#bisphenol A

Text

The number of kids being diagnosed with autism spectrum disorder ( ASD) and attention deficit hyperactivity disorder ( ADHD) has risen sharply in recent decades, and a new study points to the common plastic additive bisphenol A (BPA) as a potential reason why.

BPA is used in a lot of plastics and plastic production processes, and can also be found inside food and drink cans. However, previous research has also linked it to health issues involving hormone disruption, including breast cancer and infertility.

In this new study, researchers from Rowan University and Rutgers University in the US looked at three groups of children: 66 with autism, 46 with ADHD, and 37 neurotypical kids. In particular, they analyzed the process of glucuronidation, a chemical process the body uses to clear out toxins within the blood through urine.

The research found that kids with ASD and ADHD couldn't clear out BPA and another similar compound called Diethylhexyl Phthalate (DEHP) with as much efficiency as other kids, potentially leading to longer exposure to their toxic effects.

Continue Reading.

314 notes

·

View notes

Text

BPA SUPPLEMENTS: NOW AVAILABLE FOR EMPLOYEES!

While Business Inc. has sold BPA supplements to the public for a long time now, we now offer them in the shop for our employees to enjoy benefits, like cancer!

OH BOY!!!

Join our discord server to get your very own:

discord.gg/mnnUBRc9zy

3 notes

·

View notes

Photo

Reduced health risks with new epoxy resin monomer

Epoxy resin monomers used in industry can result in severe contact allergies. Researchers at the University of Gothenburg have now developed a new type of epoxy resin monomer that is far less allergenic and is based on a renewable material. The epoxy resin monomers used today contain residues of the endocrine disruptor Bisphenol A (BPA). The new monomer derived from ordinary sugar is not based on BPA.

Epoxy resin monomers have been used for a long time in the construction industry and, more recently, in the production of the plastics used in wind turbines. The monomer is produced from BPA, which is derived from petroleum. The risk of developing a contact allergy when handling epoxy resin monomers is considerable, and sometimes it is not even enough to wear protective clothing.

"When we started our research, we had three goals. The monomer should be far less allergenic, be based on an easily accessible and renewable starting material, and not based on BPA, which is a known endocrine disruptor," says Kristina Luthman, Professor of Medicinal Chemistry at the University of Gothenburg.

Read more.

#Materials Science#Science#Allergens#Safety#Resin#Epoxy#Bisphenol A#Sugar#Biomaterials#Polymers#University of Gothenburg

22 notes

·

View notes

Text

Understanding BPA-Free: What It Means and Why It Matters

Bisphenol A (BPA) is a chemical commonly used in the production of plastic products, such as water bottles, food containers, and even baby bottles. However, studies have shown that exposure to BPA can have harmful effects on human health, including disrupting hormone levels and increasing the risk of certain cancers, diabetes, and obesity.

As a result, many manufacturers have started to produce BPA-free products. In this article, we will explore what BPA-free means, why it matters, and how to identify BPA-free products.

What is BPA?

BPA is a synthetic chemical used in the production of polycarbonate plastics and epoxy resins. These materials are commonly used in the production of a wide range of products, including food and drink containers, eyeglass lenses, and medical equipment. BPA is also used to coat the inside of metal cans to prevent corrosion and contamination.

Why is BPA Harmful?

BPA has been shown to disrupt hormone levels in the body, particularly estrogen. This can have a range of negative health effects, including an increased risk of breast and prostate cancer, infertility, and obesity. BPA has also been linked to an increased risk of diabetes, cardiovascular disease, and developmental disorders in children.

What Does BPA-Free Mean?

BPA-free refers to products that do not contain bisphenol A. Instead, these products are made from alternative materials that do not leach harmful chemicals into food or drink. BPA-free products are often made from materials such as glass, stainless steel, or plastics that are free of BPA and other harmful chemicals.

How to Identify BPA-Free Products?

Many manufacturers label their products as BPA-free, making it easy for consumers to identify them. Look for labels or packaging that explicitly states that the product is BPA-free. It is worth noting, however, that not all products that are marketed as BPA-free are necessarily safe.

Are BPA-Free Products Safe?

While BPA-free products are generally considered safer than those containing BPA, there is still some debate over their safety. Some studies have suggested that the alternative materials used in BPA-free products may also have negative health effects, particularly if they are heated or used with acidic foods or drinks.

For example, some types of BPA-free plastics have been shown to leach harmful chemicals into food or drink when exposed to high temperatures or acidic foods. Similarly, some types of stainless steel may contain trace amounts of nickel or other metals that can be harmful to people with certain allergies or sensitivities.

Tips for Reducing BPA Exposure in Your Daily Life

In addition to choosing BPA-free products, there are several other steps you can take to reduce your exposure to BPA and other harmful chemicals:

Use glass or stainless steel containers for food and drink storage. These materials are less likely to leach harmful chemicals into your food and drink.

Avoid microwaving plastic containers. Heat can cause plastic to break down and release harmful chemicals into your food.

Choose fresh or frozen foods over canned foods. Many canned foods are lined with BPA-containing materials, which can leach into the food.

Wash your hands frequently. BPA and other chemicals can be found in dust and on surfaces, so washing your hands regularly can help reduce your exposure.

Choose personal care products that are free of BPA and other harmful chemicals. Look for products that are labeled as BPA-free, paraben-free, and phthalate-free.

Conclusion

BPA is a chemical commonly used in the production of plastic products, but exposure to this chemical can have harmful effects on human health. BPA-free products offer a safer alternative, but it is important to choose products from reputable manufacturers and to be aware of the potential risks associated with alternative materials.

By understanding what BPA-free means and how to identify these products, consumers can make informed decisions about the products they buy and use.

If you’re looking for BPA-free eco-friendly water filter jugs in Australia, look no further than Ecobud. We offer a range of high-quality, affordable, and practical products designed to help you positively impact your health and the environment. Call us today at 1300 886 373 to place an order or to learn more about our products and services!

READ MORE >>

#food container#clean water#lifestyle#environmentally friendly#alkaline water#stylish#bpa free#bps free#eco friendly#recyclable#wellness#gentoo lite#water bottle#healthy drinks#healthy drinking#water filter jug#water#health#bisphenol A#label#packaging#safe#allergy#sensitivity#microwave#frozen#fresh#paraben free#phthalate free#safe alternative

0 notes

Text

Global Bisphenol A Market Is Estimated To Witness High Growth Owing To Growing Demand for Sustainable Packaging

The global Bisphenol A market is estimated to be valued at USD 6,589.69 million in 2021 and is expected to exhibit a CAGR of 6.01% over the forecast period of 2022 to 2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Bisphenol A (BPA) is a chemical compound used primarily for the production of polycarbonate plastics and epoxy resins. It is widely used in the packaging industry due to its superior strength, durability, and resistance to heat and chemicals. The demand for BPA in packaging applications is driven by the need for sustainable and eco-friendly packaging materials.

B) Market Key Trends:

One key trend driving the global Bisphenol A market is the increasing demand for sustainable packaging solutions. With growing consumer awareness and environmental concerns, there is a shift towards using packaging materials that are recyclable and have a lower carbon footprint. BPA-based polycarbonate plastics offer excellent recyclability and can be used in a wide range of packaging applications, including bottles, containers, and films. This trend is expected to drive the demand for BPA in the packaging industry.

C) PEST Analysis:

Political: The regulatory landscape plays a crucial role in the Bisphenol A market. Several countries have imposed restrictions on the use of BPA due to concerns over its potential health effects. However, most regulations focus on limiting BPA exposure in food contact materials, while other applications such as electronics and automotive industries remain unaffected.

Economic: The growth of the Bisphenol A market is influenced by economic factors such as GDP growth, disposable income levels, and consumer spending patterns. The increasing population and rising income levels in emerging economies are expected to drive the demand for BPA in various end-use industries.

Social: Changing consumer preferences towards sustainable and eco-friendly products are impacting the Bisphenol A market. Consumers are increasingly conscious of the environmental impact of packaging materials and are opting for products that are recyclable and plastic-free. This trend is expected to drive the demand for sustainable packaging solutions based on BPA.

Technological: Advancements in technology have led to the development of alternative materials to replace Bisphenol A in certain applications. However, BPA continues to be the preferred choice for many industries due to its unique properties such as high strength, durability, and transparency. Technological advancements in the BPA production process have also resulted in improved cost-efficiency and environmental performance.

D) Key Takeaways:

1: The global Bisphenol A market is expected to witness high growth, exhibiting a CAGR of 6.01% over the forecast period, due to increasing demand for sustainable packaging solutions. The need for eco-friendly packaging materials and the unique properties of BPA make it a preferred choice for various applications.

2: The Asia-Pacific region is expected to be the fastest-growing and dominating region in the Bisphenol A market. The region is witnessing rapid industrialization and urbanization, leading to increased demand for packaging materials. Moreover, the presence of key players in the region and favorable government policies are contributing to market growth.

3: Key players operating in the global Bisphenol A market include Chang Chun Group, Covestro AG, Dow, Hexion, Kumho P&B Chemicals Inc., LG Chem, Lihuayi Weiyuan Chemical Co. Ltd, Merck KGaA, Mitsubishi Chemical Corporation, Mitsui Chemicals Corporation, Nan Ya Plastics Industry Co. Ltd, Nantong Stars Synthetic Material Ltd, Nippon Steel Chemical & Material Co. Ltd, PTT Phenol Company Limited, SABIC, Samyang Holdings Corporation, Shanghai Sinopec Mitsui Chemicals Co. Ltd, and Sinopec Mitsubishi Chemical Polycarbonate (Beijing) Co. Ltd. These companies are focusing on product development, strategic partnerships, and expanding their production capacities to meet the growing demand for BPA in various end-use industries.

#Coherent Market Insights#Specialty and Fine Chemicals#Bisphenol A#Bisphenol A Market#advanced materials

0 notes

Text

Potential health risks of BPA

Bisphenol A (BPA) is a chemical used in the production of a wide range of consumer products, including plastic containers, thermal paper, and certain types of food packaging. However, there are growing concerns about its potential health risks and its effects on the human body. Here are some more details about the potential dangers of BPA:

Increased risk of heart disease: Studies have shown that…

View On WordPress

0 notes

Text

The Limit Value Scam

by Dr.Harald Wiesendanger– Klartext

What the mainstream media is hiding

Limit values are supposedly there to protect us. In fact, they protect more business interests: they lull us into a false sense of security so that we don’t ask, don’t worry, don’t rebel, don’t refuse to consume. In this way, they serve to dumb down the people – often with downright criminal intent. Because a state that…

View On WordPress

#Bisphenol A#Consumer Deception#Consumer Protection#Dose Effect Model#Glyphosate#Harald Wiesendanger#Limit values#Microplastic#Nanoparticles#No Observed Adverse Effect Level#NOAEL#REACH#Reversal of the Burden of Proof#Safety Factor#TDI#Tolerable Daily Intake

0 notes

Text

Sind Einwegbecher giftig?

Wer sich am Morgen auf dem Weg zur U-Bahn noch schnell seinen Kaffee “to go” holt, der denkt bestimmt dabei nicht an Gifte, die er mit dem geliebten Heißgetränk aufnimmt. Denn der sogenannte Pappbecher besteht nicht nur aus Pappe. Die DKV Deutsche Krankenversicherung warnte bereits 2016: “Die Innenseite der üblichen Coffee-to-go Becher ist mit Plastik beschichtet, damit der Kaffee die Pappe nicht…

View On WordPress

#Bisphenol A#Deutsche Krankenversicherung#Diisodecylphthalat#DKV#Einwegbecher#McDonald&039;s#Pappbecher#perfluorierte Polymere#Polymere#Starbucks

0 notes

Text

Choosing a fabric for your new sofa

Choosing a fabric for your new sofa http://wp.me/p7lU3-Qv

Design decisions influence our health –so your choice of a sofa fabric could influence you and your family in ways far beyond what you imagined. Our children start life with umbilical cords infused with chemicals that affect the essence of human life itself – the ability to learn, reason and reproduce. And fabric – which cocoons us most of the time, awake and asleep – is a contributor to…

View On WordPress

#bisphenol A#body burden#CDC#Centers for Disease Control and Prevention#Dispersant#Dye#Food Rules#formaldehyde#Michael Pollan#National Institutes of Health#Polybrominated diphenyl ethers#Surfactant#United States

0 notes

Text

Do people know most paper receipts are harmful to their health?

I'm going to get up on my soapbox for a minute, but do people realize how pretty much everyone is being overloaded with endocrine disruptors like BPA/BPS on a near-daily basis??

I don't think many people understand that ever since most of the world transitioned to thermal paper receipts (cheaper than ink), almost every receipt you handle from the gas station to the grocery store to the Square terminal printer at the local co-op is coated with Bisphenol-A (BPA) or its chemical cousin Bisphenol-S (BPS).

These chemicals have not only been proven to cause reproductive harm to human and animals, they've also been linked to obesity and attention disorders.

Not sure if your receipt is a thermal receipt? If you scratch it with a coin and it turns dark, it's thermal.

BPA/BPS can enter the skin to a depth such that it is no longer removable by washing hands. When taking hold of a receipt consisting of thermal printing paper for five seconds, roughly 1 μg BPA is transferred to the forefinger and the middle finger. If the skin is dry or greasy, it is about ten times more.

Think of how many receipts you handle every day. It's even worse for cashiers and tellers, who may handle hundreds in a single shift. It is also a class issue, since many people who work retail and food service are lower-income and will suffer worse health consequences over time from the near-constant exposure.

Not only that, receipts printed with thermal ink are NOT recyclable, as they pollute the rest of the paper products with the chemicals.

People don't know this and recycle them anyway, so when you buy that "green" toilet paper that says "100% recycled"? Yup, you are probably wiping your most sensitive areas with those same chemicals (for this reason, I buy bamboo or sugarcane toilet paper as a sustainable alternative to recycled paper).

This page from the Minnesota Pollution Control Agency has some good links if you want to learn more.

As consumers, we need to demand better from our businesses and from our governments. We need regulation of these chemicals yesterday.

If you are a buyer or decision-maker for a business, the link above also contains a shortlist of receipt paper manufacturers that are phenol-free.

If you work at a register, ask customers if they want a receipt. If they don't and you can end the transaction without printing one, don't print one!

As a consumer, fold receipts with the ink on the inside, since that's where the coating is. Some more good tips here.

And whatever you do, DO NOT RECYCLE THERMAL RECEIPTS

#i realized the other day that lots of ppl i talked to had no idea this was even a thing#important psa#demand more from your retailers and governments#environment#bisphenols#bpa free#bpa/bps#retail#food service#shopping#working class#capitalism#endocrine disruptors#endocrine disorders#adhd#eco lifestyle#environmental pollution#pollution#toxic chemicals#reproductive health#science#health#environmentalism#eco conscious#human health#consumer goods#consumer awareness#green living#green business#ecofriendly

381 notes

·

View notes

Photo

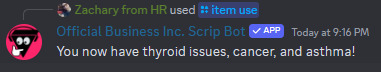

What is BPA and why is it in so many plastic products?

Bisphenol A, or BPA, is a chemical widely used to make hard, clear plastics. It is an endocrine disruptor that has been linked to many negative health effects, including cardiovascular diseases and diabetes. In 2013, the U.S. government banned its use in baby products that come into contact with food, like bottles or the packaging of infant formula.

At the time, the U.S. Food and Drug Administration concluded that some exposure was safe for adults. But other health agencies, including the European Food Safety Authority, have concluded that the levels of BPA the FDA considers safe may have adverse health effects for adults as well.

In early June 2022, the FDA signaled that it is reconsidering what amount of exposure to BPA is safe for adults, announcing that it would reconsider its guidance on the use of BPA in plastics that come into contact with food.

As a synthetic polymer chemist, I think a lot about how to design new polymers, with particular focus on how to do so sustainably. It's natural to wonder why companies don't simply replace BPA with another chemical if health is such a concern. The secret to what makes BPA such an irreplaceable ingredient in plastics is the same thing that leads to its health risks—the molecule's chemical structure.

Read more.

48 notes

·

View notes

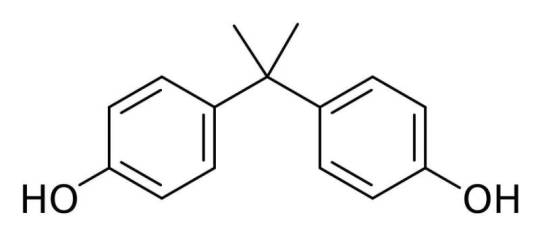

Photo

Network Failure

October 2021 saw the biggest communications outage in history. Facebook went down. Although the disruption only lasted six hours, it caused worldwide chaos and cost Mark Zuckerberg $6 billion. Researchers have discovered that our brains experience similar network failures in response to bisphenol A. We’re exposed to this chemical every day – it’s in food packaging, shopping receipts, and medical equipment. Here, we see neurons (black) from mice exposed to bisphenol A for two months. Compared to untreated cells, the number of dendritic spines on these neurons decreased by 42%. These long thin structures allow neurons to talk to each other, and are vital for learning and memory. Mice exposed to bisphenol A suffered from anxiety and disrupted memory processing, and the scientists have uncovered how the chemical causes these changes to the brain’s network. This work explains how a ubiquitous chemical can disturb our brains, supporting efforts to regulate its use.

Written by Henry Stennett

Image from work by Sung-Ae Hyun, Moon Yi Ko & Sumi Jang, et al

Department of Advanced Toxicology Research, Korea Institute of Toxicology, KRICT, Daejeon, South Korea

Image originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in and on the cover of Disease Models & Mechanisms, July 2022

You can also follow BPoD on Instagram, Twitter and Facebook

14 notes

·

View notes

Text

Bisphenol A (BPA)

BPA is found in polycarbonate plastic which is used for containers to store food and beverages, such as water bottles.

It can be toxic to plants at higher concentrations.

BPA is not normally a problem in food grade plastics but it, as well as lead, has been found in the new fabric pots.

Although BPA is not found in food grade plastic, it has been highly studied and it provides insight into how other plastic chemicals might behave. Due to health concerns, BPA is sometimes replaced with two similar chemicals BPS and BPAF. Testing of all three of these shows that BPA and BPS have a half-life of less than a day. They don’t last long in soil. BPAF has a half-life of about 30 days, which is still short compared to many other chemicals, but not nearly as good as for BPA.

This same study compared two soil types and found that the half-life in soil with a higher organic matter level was 60% higher, showing that it absorbed onto the organic matter which protected it from degradation. Presumable the organic matter also keeps BPA away from roots.

2 notes

·

View notes

Text

Bisphenol S Prices Trend, Pricing, Database, Index, News, Chart, Forecast

Bisphenol S (BPS) prices have been a focal point for various industries, particularly those involved in the production of plastics and resins. This chemical, which serves as a substitute for Bisphenol A (BPA), has seen fluctuating prices due to a variety of market dynamics and regulatory pressures. The demand for BPS has increased as manufacturers seek safer alternatives to BPA, which has been scrutinized for its potential health effects. Consequently, the pricing of BPS is influenced by several factors, including raw material costs, production capabilities, regulatory developments, and market demand.

One of the primary drivers of Bisphenol S prices is the cost of raw materials used in its production. These materials include phenol and sulfuric acid, which are subject to global supply and demand fluctuations. Any changes in the availability or price of these raw materials directly impact the cost of producing BPS. Additionally, the energy costs associated with manufacturing processes play a significant role. As energy prices rise, the cost of production for BPS can also increase, leading to higher market prices.

The production capacity of Bisphenol S is another critical factor that influences its market price. Limited production facilities or any disruptions in existing production lines can lead to shortages in supply, which in turn drive up prices. Conversely, the establishment of new production plants or the expansion of existing ones can increase supply, potentially leading to a decrease in prices. Manufacturers constantly balance production costs with market demand to set prices that ensure profitability while remaining competitive.

Get Real Time Prices of Bisphenol S (BPS): https://www.chemanalyst.com/Pricing-data/bisphenol-s-1224

Regulatory developments significantly impact the pricing of BPS. As governments and health organizations impose stricter regulations on BPA due to its endocrine-disrupting properties, the demand for safer alternatives like BPS has risen. This increased demand can push prices upward. Moreover, any new regulations that affect the production processes or safety standards for BPS can also impact its cost. Manufacturers must adhere to these regulations, which may require additional investments in technology or compliance measures, thus influencing the overall price of BPS.

Market demand for Bisphenol S is driven by its applications in various industries, including plastics, coatings, adhesives, and thermal paper. The push for BPA-free products has led to a surge in demand for BPS in consumer goods, automotive, electronics, and other sectors. As more companies seek to market their products as BPA-free, the reliance on BPS increases. This growing demand often results in higher prices, especially if the supply does not keep pace with the rapid rise in consumption.

Global trade dynamics also play a role in determining Bisphenol S prices. International trade policies, tariffs, and import-export regulations can affect the availability and cost of BPS. For instance, tariffs on raw materials or finished BPS products can increase costs for manufacturers and consumers alike. Additionally, geopolitical factors and trade disputes can disrupt supply chains, leading to price volatility.

Technological advancements in production methods can influence the cost structure of Bisphenol S. Innovations that improve production efficiency or reduce waste can lower manufacturing costs, potentially leading to lower market prices. Conversely, the adoption of new technologies may require significant initial investments, which could be reflected in higher prices until the costs are amortized over time.

Economic conditions globally and regionally affect Bisphenol S prices. Economic downturns can lead to reduced industrial activity and lower demand for BPS, potentially decreasing prices. On the other hand, periods of economic growth can boost industrial production and consumer spending, increasing the demand for BPS and driving up prices. Inflation rates also affect production costs, including labor and materials, which can be passed on to the final price of BPS.

Sustainability trends are increasingly shaping the market for Bisphenol S. As environmental concerns grow, there is a push for greener and more sustainable production processes. Manufacturers investing in sustainable practices may incur higher costs, which can be reflected in the pricing of BPS. However, these efforts can also lead to long-term cost savings and enhanced brand reputation, potentially stabilizing prices over time.

In conclusion, Bisphenol S prices are influenced by a complex interplay of factors including raw material costs, production capacities, regulatory changes, market demand, global trade dynamics, technological advancements, economic conditions, and sustainability trends. The ongoing shift away from BPA in favor of safer alternatives like BPS continues to shape the market, creating both challenges and opportunities for manufacturers and consumers. Understanding these dynamics is crucial for stakeholders across the supply chain as they navigate the evolving landscape of the chemical industry.

Get Real Time Prices of Bisphenol S (BPS): https://www.chemanalyst.com/Pricing-data/bisphenol-s-1224

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

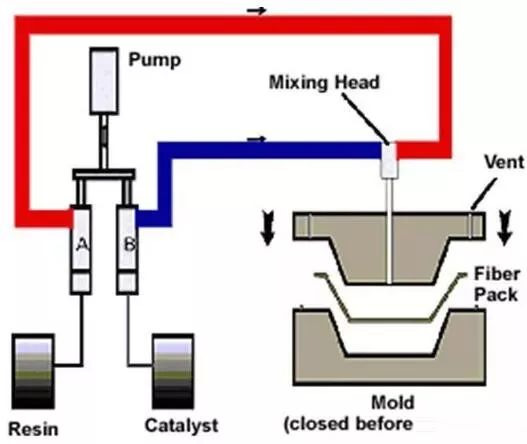

What is the RTM Molding Process for Composite Material?

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

Epoxy resin has good wettability, matching and adhesion to reinforced materials.

The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#RTM#RTM molding process#epoxy resin supplier#epoxy resin system#RTM process#resin transfer molding#epoxy composite material#epoxy resin curing system#composite material

0 notes

Text

The global bisphenol A market is likely to showcase a growth of around 6% during the forecast period.

0 notes