#steelfabrication

Text

Outsource Steel Erection Drawing and Detailing Services in USA at very low price

CAD Outsourcing Consultant specializes in providing comprehensive Steel Erection Drawing and Detailing Services. Our team of skilled professionals excels in delivering precise and efficient solutions for all your structural erection drawing needs. With a focus on excellence, we offer Outsource Erection Drawing Services tailored to meet the specific requirements of your Steel Detailing projects. Our Structural Erection Drawing Services utilize cutting-edge AutoCAD technology to ensure accuracy and adherence to industry standards. As your trusted Steel Detailing Consultant, we understand the critical role that precision plays in steel construction projects. Our experts are committed to delivering best AutoCAD Erection Drawing Services, ensuring seamless coordination between various project elements. When you choose CAD Outsourcing Consultant, you gain access to a dedicated team of CAD Services professionals who prioritize quality and timely delivery. We also provide you with skilled professionals Steel Fabricators to bring your Steel structure to life.

Why choose CAD Outsourcing Consultant for your Steel Erection Drawing and Detailing needs?

- Expert Steel Detailing Consultants: Our team comprises experienced professionals with a deep understanding of steel construction requirements.

- Precision with AutoCAD: We use advanced AutoCAD technology to create detailed and accurate erection drawings.

- Timely Delivery: We prioritize meeting deadlines to ensure your project progresses seamlessly.

- Cost-Effective Solutions: Our services are designed to provide value for money, optimizing your project costs.

- Comprehensive CAD Services: Beyond steel detailing, we offer a range of CAD services to cater to diverse project needs.

We offer our Erection Drawing Services USA and covered other cities: Ohio, California, Massachusetts, Idaho, Nebraska, Delaware, Wisconsin, South Carolina, New Hampshire and Georgia.

Visit Us:https://www.cadoutsourcing.net/shop-drawing-services/united-states-shop-drawings-service.html

Portfolio:https://www.cadoutsourcing.net/shop-drawing-services/steel-shop-drawings-erection-drawings.html

Software Expertise:AutoDesk AutoCAD, Revit, Tekla Structures, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

Get in Touch with Us:Website: https://www.cadoutsourcing.net/shop-drawing-services/steel-detailing-fabricating.html

Partner with CAD Outsourcing Consultant for reliable and efficient Steel Erection Drawing and Detailing Services.

Check Out my Latest Article "Why Steel Fabricators Prefer Tekla Structures Software?" is now available

https://www.linkedin.com/pulse/why-steel-fabricators-prefer-tekla-structures-software-2x5gf

#SteelErectionDrawing#ErectionDrawingServices#AssemblyDrawing#SteelFabrication#SteelDetailing#CADDrawingServices#Engineering#Building#Structure#BIM#B1M#Construction#CADServices#CadOutsourcing#Architect#Engineer#CADDraftman#BIMModeler#CadOutsourcingCompany#CAD#CADD#CADDesign#CADDrawing#CADDrafting#AutoCAD#Revit#TeklaStructures

4 notes

·

View notes

Text

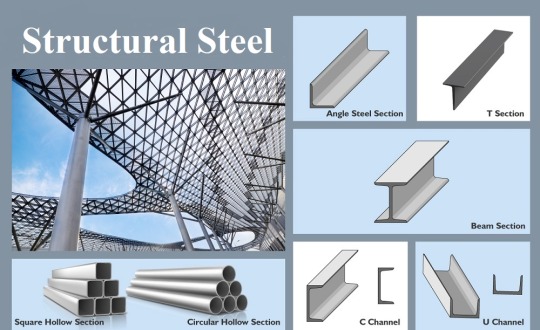

Ronik Chandrakanth Bldg Mat Tr LLC, a premier steel supplier in UAE, is now on TradersFind! Offering a comprehensive range of top-quality steel products, including coils, structural steel, plates, bars, and fencing solutions. Your one-stop destination for all your steel needs. Discover reliable steel solutions for all your construction and industrial needs here:

https://www.tradersfind.com/seller/ronik-chandrakanth-bldg-mat-tr-llc

#ChandrakanthBldgLLC#SteelSupplier#UAESteel#SteelProducts#StructuralSteel#SteelCoils#SteelPlates#SteelBars#FencingSolutions#SteelFabricator#IndustrialSupplies#BuildingMaterials#B2BPortal#TradersFind#SteelDistributor#MetalSupplier#ConstructionMaterials#IndustryLeader#SteelInnovation#SteelQuality#SteelExcellence#SteelSolutions#UAEConstruction#SteelFabrication#SteelCustomization#SteelExpertise#SteelSupplyChain

2 notes

·

View notes

Photo

Need a reliable steel supplier? We offer a wide range of structural steel as well as custom fabrication services. Call us for a quote today!

#galvanizedpipe#steelsupplier#newjersey#custom#steelfabrication#delivery#jobsite#reliable#galvanized#steel#nj#steelpipe

2 notes

·

View notes

Text

EXTRA DEEP BOWL WITH COLOUR & PRINTING

AARSHNIK as a leading manufacturer & exporter of AMMO BOX, Metal Fabricated Products, Barware, Petware, Kitchenware, Gardening Tools, Furniture, and Motorcycle Carriers for the last 17 years. We are socially compliant with BSCI; SEDEX/SMETA; SCS; FCCA & ISO 9001:2015.

#steel#Steelers#steelers#steelfabrication#mixingbowl#mixingbowls#mixingbowlset#mixingbowlsalad#mixingbowlmurah#mixingbowlenamel#bowls#bowlset#bowlsclub#bowlsofinstagram#deepmixingbowls#deepmixingbowl#kitchenware#kitchenwares#kitchenwarehouse#kitchenwareset#saladbowl#saladbowls#saladbowl🥗#saladbowloftheworld#Bowls#extradeep#Hearty stews and satisfying salads#creamy pasta#and steaming biryani#every dish you can think of gets more attractive and appealing in our extra-deep bowl. Offer generous single servings

3 notes

·

View notes

Text

What are the Processes of Metal Fabrication?

Metal fabrication is the process of creating parts and components out of raw metal stock. There are a variety of different processes that can be used, depending on the desired outcome. In this blog post, we'll take a look at the most common ones. So what are the processes of metal fabrication? Let's find out!

The first step in the metal fabrication process is to create a prototype. This helps the engineers perfect the design before it goes into production. Once the prototype is approved, the next step is to create the tooling. This is done by creating dies, molds, or jigs that will be used to shape the metal in the desired shape.

After the tooling is created, it's time to start fabricating the parts! This is done by cutting, bending, and assembling the metal into the desired shape. Once all of the parts are created, they are then welded or fastened together to create the finished product.

The final step in the process is to finish the product. This can be done by painting, plating, or powder coating the metal.

Processes of Metal Fabrication are:

Cutting

Formed

Welding

Finishing

Testing

Packing

Metal fabrication involves a number of complex and specialized processes, including cutting, forming, welding, finishing, assembly, testing, and packaging. Whether you need metal parts for your next project or want to start your own metal fabrication business, it is important to work with a reputable company that has the expertise and experience to deliver high-quality results.

https://sites.google.com/view/steelfabrications/blog/what-are-the-processes-of-metal-fabrication

#steel fabrication#steel fabricators#steel cutting#steel welding#steelfabrication#canada best steel faricators

2 notes

·

View notes

Text

We are experts when it comes to plasma cutting steel plate! We make sure all of our customers pieces are fabricated with quality and accuracy to ensure total satisfaction. Call us for a quote today! https://tinyurl.com/5xm2d6un

0 notes

Text

Steel Structures Shaping the Future: A Detailed Analysis of the Structural Steel Market Dynamics

The global structural steel market size was valued at USD 174.51 Billion in 2030 and is likely to register a compound annual growth rate (CAGR) of 5.9% from 2024 to 2030. The market growth is attributed to the growth in the construction sector and rising demand for steel as a green and sustainable material. Structural steel is utilized for construction-related applications. Its high carbon content offers high strength and low ductility. It is available in the form of various shapes such as I-beam, Z-shape, angle, tee, bar, and rod, depending upon the applications. It can be customized into a variety of shapes in different thicknesses and sizes owing to its ductility. Based on application, the market is segmented into residential and non-residential, where the latter dominates the market, in terms of revenue share.

Structural Steel Market Report Highlights

Based on region, Asia Pacific dominated the global market in 2022 on account of the growing infrastructural developments in the region

The non-residential application segment is anticipated to register the fastest CAGR, in terms of revenue, over the forecast period due to the rising renovation activities and spending on infrastructure development

The industrial sub-segment led the non-residential application in 2022. Increasing construction of lightweight industrial building systems that make use of thin sheet-covered surfaces is the recent technological development, which is driving the demand for high-strength structural steel

Middle East & Africa is expected to grow at a considerable CAGR, in terms of revenue, over the forecast period. The growth can be attributed to the upcoming infrastructure-related projects in the Middle East

For More Details or Sample Copy please visit link @: Structural Steel Market Report

Growing spending on the commercial sector & infrastructural developments across various nations is augmenting the product demand in non-residential applications. The segment is further divided into industrial, commercial, offices, and institutional. Structural steel is widely used in numerous industrial sectors owing to its high strength-to-weight ratio. In the construction industry, it is utilized in designing and building industrial spaces, such as warehouses, bridges, and factories. Growth in the manufacturing sector is expected to propel the need for new factories and plants. For instance, after the emergence of the COVID-19 pandemic, various new facilities were established to meet the rising demand for PPE in the U.S.

Asia Pacific was the dominant regional market in 2020 and this trend is anticipated to continue over the forecast period. The growing construction spending in the developing economies of the region is anticipated to augment the product demand. For instance, in August 2021, India announced that it aims at spending INR 100 trillion (USD 1.35 trillion) on infrastructure development for boosting economic growth and jobs in the country. The competitive rivalry is extremely high in the market due to the presence of several small- and large-scale players spread across the world. The companies are striving to recover from their losses caused by the COVID-19 pandemic and are taking initiatives, such as mergers & acquisitions and capacity expansions, to further widen their reach.

#SteelMarket#ConstructionMaterials#BuildingIndustry#InfrastructureDevelopment#SteelStructures#StructuralEngineering#SteelFabrication#ConstructionSector#BuildingMaterials#SteelDemand#ConstructionTrends#SteelProduction#BuildingDesign#ArchitecturalSteel#SteelSupplyChain#UrbanDevelopment#IndustrialConstruction#StructuralSteelDemand#SteelManufacturing#SteelIndustryInsights

0 notes

Text

Stainless Steel 409M Coils Manufacturers

Padmavati Steel & Engg.Co.

Advancing Industrial Excellence: Stainless Steel 409M Coils Manufacturers Leading the Way

Introduction: In the landscape of stainless steel production, precision, resilience, and innovation are vital. Among the spectrum of stainless steel alloys, Stainless Steel 409M coils shine as exemplars of quality and performance, valued for their robust mechanical attributes and resistance to corrosion. Pioneering advancements and setting new standards in manufacturing, producers of Stainless Steel 409M coils are pivotal in propelling industrial capabilities and addressing the evolving needs of various sectors.

Unveiling Leading Manufacturers of Stainless Steel 409M Coils:

Innovative Production Enterprises:

With a focus on cutting-edge technology and superior craftsmanship, Innovative Production Enterprises stands at the forefront of Stainless Steel 409M coil manufacturing. Utilizing state-of-the-art facilities and a team of skilled professionals, they fabricate coils that surpass industry benchmarks in mechanical strength, corrosion resistance, and dimensional precision. Their dedication to research and development ensures continuous enhancement and alignment with emerging market dynamics.

Precision Metal Fabricators:

Precision Metal Fabricators are renowned for their meticulous production of Stainless Steel 409M coils, precisely tailored to meet diverse industrial requirements. Employing a methodical manufacturing approach and stringent quality checks, they deliver coils renowned for exceptional performance and longevity. Their client-centric ethos and unwavering commitment to excellence have established them as a trusted source in the stainless steel manufacturing sphere.

Reliable Stainless Steel Industries:

Reliable Stainless Steel Industries specialize in crafting high-caliber Stainless Steel 409M coils, addressing the needs of sectors ranging from automotive to construction. Armed with advanced technology and a culture of innovation, they manufacture coils distinguished by superior mechanical properties, formability, and surface finishing. Their agility in production and unwavering focus on customer satisfaction position them as preferred partners for discerning clientele.

Technotron Fabrication Solutions:

Technotron Fabrication Solutions are experts in producing precision-engineered Stainless Steel 409M coils, precisely tailored for critical applications. Adhering rigorously to quality standards and continuous improvement principles, they uphold international benchmarks throughout the manufacturing process. Their nimble production capabilities and commitment to customer-centricity make them indispensable allies for enterprises seeking top-tier stainless steel coil solutions.

Conclusion: Manufacturers of Stainless Steel 409M coils epitomize excellence in stainless steel production, setting new standards for quality, reliability, and innovation. Through cutting-edge manufacturing processes, rigorous quality controls, and a steadfast commitment to customer satisfaction, these manufacturers empower industries to achieve unprecedented levels of performance and efficiency. As cornerstones of the stainless steel supply chain, they play a pivotal role in propelling industrial advancement and shaping the future of manufacturing across diverse sectors.

#CoilManufacturing#StainlessSteelCoils#IndustrialCoils#CoilProduction#MetalCoils#CoilSuppliers#SteelIndustry#ManufacturingExcellence#CoilSolutions#QualityCoils#CoilTechnology#EngineeringSolutions#SteelFabrication#PrecisionCoils#InnovationInCoils

0 notes

Text

DA Steet Buildings provides the highest-quality custom steel buildings, and prefab metal buildings across Canada. No matter what your needs are, we have a solution for you. To learn more visit our website.

#steelbuildings#steel#steelbuilding#steelstructures#metalbuildings#construction#steelconstruction#steelstructure#building#architecture#barndominium#engineering#metalbuilding#garage#buildings#structuralsteel#workshop#steelbuildingsolutions#steelgarage#steelshop#garages#steelfabrication

1 note

·

View note

Text

30.5m Road Over Bridge for Indore

0 notes

Text

#FabricationServices#MetalFabrication#StructuralSteel#SheetMetal#CustomFabrication#SteelFabrication#Welding#PrecisionFabrication#FabricationExpertise#QualityFabrication#FabricationTechnology#IndustrialFabrication#FabricationSolutions#FabricationProjects#FabricationWorkshop#FabricationSkills#FabricationProcesses

1 note

·

View note

Text

Ocean Oilfield Services FZE is a most recognised company Oil & Gas, Energy, and Power industries has now joined TradersFind. Offering a comprehensive range of services including Oil drilling, heavy steel structural fabrication, workover & snubbing, pipeline laying, and procurement. Explore a diverse range of products and services to meet all your oilfield needs.

Click here to view the catalog -

https://www.tradersfind.com/seller/ocean-oilfield-services-fze

#OceanOilfieldServices FZE#TradersFind#oilandgas#energy#power#oilfield#steelfabrication#workover#snubbing#epiccontracting#fueltankfabrication#pipelinelaying#majorshutdownprojects#procurements#supplychain#logistics#offshoredrilling#warehousing#shipyard#tradersfindbusiness#oilfieldservices#steelsupplier#industrialservices#oilfieldsolutions#energyindustry#fabricationservices#offshoreoperations#oilfieldequipment

2 notes

·

View notes

Photo

Check out these schedule 40 8 inch pipe cut to size for one of our customers! We offer a variety of different steel tubing sizes and different schedules. Call us for a quote today! https://bit.ly/3ytiMHw

2 notes

·

View notes

Text

EXTRA DEEP BOWL WITH COLOR

AARSHNIK as a leading manufacturer & exporter of AMMO BOX, Metal Fabricated Products, Barware, Petware, Kitchenware, Gardening Tools, Furniture, and Motorcycle Carriers for the last 17 years. We are socially compliant with BSCI; SEDEX/SMETA; SCS; FCCA & ISO 9001:2015.

#.#steel#Steelers#steelers#steelfabrication#mixingbowl#mixingbowls#mixingbowlset#mixingbowlsalad#mixingbowlmurah#mixingbowlenamel#bowls#bowlset#bowlsclub#bowlsofinstagram#deepmixingbowls#deepmixingbowl#kitchenware#kitchenwares#kitchenwarehouse#kitchenwareset#saladbowl#saladbowls#saladbowl🥗#saladbowloftheworld#Bowls#extradeep#fabrication#utensils#germanbowl Hearty stews and satisfying salads

2 notes

·

View notes

Text

The Art and Science of Steel Fabrication: Crafting Tomorrow’s Structures

In the grand tapestry of construction and manufacturing, there exists a pivotal craft that melds artistry with engineering precision – steel fabrication. Beyond the raw strength of steel lies a meticulous process, where skilled artisans transform malleable metal into the skeletal framework of our modern world.

Understanding Steel Fabrication

The fabrication of steel is the process of transforming raw steel into predefined shapes and structures through cutting, bending, and assembling. This intricate craft involves skilled professionals who meticulously craft everything from small components to large structures. The journey of steel from its raw form to a finished product involves several crucial steps.

1. Design and Planning

The process begins with meticulous design and planning. Engineers and architects collaborate to create detailed blueprints that outline the specifications and requirements of the final product. Advanced computer-aided design (CAD) software ensures precision in every detail, allowing for accurate representation and modification before actual fabrication begins.

2. Material Selection

Steel fabrication relies on a variety of steel types, each with its unique properties and applications. Commonly used steel grades include carbon steel, stainless steel, and alloy steel. The choice of material depends on factors such as strength requirements, corrosion resistance, and the final application of the fabricated product.

3. Cutting:

Once the design is finalized and the materials selected, the steel goes through the cutting process. Various cutting methods, such as sawing, shearing, or laser cutting, are employed based on the thickness and type of steel. This step is crucial for shaping the steel into the desired components before the subsequent processes take place.

4. Shaping and Forming

After cutting, the steel components undergo shaping and forming processes to achieve the intended design. Techniques like bending, rolling, and stamping are employed to give the steel its required shape. Precision is key in this stage, as any deviation from the design can compromise the structural integrity of the final product.

5. Welding and Assembly

Welding is a fundamental aspect of steel fabrication, where individual steel components are fused to create a unified structure. Skilled welders use various welding techniques, such as arc welding, MIG (Metal Inert Gas) welding, or TIG (Tungsten Inert Gas) welding, depending on the project’s requirements. The assembly phase involves combining all the fabricated components into the final structure, adhering to the specifications outlined in the design.

What are its Applications?

It is a versatile process with applications across numerous industries. Its adaptability, strength, and durability make it an ideal choice for a wide range of projects.

1. Construction Industry

Steel fabrication is a cornerstone of the construction industry, providing the framework for buildings, bridges, and other infrastructure. From structural beams and columns to intricate architectural elements, steel plays a pivotal role in ensuring the stability and longevity of modern structures.

2. Manufacturing

The manufacturing sector relies on the fabrication of steel for the production of machinery, equipment, and industrial components. The precision and strength of fabricated steel make it a preferred material for manufacturing applications, ensuring the reliability of the finished products.

3. Automotive

In the automotive industry, the fabrication of steel is essential for crafting vehicle components that require strength, durability, and precision. From chassis and frames to engine components, steel’s versatility makes it a preferred material for ensuring the safety and performance of automobiles.

4. Aerospace

Aerospace engineering demands materials that can withstand extreme conditions, and steel fabrication meets this requirement. Aircraft components, such as wings, fuselage structures, and landing gear, often undergo meticulous steel fabrication processes to meet the stringent safety and performance standards of the aviation industry.

5. Energy Sector

In the energy sector, the fabrication of steel is crucial for constructing power plants, pipelines, and offshore structures. The ability of steel to withstand environmental challenges, such as extreme temperatures and corrosive conditions, makes it an indispensable material for energy infrastructure projects.

Innovations in the Fabrication of Steel

As technology continues to advance, innovations in steel fabrication are driving the industry toward greater efficiency, sustainability, and cost-effectiveness.

1. Advanced Robotics

The integration of advanced robotics into fabrication processes has revolutionized efficiency and precision. Robots can perform repetitive tasks with unparalleled accuracy, reducing the margin of error and enhancing overall productivity. This not only accelerates the fabrication process but also ensures consistency in the quality of the finished products.

2. 3D Printing

Additive manufacturing, or 3D printing, has made significant inroads into steel fabrication. This innovative technique allows for the layer-by-layer construction of complex steel structures, offering unprecedented design flexibility and resource efficiency. While 3D printing in steel fabrication is still in its early stages, it holds tremendous potential for revolutionizing the industry in terms of speed and customization.

3. Sustainable Practices

The steel industry is increasingly adopting sustainable practices to minimize its environmental impact. Recycling of steel is a common practice, with scrap steel being melted down and reused in the fabrication process. Additionally, efforts to reduce energy consumption and minimize waste are driving the industry toward a more environmentally friendly future.

Conclusion

Steel fabrication is both an art and a science, a process that transforms raw steel into the backbone of modern infrastructure. From towering skyscrapers to intricate machinery, the fabrication of steel shapes the world around us.

As technology advances, the industry evolves, embracing innovations that enhance efficiency, sustainability, and precision. With its versatility and strength, steel remains an indispensable force, continually pushing the boundaries of what is possible in construction, manufacturing, and beyond.

#steelfabrication#innovation#buildingdesign#Manufacturing#SustainableSteel#engineering#fabrication#sustainabledevelopment

0 notes