#elastomers

Text

Bright and tough: A material that heals itself and glows

A research team at the RIKEN Center for Sustainable Resource Science (CSRS) has succeeded in developing a self-healing material that is also capable of emitting a high amount of fluorescence when absorbing light. The research, published in the Journal of the American Chemical Society, could lead the way to the creation of new materials such as organic solar cells that are more durable than current types.

In 2019, Zhaomin Hou and his team at RIKEN CSRS successfully copolymerized ethylene and anisylpropylene using a rare-earth metal catalyst. The resulting binary copolymer displayed remarkable self-healing properties against damage. The copolymer's soft components, alternating units of ethylene and anisylpropylene, coupled with hard crystalline units of ethylene-ethylene chains, acted as physical cross-linking points, forming a nano-phase-separated structure that proved crucial for self-healing.

Building upon this success, they incorporated a luminescent unit, styrylpyrene, into a monomer and then formed polymers that also included anisylpropylene and ethylene. This process led to the synthesis, in a single step, of a self-healing material with fluorescence characteristics.

Read more.

#Materials Science#Science#Self healing#Fluorescence#Light#Polymers#Copolymers#Luminescence#Elastomers

37 notes

·

View notes

Text

#skinrite#shore hardness#rubbers#polymers#moldrite 25#mold making material#kastez resin#environmolds#elastomers#durometer

0 notes

Text

#polymers#polymer#engineering#polymerclay#plastics#chemistry#polymerclayart#polymerclayearrings#plastic#polymerclaycreation#polymerclaystuds#polymerclaycharms#elastomers#polymere#polymereclay#polymerclaylove#polymo#polymerc#technology#manufacturing#oilandgas#materialsengineering#laboratory#construction#automotive#materialscience#chemicals#science#ceramics#aerospace

0 notes

Text

#silicone#cirurgiaplastica#siliconemolds#mamoplastia#cirurgiaoplastico#siliconemold#estetica#rinoplastia#elastomers#polymers#technology#polyurethane#rubber#materials#sustainability#Innovation

0 notes

Photo

Polymers are another ETP ( Export Trade Product) that Nozhan Polymer Co is handling The four basic polymer structures are linear, branched, crosslinked, and networked In the next posts. In detail, we'll explain fully, and then all types of polymers we can export will be introduced fully #polymers #polymer #engineering #polymerclay #plastics #chemistry #polymerclayart #polymerclayearrings #plastic #polymerclaycreation #polymerclaystuds #polymerclaycharms #elastomers #polymere #polymereclay #polymerclaylove #polymo #polymerc #technology #manufacturing #oilandgas #materialsengineering #laboratory #construction #automotive #materialscience #chemicals #science #ceramics #aerospace (at Nozhan Polymer Co) https://www.instagram.com/p/CqnvLjhueu-/?igshid=NGJjMDIxMWI=

#polymers#polymer#engineering#polymerclay#plastics#chemistry#polymerclayart#polymerclayearrings#plastic#polymerclaycreation#polymerclaystuds#polymerclaycharms#elastomers#polymere#polymereclay#polymerclaylove#polymo#polymerc#technology#manufacturing#oilandgas#materialsengineering#laboratory#construction#automotive#materialscience#chemicals#science#ceramics#aerospace

0 notes

Text

India's Elastomers Market to Grow Rapidly with a CAGR of 8.41%

Get insights into the rapidly growing elastomers market in India with a forecasted CAGR of 8.41% until 2028.

0 notes

Photo

A Material in a League of its Own: Ceresana Publishes New Study on the Global Market for Thermoplastic Elastomers Soft and flexible, yet easy and inexpensive to process: Thermoplastic elastomers (TPE) are elastic like rubber at room temperature, but can be melted and repeatedly moulded like standard plastics. "Thermoplastic elastomers offer high strength and are robust; they can be welded watertight and colored in a variety of ways. In principle, TPEs can also be recycled," explains Oliver Kutsch, CEO of the market research institute Ceresana: "These innovative materials are conquering more and more application areas. TPEs are also interesting because components can be made from renewable raw materials or combined with bioplastics." This is the fourth time Ceresana has analyzed the global market for thermoplastic elastomers: By 2031, revenues generated with TPEs are expected to increase to almost USD 27 billion. However, growth will be driven not only by increasing demand, but also by price inflation. Further information about the market study “Thermoplastic Elastomers (TPE)” (4th edition): https://www.ceresana.com/en/market-studies/plastics/thermoplastic-elastomers/

0 notes

Text

Waterborne Polyurethane Market Report–Forecast (2022-2027)

The Waterborne Polyurethane Market size is forecasted to reach US$2.2 billion by 2027, after growing at a CAGR of 5.3% during the forecast period 2022-2027. Waterborne polyurethane, which is made from hexamethylene diisocyanato, polystyrene, carbamate and other chemicals, is produced by dispersing polyurethane polymer resins in water. Waterborne polyurethane is frequently used for low volatile organic compounds (VOC), water-based paints & coatings, adhesives and ink binders that are safe for the environment. The growth of the building & construction activities are primarily propelling the Waterborne Polyurethane Market growth. However, in 2020, the shortage of raw materials, restrictions on the labor movement and other restrictions due to the Covid-19 pandemic negatively impacted the growth of the Waterborne Polyurethane industry. In 2021, the surge in the production activities, due to economic stimulus packages, ease of Covid-related regulations and other factors aided the market growth. Moreover, the bolstering transport industry will boost the demand for Waterborne Polyurethane. This, in turn, will accelerate the expansion of the Waterborne Polyurethane Market size in the coming years.

Report Coverage

The "Waterborne Polyurethane Market Report–Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Waterborne Polyurethane Market.

By Product Type : Anionic PUDs, Cationic PUDs, Non-Ionic PUDs, Single-Component Polyurethane, Two-component Polyurethane, Urethane-modified and Others.

By Finishing : Gloss, Semi-gloss and MatBy Application : Paints and Coating, Adhesive and Sealants, Elastomers, Ink Binders, Foam (Rigid and Flexible), Synthetic Fiber and Others

By End-Use Industry : Building & construction (Residential, Commercial, Industrial and Infrastructure), Transport (Automotive (Passenger Vehicles (PV), Light Commercial Vehicles (LCV) and Heavy Commercial Vehicles (HCV)), Aerospace (Commercial, Military and Others), Marine (Passenger, Cargo and Others) and Locomotive), Furniture, Electronics and Electrical (Televisions, Smartphones, Computers, Wires and Others), Packaging (Cans, Drums, Tubes and Others), Textile and Others

By Geography : North America (USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World (Middle East (Saudi Arabia, UAE, Israel and Rest of Middle East) and Africa (South Africa, Nigeria and Rest of Africa))

Inquiry Before Buying : https://www.industryarc.com/reports/request-quote?id=500379

Key Takeaways

Asia-Pacific dominated the Waterborne Polyurethane Market, owing to the growth of the building & construction activities in the region. For instance, according to the International Trade Administration (ITA), South Korea's construction industry was valued at US$164 billion in 2020, up 15.5% from 2019.

The growth of the transport industry is accelerating the demand for composite materials coatings to ensure superior protection from temperature, corrosion and more. This factor is driving the Waterborne Polyurethane industry growth.

Moreover, the surging government regulations for low VOC content in coatings and other products are accelerating the Waterborne Polyurethane Market growth.

Nevertheless, the volatility in the raw material prices of Waterborne Polyurethane may restrict the Waterborne Polyurethane during the forecast period of 2022-2027.

Request For Sample : https://www.industryarc.com/pdfdownload.php?id=500379

Waterborne Polyurethane Market Segment Analysis – By Application

The paints and coating segment held the largest Waterborne Polyurethane Market share in 2021 and is forecasted to grow at a CAGR of 5.4% during the forecast period 2022-2027. Waterborne polyurethane formulations are employed in paints and coatings to ensure superior flexibility and reduce moisture and solar radiation absorption. This enables high environmental resilience and fewer solvent emissions. Also, in Waterborne Polyurethane, the hydrophobic/hydrophilic balance is used because it offers good conditions for concentration at the polymeric particle's surface area during the dispersed stage. This property ensures the superior appearance and higher durability of paints and coatings. Thus, Waterborne Polyurethane coatings with excellent transparency, solvent resistanceand hardness have found widespread application in furniture, leatherand other industries. This, in turn, is leading to the Waterborne Polyurethane Market growth.

Waterborne Polyurethane Market Segment Analysis – By End-Use Industry

The building and construction segment held the largest Waterborne Polyurethane Market share in 2021 and is forecasted to grow at a CAGR of 5.7% during the forecast period 2022-2027. Waterborne polyurethane has several advantages, including temperature curing, superior adhesion, high strength and other advantages that ensure superior durability. Thus, owing to these benefits, it is frequently used in building and construction applications such as flooring, roofing and more. The surging demand for affordable housing, increasing demand for commercial spaceand other factors are vital for the growth of the building and construction activities. For instance, in Q3 of 2021, the development of various offices started in Germany, which included Markisches Zentrum Redevelopment (completion year Q4 2023), Minden Headquarters Building (completion year Q3 2024), Kolbenhoefe Mixed-Use Complex (completion year Q4 2023) and others. Moreover, according to the United States Census Bureau, in 2021, the total new residential construction projects started in the USA was 1,610 thousand units, an increase of 16.7% over 2020. Hence, the growth of the building and construction industry is propelling the demand for waterborne polyurethane-based paints & coatings, adhesions and more. As a result, accelerating the Waterborne Polyurethane Market growth.

Waterborne Polyurethane Market Segment Analysis – By Geography

Asia-Pacific is the dominating region as it held the largest Waterborne Polyurethane Market share in 2021 up to 41%. The growth of the building & construction activities, transportand other industries are driving the economic growth of the Asia-Pacific region. The key variables such as rising retail store building construction, rising commercial centers and more such variables are creating an opportunity for the construction industry growth in Asia-Pacific. For instance, in August 2021, New Zealand's Auckland Airport announced plans to develop 100 retail stores. The new retail area would entail the construction of a 23,000-square-meter-plus outlet center on undeveloped property near the airport's north-eastern boundary. Moreover, as of May 2022, the construction of the 466 trillion Indonesian rupiahs ($32.3 billion). Indonesia's new capital is in progress. The capital city's construction will be complete by the end of 2024. The construction activities include the construction of offices, residential apartments, shopping centers and more. Also, according to Invest India, there is a total of 115 future construction projects which are under the planning phase in India and the value of these projects is about US$11.63 million. These projects include the construction of hotels & office buildings, shopping complex and more. Therefore, the growth of the building and construction industry is propelling the demand for waterborne polyurethane to enhance adhesion and sealants. This, in turn, is accelerating Waterborne Polyurethane Market size growth.

Waterborne Polyurethane Market Drivers

Growth of the Transport Industry

The critical benefits of waterborne polyurethane include Chemical resistance, high elongation, UV resistance, low-temperature flexibility and more. These advantages result in enhancing the durability of the coatings. Thus, owing to these benefits, it is often deployed in the coating of transport vehicles elastomers, sealants and more. The factors such as the increasing adoption of passenger cars, the booming transport production and other factors are accelerating the growth of the transport industry. For instance, according to the Organisation Internationale des Constructeurs d'Automobiles (OICA), in 2021, the global automotive production was 80,145,988 units, an increase of 2% over 2020. Moreover, according to airbus the widebody aircraft production in the year 2018 was 96 units and in 2019, it was 153 units, an increase of 59.4%. Thus, the growth of the transport industry is accelerating the demand for waterborne polyurethane, thereby, driving the market growth.

Surging Adoption of Sustainable Products

Waterborne polyurethane (PU) is growing rapidly, owing to environmental legislation. For instance, the Clean Air Act and advancements in technology that have made them a feasible substitute for solvent-based analogs. Waterborne polyurethane is versatile and environmentally friendly coating material that comes in a variety of hardness and solid content levels. Moreover, their zero to low volatile organic content makes it easier to formulate them into a compliant coating for a wide range of substrates. Therefore, waterborne polyurethane adaptability and a wide range of superior properties, such as abrasion resistance, impact strengthand low-temperature flexibility, are driving forces behind their ever-increasing use in a variety of applications. As a result, the Waterborne Polyurethane Market is expanding.

Waterborne Polyurethane Market Challenges

Volatility in Raw Materials Prices

Polystyrene and other materials are utilized as raw ingredients in the manufacturing of Waterborne Polyurethane. The majority of these materials are crude oil-based derivatives that are susceptible to commodity price volatility. Moreover, the ongoing Russia-Ukraine war has highly impacted crude oil prices. For instance, according to the World Bank, Brent crude oil prices are expected to average $100 per barrel in 2022, the highest level since 2013and a more than 40% increase over 2021. This causes ethylene carbonate raw material costs to fluctuate. Thus, the fluctuations in the prices of the raw materials may restrict the growth of the waterborne polyurethane industry during the projected forecast period.

Buy Now : https://www.industryarc.com/purchasereport.php?id=500379

Waterborne Polyurethane Industry Outlook

Technology launches, acquisitions and increased R&D activities are key strategies adopted by players in the Waterborne Polyurethane Market. The top companies in Waterborne Polyurethane Market are:

Dow

Bayer Materialscience

Axalta Coating Systems

Henkel

PPG Industries

BASF

H.B. Fuller

RPM International

3M

Sherwin-Williams

Recent Developments

In January 2021, Allnex launched DAOTAN 7061/35WA, a waterborne polyurethane dispersion for the automotive OEM and vehicle refinish coating markets. The 7061 is a versatile and high-performance product that can be utilized across multiple application areas, including waterborne automotive and refinish basecoats, automotive interior & exterior primers and general industrial applications.

In January 2020, BASF, a leader in the manufacture of waterborne polyurethane, increased the capacity of water-based polyurethane dispersions by 30% in Europe. The primary goal of this development was to better serve its clients and address the escalating demand for water-based polyurethane dispersions.

In June 2019, DSM collaborated with TLF (Germany), an international business that provides specialty chemicals to the leather and allied sectors. This agreement covers both the supply and the R&D of cutting-edge, environmentally friendly technologies for aqueous polyurethane dispersions. DSM and TFL are furthering the value of sustainable leather finishes and bolstering their market positions by collaborating at various stages along the value chain.

Relevant Reports

Waterborne Coatings Market – Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Report Code: CMR 0603

Polyurethane Dispersions Market - Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Report Code: CMR 8532

Water-based Resins Market - Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth and Forecast Analysis

Report Code: CMR 89072

For more Chemicals and Materials Market reports, please click here

0 notes

Text

Access full report- https://www.databridgemarketresearch.com/reports/global-construction-elastomers-market

0 notes

Text

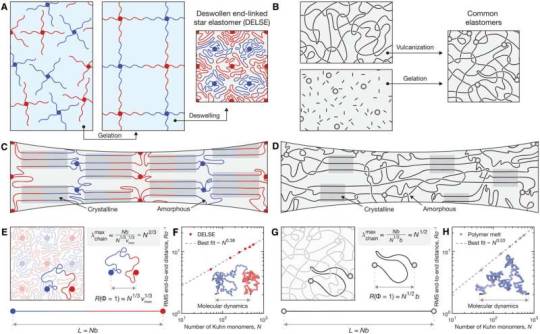

Developing a futuristic elastomer with ultrahigh strain-induced crystallization

Strain-induced crystallization can strengthen, toughen, and facilitate an elastocaloric effect in elastomers. The resulting crystallinity can be induced by mechanical stretching in common elastomers that are typically below 20%, with a stretchability plateau.

In a new report now published in Science Advances, Chase M. Hartquist and a team of scientists in mechanical engineering and materials sciences at MIT and Duke University in the U.S. used a class of elastomers formed by end-linking to achieve a percentage of strain-induced crystallinity.

The deswollen and end-linked star elastomer abbreviated as DELSE reached an ultrahigh stretchability to scale, beyond the saturated limit of common elastomers, to promote a high elastocaloric effect with an adiabatic temperature change.

Read more.

11 notes

·

View notes

Video

Bust a Move

Entering stage-left like a disco dancer with a score to settle, this tiny ‘soft robot’ makes a determined effort to cross the floor. All the more impressive as people keep sticking knives into its limbs. This quadruped robot is made from a self-healing material – an elastomer that repairs after the cuts, combined with wavy light sensors capable of detecting stress and damage then feeding the information back to a controlling computer. In this particular model, after every cut the robot adjusts its movement – it’s gait – to compensate for its injuries. Researchers believe this new generation of flexible electronics gains a form of awareness or 'damage intelligence' – they’re not only resilient to damage but can adapt to it. Similar robots may be suited to working inside or alongside the body, monitoring stresses and strains on and off the dance floor.

Written by John Ankers

Video by Hedan Bai, Young Seong Kim & Robert F. Shepherd (edited)

Sibley School of Mechanical and Aerospace Engineering, Cornell University, Ithaca, NY, USA

Video originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in Science Advances, December 2022

You can also follow BPoD on Instagram, Twitter and Facebook

68 notes

·

View notes

Text

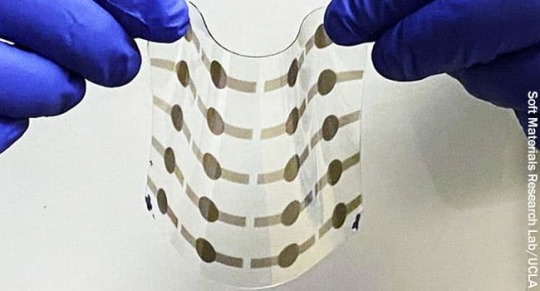

Scientists create artificial muscle stronger than human muscle

Scientists create artificial muscle stronger than human muscle

July 14, 2022 – Scientists from UCLA and nonprofit SRI International experiment with a strong, elastic polymer to create an artificial muscle, they describe as stronger and more flexible than human muscles.

Polymers are natural or synthetic substances that consist of large molecules and are building blocks of many minerals and man-made materials. In this case, researchers used electroactive…

View On WordPress

#artificial muscle#artificial muscles for humans#dielectric elastomers#dust mop#electroactive polymers#polymer#robot fish#scientists create artificial muscles#ucla artificial muscle

4 notes

·

View notes

Text

Global Top 12 Companies Accounted for 77% of total Thermoplastic Polyester Elastomer (TPEE) market (QYResearch, 2021)

Thermoplastic Polyester Elastomer (TPEE) is a block copolymer who contains a hard segment of polyester and a soft segment of polyether; wherein the amorphous is formed from the soft segment of polyether and the uncrystallized polyester. Micro-crystals play a role as physical crosslinking points formed from the hard segment of the polyester. Thermoplastic polyester elastomer has the rubber elasticity and strength of engineering plastics. Soft segment gives it flexibility to make it like rubber; hard segment assigns the processing properties which makes it like plastic. Compared with rubber, it has a better processing performance and longer life; and the same high strength characteristics compared to plastic, while the flexibility and dynamic mechanical properties is better.

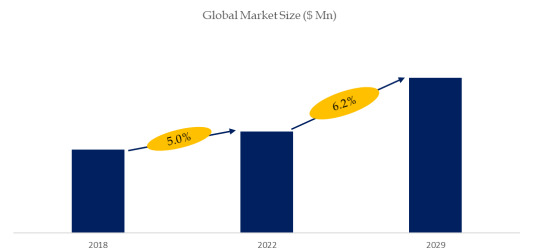

According to the new market research report “Global Thermoplastic Polyester Elastomer (TPEE) Market Report 2023-2029”, published by QYResearch, the global Thermoplastic Polyester Elastomer (TPEE) market size is projected to reach USD 1.94 billion by 2029, at a CAGR of 6.2% during the forecast period.

Figure. Global Thermoplastic Polyester Elastomer (TPEE) Market Size (US$ Million), 2018-2029

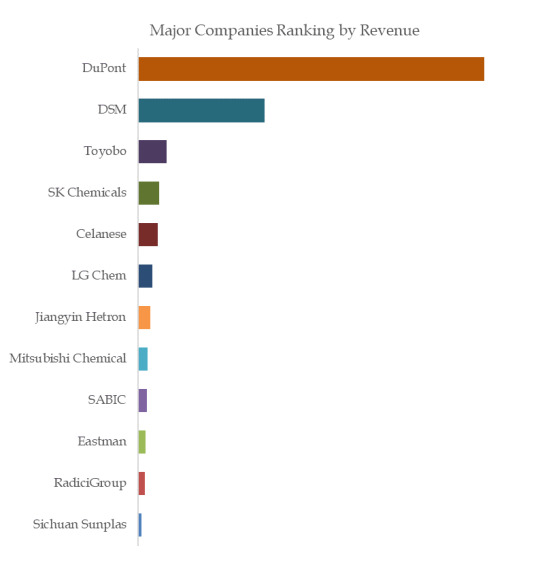

Figure. Global Thermoplastic Polyester Elastomer (TPEE) Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Thermoplastic Polyester Elastomer (TPEE) include DuPont, DSM, Toyobo, SK Chemicals, Celanese, LG Chem, Jiangyin Hetron, Mitsubishi Chemical, SABIC, Eastman, etc. In 2022, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Global Construction Elastomers Market is expected to register a CAGR of around 6% over the period of 2021-2027.

0 notes

Text

Ethylene Acrylic Elastomer (AEM) Prices Trend, Monitor, News, Analystics & Forecast | ChemAnalyst

Ethylene Acrylic Elastomer (AEM) prices, indicative of the cost of this specialized polymer, are subject to fluctuations influenced by various factors such as global market dynamics, industrial demand, and production costs. Understanding these price movements entails a comprehensive analysis of supply and demand dynamics, raw material availability, and macroeconomic indicators.

The pricing of Ethylene Acrylic Elastomer (AEM) is significantly influenced by the balance between supply and demand within industries such as automotive manufacturing, oil and gas, and industrial sealing applications. AEM, valued for its excellent heat resistance, oil resistance, and durability, is essential in various applications ranging from automotive seals and gaskets to oilfield equipment and industrial machinery components. Disruptions in the supply chain, such as fluctuations in raw material availability, production capacity, or transportation logistics, can impact the availability and cost of AEM, thereby influencing its market price.

Industrial demand plays a pivotal role in determining AEM prices. Industries such as automotive manufacturing rely heavily on AEM for its ability to withstand high temperatures and harsh environments, while the oil and gas sector utilizes it for sealing applications in drilling equipment and pipelines. Fluctuations in demand from these sectors, influenced by factors such as vehicle production levels, oil prices, and industrial activity, can lead to price volatility for AEM.

Get Real-Time Ethylene Acrylic Elastomer (AEM) Prices : https://www.chemanalyst.com/Pricing-data/ethylene-acrylic-elastomer-1211

Raw material costs significantly impact AEM prices. The price of raw materials such as ethylene and acrylic monomers, which are used in AEM production, can fluctuate due to changes in global supply and demand dynamics, feedstock availability, and energy costs. Any significant increase in raw material costs can translate into higher production costs for AEM manufacturers, thereby exerting upward pressure on prices.

Macroeconomic indicators, such as GDP growth, industrial output, and consumer spending, can indirectly affect AEM prices by influencing overall demand for products containing AEM. Economic expansions tend to drive demand for AEM-intensive products such as automotive seals and industrial gaskets, thereby supporting higher prices. Conversely, economic downturns or uncertainties may lead to reduced demand and downward pressure on AEM prices.

Regulatory changes and quality standards also play a role in shaping AEM prices. Government regulations on automotive emissions, oilfield safety, and industrial sealing requirements can impact production costs and market access for AEM manufacturers. Compliance with these regulations may require investments in research, testing, and quality control measures, influencing pricing dynamics.

Looking ahead, several factors are expected to continue influencing AEM prices. Continued growth in sectors such as automotive manufacturing, oil and gas exploration, and industrial sealing applications, coupled with increasing demand for high-performance elastomers, is likely to drive sustained demand for AEM. Moreover, advancements in polymer technologies and shifts in consumer preferences could lead to changes in market dynamics and price levels for AEM.

In conclusion, AEM prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, regulatory changes, and macroeconomic indicators. Stakeholders in industries reliant on AEM, such as automotive, oil and gas, and industrial manufacturing, must closely monitor these factors to anticipate price movements and make informed decisions. As industries evolve and regulatory requirements change, navigating the dynamic landscape of AEM pricing will remain a key challenge for industry participants.

Get Real-Time Ethylene Acrylic Elastomer (AEM) Prices : https://www.chemanalyst.com/Pricing-data/ethylene-acrylic-elastomer-1211

GmbH — S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49–221–6505–8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes