#welding and fabrication services

Text

Immortal Metals

Website: https://www.immortalmetalswelding.com

Address: 10410 66th St N Unit 2, Pinellas Park, Florida 33781, USA

Immortal Metals, a family-owned business led by Travis and Adelyn, specializes in custom metal fabrication and welding. With over 18 years of experience, they offer a range of services for residential, commercial, and industrial needs, including custom metal structures, welding, machining solutions, and heavy machinery repair. Their commitment to quality craftsmanship and personalized service makes them a prominent choice in Pinellas County, Florida.

Facebook: https://www.facebook.com/immortalmetalswelding

Instagram: https://www.instagram.com/immortalmetalswelding/

Linkedin: https://www.linkedin.com/company/immortalmetals/

Keywords:

welding services near me

sheet metal fabrication near me

metal polishing near me

custom metal fabrication near me

solar panel structure

heavy equipment repair near me

custom metal fabrication

machinery repair services

solar panel mounting structure

custom sheet metal fabrication

sheet metal custom fabrication

metal polish service

welding repair services

custom machined parts

welding repair services near me

solar panel shade structure

welding inspection services

complete welding services

welding and fabrication services

professional welder near me

welding mobile services

industrial welding projects

quality custom metal fabrication

heavy machinery repair near me

custom metal art fabrication

solar panel base structure

custom welding services

commercial metal buildings near me

custom welding fabrication near me

metal building repair service

custom metal fabrication services

solar panel carport structure

welding consultancy services

custom welding solutions

custom metal box fabrication

solar panel frame structure

solar panel internal structure

metal door repair services

metal roof repair services

commercial metal shade structures

quality sheet metal fabrication

mil spec welding

custom arc welding services

custom metal fabrication pinellas park

custom works metal fabrication

welding and brazing services near me

machining solutions near me

metal door repair services near me

metal gate repair services

metal shear repair service near me

heavy equipment machinery repair

heavy machinery mobile repair

customized auxiliary welding solutions

machining solutions pinellas park

commercial metal buildings pinellas park

robotic machine fabrication near me

flame cutting services near

unique metal projects

metalwork for residential projects

metal drilling service near me

mil spec welding service price

heavy machinery and equipment repair near me

heavy machinery and equipment repair pinellas park

high quality steel structures service

custom welding rates

custom metal structures service

custom steelwork

#welding services near me#sheet metal fabrication near me#metal polishing near me#custom metal fabrication near me#solar panel structure#heavy equipment repair near me#custom metal fabrication#machinery repair services#solar panel mounting structure#custom sheet metal fabrication#sheet metal custom fabrication#metal polish service#welding repair services#custom machined parts#welding repair services near me#solar panel shade structure#welding inspection services#complete welding services#welding and fabrication services#professional welder near me#welding mobile services#industrial welding projects#quality custom metal fabrication#heavy machinery repair near me#custom metal art fabrication#solar panel base structure#custom welding services#commercial metal buildings near me#custom welding fabrication near me#metal building repair service

1 note

·

View note

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF:

TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada:

Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic:

Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak:

Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser:

Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD:

LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India

CNC punching services in pune

Best MIG Welding Machine

Pre-Treatment for Surface Preparation in pune

Best CNC bending services India

Best SS fabrication services in India

Best spot welding services in pune

Best tube, pipe, and angle cutting services in pune

Best automotive manufacturers in pune

Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

Metal Fabrications Types

Casting

Casting is the process of pouring hot metal into a mould or die, allowing it to cool, harden, and take the desired shape. The mass manufacture of parts using the same mould repeatedly to produce similar goods is suitable for the metal fabrication process. There are numerous casting variations. Die-casting is the process of forcing liquid metal into a die rather than a mould, where the pressure retains the metal in place as it cures. The fast applications that this approach provides are its main selling point. Pouring molten metal into a mould is a permanent mould casting technique.

Cutting

Cutting a workpiece to divide it into smaller portions is a relatively typical method of metal production. While sawing is still the most common way to cut, more recent techniques include laser, waterjet, power scissors, and plasma arc cutting. Cutting might be the first step of a more involved fabrication process, or it might be the sole one.

Another method of cutting metal that employs a die is die cutting. In rotary die cutting, the material is cut using a rotating cylindrical die that is fed via a press. On thicker metal materials, flatbed die cutting is employed. When the die stamps down on the metal, it cuts out shapes.

Drawing

Tensile power is used in drawing to draw metal bending into and through a tapered die. The metal is thinned by the die's stretching action. Drawing is typically done at normal temperature and is known as "cold drawing," however the metal workpiece can be heated to lessen the effort needed.

When the finished result has a depth that is equal to or more than its radius, the procedure is referred to as deep drawing. It is typically used in conjunction with sheet metal fabrication to create hollow cylinder- or box-shaped vessels from sheets of metal.

Folding

Metal is bent at an angle during this metal engineering manufacturing process. The most typical method is using a brake press, which pinches the metal to make wrinkles in it. Holding the workpiece between a punch and a die, the punch applies pressure, causing the workpiece to crease. Typically, this method is used to form sheet metal. In addition to employing a folding machine, also known as a folder, or hammering the workpiece until it bends, folding can also be accomplished manually. The device features a flat platform where flat sheet metal is placed, a clamping bar to secure the workpiece, and a front panel that raises upward to bend the metal that is extended over it.

#bending services sydney#custom metal fabrication#sydney public art fabrication#metal engineering#welding services#linished stainless steel#steel fabrication

3 notes

·

View notes

Link

We are a West London-based family-run business offering a wide variety of services to suit any of your welding needs. Our skilled team are specialists in welding repair, custom steel fabrication, and CNC laser cutting.

#Welding Services#Metal Fabrications Company#welding workshop#fabrication workshop#welding repairs#custom fabrication#CNC laser cutting

2 notes

·

View notes

Text

Expert Welding Fabrication Services for your Industrial Needs

Staub Manufacturing Solutions offers top-notch welding fabrication services through skilled professionals and cutting-edge technology. From precision metalwork to customized solutions, they deliver excellence in welding services for diverse industrial needs. Contact them today!

0 notes

Text

Steel Shops Near You: Your Local Source for Quality Steel Products

Looking for steel shops near you? Look no further! Our local steel shops are your go-to source for quality steel products. Whether you're working on a small DIY project or a large-scale construction job, our shops have everything you need to get the job done right. From steel beams to sheet metal and everything in between, we offer a wide range of products to suit your needs. Plus, our knowledgeable staff are here to help you find the perfect steel for your project and offer expert advice on fabrication and welding. Visit our steel shops today and see why we're your local source for quality steel products.

#welders near me#metal fabrication shops near me#welding companies near me#welding services near me#welders in the northern district#steel welders near me

0 notes

Text

What is steel fabrication machines do?

Let's dive in! Steel fabrication machines are essential tools used to shape and assemble steel materials into various structures and products. From cutting and bending to welding and finishing, these machines streamline the fabrication process, making it efficient and precise. Whether you're crafting intricate designs or industrial components, steel fabrication machines are the backbone of the manufacturing industry. Explore the world of steel fabrication and unleash your creativity!

#steel fabrication#steel fabricators near me#custom sheet metal fabrication#welding machine#welding services

0 notes

Text

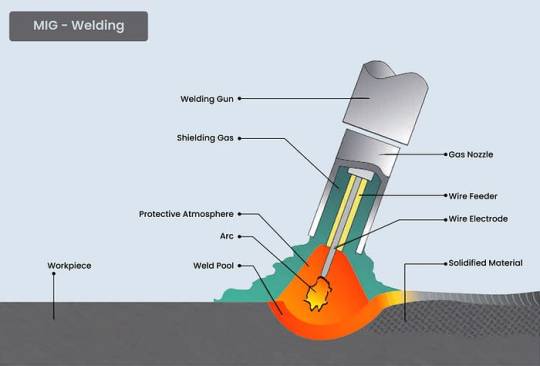

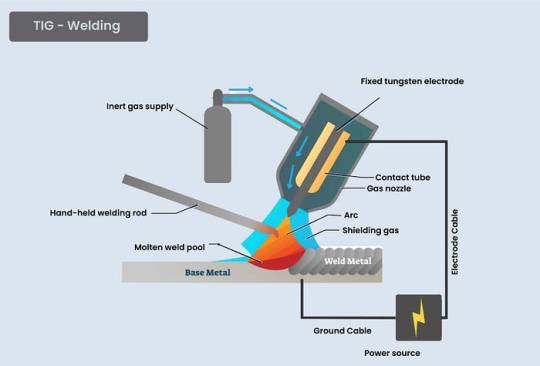

Choosing the Right Technique for Sheet Metal Welding: MIG vs. TIG Welding

Welding is a crucial process in metal fabrication, and when it comes to sheet metal cutting, two popular techniques stand out — MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. Each technique has its strengths and weaknesses, making the choice between them essential for achieving optimal results in sheet metal applications. In this blog, we will delve into the key differences between MIG and TIG welding, explore their suitability for sheet metal cutting, discuss the pros and cons of each method, highlight factors influencing the choice between them, and provide real-life examples of successful sheet metal cutting using both techniques.

What is MIG welding?

MIG welding involves a continuous wire feed that is fed through a welding gun and melted into the joint. A shielding gas, typically a mixture of argon and carbon dioxide, protects the weld pool from atmospheric contaminants. MIG welding is known for its efficiency and speed, making it a popular choice for various applications

What is TIG welding?

TIG welding is done by using a non-consumable tungsten electrode. The welder manually feeds a filler rod into the weld pool, which is protected by an inert gas, usually argon. TIG welding is recognized for its precision, control, and ability to produce high-quality welds on thin materials.

Which Welding Technique Is More Suitable for Sheet Metal Welding?

The choice between MIG and TIG welding for sheet metal cutting depends on several factors, including the thickness of the metal, the required precision, and the desired finish.

– MIG Welding for Sheet Metal Welding:

MIG welding is well-suited for cutting thin sheet metals due to its high travel speed and efficiency. It is ideal for projects where speed is crucial, such as in mass-production environments. However, MIG welding may not provide the same level of precision as TIG welding, and the heat input can sometimes be a concern for thinner materials.

– TIG Welding for Sheet Metal Welding:

TIG welding is preferred for cutting thinner sheet metals when precision and a clean finish are essential. It offers excellent control over the heat input, reducing the risk of warping or distortion in the metal. TIG welding is commonly used for intricate designs and projects where aesthetics and precision are critical.

What are The Pros and cons of MIG and TIG welding in sheet metal applications?

Pros:

High welding speed, making it suitable for mass production.

Good for thicker sheet metals.

Minimal skill requirement compared to TIG welding.

Cons:

Limited precision, which may not be suitable for intricate designs.

More heat input increases the risk of warping with thin materials.

Pros:

Excellent precision and control, making it ideal for thin sheet metals.

Clean and aesthetically pleasing welds.

Low heat input, reducing the risk of distortion.

Cons:

Slower welding speed compared to MIG welding.

Requires a higher skill level.

What Factors Need to Be Consider When Selecting the Appropriate Welding Method?

Choosing the right welding method for sheet metal cutting involves considering various factors to ensure the desired outcome. Here are some key considerations:

– Material Thickness:

MIG welding is more suitable for thicker sheet metals, while TIG welding excels in precision work on thinner materials.

– Precision Requirements:

If the project demands high precision and intricate detailing, TIG welding is often the preferred choice.

– Speed and Efficiency:

MIG welding is faster and more efficient, making it suitable for projects with tight deadlines and large production volumes.

– Skill Level:

Consider the skill level of the welder, as TIG welding requires more expertise than MIG welding.

– Aesthetics:

If the appearance of the weld is crucial, such as in architectural or decorative applications, TIG welding is often preferred for its cleaner finish.

– Cost Considerations:

Evaluate the cost of equipment, consumables, and labour associated with each welding method to determine the most economical choice for the project.

Read More-https://www.lsw.co.in/choosing-the-right-technique-for-sheet-metal-welding-mig-vs-tig-welding/

#manufacturing#aviation#construction#sheet metal fabrication manufacturers#metalworking#welding services

0 notes

Text

We are a reliable steel fabricator in NYC! We weld our steel plates with quality and precision to ensure all our customers are happy and inspections are always passed. Call us for a quote today! http://tinyurl.com/mpvmmesp

0 notes

Text

CNC Punching Services In Pune

Sawant Group in Pune offers top-notch CNC punching services for all your metal fabrication needs. With precision and efficiency at the forefront of our operations, we provide cutting-edge solutions for a wide range of industries. Trust Sawant Group for high-quality results that exceed your expectations.

Sorry, I am unable to access external websites to write content. However, I can provide you with a general idea for the section based on the information you provided. Section Heading CNC Punching Services at Sawant Group in Pune When it comes to precision metal fabrication services in Pune, Sawant Group stands out as a reliable provider of CNC punching services. Utilizing advanced technology and state-of-the-art equipment, Sawant Group offers high-quality CNC punching services that cater to a diverse range of industries and applications. At sawant group you can explore the comprehensive range of CNC punching services offered by Sawant Group. From prototyping to production runs, Sawant Group’s team of skilled professionals can handle varying complexities and specifications to meet your unique requirements. With a focus on efficiency, accuracy, and superior quality, Sawant Group ensures that each project is executed with precision and attention to detail. Whether you are looking for sheet metal punching, hole punching, or custom punching services, Sawant Group’s CNC capabilities enable them to deliver cost-effective solutions without compromising on quality. Visit Sawant Group. to learn more about Sawant Group’s CNC punching services in Pune and how they can cater to your specific metal fabrication needs.

For more info:- https://sawantgroup.co.in/

Gmail :- [email protected]

Mobile :- +91 98810 66175

#cnc punching services in pune#best spot welding services in pune#best mig welding machine#best ss fabrication services in india

0 notes

Text

0 notes

Text

Brannon machine repair | Machine Repair Service | Metal Fabricators in Northridge CA

We are your dependable and trustworthy go-to for exceptional Machine Repair Service in Northridge CA. It’s no secret that keeping industrial machinery running smoothly and efficiently is important to maintain productivity and profitability. Our skilled technicians have years of experience diagnosing and repairing various types of machines and equipment. Moreover, we also have a well-earned reputation as one of the best Metal Fabricators in Northridge CA. Our professionals can design, fabricate, and install metal products that are both functional and aesthetically pleasing. Using state-of-the-art equipment, we can turn any raw metal into a work of art, ensuring precision and quality. So, if you need our expert assistance, call us today.

#Machine Repair Service in Northridge CA#Metal Fabricators in Northridge CA#Welding and Fabrication near me#Industrial Machine Repair near me#Machinery Repair near me

1 note

·

View note

Photo

Top Class Welding Services in London with 45 Years' Expertise!

Our team of friendly and knowledgeable experts are committed to providing you with the highest quality of welding or fabrication for your project. Explore our extensive catalogue of services to find out what best suits your needs. Our prices are affordable, our turnaround time is rapid, and we accept bookings and emergency walk-in requests. We are a family-run welding and fabrication services company that has operated in the London area for over 45 years.

#Welding Services#Metal Fabrications Company#welding workshop#fabrication workshop#welding repairs#custom fabrication#CNC laser cutting

1 note

·

View note

Text

The Welding Workshop: Crafting Solutions for Your Metal Repairs

Finding reliable welding places near you can be challenging, but with The Welding Workshop, you can trust that your projects will be completed with the highest level of craftsmanship. Our certified welders have undergone extensive training and have years of experience working with a variety of metals, including steel, aluminum, and stainless steel.

Quality Craftsmanship and Attention to Detail

At The Welding Workshop, we understand the importance of quality craftsmanship and attention to detail. That's why we work closely with our clients to ensure that their vision is brought to life with meticulous attention to detail. Whether you need a custom metal sign, gate, or railing, our expert fabricators can create a piece that meets your exact specifications.

Comprehensive Welding and Repair Services

In addition to our fabrication services, we also offer comprehensive welding and repair services for all your metal needs. From industrial equipment to automotive parts, our team can handle repairs of all sizes with professionalism and efficiency. We use the latest welding techniques and equipment to ensure that your repairs are completed to the highest standards.

Safety and Efficiency

Safety is our top priority at The Welding Workshop. We adhere to strict safety guidelines and protocols to ensure that our work is completed safely and efficiently. Our team is trained to handle all types of welding projects, from small repairs to large-scale fabrication, with the utmost care and professionalism.

Choose The Welding Workshop

When you choose The Welding Workshop for your welding and repair needs, you can trust that you are getting the best service possible. Our team is dedicated to providing exceptional service and ensuring that your projects are completed to your satisfaction. Contact us today to learn more about our services and see how we can help with your next metal welding or repair project.

#welders near me#steel welders near me#welding services near me#metal fabrication shops near me#welding companies near me

0 notes