#zinc galvanized steel

Photo

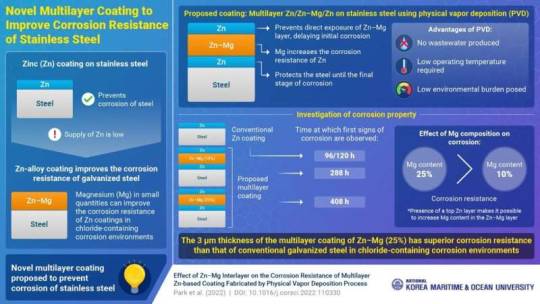

The key is in the coating: Multilayered coating to improve the corrosion resistance of steel

The strength of steel makes it one of the most robust materials known to humankind. When galvanized with zinc (Zn), it becomes more resistant to corrosion. This makes it an economical choice to use in construction and infrastructure.

In the last decade, Zn reserves have fallen appreciably, forcing us to switch to using Zn alloys. Magnesium (Mg) is the most commonly used alloy mineral, and when used in small amounts it can improve the corrosive resistance of Zn.

Now, Professor Myeong-Hoon Lee, Head of the Center of Surface Corrosion Control Engineering at Korea Maritime and Ocean University, and his colleagues have proposed a novel coating for steel that promises to increase its longevity. "During my time in the navy, I noticed a lot of machines that were rusting. So, I engaged in this research, hoping to produce better anti-corrosive steel," says Prof. Lee, explaining his motivation behind the study.

"To survive in harsh environments, high anti-corrosive materials need to be developed. Steel is one such material and increasing its life span makes the steel more sustainable," Prof. Lee explains. Their study was published in Corrosion Science.

Read more.

8 notes

·

View notes

Video

youtube

① Are you intersted in M16 wedge anchor or M16 through bolt

② Approved by ETA / CE / ICC / ISO9001 / UL / FM, etc...

③ large quantity with best price

⑤ reade more https://www.fixdex.com/

#FIXDEX hardware #wedge anchor #through bolt #threaded rods #construction bolts

#youtube#M16 wedge anchor#M16 through bolt#m16 thru bolt#fastener hardaware#FIXDEX wedge anchor#FIXDEX thru bolt#GOODFIX & FIXDEX fastener manufacturer#FIXDEX fastener factory#Ss Wedge Anchor#Concrete Fixing Anchor#Elevator Fastener#SS304 316 m16 wedge anchor#Zinc Plated Wedge Anchor Bolt#China Factory Carbon Steel Galvanized M16 Wedge Anchors#Carbon Steel Wedge Anchor Bolt#Stainless Steel Wedge Anchor Bolt#Carriage Bolt#Expansion Anchor Bolt Wedge#Through Bolt Anchor

0 notes

Text

When it comes to strength and protection, Galvanova is the name you can trust! Tata Galvanova's Alloy Coated Steel sheets are engineered to provide unmatched strength, durability, and corrosion resistance, making them a perfect choice for all your manufacturing needs.

#coated steel coil#powder coated steel#steel coating#coated steel#coated steel products#zinc coated sheet#colour coated steel#alloy coated steel#galvanized steel sheet#galvanized steel#galvanova#tata galvanova#tata steel

0 notes

Text

Best Quality Hot Dip Galvanizing Plant Manufacturers from India to Worldwide

Wire Machine Company is a Ghaziabad, India-based manufacturer of hot dip galvanizing plants. These plants are designed to provide superior corrosion protection to steel and other metals by applying a layer of zinc through a hot dip process. The company uses advanced technology and high-quality materials to produce galvanizing plants that are efficient, reliable, and durable. Their plants are capable of processing a wide range of metal products, including wires, pipes, tubes, and more. With a commitment to customer satisfaction, Wire Machine Company provides customized solutions tailored to the specific needs of their clients, ensuring that they receive the best possible product and service.

#galvanizing plant manufacturers#hot dip galvanizing equipment suppliers#zinc coating plant manufacturers#galvanizing kettle suppliers#galvanizing furnace manufacturers#zinc melting furnace suppliers#galvanizing line equipment manufacturers#automatic galvanizing plant manufacturers#continuous galvanizing plant suppliers#steel structure galvanizing plant manufacturers

0 notes

Text

Gi coils

0. 26-1050mm

Spangle

G90

0 notes

Text

True Story:

Throughout my life I have had many obsessions; fishing, the blonde I sat behind in high school biology, to have my own dog (Not just a 'family' dog), the redhead three doors down from our house, hockey, the brunette who would later become my wife, and a number of other things.

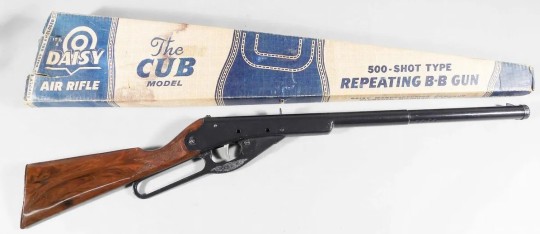

But when I was 10 years old I – like every other boy I knew – had a burning desire that made all other obsessions pale in comparison. My singular desire was to have to have a BB gun. I didn't care what kind, although for some reason I loved the look of the Daisy Model 30-30. Maybe it was because of all the Rawhide Kid, Kid Colt; Outlaw, or Cheyenne Kid comic books I consumed whilst hiding from my mother and her infernal chore list.

I wonder in retrospect if my mother believed that if a comic had 'Kid' in the title it couldn't possibly lead her flock astray, but I digress.

As far as BB guns go, I really didn't care what make or model. I just knew I had to have one. I dreamed about fighting off coyotes, black bear, and local bullies. The only requirement was that it be able to shoot a copper-clad projectile at a high rate of speed. Most of my friends already had their obsessions satisfied and it was a source of constant sorrow that I was BB gun-less.

My desire for a BB gun also filled me with a feeling of guilt because my parents ensured I had everything I needed and fulfilled many of my wants. My mother was never shy about providing me books, new or used, and Dad bought me all the fishing gear and hockey equipment I ever needed.

But Ivanhoe and shin pads couldn't fill the hole in my life left by something I had never possessed in the first place.

Any BB gun would have filled the hole.

One close friend, Skunk (don't ask), had the Holy Grail of the BB gun world – a Crosman pump rifle. This particular rifle was carried around town with much-deserved pride (oh, how I hated Skunk when he toted that gun around). I personally witnessed the sleek weapon puncture the side of a tomato juice can. I know it doesn't sound like much today, but back then, tomato juice cans were manufactured by the Ohio Boilermaker Company, made of 10 gauge, zinc-lined, galvanized steel, and, empty, they weighed 23 pounds.

Another friend actually had a BB pistol but his folks took it away from him because he put out one too many window.

There was a smattering of other BB guns in town. Most boys, who were born to more BB gun-friendly parents toted around Daisys, but I recollect other makes like Powermaster, Benjamin, and, of course, Crosman.

Mom apparently wasn't too worried about my brother and I shooting our eyes out because the Christmas after my 11th birthday my brother and I were presented with matching Daisy 102 Model 36 Cubs. My initial jealousy that my brother got his first gun at 10 while I had had to wait until I was 11 abated after a few seconds when I remembered he was my partner in crime and a pretty good friend all the way around.

The jealousy was immediately replaced with an ugly feeling of ingratitude that made me feel guilty and I tried to shake it off before my dad could see it in my eyes.

Cubs!

Yes, they were guns. Yes, they would shoot a BB. Yes, if you squinted at them, the rifles did sort of look menacing. But they were still Cubs, of all things. To those ignorant of the BB gun world, allow me to explain that the Daisy Cub was the AMC Pacer of the gun hierarchy. It was akin to eating a fast-food burger that has been sitting too long under the warmer; it looked vaguely burger-like, it would fill up an empty stomach, but no matter how you looked at it, it was never going to be a thick, mouth-watering, flame-broiled burger fresh from the barbecue grill in the back yard, dripping with grease, and topped off with the freshest of toppings.

-

Given that Christmas unreasonably seems to always fall in the dead of winter every year, and at least 8 feet of snow covered everything as far south as Des Moines and would until at least April, we were resigned that the guns wouldn't see much action until the Detroit Tigers were in spring training, at a minimum.

Dad, with a head toward solving our dilemma, came through in fine fashion. He covered the windows in the attic with a heavy, BB-proof tarp, hung up paper targets on a length of rope at one end of the cramped space and created an indoor shooting range for his two would be cowboys.

At this point it behooves me to again educate the BB gun ignorant; as a BB does not have a method of propelling itself down a barrel like a bullet, a BB gun has one of two ways to operate: 1. Compressed air (either manually pumped or by using a pre-filled CO2 cartridge), or, 2. Spring-loaded.

Take a wild stab at what method the fine folks at Daisy chose for the Daisy 102 Model 36 Cub.

Initially the BBs zipped to the targets just fine. The single light bulb hanging from the rafters was proof as it had to be replaced more than once, and we discovered the ricochet effect shooting at the chimney bricks.

By the end of January, the springs that provided the propulsion in the Cubs had lost some of their zip. To hit the targets we were required to raise the muzzles a few degrees to provide some elevation to the projectile's trajectory. By the beginning of March, the springs in both guns were so much al-dente fettuccine, and even if we managed to hit the targets – which wasn't a given – the BBs could no longer penetrate.

It wasn't long afterward that the blush fell off the rose and we were spending less and less time sharpening our sharpshooting skills.

I had some Two Gun Kid and Apache Kid comics to read.

-

Spring does show up every year, even to Northern Michigan's Keweenaw Peninsula. It's magical warmth causes the snow banks to shrink, gradually at first, and then disappear like cotton candy in a rain storm. It turned the roads into nearly impassable slush and mud, and boys' yearnings to everything summer: baseball, fishing, camping, freedom, no school.

In the spring and summer, Mom's infernal chore list was only a threat if one couldn't sneak out of the house before she latched onto an arm or ear. Avoiding Mom wasn't all that difficult, mostly because my brother and I had five younger siblings who always seemed to be crying for something or other and, as a result, Mom was almost continually distracted.

The first few glorious days of summer were spent in pursuit of birds and small animals with our new but impotent weapons. The hunts turned out to be exercises in futility because even if we managed to hit a chipmunk or squirrel, the BBs would do little more than tickle them.

It wasn't too many days before the Cubs were left in the hall closet to gather dust. What was the point of toting around a firearm that wouldn't fire? Nobody feared us, and the bears and coyotes were scarce, so our pursuits turned to fishing or swimming or that old trusty standby, finding ways to pester the neighborhood girls.

-

A few weeks into summer found a group of us kids, who had all successfully dodged our respective mother's chore lists, looking for mischief to get into. Picking on the girls was terrific fun but even that had gotten old. How often can you bomb a tea party with water balloons before it loses its attraction?

Fishing was always a draw for me, but nobody else wanted to slog the three miles to the river. A pick up baseball game was mentioned, but there were only eight of us, and, unless we wanted to play with older kids who would take over everything, or worse, girls, it was a non-starter.

Somewhere in our lethargy, the conversation turned to World War II. Over for some time, it was still a favorite subject. One friend's father had actually been in Normandy, and later on was stationed in Paris after it was liberated. He had been a supply clerk and never saw combat, but he still was a hero to us wide-eyed war junkies.

Most of us wouldn't have been able to find Normandy on a map, and whenever I heard of La Madeleine or other French towns I couldn't help picturing Mom's jar of orange marmalade that was always on the breakfast table. But even in our ignorance, we still loved talking about the war.

And then somebody casually asked, why not have a war of our own? For real. With guns. BB guns, albeit, but guns nevertheless. We could map out a large area south of town, stake out territories and try to capture the other's flags. We could set up rules of engagement and follow them to the letter. No targeting someone above the neck. No shooting if the target is closer than 10 feet. If you are hit anywhere but the arms or legs, you are out until the campaign was over and the new one began. Skunk could only pump his gun once; anything more would give him an unfair advantage.

The three boys who weren't already wearing Coke-bottle glasses had to see if they could filch safety goggles from their dad's garages or find something else to protect their eyes.

Breathless, my brother and I raced home to grab our guns and I crept up to our room to grab the half-filled, cardboard carton of ammunition Even employing stealth, we heard Mom yelling for us as the screen door banged behind us and we made our escape and headed to the field of battle.

Most boys are brain dead. At least I was and I can honestly say the thought of how stupid we were being never crossed my gray matter. I can't speak for my brother, but he was right by my side and I don't recall him voicing objections.

If we had stopped to think we would have recognized that if we were found out, not only would Dad bend our guns against the trunk of the maple tree in the back yard, but he'd wear out his razor strop on our heinies.

Perhaps common sense was out pestering the girls that afternoon because it was nowhere to be found when we all met up in the field under the giant cherry tree that we had designated as the demilitarized zone.

In short order we formed two, four-person armies and hammered out the theater of operations. We had to stay in between the two dirt roads to the east and west, and the northern edge of the pond was the southern boundary. The Pelkkanen's (who happened to be out of town) outhouse would represent the northern border of our combat arena.

We tore up the tee shirt pinched from somebody's clothesline and each team took half as a flag. We would split up, set up our head quarters and wait 20 minutes before launching hostilities.

None of us had a watch, so approximately 4 minutes later, we were all slinking through the waist-deep weeds and bramble bushes, crouching behind cedar bushes and pine trees looking for the enemy. Strategy? Ha! We just moved towards the opposite end of the war zone until, hopefully, we'd engage somebody to shoot at.

That's exactly what happened. The two skirmish lines met in an opening in the shrubbery and began firing as fast as we could work the levers on our guns. BBs flew like confetti and boys fell with over-dramatic flair. The BBs had a slightest of stings, except for Skunk's shots, but even those weren't terrible.

Through four successive battles the teams went at it. mostly adhering to the rules. One boy caught a BB in the ear that made him yelp, and in the fourth skirmish I took one in my lower lip which immediately began to swell. The pain wasn't too terrible and I fought on.

Tied two battles to two, we determined to settle the issue of supremacy in one last engagement. To the victor would belong the spoils, whatever they were. Possibly an empty tomato juice can.

Unfortunately, the other team had at least one boy who wasn't addle-minded and had something up their sleeves; they had no intention of a frontal assault.

We found out too late that three of the opposition moved to the west side of the combat zone and made somewhat of a ruckus, drawing our attacking force on the run, while their fourth slipped by unobserved on the east side, waltzed into our base, swiped our flag and redeployed back to his base.

We lost the battle and thus the war without firing a shot. While certainly the defeat stung, my brother and I took the whipping in stride and opined that we'd know better next time. One of our team yelled some of the worst Finnish words he knew; paska, and kusipaa and paskiainen being chief among them. (For those who don't speak Finn, trust me, they're pretty tame by today's standards.)

For some unknown reason that escaped the others in our army, Skunk was livid. How could we lose so easily with such superior firepower? The tyhmät päät must have cheated! He was going to exact some sort of revenge. I tried telling him we just lost and that's the way it goes sometimes. But he was beyond reasoning with.

Skunk set off to the other side of the field with the rest of the team following behind. He would later claim he only pumped his gun once, but my brother and I would both rat him out to the fellows that we both had seen him pumping the gun multiple times as he advanced on the other army's position. How many times did he pump the pump? I have no idea, but it was more than one.

The other team emerged from hiding and began rubbing it in as we approached - as we would have done had we been the victors. Without a word Skunk raised the Crosman and took bead on one of our friends, Jussi. The intended target yelled and spun around to take cover when the BB punctured the denim and skin that covered his keister.

We were all in shock as we watched a small, dark, wet spot appear and grow slowly larger on the wounded boy's left buttock. Even Skunk was mortified at what he'd done. We were all shocked and most of us were crying except for - oddly enough - the boy with the BB in his butt. He handled being shot with remarkable aplomb.

The youngest boy in our gang lost control of his bladder and he peed his pants. (nobody gave him flack for the leak - he was only 8 and, frankly, some of us struggled to keep from peeing in our drawers, too.)

Skunk tossed his gun aside and ran off, all the while crying how sorry he was. The rest of us gathered around our wounded comrade and dithered back and forth about what to do. Jussi gingerly lowered his trousers baring an expanse of pale white flesh with an ugly purplish circle the size of a nickel surrounding a BB-sized darker hole. Bright blood trickled from the wound and dripped down into his pant leg.

Someone suggested sucking out the BB like we might suck out rattlesnake venom. Even Jussi was taken aback by the suggestion and in no uncertain terms bellowed, "Ain't nobody sucking on my arse!"

I picked up Skunk's Crosman and we helped the only real casualty of what we'd come to refer to as the War of the Keweenaw hobble home to have his mom administer first aid.

-

Either Jussi's parents were brighter than we gave them credit for and didn't buy the story that their son was injured by a branch when he fell out of a tree, or Jussi just told them the truth.

Whatever the case, in short order, all of our parents were brought up to speed and that evening found my brother and me in the backyard with Dad. Our Cubs on the ground at our feet.

Without words he gestured for me to hand him my gun. I did so waited for him to slam the gun against the tree trunk. Instead, he raised his knee and bent the barrel of the gun over it like it was Play-Doh. He tossed my Cub aside and repeated the ceremony with my brother.

We waited for him to pull out his strop but it wasn't forthcoming. Even his belt stayed cinched around his waist. He just looked at us sadly and shook his head.

He hugged us both and whispered, "I'm disappointed in both of you."

We would have rather had him wear out the razor strop on our butts. That was a punishment we could understand, even if it was a painful. "Please yell at us, Dad!" I screamed in my head.

Both my brother and I were sobbing uncontrollably. The worst punishment imaginable had been handed down - Dad was disappointed in us. It was a pain we would strive hard to never feel again.

-

All of us who had participated in the War of the Keweenaw had received punishments of varying degrees. We all lost our guns, except Skunk, who, in his remorse and shame, presented it to Jussi in atonement.

My brother and I would spend the next several months trying to make Dad proud of us again. We stopped sneaking out of the house and even willingly worked on Mom's infernal chore list that seemed to keep growing, and completed everything on it that an 11 and 10 year-old could. As much as we would have liked to do so, we just weren't able to reshingle the house and garage roofs on our own, but we willingly helped Dad do the job.

Eventually, after a time, Dad returned to his normal, boisterous, and joking self and life went on and it was good.

-

I never owned another BB gun. A handful of years later I received a Remington .30-06 just in time for deer season, and I've owned multiple rifles, shotguns and pistols since then, but I've never had an 'obsession' for the guns. They are nothing more than tools that I always handle with the respect they deserve.

-

Note: A dozen or so years ago I was able to visit my old home town and reconnect with the few of my friends who still live in the area. Skunk and Jussi are still best of friends and I can still see the boy in both through the grey. Jussi grinned at me when I brought up The War of the Keweenaw, went to his basement and returned with the Crosman BB gun. He claimed it still worked perfectly.

Although I declined to do so when he offered to let me feel the bump, he asserts the BB is still lodged firmly in his buttock.

51 notes

·

View notes

Text

Rocstor Y10C181-B1 Rocbolt Desktop and Peripherals Security Locking Kit with 8’ Cable and Key Lock – Galvanized Steel, Nickel, Zinc Alloy – 8 ft. (2.5m) – for Notebook, Desktop Computer, Black

http://i.securitythinkingcap.com/T1H4sF

2 notes

·

View notes

Text

What Materials Are Frequently Utilized In Iron Work Services, And Also Just How Do They Contribute To The Total Toughness?

In the wide realm of building and also construction, iron job solutions command a substantial location as a result of their necessity in developing resilient structures. The integral stamina, convenience, and also longevity of iron make it an optimal product for numerous applications varying from constructing frameworks to crafting complex decorative aspects.

However, the total long life as well as efficiency of iron-based frameworks are not exclusively contingent on the natural buildings of this metal; they are equally affected by the type of materials utilized combined with iron as well as the particular treatments applied during the construction procedure.

The extensive use alloys-- compounds made by incorporating two or even more metallic elements-- is a testimony to this reality. Alloys boost the physical buildings of pure metals, making them preferable for particular applications.

For instance, adding carbon to pure iron results in steel-- an alloy known for its increased strength and resistance versus wear and tear. Similarly, surface treatments like galvanizing can considerably improve corrosion resistance, consequently expanding the lifespan of iron frameworks.

This article aims to clarify these typically made use of materials in iron job services while elucidating exactly how they add towards boosting general sturdiness.

Checking out the Function of Alloys and Treatments in Enhancing Long Life of Structures

The unification of alloys and treatments in iron work services becomes a perfect symbol of strength as well as long life, dramatically boosting the sturdiness as well as life expectancy of frameworks.

Alloys are a fusion of 2 or more metallic elements, which when combined, existing superior homes contrasted to individual parts. Significantly, steel - an alloy predominantly made up of iron and also carbon - is renowned for its high tensile strength as well as malleability. It has become a staple in building due to these top qualities combined with its resistance to environmental results such as rusting. Other prominent selections consist of cast iron, identified by its terrific solidity as well as put on resistance, making it excellent for applications where toughness is paramount.

Moreover, various treatments have been created to additionally improve these intrinsic characteristics of alloys made use of in the field. Hot-dip galvanizing involves finish iron or steel with zinc, giving cathodic defense that prevents deterioration successfully. Similarly, powder layer uses added protection versus weathering whilst at the same time supplying a visually pleasing finish. The procedure entails using powdered paint electrostatically onto steel surface areas after that treated under warm to develop a difficult shell-like layer over the product's surface area.

These treatment approaches not only add in the direction of enhancing general architectural integrity but additionally supply considerable financial benefits by minimizing maintenance expenses and also expanding service life cycles.

#iron works#iron works near me#ironworkers#ornamental iron works#ironwork#wrought iron#metalwork#iron fabrication#iron designs#iron gates#iron fences#iron railings#iron sculptures#custom ironwork#architectural ironwork#decorative ironwork#ironworking tools

3 notes

·

View notes

Note

Hey Cy (can I call you Cy? What about Cybal?) What's your favorite or strongest welding process? What's the most difficult metal or alloy you've welded successfully? What's your least favorite process and alloy? Do you have any favorite stories in the shop you currently work at or just from engineering or welding jobs in general? If you've already told those stories then what are the tags?

Sure thing! I haven't actually thought of any sort of tumblr name other than my URL and I guess those work.

So my favorite welding process is, by far, stick welding. It's my first arc, first love, and the first prices I felt like I was actually good at. It's also the last time I really had a ton of fun welding, when I got ahold of a pound of general purpose stainless rods for a personal project. It's really fun to strike an arc and then just being along for the ride, and it smells like woodsmoke. The great tragedy is that I actually kind of hate most professional situations that call for stick welding. I like working on a table or saw horses in a shop, not in a mud pit or crawling across beams.

My strongest process is semiautomatic wire fed. I'm particularly fond of flux core, as it's the one I actually use at work. I'm good for everything from like ⅛" to... technically my certification is for unlimited thickness, but I've only done up to 2".

Either way, I prefer welding if I get to crack a slag layer when I'm done.

Honorable mention for TIG: I love you, but it's been fucking ages and these days I'm lucky if I can run a stack of dimes and not a stack of blobs.

My most difficult metal... So, most of the time I'm just working with structural steel. You know, boring, low alloy stuff. I've worked with stainless and aluminum, and both of those were pretty fun, but they were the sorts we use in a trade school, so pretty easy, all things considered.

The actual worst stuff I've had to work with is zinc. Ok, technically I'm not actually welding the zinc, I'm welding through it, but it's still the actual worst. It spits and sputters and spatters and tries to throw the whole damn weld back out at me. The only times I've been genuinely concerned that I'd say myself on fire with sparks was from going slightly too fast/slow and having the weld shot out, over my mask, on top of my head. Yesterday, I also got up close and personal with how much it can fuck up a job, even if you don't have to weld it. The place that does our galvanizing charges by weight, so they basically smear on as much as they can, and in addition too warping the fuck out of our precisely drilled holes, and made them so much larger the frames would no longer fit where they needed to go. Even grinding it gums up my wheels and smells like cherries if you lean hard enough to actually get through all that shit.

For whatever reason, my work frequently breaks the "weld first, then galvanize" rule for logical reasons. I once had to weld through galvanized shit for three months because the job only called for half of each piece to be galvanized, and we were too cheap to do the whole thing after I'd done them.

Galvanization sucks and I hate it.

Most of my stories from work are along the lines of spot the OSHA violation, we almost built an entire floor backwards because apparently I'm the only one who can read prints, and we actually built this flight of wall rails backwards because the engineers programed these cuts, why would the fabricator need prints? At least that last time I finally got proper respiration PPE, because both me and my helper were getting sick welding through the paint fixing that job, and my helper is the owners son.

Oh, and one day I watched two people in a row set themselves on fire with the acetylene torch, and a third one almost setting his fuel line on fire when he set the torch down, still lit, and walked off to move the stuff he set it down on.

When I lay it all out like that, it almost sounds like I'm not paid enough to deal with this shit.

5 notes

·

View notes

Text

Telescopic Steel Baton - Self Protection For Women When Danger Arises

The space catapult is known to order long time for use on the moon (and maybe other planets) and there never question about its feasibility. But on the moon might be simpler to build: You don't want a vacuum tube, the escape velocity is lower (only 2.4km/s) and the rail could be laid round the surface on the whole space. At the end the rail in order to offer hold the projectile down against the centrifugal stimulate. Maybe steel pipe pile for future interplanetary as well as interstellar travels will come in or develop on the moon during moon orbits, transportation around done together with rail firearm. Even hydrogen and oxygen as rocket fuel can be achieved on the moon, whenever we find water there. The vitality stems from solar panels during the half-month-day belonging to the moon.

If ever you see squirrels over your neighborhood, always be be safe if you'll assume they will will invade your feeder at a time. So choose the place wisely. Specialists . hang your feeder on a height where they can't reach the following.

Check your plumbing. Older houses frequently have either copper pipes or galvanized pipes. A galvanized pipe is a steel pipe with a protective coating of zinc that should extend existence expectancy from the pipe. Galvanized pipes can last up to 50 years on average, but if you live in a with a greater amount of minerals within the water supply - the pipes can corrode easily. Have your pipes inspected and consider replacing them in the event the corrosion is extensive.

Most folks can execute sufficient job with the hacksaw if they are rigorous. The objective is actually to cut a straight edge when cutting pipe so that the piece will completely match into its fitting. Cemented plastic pipe joints want all the surface speak to they can get, so fitting round tube that does not bottom out is problems.

Finally the tube passes through a cutoff that cuts the tube towards the required lengths. The steel tube generally moves through the mill at fast speed. The time it takes from entering in the mill on the time it passes with cutoff is simply few only a few.

The USA is in a pickle with cookie container. We don't have any money, we all owe money like outdoors. When you're locked in the room which appears no doors - then suddenly, a door opens, what is the next step? Round Structural Steel Tubing Tell you that door, don't then you? By getting our oil and coal out in the ground, we can turn the us around, and also the powers that be comprehend it. So, despite what you hear about oil and gas being in the past, hold on your hat, considering the winds of change are blowing, and contrary to popular belief, it isn't turning wind mills. The U.S. will end the world's largest producer of oil and gas soon.

It 's better to use opaque plastic tubing because clear plastic allows sunlight to enter it. Algae will grow on the inside, providing there are nutrients and sunlight reward. The algae colonize the as a part of hose, lowering the internal diameter through which water is pumped. This yet again causes a pressure swim. Opaque tubing makes it very difficult for sunlight to penetrate and as a result it makes it tough for algae to develop.

3 notes

·

View notes

Text

Emerging corporates may find it difficult to explore new opportunities and sustain competitiveness in the ever-changing markets. Ecafez provides such businesses with the platform to leverage expert advice, guidance and strategies, thus, bridging the gap between their goals and vision.

#digital knowledge sharing platform#cold rolled steel#colour coated steel#hot rolled steel#tata steel#galvanized steel#steel manufacturing#cr steel#cr sheet#cold rolled coil#hot rolled sheet#hot rolled coil#hr sheet#hr steel#coated steel coil#steel#steel coating#galvanized steel sheet#zinc coated sheet

1 note

·

View note

Text

Periodic Table Championship:

Round 2, Day 4, Manganese vs. Zinc

The second match of day 4 of round 2 has two transition metals facing off, element 25, manganese, facing off against element 30, zinc. Last round, manganese beat protactinium with 82.5% of the vote, while zinc had a slightly more decisive match, beating francium with 86.6% of the votes. A reminder of our challengers:

Manganese is a hard, brittle transition metal with four known allotropes of the solid element. Alpha manganese, the room temperature form, has a complex body-centered cubic unit cell with 29 atoms per primitive unit cell. Manganese is primarily used as an alloying element in steels, but other applications include batteries and resistors. It (along with magnesium) was named for the Magnetes regions, located in modern Greece and modern Turkey.

Zinc is a brittle, diamagnetic transition metal that crystalizes with a hexagonal crystal structure at room temperature. It is an essential trace element in animals and plants, and the second most abundant trace element in humans, after iron. Aside from its biological role, zinc is primarily used in galvanizing and alloying, including bronze and brass alloys. Its name is likely derived from German, however the exact origin is uncertain.

2 notes

·

View notes

Text

Candlestick prototype! Meant for holding tea lights and hopefully not catching on fire.

I might need to redo it in a different material, though. Right now it's galvanized steel because that's what I had on hand. But apparently that can give off toxic zinc fumes if it gets hot enough? So I might try copper instead, or stainless steel if I can find it. Or just hope the candle doesn't get hot enough.

7 notes

·

View notes

Text

Shandong Dingxinda Steel Group is a modern enterprise integrating the research, production and operation of galvanized sheet, color coated sheet, cold rolled sheet, aluminized zinc plate, aluminized magnesium zinc sheet, and galvanized steel pipe (square tube, round tube, rectangular tube). It covers an area of 1500 mu and employs more than 889 people.

2 notes

·

View notes

Text

Customized HDG Head Screw Gr 8.8 - Ananka Fasteners

Ananka Group is the best leading high-quality Screw Manufacturer in India. We have a wide range of screws, with ready stock for export and supply. We take orders and manufacture as per the customers’ requirements. We are India’s largest manufacturer of bigger diameter Screws and Bolts in high tensile and stainless steel grades, as well as fasteners, for major contractors and consultants working on projects in power, renewable energy, wind, and infrastructure sectors in India. We specialize in Wood screws, Thread Cutting screws, and other Screws.

Screws Specification

Screw size:- Imperial Size: 3/8 to 8″, Metric Size: M10 to M100

Screws Length:- 3 mm to 200 mm

Screw:- UNF, BSW, BSF, METRIC, UNC, or as required

Standard of Screws:- DIN 84, DIN 85, DIN 912, DIN 916, DIN 931, DIN 933, DIN 960, DIN 961, DIN 963, DIN 964, DIN 965, DIN 966, DIN 6912, DIN 6921, ASME B18.2.1, ASME B18.3, ASME B18.6.2, ASME B18.6.3, ASME B18.6.4, ASME B18.7

Form of Screws:- Hex, Threading, Square, Round as per Gauge Etc.

Raw materials Source:- JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin, etc.

Threads Configuration:- ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads

Certification:- Dual Certified As per ASTM & ASME Codes

Popular Types of Screw:- Hex Head Cap Screws, Socket Set Screws, Anchor Screws, Blind Rivet, Socket Head Screws, Concrete Screws, Shoulder Screws, Panel Screws, Threaded Screws, Machine Screws etc.

Threads:- Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically

Test Certificate of Screws:- as per EN 10204 / 3.1 Manufacturer Test Certificate

Additional Certifications:- PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified

Production process:- M24-M100: hot forging, M2-M24: Cold Froging, for custom-made connecting element machining and CNC

Head drive of Screws:- Six-Lobe,Phillips,Phillips/Slot, Slotted etc

Packing of Screws:- IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request

Surface Coating:- Ptfe Coated Screws,Phosphate Coating,Teflon Coating, Zinc Coating, Hot Dipped Galvanizing Coating, Cadmium Coating, Xylon Coating

Screws finishing:- Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel

Zinc (blue, black, yellow, white), black oxide

Source:- https://anankafasteners.com/screw-manufacturer-in-india/

Call & WhatsApp:- +91 83690 74984

Mail:- [email protected]

Website:- https://anankafasteners.com/

2 notes

·

View notes

Text

Essential Guide to MS Pipes: Applications and Advantages

Mild steel pipes, commonly referred to as MS Pipes, are widely utilized in various industrial and construction sectors due to their affordability and impressive mechanical properties. This guide explores the applications, benefits, and considerations associated with MS Pipes.

Understanding MS Pipes

What are MS Pipes?

Overview of mild steel composition and properties.

Comparison with other types of steel pipes, highlighting distinct features.

Manufacturing Process of MS Pipes

Description of the steelmaking process tailored to MS Pipes.

Insights into the shaping, welding, and finishing processes that define their quality and usability.

Types of MS Pipes

Seamless MS Pipes: Made without any welds, ideal for high-pressure applications.

Welded MS Pipes: Manufactured with a seam, typically used in low-pressure applications and structural jobs.

Galvanized MS Pipes: MS Pipes coated with zinc to prevent rust, used in outdoor or corrosive environments.

Applications of MS Pipes

Construction and Infrastructure: Utilization in scaffolding, architectural frameworks, and structural foundations.

Automotive Industry: Components such as exhaust systems, which require durability and resistance to corrosion.

Plumbing and Water Supply: Pipes for water delivery systems and sewage networks, chosen for their strength and ease of installation.

Machinery Manufacturing: Support frames and components within machinery where cost-effective and robust materials are needed.

Benefits of MS Pipes

Cost-Effective: MS Pipes provide a good balance of toughness and ductility at a lower cost compared to other types of steel.

Machinability: The softness of mild steel allows for easier cutting and welding, making MS Pipes favorable for complex constructions.

Recyclability: Like most steel products, MS Pipes are fully recyclable, promoting environmental sustainability in construction practices.

Adaptability: They can be customized in various diameters and thicknesses to suit specific requirements, enhancing their application scope.

Maintenance and Durability

Corrosion Issues: Although less resistant to corrosion than stainless steel, preventive measures like galvanization can extend their life.

Maintenance Tips: Regular inspections and maintenance routines to ensure longevity and performance.

Future Trends in MS Pipe Usage

Advances in material engineering that could enhance the properties of MS Pipes.

The growing importance of sustainability in material selection, emphasizing the role of recyclable and durable materials like MS Pipes.

Conclusion MS Pipes are a fundamental component in numerous industrial applications, revered for their versatility and cost-efficiency. By understanding the full scope of their applications and benefits, industries can make informed decisions that leverage the strengths of MS Pipes to meet specific operational demands.

More Read : Ms pipe

0 notes