#rapid manufacturing company

Text

📦Unlocking Business Opportunities: ARRK’s Comprehensive Services📦

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

📈About ARRK: Get the best Product Development Services 📈

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

ARRK offers a wide range of services aimed at supporting businesses in bringing their products from conception to market. These services include:

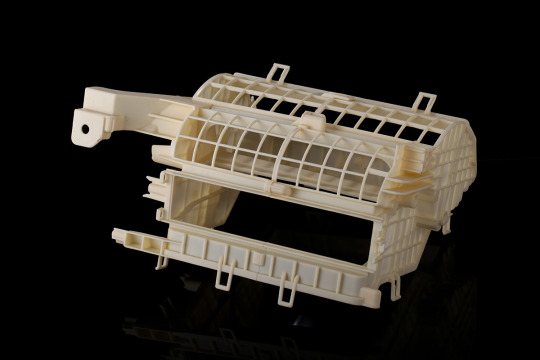

3D PRINTING

Our 3D printing service and additive manufacturing solutions cover any requirement with the help of advanced technology and a variety of high-quality materials, as well as our signature design and engineering expertise. Our capability is a prototype ready for evaluation or production, and the differentiation relies on the various processes we manage.

VACUUM CASTING

Easily reproduce your design with the vacuum casting process by using a 3D printed or machined master to create RTV silicone rubber molds. This is a cost-effective solution with consistent prototypes, be it in small quantities or in the region of hundreds.

CNC MACHINING

Computer Numerical Control (CNC) machining is when software controls machinery to make precision cuts by removing material from a workpiece to create unique parts. Plastic and metal components can be prototyped or produced with our medium or low-volume CNC machining

MICROWAVE MOLDING

Microwave Molding is a quick manufacturing process that works by micro pelletizing a thermoplastic resin to create prototypes. The fine particles are heated and melted in a silicone mold similar to our Vacuum Casting solution. The result is a lot faster and ready for the evaluation process.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

LIGHTING PROTOTYPE

As prototyping experts, we rely on our engineering skills and manufacturing technology to make lighting prototype models that reach high-quality standards and accomplish design guidelines. Optics, electronics, mechanics, and analysis convene to produce excellence.

INJECTION MOLDING

Our high to low-volume injection molding services allow companies to get as many custom parts as needed since this process’s main features are repeatability and competitiveness. Injection molding works by injecting melted plastic into a mold, cooling it afterward, and solidifying it. It’s generally a mass-production solution. If you want to get more information about product development, you can navigate to this website.

DIE CASTING

Die casting is a process that inserts molten metal under high pressure into reusable molds called dies to produce high-quality components for multiple purposes. ARRK can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

💼 Connect with Us Today! 💼

From concept to creation, ARRK is your one-stop destination for comprehensive product development services. Reach out to us via our official channels:

🏢 Business Address: Block E-10-01, Oasis Ara Damansara, Jalan PJU 1A/7, Ara Damansara, Petaling Jaya, Selangor, 47301 Malaysia

📞 Phone: +60 377347692

🌐 Website: ARRK Official Website

🕘 Hours of Operation: Monday-Friday: 8:30 am-5:30 pm

Social Media: Don't forget to follow us on social media for the latest updates, tips, and success stories:

👍 Facebook: ARRK Business

🔗 LinkedIn: ARRK

🕊️ Twitter: ARRK

Choose ARRK and embark on a journey where innovation meets precision, ensuring your ideas are not just realized, but perfected at every stage of the product development process.

#rapid manufacturing company#rapid prototyping and manufacturing#3d printing prototype service#cnc cutting machine supplier

1 note

·

View note

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

1 note

·

View note

Text

Revolutionizing Production with Rapid Manufacturing Systems and Rapid Tooling

Traditional ways of making things can take a long time, cost a lot, and make it hard to change the design. Rapid Manufacturing Systems, on the other hand, have changed the way goods are made. RM Mold knows how important time is to modern businesses and has used the power of these tools to get results that are better than expected. RM Mold shortens production times without sacrificing quality by using cutting-edge technologies like 3D printing, CNC machining, and injection casting. Please visit us: www.4shared.com/web/preview/pdf/FCn8uZeTku?

0 notes

Link

The blogger promotes CNC manufacturing companies with his informative and educative blogs. He writes extensively on the role these companies play in the manufacturing process.

1 note

·

View note

Quote

ADDITIVE MANUFACTURING & 3D PRINTING

#3d metal printing companies#3d priniting post processing services#additive manufacturing companies in bangalore#additive manufacturing service in india#additive metal 3d printing#metal 3d printing companies in bangalore#metal 3d printing companies in india#metal 3d printing in rapid prototyping#metal 3d printing india#metal 3d printing rapid prototyping#metal 3d printing raw material#metal 3d printing service bangalore#metal 3d printing services in india#metal additive manufacturing service providers#post processing of 3d printed

0 notes

Link

Need to create exclusive aluminum parts in a short period of time? Want professional help with executing even the most complex manufacturing projects? Then Ideal Machined Components can help. We have years of experience in providing service to a wide range of aluminum machining service industries that have quality requirements for aluminum parts, and can handle challenging tasks with ease. Machining companies near specialists will guide you through the entire process.

#Machining Companies Near Me#Precision Machining Company#Aluminum Machining Near Me#Aluminum Machining Service#Custom Machining Services Near Me#Rapid Machining Services#Machining and Manufacturing Services#Large Component Machining#Medical Machining Companies#Machining Parts Suppliers

0 notes

Text

Art in the Stations: Renaissance Center

As I got off the People Mover at Renaissance Center, I was lead down a tunnel walkway from the platform and into a colorful tiled space. Home to the General Motors Headquarters, this is the same station you'd be able to use if you lived, worked, and played in the neighborhood. Home to restaurants and shops, the "Ren Cen" is a staple in the Detroit skyline.

"Path Games" by George Woodman features 2,625 ceramic tile modules, silk screened and manufactured in Italy. The vibrant design represents the connectivity of cultures in Detroit, linking together to create multi-colored orientations of continuous pattern. Throughout his 60-year career, Woodman explored color and abstraction in a variety of forms, including landscape, geometric, and patterned, and later pivoting toward figure, sculpture, and architecture.

Standing strong is "Siberian Ram," a cast-bronze sculpture by Marshall Fredericks with a Pewabic tile backdrop. The green tiles behind Siberian Ram were donated from Stroh's Brewing Company and can also be seen in this unique green color at Cadillac Center.

Fredericks was one of Michigan’s most prolific sculptors, with 29 in total. Known for his sculptures depicting animals and nature, the original Siberian Ram was first completed in 1941 and on display at Frederik Meijer Gardens and Sculpture Park in Grand Rapids. Hosting the largest collection of his work, you can also see "The Boy and the Bear" and "Seven Saints and Sinners" at Meijer Gardens.

The green tiles behind Siberian Ram were donated from Stroh's Brewing Company and can also be seen in this unique green color at Cadillac Center.

#artinthestations#detroitpeoplemover#marshallfredericks#pewabicpottery#pewabic#renaissancecenter#downtowndetroit#georgewoodman#rideforfree

68 notes

·

View notes

Text

Germany Should Have Listened to Trump

Tuesday 2.27.2024 Wall Street Journal

By Walter Russell Mead

Trump was right about Berlin’s self-defense and risky energy dependence on Russia.

The lower house of Germany’s Parliament voted to legalize the recreational use of cannabis last week. It was a timely move. Germany’s leadership class is going to need all the mellow it can find in a world that isn’t going Germany’s way.

Russian advances in Ukraine and American paralysis over the next aid package are reinforcing the reality that Germany needs to defend itself but lacks the power to do so. So are developments in the Red Sea, where German manufacturers must cope with shipping delays as the Biden administration fails to keep the vital waterway clear.

Forget the 2% of gross domestic product that Germany has repeatedly promised and failed to spend on defense. Defense Minister Boris Pistorius shocked many observers this month when he said that in the new world situation, Germany may have to spend as much as 3.5% of GDP for defense.

The economic news is also grim. Last year Germany’s GDP shrank 0.3%, and last week the government slashed 2024 growth estimates to a pitiful 0.2%. Economists expect negative growth during the first quarter of 2024, placing the country in recession. The outlook for housing is bleak, with business confidence reaching all-time lows. The news in manufacturing is little better. This month the widely followed HCOB German Flash Composite Purchasing Managers’ Index fell to 46.1, the eighth month in a row that the index has pointed to decreasing economic activity.

Energy prices are a particular sore spot. The chemical giant BASF announced €1 billion in spending cuts in its German operations, blaming a mix of weak demand in the German market and “structurally higher energy prices.” Enormous U.S. subsidies under the so-called Inflation Reduction Act are leading German companies to look across the Atlantic.

Chinese competition is another massive worry. China long ago passed Germany as the world’s largest car producer. Increasingly, especially in electric vehicles, it is challenging Germany as both a low-cost and high-quality manufacturer. Beijing aims to marginalize German capital goods and automobile companies in China while Chinese exporters challenge German dominance in world markets.

With the associations representing the small and medium-size Mittelstand firms that make up the heart of the German economy warning in a rare joint open letter about Germany’s loss of competitiveness, Economy Minister Robert Habeck isn’t mincing words. The economy is in “rough waters.” The “competitiveness of Germany as an industrial location” is in doubt.

It isn’t all doom and gloom. The outlook for the service sector is brighter than for manufacturing, and as the Journal reported last week, the Ifo Institute’s business-climate index improved slightly this month. The best that can be said for the outlook? “The German economy is stabilizing at a low level,” according to Ifo’s president.

Meanwhile, Germany’s dysfunctional three-party coalition government is paralyzed by internal struggles. The largest party in the coalition, Chancellor Olaf Scholz’s Social Democratic Party (SPD), is deeply divided over foreign policy, with many nostalgic for good relations with Russia and allergic to military spending. The SPD also wants Biden-like government spending initiatives to revive the German industrial machine and expand social benefits. The Greens, the next-largest party, are by German standards foreign-policy hawks but continue to press for a rapid energy transition that drives up costs for business and consumers. The third party in the coalition, the Free Democrats, wants to hold the line on government spending. As if this weren’t enough trouble, the conservative opposition parties have a blocking minority in Parliament’s upper house.

This is not where Germans thought they would be. Sixteen months ago, I visited Berlin and heard from a stream of government officials, think tankers and economists that everything was working fine. Russia was failing in Ukraine. The energy transition would boost German competitiveness and employment. Germany’s Mittelstand would handle anything China could throw at it.

Under the circumstances, it’s no surprise that antiestablishment parties are growing in Germany. The far right Alternative for Germany (AfD) currently has more support than any of the governing parties, with one recent poll showing the AfD at 19%, the Social Democrats at 14%, the Greens at 13%, and the Free Democrats at 4%.

The most bitter pill of all for Germany’s establishment may be the realization that on the most important issues facing Germany, Donald Trump was right where they were wrong. Getting in bed with Vladimir Putin for cheap energy was both foolish and deeply disloyal to the West. German defense policy was self-defeating and dangerous. China wasn’t a reliable partner.

“Ich bin ein Berliner,” was President John F. Kennedy’s message to Germany. If Donald Trump returns to the White House, his message will likely be “Das habe ich gleich gesagt,” or “I told you so.”

#Today's#Wall Street Journal#Trump Was Right About Everything#trump 2024#trump#president trump#repost#donald trump#art#nature#democrats#Biden#Obama#love#Russia#Germany#landscape#fashion#leadership#honest#integrity#guts#energy#GNP#NATO#DIY#GIF#IG#Europe#listen

41 notes

·

View notes

Text

youtube

Excerpt from this story from the Associated Press (AP):

A tiny, low-priced electric car called the Seagull has American automakers and politicians trembling.

The car, launched last year by Chinese automaker BYD, sells for around $12,000 in China, but drives well and is put together with craftsmanship that rivals U.S.-made electric vehicles that cost three times as much. A shorter-range version costs under $10,000.

Tariffs on imported Chinese vehicles probably will keep the Seagull away from America’s shores for now, and it likely would sell for more than 12 grand if imported.

But the rapid emergence of low-priced EVs from China could shake up the global auto industry in ways not seen since Japanese makers exploded on the scene during the oil crises of the 1970s. BYD, which stands for “Build Your Dreams,” could be a nightmare for the U.S. auto industry.

“Any car company that’s not paying attention to them as a competitor is going to be lost when they hit their market,” said Sam Fiorani, a vice president at AutoForecast Solutions near Philadelphia. “BYD’s entry into the U.S. market isn’t an if. It’s a when.”

U.S. politicians and manufacturers already see Chinese EVs as a serious threat. The Biden administration on Tuesday is expected to announce 100% tariffs on electric vehicles imported from China, saying they pose a threat to U.S. jobs and national security.

11 notes

·

View notes

Text

“In his study of [the international coffee] market, scholar Joseph Nevins finds that the big changes occurring between the mid-1970s and the mid-1990s are related to the “longer-term struggle over the distribution of income related to the crop.” In the early part of this period, growers pulled in an average of around 20 cents for every dollar of coffee revenue. They were aided by an agreement called the International Coffee Accord (ICA) of 1962, which acted as a sort of cartel plan, constraining and arranging supply. In the wake of the Cuban Revolution, the Kennedy administration supported the ICA and its concessions to Third World workers as a Cold War tool to head off communist onshoring in the Western Hemisphere. But as the U.S. strategy changed, the country and its free-market Latin American proxies abandoned the ICA in 1989. The results were quick: By the mid-1990s, the grower share was down from 20 to 13 percent. Roasters, traders, and retailers in the drinking countries improved their share from 54 to 78 percent. That big, fast shift was partly thanks to repressed grower wages, partly thanks to repressed domestic service wages in the West, partly thanks to consolidation in the industry, and partly thanks to new high-priced coffee drinks. Starbucks went public in 1992, and if it seemed to be growing like a tech company in the ’90s, that’s because both thrived on the same social changes.

“Worsening conditions for workers in Mexico and in the rest of the Americas pushed people north, rapidly increasing the undocumented immigrant population in the United States. The Bracero program was over, but the jobs still needed doing. Caught in between employers who were hiring migrants and nationalist restrictionists, the Reagan administration legalized a few million undocumented workers while increasing border enforcement. Even though the vast majority of narcotics came into the country via legal ports of entry, conservatives and liberals alike framed border enforcement as a central front in the war on drugs. Increasing the costs of crossing couldn’t stanch the increase of people—they were responding to larger factors: Out-migration from Mexico’s coffee-producing areas increased after the dissolution of the ICA, for example. This tendency intensified after the North American Free Trade Agreement went into effect in 1994, pushing Mexico further toward cheap manufacturing exports and cheap imported American corn.

“The glut of cheap labor and commodities in this period undermined labor protections in the center as well as on the periphery, and the United States lost union jobs at a rapid clip. Reagan undermined the bulwark of government jobs by bringing Boulwarism to the White House. His signature incident occurred in his first year, when he fired more than 11,000 striking air traffic controllers and decertified their union. To the press, the president quoted an air traffic controller who quit the union and reported to work as ordered: “How can I ask my kids to obey the law if I don’t?” Once again, questions of individual criminality put the Reaganites on firm ground. Organized labor took to rearguard action, holding on to its institutions by agreeing to two-tiered contracts that reduced benefits and protections for new or future members. Capital shook off the midcentury labor agreement like a bad habit, reducing its accountability to its own workers the way it previously reduced accountability to the broader communities. The second part didn’t require as many votes.”

Malcolm Harris, Palo Alto

15 notes

·

View notes

Text

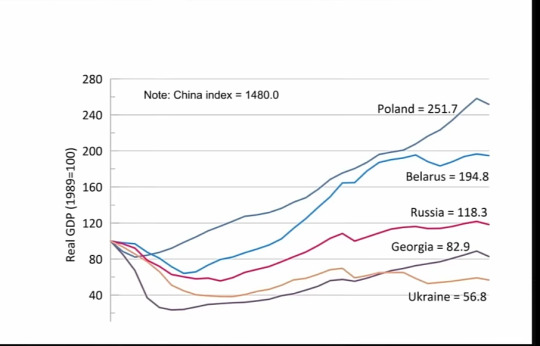

This is an index of Economic growth of select ex-Communist countries: Russia, Ukraine, Belarus, Poland, and Georgia, with a mention of China.

Poland, among the Eastern European ex-Communist countries, did the best. And it is true that Poland's economy is now more than 2.5x the size it was before the Warsaw Pact countries collapsed, having received ENORMOUS aid funds from the EU and US, and was even brought into the European Union, becoming fully integrated into the Western Imperialist fold.

There's just no way to credibly say that Neoliberalism served the economic growth of Poland. The massive economic intervention by the West into Poland's economy is antithetical to Neoliberalism. And so, we can conclude Neoliberalism was NOT a cause for Poland's economic growth.

Second best, as you can see, is Belarus, having grown to nearly twice the size its economy was in 1989. But what's interesting about this is that Belarus was the one Eastern European nation that did NOT adopt a Neoliberal Capitalist model. It is still to this day a largely publicly-owned economy, depending largely on large State-owned Machining and Manufacturing companies that employ large swaths of the population. Its education system as well has changed little since 1989, and Belarus still has one of the best education systems among Eastern European countries.

Russia is an interesting case because it began down the road to Neoliberalism, oligarchs formed out of the ex-Soviet heartland, with criminal enterprises and private corporations becoming nearly indistinguishable from one another for a time.

However, in very important ways, Russia has begun moving away from the Neoliberal model, even re-Nationalizing certain key resources and vastly increasing Social spending, Healthcare spending, and Infrastructure projects. This increase is reflected in the graph as a sudden stop in Russia's decline in the early 2000's and a steady, if slow, growth since then.

I don't personally know a whole lot about Georgia, and so I will decline to comment on the economic state of the country at this time, and will do some research on the economic system of Georgia.

Last, and certainly least, comes Ukraine, which followed a process similar to Russia's, indulging in the worst Neoliberal impulses for Privatization and Deregulation. With that said, much of Ukraine's previously strong Socialist Labor Protections, broad Union Rights, and huge public assets still remained at the time of the Euromaidan coup.

And what you see since 2014 is the very rapid deregulation, privatization and Union smashing of the Ukrainian economy. The entire country is for sale. Don't take my word for it, take Zelensky's when he made that weird video praising BlackRock and JP Morgan Chase as the future of Ukraine. Zelensky has made it crystal clear: any and all State Assets are up for the highest bidder to take. Mostly Western Corporations that see an opportunity to suck the wealth out of yet another country's working class. And the results have been so far predictable: huge increases in poverty along with economic decline and stagnation. I mean, peeling Ukraine away from its largest trading partner was always going to be bad for Ukraine, and the economic indicators make it clear that Neoliberalism is destroying their Working Class.

And lastly a simple note on China: China's economy has grown 1'480% since 1989. A staggering figure for a Nation that had been among the poorest in the world for the 19th and much of the 20th Centuries. China of course is no longer a Communist style Command economy, or is it? China still has no Private Property, all property must be leased from the State, and though China has opened up its economy, it hasn't exactly followed the Neoliberal model either.

Instead China has led global economic growth as a sort of mixed economy. Much of it remains under Command control, being massive State-owned enterprises, and the CPC has huge stakes in Private companies throughout the Chinese economy. Virtually all of China's resources remain under Govt control, under Public ownership.

I won't go much further into it, the point is clear: China, whatever its economy may be called, it is NOT Neoliberal Capitalism. So for our purposes, China's massive economic growth cannot be attributed to Neoliberalism by any means.

So just something to think about. It seems pretty obvious that Neoliberalism offers nothing to the Working Classes. All it offers is more poverty and stratospheric inequality.

*Update*

Just an added side note: one thing each of the countries that have displayed economic growth since the fall of the Soviet Union have in common is an Industrial Policy. Poland, China and Belarus each have had an industrial policy with large-scale Govt intervention. This is also antithetical to Neoliberalism, and the countries that have not had an industrial policy were also the same countries to follow the Neoliberal model.

A clear Industrial Policy seems like an essential character of an economy growing on Main Street, not Wall Street.

#neoliberal capitalism#neoliberalism#capitalism#fuck capitalism#fuck neoliberalism#us news#us politics#socialist news#socialist politics#socialist worker#socialism#communism#marxism leninism#socialist#communist#marxism#marxist leninist#progressive politics#politics#us imperialism#capitalist imperialism#imperialism#anti imperialist#anti imperialism#anti capitalism#anti capitalist#economics#economy#economic news#geopolitics

59 notes

·

View notes

Text

[230303] ATEEZ are showing the world another side of K-pop by Taylor Glasby of i-D

Going stratospheric despite their small agency beginnings, the arena headliners discuss manifesting success and their secret ambitions.

ATEEZ have just played a raucous show to 20,000 fans at London’s O2 Arena. Backstage, with the adrenalin still pumping, Hongjoong, Seonghwa, Yeosang, Mingi, San, Wooyoung, Yunho and Jongho are talking about football. Mingi, deep-voiced, his cropped hair cotton candy pink, is a Chelsea fan. Jongho, the band’s youngest at 22, follows Spurs. “Which is better?” asks Mingi. My tentative, uninformed guess (“Spurs?”) yields triumphant hoots and disappointed groans, as Jongho reaches over for a fist bump and hi-five. This exchange isn’t so much about football, as it is a reflection of ATEEZ wanting to make everyone they encounter feel welcome – a habit unchanged despite their stratospheric rise through the global pop landscape since debuting in late 2018.

During their week-long stay, they meet fans (known as ATINY) at a signing event, make late-night TikToks beneath the glow of Big Ben, go live on YouTube from a cosy corner of a hotel room, and watch South Korean forward Son Heungmin score at a Tottenham Hotspur game. The club’s home stadium (soon to host Beyoncé’s five London concerts) leaves a lasting impression on Yeosang: “When I saw how big it was and how loud the people were, I thought about how I want to be an artist that can play there,” he says in his slightly raspy voice. Wooyoung’s thoughts, however, linger Stateside in the wake of their most recent EP, Spin Off: From The Witness, earning them a second Top 10 entry on the Billboard 200 in early January. “I don’t know if it’s a team goal or my own,” he admits, “but I do want a #1 on the Billboard Hot 100. Hoping for it to happen is the easy part, but what’s necessary is the confidence and bravery in the belief that it will happen.”

ATEEZ’ ambitious nature is an overarching constant to their rapid growth as individuals and artists, useful as both a touchstone of their success and a beacon for their creative output. It was present on their first record, Treasure EP1: All To Zero, which set up a rebellious narrative (now a complex and sprawling alt-world storyline) just as much as it drives their meteoric singles and the exploratory genre-overlaps of their B-sides. As a result, they’ve become a prolific and landmark group. The World EP.1: Movement (their ninth EP, out in July 2022) was ATEEZ’ first platinum-selling release, a major accomplishment for an idol group from a relatively small K-pop agency.

Hongjong, the band’s leader, thinks and talks fast (today, in English) but he pauses to take a moment to muse over their trajectory. “Many people say that I can be proud of being a group from a small company that has made their own way. So if we continually do it like this with ATINY, then in the future people might agree that ATEEZ have made a change in K-pop. I think for now though, we haven’t done enough.”

They hope, notes Seonghwa (the band’s eldest member at 24), that their achievements will eventually be on a broader scale. “We’d love to be the people behind that movement,” he says. Hongjoong nods in agreement: “I want for us to provide people with a better understanding of K-pop worldwide. There are people who continue to say that K-pop is so technical and manufactured but K-pop isn’t just a single genre; each group has a different type of art and I want to show how we express our art to everyone. When I look into the crowd at concerts, I can see so many people of all ages and backgrounds yet stereotypes against the artists and the fans still exist.”

In the early days of ATEEZ, it was evident that Hongjoong and Mingi played a key role alongside their music production team, Edenary, and that a sense of individualism seemed to be encouraged in the group’s performances. These are both now acknowledged as strengths in their arsenal. The Fellowship: Break The Wall, their third world tour, serves to highlight their unified stance while showcasing the members’ idiosyncrasies — from dance style to sense of humour — but also how comfortably they inhabit the stage.

“During our 2019 Expedition tour, we learned a lot about how to perform with every show we did,” says Yunho, an effortlessly impressive dancer. “Then during the pandemic, we studied and developed how to really make the performance; working on the stage configuration and synchronisation of moves amongst ourselves. When we came back to Europe and the US last year for the Fellowship: The Beginning of the End tour, we were able to see how everything we’d worked on and our personal growth came together on that stage.”

For some members, the process has involved looking beyond the stage in order to feel more at home on it. Yeosang’s regimented program of working out put him physically and mentally in a stronger place: “I relieve my stress while exercising, but my breathing got better and my muscles also got better, so overall it connected into a great result on stage.” San and Seonghwa also turned inward, sifting through mental libraries of borrowed or imaginary traits to build and inhabit new characters for their performances.

“I always have a lot of imaginative thoughts,” says Seonghwa, whose general serenity is replaced by a lightning-strike energy on stage and sparks of playfulness when you least expect it. “Even before sleeping, I tend to think about fantastical things,” he continues. “I use these to decide on how I’m going to be on stage and make sure the atmosphere matches with elements like my outfit.”

“For San, it’s movies and dramas [that inspire his performances], he takes those characters on,” explains Wooyoung. San, widely lauded for having an explosive stage presence, makes his creative choices the day of. “If there’s something I think of that I want to do that day, I share it with everyone to see if it will be okay. Then we create that image together and I simply express myself.”

Wooyoung, who is both mischievous and magnetic, looks to those he admires for guidance. “I mostly look at videos of our seniors – Jimin (BTS), Taeyang (Big Bang), Hoshi (SEVENTEEN), there’s so many – I get inspiration from them and make it my own on stage.” It’s a process also adopted by Yunho. “There are artists that I can pull from, like Rain, learning from them in order to realise my own style,” Yunho says. “On stage, it’s just me, I’m myself, but I have all this in the back of my mind.”

The title of their current tour, The Fellowship: Break The Wall, is derived from last summer’s single, “Guerrilla”, on which the phrase “break the wall” is chanted with increasing ferocity, culminating in a screamo-style vocal outro. It’s one of the show’s many high points, with ATINY putting their everything into screaming along with the band. The atmosphere grows feverish, the stage bathed in red light as the giant screens flash through the dystopian city of their storyline. It’s unbridled to the point of being transcendental. San grins, reflecting on this moment. “It’s difficult to explain,” he says of the experience, while Hongjoong sees in it the removal of cultural barriers through music. “I see ATINY during ‘Guerrilla’ singing along really loud and really tough,” he says. “They come to our show, they memorise our lyrics, they shout. That’s how they’re breaking the wall, by coming together.”

Since last October, ATEEZ have been playing arenas across Asia, the US and Europe, adding extra nights as they go in order to accommodate the demand, and garnering rave reviews — even from broadsheet media, for whom K-pop remains a confusing phenomenon — in the process. But their feet, heart and heads remain earthbound. “Nothing in this world is guaranteed,” says Wooyoung. “We’re always grateful for everything. It’s something we’ve discussed as a group, but it’s all thanks to ATINY’s love and support that we’re where we are now. To become global artists and a good influence on even more people, we have to hold a sense of responsibility to give our all on stage and deliver our truth. Honestly, it’s less about dreaming of an unknown future and more about how we have to work harder so we can go even higher and pave our own path.”

ATEEZ’ success is holistic in form: personality, performance and music. A harmonious but intriguing balance of authenticity and polish. Their impressive discography features recurring motifs (waves, moon, light) and ideologies (power, truth, rebellion, movement), yet Mingi and Hongjoong — who have written lyrics on every ATEEZ track so far — admit they’re still learning how best to combine what’s on their minds with what’s conducive to furthering their storyline. It is, they agree, not always an easy task.

“It’s absolutely hard to focus on so many themes,” says Hongjoong. “Sometimes my brain stops, so I watch movies or our music videos again. I think too much when I write but, after that work, the lyrics have more power for the fans who know our storyline; they get different emotions and a different effect when I’ve done that work well. It’s really hard but it’s important to do.”

Hongjoong had an epiphany when he picked up a camera while touring last year. “There's such fierce competition – not just in music but all industries – so if there’s no purpose, I’ve always found it really hard to create freely. We have continuous deadlines. I do the first album, then the second, and once I complete the second album I have to start on the third. I’ve found my hobby with a film camera. I walk around taking photos and I can see that even if I have no immediate purpose, I can create something.” It’s something that’s changed his approach to songwriting. “These days, when I write lyrics or produce a song, I just start from zero,” he explains. “Before, if we had a pirate theme, for example, I would start with that as a topic. That’s why I found it so hard.” He now works backward, getting down exactly what he wants to say before connecting it to the narrative markers. “It’s quite different but it’s more comfortable for me and the results are better than before.”

Hongjoong and Mingi, the group’s rappers, point to last year’s "Halazia” as the hardest storyline track to pen. “The atmosphere of the song is already quite difficult and complex,” Hongjoong notes, looking over to Mingi, who explains his process of cataloguing his many thoughts to later draw from. “I write down a lot of them as memos on my phone, so I always go back to them to see if they match what we’re going through (as a group); that’s how I write my lyrics,” he says. “Sometimes I’ll think of it as writing a script, to really get into that persona."

Mingi and Hongjoong are not the only collectors and creators in ATEEZ. “In my case,” says Seonghwa, “I always memo whenever I hear a line from a song or a line from a poem that I like, just for me to look back on. I’m the type to jot down my feelings if I experience something special. These help me when I write letters or want to say something to ATINY because I’m able to better word my feelings.” San, meanwhile, cites legendary South Korean poet 나 태주 (Ra Tae-joo) as an influence. “I love poems too — I’ve been writing my own but I keep them to myself,” he says. “They can be about my feelings on a certain day, the weather, objects or characters. I’m able to lay out my feelings like this.”

Now in their fourth year, ATEEZ remain as set on the idea of constantly challenging themselves as they were when they were hungry rookies. Take Jongho for example, whose rich, gut-punching vibrato forms the backbone of many of their songs. When he listened back to The World EP.1: Movement for the first time, he admits that he was “worried because my voice was used in ways that I hadn’t tried before, and I wondered how my vocal colour was going to fit”. He sat down with their producers and worked through “how we could still make it still an ATEEZ song and match my tone, while trying something new. I’ve gained more confidence — it makes me want to do better for all the albums to come.”

Hongjoong laughs. “It means our next albums are, uh, a big thing,” he reveals, knowingly. “There are so many good K-pop and pop stars that if we want to go higher, we have to have more good songs and try other genres, too.” But even as he muses on ATEEZ’ continuing expansion, the idea of one day becoming ‘too big to fail’ doesn’t appeal to him. “No, absolutely not that,” he says, gaze steady. “I want ATINY to be able to tell us if something is bad. I like it when they do this because we don’t want to just give them our popularity. I want to give them good quality, not just a song or a video or a performance.” Does the fact that music is subjective; that no single song can please everybody, bring some comfort? “We try to find the middle ground,” Hongjoong says. “The first thing to note is that if we think it’s really great but someone else says that they think it’s trash, then we don’t really care what they think. But when we’re unsure and questioning and someone says, ‘Yeah, it’s bad’, then ok, we go back to square one.”

The thought of ATEEZ honing their creative output through repeated baptisms of fire might well upset some fans, but the band are not only accustomed to the fame game’s highs and lows but wholly pragmatic in the face of its shadows. So when Wooyoung says he’s aware of “many people” who openly disparage their music, Hongjoong shrugs a little as he responds. “Yeah, there are. We talk about this a lot together, but if there are many more haters than before, it just means we’re more popular than before,” he reasons.

The group finds positive equilibrium via a heartfelt focus on ATINY, and all that comes with being an idol group who are years into a very successful career. “When we look at line-ups now, we’re closing the show,” says Wooyoung. “And as we perform, we see the other artists watching us, and we realise we have more responsibility. Firstly to ATINY, who have been loving us and supporting us from the start, but there’s also a responsibility to spread K-pop and Korean culture because we’re travelling around the world as Korean artists.”

One of ATEEZ many dualities is that while they have big, burning aspirations — Billboard charts, Grammys, performing at the Super Bowl — that make them look at each other starry-eyed, some of their ambitions are precious in a different way: they’re simpler, more immediate. “I’d like to be happier than the day before,” says Mingi. “And I want for us to never change our sincerity toward music and gratitude to our fans,” adds Seonghwa. This is echoed by San, who adds that ultimately, “I’d be satisfied if ATEEZ’ name came up when someone asks who the coolest artist is at the end of the year.”

“I want to make more events with ATINY,” says Hongjoong. “That’s a goal for this year because we always miss them and they always miss us.” Jongho, sitting in the middle of the group, is smiling. He’s been manifesting a more personal ambition. “By next winter I want to be able to snowboard,” he says. “I want to buy my own board, go down the mountain and not fall.”

89 notes

·

View notes

Text

The Potential of High-Tech Rapid Prototyping

High-tech Rapid Prototyping has become a game-changer in the rapidly changing fields of innovation and technology, altering the way things are planned, developed, and introduced to the market. This dynamic process, which promotes creativity, shortens time-to-market, and ultimately drives unmatched innovation, has emerged as a key component for companies looking to maintain their leadership positions in their respective fields.

The Innovation-Promoting Technologies

The 3D Printing Process

3D printing is a key component of the fast prototyping revolution because it allows digital models to be layered into actual items. This technology has made it easier to produce intricate, personalized prototypes and greatly reduced design cycles.

Machining using computer numerical control (CNC)

Prototypes made of different materials may be accurately cut, shaped, and assembled with the help of computer-controlled gear thanks to CNC machining from CNC Machining Manufacturer. This adaptable technique works especially well for creating prototypes with intricate geometries and great accuracy.

Using Injection Molding

Rapid prototyping is greatly aided by injection molding, a process that is frequently employed in mass manufacturing. The appearance, feel, and functioning of the final product are accurately represented by injection-molded prototypes.

Benefits of Rapid High-Tech Prototyping

Quicker Iterations in Design

Design revisions may be completed quickly and affordably using rapid prototyping. Instead of weeks or months, designers may test several iterations of a product, improve functionality, and fix bugs in a matter of days.

Economy of Cost

High-tech fast prototyping decreases the upfront expenses associated with traditional manufacturing methods by eliminating the need for expensive equipment and molds. This makes it possible for companies to test concepts more affordably before committing to large-scale manufacturing.

Improved Cooperation

Improved cross-functional team communication is facilitated by prototyping. A prototype may be physically interacted with by stakeholders, who can offer insightful input and encourage cooperation between end users, engineers, and designers.

Sensitivity to the Market

Being able to react swiftly to customer input and industry developments is critical in businesses that move quickly. Businesses may maintain their agility, adjust to shifting customer needs, and obtain a competitive advantage in the market by using high-tech fast prototyping and Precision CNC Machining.

Follow our Facebook and Twitter for more information about our product.

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company#Precision CNC Machining Manufacturer Company

1 note

·

View note

Text

Rapid prototyping is a manufacturing process that uses 3D printing technology to create a rapid prototype. This allows rapid prototyping companies to test and iterate on product designs quickly before investing in more expensive manufacturing processes.

0 notes

Link

The blogger works with CNC manufacturing companies that produce samples for leading as well as upcoming manufacturers. A CNC company comes into picture whenever there are new products to be launched.

0 notes

Photo

Additive Manufacturing & 3D Printing are interchangeable terms as they both describe the same process. It’s a technology where 3D parts are produced layer by layer from a material.

Additive manufacturing Process

The Additive manufacturing Process involves uploading your Computer-Aided-Design (CAD) designs directly to 3D Printer to deposit material, layer upon layer, in precise geometric shapes creating the desired Metal 3D model.

Metal Additive Manufacturing

Metal Additive Manufacturing or Metal 3D Printing is Production of 3D Parts layer by layer from a metal Material.

The print head moves horizontally and vertically and puts a new layer of build material with every pass making it possible to manufacture objects using a variety of materials.

The Metal Additive Manufacturing Technique is also involves using 3D object scanners to scan the object and direct 3D Printer to deposit material, layer upon layer creating the metal 3D Model.

This technology makes it possible for manufacturers to produce complex metal parts without any design constraints of traditional manufacturing. There are numerous benefits of 3D printing over Traditional Manufacturing namely no design constraints and complex parts can be corrected and printed quickly.

Metal Additive Manufacturing Materials

The most common Metal Additive Manufacturing Materials are namely Aluminum Alloy - AISi10Mg, Super/ Nickel Alloy - Inconel 718, PH1, GP1 and CX, Inconel 625 and HX, Stainless Steel - SS316L, Titanium - Ti6AI4V and Ti6AI4V ELI, Cobalt Chrome- MP1, Maraging Steel- MS1, Copper- CU etc.

Metal Additive Manufacturing Applications

There are numerous Metal Additive Manufacturing Applications as Additive Manufacturing is ideal for production of Low Volume and speciality Parts. We can design Functional Metal Prototypes, spare and obsolete Parts, Surgical and Dental Implants, Jewellery and decorative Arts and custom Tools quickly.

Metal Additive Manufacturing Advantages

There are numerous Metal Additive Manufacturing Advantages namely

• Design Flexibility - Use Smarter Design Geometries

• Quick Evaluation of Designs

• Create Complex Parts to deliver Maximum Performance

• Eliminate Tooling and Fixture Costs

• Rapid Product Development

• Low Raw Material Wastage

• Simplify Supply Chain using On Demand Tooling

Benefits of Metal Additive Manufacturing (Metal 3D - Printing) in Aerospace, Space, Defense, Automotive, Tooling, Oil & Gas Industry

We are outlining the benefit of Metal Additive Manufacturing across various Industries

• Create Complex Parts to deliver Maximum Performance

• Use Smarter Design Geometries

• Eliminate Tooling and Fixture Costs

• Increase Durability and Lifecycle of Parts

Benefits of Metal Additive Manufacturing in Defense Industry

• Rapid Product Development

• Reduce Part Weight by Producing optimised components

• Low Raw Material Wastage

• Produce Custom Spares and Components

Benefits of Metal Additive Manufacturing in Automotive Industry

• Design of 3D Printed Scale Models

• Prototype Validation in Pre - Manufacturing Stage

• Produce Samples and Tools at Low Cost

• Produce Custom and Lightweight Parts

Benefits of Metal Additive Manufacturing in Oil & Gas Industry

• Design Flexibility & Faster Product Development

• Economic Low Volume Production

• Faster Re-Manufacturing of High Value Components

• Simplyfy Supply Chain using On Demand Tooling

Veer-O-Metals is one of the leading Metal Additive Manufacturing company In India offering complete Metal 3D Printing Solution across Industries namely Aerospace, Space, Defense, Automotive, Heat Sink, Oil and Gas, Product Development, Conformal Cooling, Medical, Digital Inventory etc.

Veer-O-Metals (VOM) was established in 1965 and has augmented cutting edge manufacturing technology in the field of metal additive manufacturing which is an automatic process of manufacturing objects (Parts, Prototypes, tools & even assemblies) directly from their CAD models without any cutter, tools and jigs & fixtures.

As an organization VOM holds equal responsibility in meeting the industry standards, which keep us abreast of all the mandatory certifications, needed for a healthy sustenance. VOM has obtained the below certifications to meet the standards.

• AS 9100D: Certified ISO 9001

• ISO-45001:2018

• EN 15085 LL-C (Certification)

• ISO 14001: 2015

• Certified IATF 16949: 2016

• ISO 27001: 2013

You can call us at +91- 9739991967 or contact us at [email protected] or visit www.veerometals.com for all you Additive Manufacturing requirements.

#post processing of 3d printed#metal additive manufacturing service providers#metal 3d printing services in india#metal 3d printing service bangalore#metal 3d printing raw material#metal 3d printing rapid prototyping#metal 3d printing india#metal 3d printing in rapid prototyping#metal 3d printing companies in india#metal 3d printing companies in bangalore#additive metal 3d printing#additive manufacturing service in india#additive manufacturing companies in bangalore#3d priniting post processing services#3d metal printing companies

1 note

·

View note