presentation that you’ll be proud to showcase. The Low Side Fuel System exemplifies this commitment, utilizing only the highest-quality components to ensure optimal fuel delivery and engine performance. Compatible with Chevrolet Corvette C7 models from 2014 to 2021, including the C7ZO6 and C7ZR1 variants, this fuel system upgrade is designed to keep your vehicle at the peak of its performance, providing consistent fuel delivery and power output. Trust Cordes Performance Racing to go the extra mile in upgrading your Corvette’s fuel system, delivering reliability and performance that you can count on for every drive.

7.) Forgestar D5 Drag Wheel

18×12 5×120.65 50mm Gloss Black w/ Machined Lip

The Forgestar D5 Drag Wheel in 18×12 size with a 5×120.65 bolt pattern and 50mm offset is a game-changer for high-performance builds like the 800hp C7 Z06 Corvette. Forgestar performance wheels are renowned for bridging the gap between forged and cast wheels, delivering exceptional strength and lightweight characteristics crucial for demanding applications. Using an innovative rotary formed production process, Forgestar creates a lightweight cast wheel with strength and impact values comparable to forged wheels, making them ideal for street, racing, and drag racing applications. The Drag Wheel variant is drag strip approved with SFI 15.1 and 15.2 ratings, ensuring top-notch safety and performance standards. The wheel features a rotary forged flow-formed barrel, monoblock construction, and a Gloss Black finish with a machined lip, combining aesthetics with functionality. Its lightweight design not only enhances acceleration and handling but also clears big brake kits for improved stopping power. The raised center cap adds axle clearance convenience, while bead knurling ensures secure tire fitment. With a load rating of 1600 lbs and meticulous attention to detail in construction, the Forgestar D5 Drag Wheel is a must-have for high-performance enthusiasts looking to maximize their C7 Z06 Corvette’s potential on the drag strip and beyond.

Mickey Thompson ET Street S/S Tire – P345/35R18

The Mickey Thompson ET Street S/S Tire in P345/35R18 size is a high-performance street-to-strip tire designed for enthusiasts seeking exceptional traction on both the street and the drag strip. Featuring radial construction and the renowned R2 compound, this tire delivers superior performance in 15- to 20-inch fitments. It is D.O.T. approved for street use, making it a versatile choice for daily driving and track days alike. The ET Street S/S tire boasts an equivalent tread void as the ET Street Radial II but with improved hydroplane resistance, ensuring excellent dry traction while maintaining safety in wet conditions. The proven R2 compound, also used in top “drag radials,” provides superior traction at the strip, often requiring minimal or no burnout for optimal performance. Tubeless construction adds convenience with a leak-free seal, eliminating the need for tubes. With specifications like a centerline tread depth of 6.0/32″, an inflated overall diameter of 27.8 inches, and a maximum rim width of 13.5 inches, this tire offers a perfect balance of performance and durability. Whether you’re hitting the drag strip or cruising the streets, the Mickey Thompson ET Street S/S Tire is the ideal choice for enthusiasts seeking exceptional traction and performance in a street-legal package.

By combining top-notch performance upgrades from industry leaders, the Chevrolet Corvette C7 Z06 transforms into an 800hp powerhouse ready to dominate the streets and the track. The Kooks Headers and Exhaust system, along with the Borla ATAK Axleback exhaust, not only optimize exhaust flow but also enhance the aggressive exhaust note, while the Cordes Performance 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank ensure optimal engine cooling and power delivery. The Cordes Performance Low Side Fuel System keeps fuel delivery consistent, while the Forgestar D5 Drag Wheels and Mickey Thompson ET Street S/S Tires provide traction and stability necessary for harnessing the massive power output. Together, these meticulously selected upgrades create a harmonious synergy, elevating the Corvette C7 Z06 to 800hp and delivering an exhilarating driving experience that’s as thrilling as it is refined.

As always, if you need any assistance with selecting the right parts for your car, feel free to shoot us an email at [email protected] or give us a call at (480) 966-3040. Whether it’s helping you pick the best parts, or being a shoulder to cry on, we’ll be here!

#800hp C7 Z06 Corvette#Borla ATAK#c7 z06#Chevrolet#Cordes Performance#Corvette#Engine Bay Ice Tank#exhaust#Forgestar Drag Wheels#Headers#kooks#Low Side Fuel System#Mickey Thompson

2 notes

·

View notes

Text

Threaded Equal Tee Exporters in India

INTRODUCTION:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

The most popular kind of pipe fitting that can be used to combine or divide liquid streams is a threaded tee fitting. The ASTM A182 SS Threaded Tees can be accessed via a female-threaded side outlet and female thread sockets, solvent-weld sockets, or solvent-weld sockets.

Threaded Equal Tees can be used to divert a pipe run, connect pipes of different diameters, or do both. A stock list of forged threaded tees made in various materials, sizes, and wraps is available at Shasan Piping Solution. Additionally, the screwed tee made of alloy steel can also be used to transfer two liquid combinations. Based on their three connections, tees can be classified as equal or unequal in size, with equal tees being the most often produced kind.

DESCRIPTION:-

These threaded tee fittings have undergone additional treatments, one of which includes surface treatments, to improve their outer layer. The threaded tee ASME B16.11 is available in several completions. Typical finishes for the outer layer of the threaded tee include electroplating, nickel plating, white coating, dark cast, gold plating, excited finish, and so forth. While these treatments provide an external advantage to the ASME B16.11 threaded tee features, there should occasionally be an opportunity to further enhance its mechanical qualities, such as by boosting its resistance to and tensile strength of erosion.

Most commonly, cast metal or bronze, forged alloy and carbon steel, or cast dark or flexible iron could be used to make threaded screwed tee fittings. Alternatively, alternative materials such as stainless steel, aluminum, nickel, cast iron, bronze, plastic, elastic, copper, metal, polypropylene, etc. might also be used to make the ASTM A182 SS Threaded Tees. There are three tension ratings available for the ASME B16.11 threaded tee fitting aspects: Class 2000, Class 3000, and Class 6000.

Presumably, the earliest technique for connecting pipe systems is represented by the threaded tee fitting characteristics of ASME B16.11. The ASME B16.11 threaded tee fittings, often called little drag pipework, are mostly used for small pipe diameters, much as socket weld fittings. Little drag pipe is typically defined as piping with an apparent diameter of NPS 2 or less.

SPECIFICATIONS:-

1. Specifications- Forged Threaded equal tee

2. Dimension Specification- ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

3. Threaded equal tee Forged Fittings Thread- NPT, BSPT, BSPP

4. Threaded equal tee FittingsType- DN15-DN1200

5. End- Threaded, Welding, JIC

6. Threaded equal tee Fittings Pressure Rating- Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee, Connection, Welding

7. Bending Radius- R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 8. Threaded equal tee

8. Size Range- 1/8" NB TO 4" NB

9. Manufacturing process- Push, Press, Forge, Cast, etc.

10. Threaded equal tee Test Certificates- EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc

11. Origin & Mills - Japanese, Indian, USA, Korean, European, Ukraine, Russian

12. Key markets and industries for Threaded equal tee Fittings- Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals and acids.

13. Application - Threaded equal tee To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc.

BENEFITS:-

High-Quality Products: Threaded equal tee exporters provide products that meet international standards such as ASME 16.11, MSS SP-79, and BS 3799. This ensures that the tees are of superior quality and suitable for various industrial applications.

Wide Range of Options: Exporters offer a diverse range of threaded equal tees, including different sizes, pressure ratings, and materials. This variety allows customers to find the perfect fit for their specific requirements, enhancing flexibility and compatibility with existing systems.

Ease of Installation: Threaded connections offer ease of installation, allowing for quick and hassle-free assembly of piping systems. Threaded equal tees provide a secure and reliable connection without the need for specialized tools or welding, saving time and labor costs during installation.

Versatility: Threaded equal tees are versatile components that can be used in a wide range of industries and applications, including petroleum, chemical, construction, and shipbuilding. Their ability to connect three pipes of equal diameter at right angles makes them essential for branching and distributing fluid flow in piping systems.

Customization Options: Exporters often offer customization options for threaded equal tees, allowing customers to tailor the fittings to their specific needs. Whether it's a particular size, material, or threading requirement, exporters can accommodate various customization requests to meet customer specifications.

Reliable Supply Chain: Exporters ensure a reliable supply chain, ensuring timely delivery of threaded equal tees to customers worldwide. With a robust manufacturing infrastructure and efficient logistics network, exporters can fulfill orders promptly, minimizing downtime and maximizing operational efficiency for businesses.

CONCLUSION:-

In conclusion, threaded equal tee exporters play a crucial role in providing high-quality fittings for industrial piping systems. By offering a wide range of options, ease of installation, versatility, customization capabilities, and a reliable supply chain, exporters empower businesses to optimize their piping systems for enhanced efficiency and performance. Threaded equal tees serve as integral components in various industries, facilitating the distribution and control of fluid flow in piping networks. With a commitment to quality, reliability, and customer satisfaction, threaded equal tee exporters contribute to the success and competitiveness of industries worldwide.

CONTACT US:-

Phone :+91-88797-09191

Phone :+91-22-6651 8642

E-mail : [email protected]

#Threaded Equal Tee Manufacturers#Threaded Equal Tee Suppliers#Threaded Equal Tee Stockists#Threaded Equal Tee Exporters#Threaded Equal Tee Manufacturers in India#Threaded Equal Tee Suppliers in India#Threaded Equal Tee Stockists in India

0 notes

Text

Global Top 5 Companies Accounted for 8% of total Stainless Tube market (QYResearch, 2021)

The Stainless Tubes are made of stainless steel round steel, plate (flat plate or coiled plate), hollow long strip steel products processed by special process, steel with open ends and hollow section, and its length and section circumference are relatively large. It includes various shapes such as a circular tube, a square tube, an elliptical tube, and a triangular tube. Because the stainless steel pipe has a hollow section, it has the excellent performance characteristics of stainless steel and low maintenance cost. It is suitable as a conveying pipe for liquids, gases, etc. Stainless Tubes are one of the important products in the steel industry and is extremely used widely in the national economy.

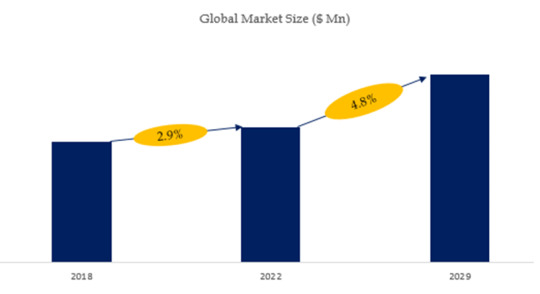

According to the new market research report “Global Stainless Tube Market Report 2023-2029”, published by QYResearch, the global Stainless Tube market size is projected to reach USD 50.16 billion by 2029, at a CAGR of 4.8% during the forecast period.

Figure. Global Stainless Tube Market Size (US$ Million), 2018-2029

Figure. Global Stainless Tube Top 5 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Stainless Tube include ThyssenKrupp, Tenaris, Pohang Iron & Steel (POSCO), Baosteel, Centravis, Tubacex, ArcelorMittal, Nippon Steel & Sumitomo Metal (NSSMC), Outokumpu, Tianjin Pipe (Group) Corporation, etc. In 2021, the global top five players had a share approximately 8.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Video

youtube

Platform Beds - Domestic or Import?

Do you buy domestic or import? Do you purchase a metal bed or wood bed? What style of bed do I want? These are all important questions to ask yourself before making click here your platform bed purchase. This article looks at these different questions and discusses these choices.

Platform beds are an interesting category in furniture today. They’ve been around since the late Neolithic age dating back as far as 4000 B.C. when they were nothing more than huge slabs of stone covered with bracken and slept on. Today’s beds are much more attractive and comfortable than those early Neolithic beds used by our prehistoric ancestors and in this article we’ll talk about the many varieties of platform beds available to us today.

Platform beds are best described as a bed with its own foundation built into it for the purpose of being used with just a mattress. As such there are many different ways in which to create a bed with this description. Let’s take a look at some of these varieties. Domestic wood beds are made in the same country as where you are purchasing the bed from. Most often this means it is made in the USA. Manufacturers of these wood beds will use a combination of North American woods including but not limited to oak, maple, ash, pine, aspen, ect.

Wood beds made in the United States are often found to use slat systems which are slats connected together using a polypropylene material that correctly spaces out the slats. Center support beams are often used which will run parallel with the side rails. The advantage of buying beds manufactured in the United States is that parts are easy to obtain as well as service. These beds will often cost more than their import counterparts but are made well and are sure to last.

Import wood beds are just as they sound, made overseas from imported wood. There are many import manufacturers based in Malaysia, China, Indonesia that manufacturer wood platform beds. These beds will be made from tropical hardwoods or other mixed hardwoods. Ramin is a popular wood used in these beds. These beds most often feature wood slats that are connected together with a nylon material that spaces out the slats. Additional leg supports are often used beneath these beds to provide additional center support. Since many of the factories that make these beds make them for a variety of distributors who bring them into the United States it is not uncommon to see similar or identical styles from vendor to vendor. Most often they are made similar enough that the pricing should also reflect that similarity.

The only real disadvantages of buying import beds are obtaining parts for them. Because they are made overseas and brought over on containers, obtaining parts is challenging. Metal beds are of course made from steel. These beds are usually tubular in nature meaning that it is made from steel but using hollow tubes to form the various structures of the headboard and footboard. Side rails will be substantial and will typically weigh the most. Hollow steel cross bars are often used across the rails to form the foundation. Paneling or wood slats may be used across the foundation. These beds are available from North American manufacturers but are also slowly being built overseas as import models.

1 note

·

View note

Text

Who are the Top Flange Manufacturers in Usa ?

In the elaborate world of business pipelines, endless components work collectively to make certain safe and efficient fluid glides. Among these vital elements are flange, the unsung heroes that join pipes, valves, and different devices. Arcellor Controls, a dependent on companion in industrial automation solutions arcellor manipulate ON Arcellor Controls, recognizes the importance of superb flanges. But with several producers in the USA, how do you identify the top contenders?

Flanges: The Cornerstones of Secure Connections

A flange is a ring-shaped steel element with holes drilled around its circumference. It is connected to the ends of pipes, valves, or other equipment the usage of bolts and gaskets to create a stable and leak-evidence connection. Flanges are an essential part of flange couplings, which might be assemblies that are a part of pipes or tubes together completely. Flanges are available in diverse sorts, each suited for precise applications and pressure requirements:

Weld Neck Flange: Considered the strongest and most flexible flange kind, proposing an extended neck that is welded to the pipe for top-quality strain dealing with. This is a famous choice for high-strain packages.

Slip-On Flange: A price-effective option that slips over the pipe quit and is welded at the backside for a good stress score. This is suitable for lower strain packages where ease of meeting is vital.

Threaded Flange: Ideal for low-stress applications wherein frequent disassembly is needed, providing internal threads that screw onto the pipe. This is a superb option for clean renovation.

Socket Weld Flange: Similar to a slip-on flange however with a smaller internal socket for welding, supplying right strength in smaller diameter pipes. This is a space-saving option for programs with confined rooms.

Blind Flange: A stable disc-formed flange used to seal off the stop of a pipeline. This is useful for separating sections of a pipeline for upkeep or destiny growth.

The Advantages of Using Flanges

Flanges offer several benefits in business piping structures:

Leak-Proof Connections: The combination of bolts and gaskets ensures a tight seal, stopping leaks and safeguarding towards environmental contamination.

Easy Assembly and Disassembly: Flanges permit for easy connection and disconnection of pipes and systems, facilitating preservation and repair techniques.

High-Pressure Rating: Different flange sorts are designed to resist various pressure degrees, accommodating diverse business programs. Flange selection is vital for the safe operation of flange couplings in excessive-strain structures.

Versatility: The extensive form of flange kinds and substances guarantees compatibility with various pipe sizes, pressures, and fluids. This permits flexibility in designing and constructing exclusive sections of a pipeline.

Top Flange Manufacturers in the USA

While a definitive rating can be subjective and rely on unique desires, a number of the top flange producers within the USA are renowned for their best, reliability, and numerous product services:

Shaw Stainless and Alloy: A main manufacturer of incredible flanges in diverse grades of stainless-steel, alloy metal, and carbon metallic.

Texas Flange: Specializes in a comprehensive range of ASME and non-code flanges, catering to numerous industries like petrochemical, system, and waterworks.

SWEP International AB: A global dealer of flanges and different piping components, recognized for his or her commitment to international requirements and nice management.

Conclusion

Flanges are the silent workhorses of business pipelines, the crucial components forming the inspiration of secure and reliable flange couplings. Understanding special flange types, their benefits, and legitimate manufacturers inside the USA empowers you to make knowledgeable selections on your specific wishes. When it comes to industrial automation solutions, Arcellor Controls is your one-prevent shop for tremendous flanges and different essential components. We associate with leading manufacturers to offer you with the excellent possible products in your commercial initiatives.

0 notes

Text

Matco Industry: Top Fencing Supplier in the Realm of Manufacturing and Construction

With 10+ years of experience, the Matco industry has been regarded as one of the top suppliers and manufacturers of all fencing and construction-related needs, with excellent customer support service. We offer a variety of goods, like sandwich switches and stainless steel coils, to precast concrete blocks in Saudi Arabia and many more countries, like the UAE, Oman, Iraq, Qatar, North Africa, Egypt, the USA, and many more. Our u channel in Saudi Arabia and the strut channel in Saudi Arabia make us great at meeting large orders without failing customer expectations. Here are many more reasons that make the Matco Industry your best friend when it comes to construction and fencing needs.

Is fencing even important? Is it worth the additional hassle?

Customer satisfaction is our top priority; that’s why the Matco industry offers seamless integration for all your fencing needs. From buying excellent-quality fencing materials like c-channel, u-channel, and uni strut in Saudi Arabia and many more to steel construction in Saudi Arabia, we offer both manufacturing and supply solutions. Fencing provides extra security and protection from unwanted access to your property. Be it temporary fencing to save up some cost or permanent fencing that pays for itself over time, you will be amazed by the quality of our fencing materials and our priority customer support.

Key Advantages of Opting for Matco Industry’s Fencing Supplies over Others

Every product developed within our facility is manufactured and tested to the best standards in the industry. Hot-rolled structural steel used in c-channel manufacturing in Saudi Arabia is just one of the few examples of industry-leading construction equipment that offers best-in-class quality and strength. If you’re looking for a bollard in Saudi Arabia, then the Matco Industry is there to serve. Matco Industry also provides comprehensive solutions for fencing, roofing, coils, pipes, tubes, and much more. Get in touch with us at our website, matcoindustry.com.

Matco Construction Supplies: Sturdy Yet Pocket-Friendly

Matco Industry’s construction and structural supplies offer ease of use and quick application. We’re the leading supplier of precast concrete blocks in Saudi Arabia and 100+ countries. Precast concrete blocks are treated within the plant during their manufacturing and are made into blocks of the desired shape to save time during construction and ensure less broken concrete goes to waste. Similarly, we are leading professionals when it comes to the supply of the best bollards in Saudi Arabia and provide the best c-channel in Saudi Arabia that can be used in a multitude of construction applications like framing and support beams.

What Do You Get When Selecting the Matco Industry?

Excellent customer support has been our utmost priority. It’s our mission to provide our clients with the best experience possible when serving their construction needs.

Our operations are handled with tremendous conviction. Hence, the Matco industry offers a reliable flow of tasks throughout your project.

Our online website also offers secure online shopping for all the products we deal in. Scan and purchase what’s best for you.

With high regard to our morals and standards, we operate with supreme diligence and leave no trace of less-than-optimum service.

Modernized machinery and facilities at Matco Industries provide top-quality products with service quality checks to ensure a great user experience.

All this concludes is that Matco’s promise of excellent and unwavering customer service pushes them to provide the best possible construction and fencing supply all across the UAE. From steel construction in Saudi Arabia to U-channel in Saudi Arabia, Matco Industries offers a complete one-stop solution to every fencing and construction need out there. Experience it for yourself at matcoindustry.com.

source url:- https://medium.com/@matcoindustry/matco-industry-top-fencing-supplier-in-the-realm-of-manufacturing-and-construction-83784b9b72c7

#bollard saudi arabia#c channel saudi arabia#precast concrete block in saudi arabia#steel construction in saudi arabia#strut channel saudi arabia#u channel in saudi arabia#unistrut saudi arabia

0 notes

Text

The Top Tubes Manufacturers, Supplier & Exporter in USA - Mcneil Instruments

Mcneil Instruments is a top tube manufacturer supplier & exporter in the United States, with a 37-year history of reliability and quality. Our products, which include hastelloy and alloy steel tubes, are put through a thorough testing process to guarantee strength and longevity. As top tube suppliers, we meet the demands of different industries with a wide selection of products, such as seamless and stainless steel tubes. For all of your tube needs, McNeill Instruments provides dependable solutions because of our expert engineering and premium materials. Get in touch with us right now for exceptional tube solutions that go above and beyond.

0 notes

Text

youtube

ELGi | OF SERIES | OIL FREE SCREW AIR COMPRESSORS | CLASS ZERO OIL | ALWAYS BETTER

ELGi is one of the very few companies that design and manufacture oil-free airends for air compressors. With in-house oil-free technology, the compressors are engineered to deliver maximum #uptime and #reliability.

ELGi’s Oil-Free Air Compressors have helped thousands of customers worldwide to meet air quality requirements, especially in critical industrial applications with absolute intolerance to the presence of oil during the manufacturing process. Right from the sustainable production of premium organic wine in France, manufacturing of superior quality rice brand oil in Thailand, paper manufacturing in Indonesia, chocolate manufacturing in Italy, food processing in the USA, pharmaceutical manufacturing in Europe and Singapore, semiconductor manufacturing in Malaysia, power generation in the Philippines, or medicine and vaccine manufacturing in India. ELGi’s Oil-Free Air Compressors have been reliably delivering contamination-free, environmental-friendly, class zero oil-free air, in line with ISO 8573-1 standards. ELGi’s manufacturing facility for oil-free compressors is also ISO 22000 certified for compliance with food safety management systems. Customers worldwide have experienced the benefits of the low total cost of ownership, high reliability, consistent air quality, efficient airflow, reduced risk of contamination of downstream parts and applications, best-in-class service support, unmatched warranty, and quicker return on investment. With adherence to superior safety norms, the OF series compressors not only have low energy losses and low air outlet temperatures but are highly reliable and compact. All these advanced features are thus integrated into one simple design that drives reliability and performance.

The ELGI OF series oil-free screw air compressor for critical industries. ELGI is one of very few air compressor companies in the world to design and manufacture oil-free air ends. With high reliability and performance, the ELGI OF series of oil-free screw compressors has multiple benefits for the customer. The ELGi’s OF series compressors come with unique η-V rotors that are designed to run at low speeds, reduce pressure losses, and increase stage efficiencies, leading to an optimized compressed air system. The slow speed of air ends leads to lesser wear and tear, lesser vibration, and enhanced life of the compressor. The timing gears are adequately placed to ensure the rotors are not in contact for effective functioning and consistent air and performance across the product lifecycle. The ELGi’s unique two-layer coating process provides a smooth and uniform surface. This also ensures porosity-free uniform coating on the rotors. The carbon impregnated robust stainless steel air seals prevent air leakage from the compression chamber by radial and axial sealing. The air-cooled compressors come with an aluminium bar and plate-type heat exchanger. The water-cooled compressor has water-in tube features with an extended cooler tube surface and systems that ensure low fouling and lower pressure drop across the cooler.

The ELGi’s OF series oil-free compressors come with the best-in-class warranty program. They are available in air-cooled and water-cooled variants with fixed speed and variable speed options operating in the range of 1.5 to 10 bar. The ELGi OF series compressors are an ideal solution for critical industries that need clean class zero oil-free air with a low total cost of ownership, easy maintenance, and unrivalled customer service. The ELGi OF series oil-free screw air compressor for critical industries.

0 notes

Text

Superior Steel Tube Manufacturer in USA

Piping Project is one of the Best Steel Tube Manufacturers in USA. We are manufacturers and suppliers of all types of seamless and welded Steel Tubes in sizes range of 12.7mm to 906mm OD, in wall thickness up to 40mm. Seamless Steel Tubes and welded Steel Tubes are made from a different materials.

Seamless and welded steel tubes have distinct structural properties and production methods. By heating and piercing a solid billet, Steel Tube Manufacturers are created that are flat and don't have welding connections. Strength and longevity are increased by the smooth construction, which guarantees a homogeneous and constant structure.

To Find Out More mainly Visit: Steel Tube Weight Chart

Website: pipingprojects.us

0 notes

Text

Structure and Support | Goel Scientific | Canada | USA

We supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers, in Canada, the USA Goel Scientific Glass

#Best#Top#supply Glass plants that are supported in a tubular structure formed of galvanized steel tubes Manufacturers#in Canada#the USA Goel Scientific Glass

0 notes

Text

Steel Stair Stringers and Stair Treads | AAIT

AAIT, a scaffolding equipment company in the USA, manufactures Steel Stair Stringers for better accessibility at heights. Scaffolding is a structure that supports loads, and the structure itself consists of different scaffolding accessories. These include tubes, clamps, base jacks, ladders, planks, etc. One of the many pieces of scaffolding equipment is steel stair stringers, which is a structural member that supports the treads and risers in a standard staircase.

0 notes

Text

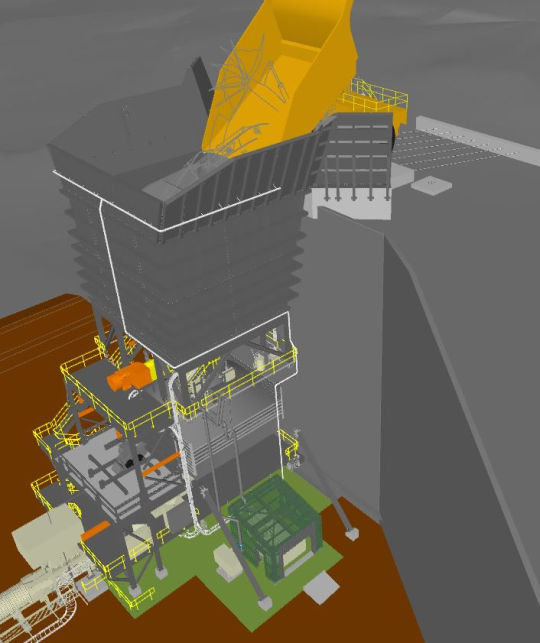

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

Stainless Steel 304 Buttweld Fitting Manufacturers in India

Divine Metal & Alloys Stainless Steel 304 Pipes Fittings are comprised of 18/8 chromium-nickel composite. The material has 18% chromium and 8% nickel in its Alloys. This makes the material more grounded, with 215 MPa of least yield strength and 505 MPa of least elasticity. The blend makes the material erosion-safe and high-temperature-competent up to 889 degrees Celsius. Divine Metal and Alloys is a producer and provider of these fittings. The 304 Stainless Steel Buttweld Fittings go under the standard ASTM A403, and the external measurements range from 12 inches to 48 inches. For seamless fittings, the diameters range from 12 to 10 inches. There are various sorts, for example, the SS 304 Pipes Fittings, which are used to redirect streams, and the SS WERKSTOFF NR. 1.4301 Tee, which is used to associate three Pipes at one junction.

Specification Stainless Steel 304 Buttweld Fitting

SpecificationsASTM A403ThicknessSCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75sizeSeamless Buttweld Fittings: 1/2" - 10"

Welded Buttweld Fittings: 1/2" - 48"TypeDN15-DN1200DimensionsASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10Bending RadiusR=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Stainless Steel Pipe FittingSize Range½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 Stainless Steel Buttweld FittingElbowsAngle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D .

Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISOConnectionWeldingManufacturing processForge, Cast, Push, Press, etc.Origin & MillsIndian, USA, Korean, Japanese, European, Ukraine, RussianKey markets and industries

Bitumen upgraders.

Heavy oil refineries.

Petrochemicals and acids.

Nuclear power (mostly seamless).

Test CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etcSpecialized manufacturer of90º Elbows, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe BendApplication & uses

Fittings To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc

Schedule 10 fittings are an economical alternative for lower-pressure applications.

Schedule 40 fittings have a thicker wall for higher-pressure applications.

0 notes

Text

Pipe Fit-Up Outer Clamp Manufacturer - USA, Australia, Malaysia, Singapore, Russia, Egypt

SPM’s Pipe Line-up Outer Clamp (Tack Type) is precision Bored for Perfect Roundness and Pipe Sizing. We are manufacturer and supplier of Pipe Fit-up Outer Clamp in Russia, USA, UAE, Australia, Malaysia. Our Tack type Clamps are ruggedly built of quality steel to last longer. Additional sizes are available upon request. All pipe fit-up outer clamps are precision fitted to the proper specification to ensure proper alignment and quick clamping with a convenient hand lever for quick line-up of the pipe.

1 note

·

View note