Text

5 Thermal Insulation Tips From Thermal Insulation Experts

The term thermal insulation is used to describe a material that creates a barrier between the item to be insulated and the environment.

This barrier prevents the transmission of heat, noise, electricity, and the like. There are several locations that you can notice the use of insulation around, these include:

The insulation used in buildings – improves comfort and saves energy

Insulating electrical objects (such as a cable) – help to limit electricity and magnetism

When the insulation used on glass – saves power

The insulation used on cars or machines – prevents noise

The insulation used on components such as piping and equipment – restricts thermal energy

Insulation is said to be a key feature of an oil refinery or industrial process plant. If you take a close look at the industrial plants, you would find that they are surrounded by insulated pipes, equipment, vessels, tanks, and the like.

These mechanical components receive insulation either for heat conservation, cold conservation, process control, or personnel protection purposes.

What is thermal insulation?

We often see the word thermal used with insulation as “thermal insulation”. The word thermal is related to heat, and the term thermal insulation describes that the insulation material or insulation system under this category will restrict or resist the flow of heat energy into or out of an object or item.

Acoustic Insulation

Note that acoustic insulation differs from thermal insulation as the insulation material or system under this category deals with noise instead of heat.

The Use of Thermal Insulation in Refinery

To give you a fair idea, a medium-size oil refinery contains about 73 miles of insulated pipes and 2.5 million square feet of insulated equipment.

Thermal Insulation Materials

There is not one, but different types of insulations used to insulate the mechanical components of a refinery or industrial process plant.

Reference to table 1 of BS 5970 may be made for a better understanding of the insulation material used for pipework, ductwork, associated equipment, and other industrial installations.

RELATED COURSES FOR INSULATION

Insulation Inspector Level 2

Insulation Inspector Level 3

Diploma in Insulation

Corrosion Under Insulation

RELATED ARTICLES FOR INSULATION

Master The Skills of INSULATION

9 Simple (But Important) Things to Remember About Corrosion Under Insulation or CUI

Enhance Your Cold Insulation Skills

The Use of Insulation in Refineries

#insulation#thermal insulation#Refinery#refinerylife#pipes#rockwool#insulationinspector#qaqc#oilandgasindustry#quality#qualitycontroller#qualitycontrol#coatinginspector#refineryinsulation#inspection#qcinspector#foamglass#cellularglass

0 notes

Text

What Does a Quality Control Inspector Do?

There are a lot of fascinating roles within the world of gas and oil. Perhaps amongst the most fascinating due to its sheer potential is that of a quality control inspector (QC Inspector for short). It’s one of those terms that is exactly as it sounds, but there are a lot of really interesting facets to this when looking at it as far as a career path.

What does a quality inspector do?

In short, inspect and “sign off” on the quality/integrity of everything from the raw materials to the finished product as it gets prepared to be sent out of the establishment and out into the world. In order to pass certain tests, the inspector must use specific criteria and focus on every part of every task assigned.

Working as a quality inspector or QA/QC inspector is a wonderful job for those looking for the responsibility of assessing all of those criteria against each part of the process, right up to the final product. However, it does comes with some pretty specific requirements!

Requirements to be a quality control inspector

If you’re looking at the idea of becoming a quality inspector, you’ll need to get certified in quality control and have real-time experience (as in hands-on) in the particular work field that you’re interested in. It’s very rare for someone to simply land a job right away as a quality controller or inspector.

This is because those in the industry must have some built-in understanding of the quality that they’re inspecting, as you can imagine.

What you should have

Generally, these are the requirements that you’ll want to have on-hand in order to be proficient and qualified in this job position as a QA or QC:

A high school education

Certification in the quality control field of your choice

Real-time experience in the relevant field

Great organization and attention to detail

Use of Microsoft Office, spreadsheets, etc

Extensive knowledge of QC standards and requirements

There are some who agree that having a bachelor’s degree and industry demanded certification could be a helping hand when applying for a job, but it depends on the hiring committee and their perspective.

Quite often, going for online training and certification and courses specific to your field is going to be just as good since most of these are entirely focused on producing a better workforce specific to the oil and gas industry.

Is a QC job a good one?

Absolutely. If you are someone who enjoys the process of things and also knowing that you are an integral part of that process, a quality control inspector is going to be a fantastic choice when wanting to hold a position that helps you enjoy a good way to earn income, and also make a difference.

The other thing is that this kind of job position has plenty of room for growth and adjustment as requirements shift and update as time passes. For those that love the idea of working in a fast-shifting workplace, this is a great component to keep in mind.

Much more than just a regular job position, working as a quality control inspector has many advantages to consider when looking for a diverse position from one role to another.

Quality Control Inspector Duties and Responsibilities

Watch the video below to learn more about the duties and responsibilities of a quality control inspector.

https://www.youtube.com/watch?v=8lajhra4aoQ

#quality#quality control#quality inspector#education#learning#online learning#online course#onlinetraining#training#career#courses#institute#OilandGas#inspection#quality control inspector#skills#skill development#qaqc

0 notes

Text

Top Courses for Engineers to Take

The world is always hunting for engineers of all kinds, some of which are going to be more demanding than others. When you’re looking at the opportunity to help create a profitable and enjoyable future as an engineer, you’ll want to focus on getting the right courses to help you move forward at your own pace. Here’s what you should know.

Picking Courses for Engineers

The courses that you choose are going to determine where your area of expertise lies, of course. As such, picking the right kind of courses will be a matter of going toward what you want most in your professional future. Some of the best examples to consider include:

Piping

Civil

Thermal Insulation

Electrical and Instrumentations (E & I)

Passive Fireproofing

Fire and Safety

Protective Coating

Quality Control

There is something so reassuring about knowing that you are arming yourself with a selection of courses that are going to help you become a stronger candidate as an engineer but also help you feel more secure in the positions that you are aiming for.

When you are looking at your options for institutions, you’ll want to focus on ones that specify those in the oil and gas industry so that you know your options will be limited to those that are going to help you find your way up the ladder in your field.

Tips for Finding Training Courses and Certifications for Engineers

If you’re looking for a way to make sure that you are looking at the right certification courses for mechanical engineers or electrical engineers, or even those more specialized, you’ll want to remember these factors.

Certification is worth the extra time and effort

There are some courses that won’t provide a certification at the end. While these are great for general interest, you’ll want to prioritize those with the certification. Sure, they will take a bit more effort and time, but the certification is what you need to help guarantee you the role that you are searching for in the future.

Online courses will be the best choice in the modern-day world

You can find the best online course for engineering students at online-focused institutions. These give the same quality and professionalism as classic in-person lessons, but they’ll be online so that you’ll be able to focus on fitting them into your schedule in a way that works for you.

Don’t overlook the basics When Selecting Courses for Engineers

Some of the examples above seem really basic. But the thing is, you don’t just want to go for the really specialized options for your dream position. The basic building blocks will be crucial to building a profitable career as the specialized ones. Build a strong foundation and the rest of your career will follow suit.

The right online program is going to offer a great way for you to enjoy making sure that you can enjoy a sense of professionalism that is going to go beyond the classroom — virtual or otherwise — and into a successful career, but it really is that simple. Focus on making sure that you can always find your way forward by relying on a certification program without an industry that is as focused on your success as you are!

#career#courses#education#online learning#online course#training#qaqc#quality#skills#skill development#development#professional

0 notes

Text

What You Need To Know About Employment in the Oil and Gas Industry

If you’re considering taking employment in oil and gas industry or looking forward to starting a career in the industry, you aren’t alone, there are hundreds of thousands of people like you who are considering making a career in the oil and gas, or applying for a job available in the oil and gas industry every day.

In the most recent years, the oil and gas career path has been growing more and more popular for those entering the industry for the first time as well as those looking for a way to get into a new career path when looking for a change.

Here’s what you should know about employment in the oil and gas industry, and what you should be knowing before you apply for a job in the oil and gas industry.

What Kind of Employment is Out there in the Oil and Gas Industry?

While there are a lot of people out there searching for employment in the oil and gas industry, there are as many work positions as there are searchers.

This means that choosing the right position within the oil and gas, refinery, or industrial process plant is going to be an important task.

Decide The Position You Want for the Employment

One of the important tasks to decide is choosing the employment position, and answering one of the 3 questions is necessary for that

Do you want something highly technical such as an engineer?

Or are you looking for something a bit more fluid and organization-based, such as a quality control inspector or QA QC Inspector?

Or perhaps something in between?

Know the Oil and Gas Industry First

Before you start taking up your career in any industry around the world, the very first thing that you should know is about your industry. When it comes to oil and gas, you need to know is how the oil and gas industry work, and if there are any segments in the oil and gas industry.

Segments in the Oil and Gas

The 3 segments that an oil and gas industry has are as follows:

Upstream

Midstream

Downstream

Let’s take the downstream for example, the downstream segment refines crude oil and is used for processing the purification of crude natural gas. Once done, the segment then markets and distributes the refined products derived from crude oil and natural gas.

You Then Need to Know the Work Carried Out in the Oil and Gas

There are thousands and thousands of work carried out in the downstream segment to make it function, following are some of the examples:

Civil work

Electrical work

Instrumentation work

Piping work

Insulation work

Paint Coating work

Fireproofing and Fire protection work

Quality Control Work

Safety Work

The Work Positions for the Employment in the Oil and Gas

Every work carried out in the oil and gas industry has its own department and every department has employees with the specific work discipline to carry out a task he/she has been employed for.

Listed below are some of the most popular work disciplines that you can find in the oil and gas industry:

Labors and Helpers

Skilled Technicians

Chargehands and Foremans

Supervisors

Engineers

Managers

Quality Control Inspector or QA QC Inspector, Also Known as Quality Controller

Safety Officer

Choose the Right Work and Work Discipline

Whatever you do end up choosing and deciding the department and the work discipline you will be looking for the employment in the oil and gas industry, but remember in mind the following:

You’ll want to have the right education, skills, and oil and gas training and certification for the position you will be working for or applying for employment in the oil and gas industry.

Apply for the Right Job with the Relevant Skills and Qualification

After you know the work and the relevant disciplines in oil and gas, the next is to make sure you apply for the right position and have the necessary skills and qualifications to help you get a job and start a career, or help you find your new career path as easy as possible in the oil and gas industry.

How Should I Pick a Job Position in the Oil & Gas?

Regardless of what you end up deciding as far as the focus in the oil and gas employment or job search, you will want to keep the right focus when on the hunt for the right job position itself.

Here are some of the important tips to help you make it as fruitful as possible. From bottom positions to top, highly coveted ones, here are the focus points to keep in mind.

Research the Different Positions and Promotion Opportunities in the Oil & Gas

Every potential position in the oil and gas industry is going to offer your different promotions, salary hike, and the like.

Depending on where you want to get to in the career path, you’ll need to keep that ladder to success firmly in mind to make sure that you get to the end goal you had in mind.

Keep in Mind Your Tasks and Responsibilities for the Employment in Oil and Gas

Every work position in the oil and gas industry features different tasks and responsibilities. And the industry employs competent individuals or groups of individuals to carry out the tasks following the set guidelines to meet the desired result.

Whether simple or challenging, picking your position based on being assigned the right kinds of responsibilities will help you see where your potential lies and what you most enjoy doing in the run of the day.

Ask About Benefits Working in the Oil & Gas Industry

The benefits are often critical to helping you understand what you want to get out of your career path in the oil and gas industry.

After all, everyone picks jobs and looks forward to employment in the oil and gas-based on those benefits, so why not grab them?

Make Sure You Have the Right Oil and Gas Skills Certifications in Place

Lastly, the oil and gas training and certification courses are going to be crucial to making sure that you land the position you are searching for.

If you are lacking one or two or missing skills or qualifications, or you want to add a qualification to enhance your resume before you apply for an available job get them online.

There are various oil and gas institutions that offer oil and gas education online.

These online courses can help you have the fresh and relevant certification that you seek, and set you apart from the crowd in the job market.

Conclusion

Whether you end up researching jobs for engineers, jobs for freshers, or just general positions for employment in the oil and gas industry or a career in the oil and gas industry, you’ll find that these tips are going to help you put your best foot forward into a fulfilling career in the oil and gas industry, Enjoy!

Watch the Video to Learn More About Oil and Gas

https://www.youtube.com/watch?v=oL-VUsC2Jqs

#career#course#insulation#institute#education#quality#qaqc#training#onlinetraining#learning#online learning#online course#fireproofing#tricks#tipandtricks#diploma#coating#painting#oilrefinery#certificate

0 notes

Text

How to Choose the Right Professional Certification

There are a lot of options out there in this modern world to get a professional certification. This is great when you look at something like convenience and choice, but it can also be a little overwhelming when you are hunting for a leader amongst the options that seem to be overwhelming. When it comes to choosing the right professional certification (and trying to understand what the right call is), this is your guide to it all!

Understand what professional certification is?

Let’s take a look at a few professional certification examples so that you can see just what you should be aiming for within the gas and oil industry. Some of the most common institutions that offer professional certifications in the various work field for the industry like oil and gas incudes but are not limited to the following:

American Petroleum Institute (API)

The Institute for Oil & Gas Sector (IOGS)

Institute of Corrosion (ICorr)

National Association for Corrosion Engineers (NACE)

American Standards for Non-Destructive Testing (ASNT)

American Standards for Testing and Material (ASTM)

These are just some of the few ones that most people are searching for when looking at the idea of centering their education and understanding what institutions and/or certifications will be most useful in the industry. So, how do you choose the right ones? Take a look.

Know Where to Get the Certification for Your Professional Development

There are all sorts of classes and training courses out there. You’ll be best prepared to look for online certification courses. They are the most convenient choice for you to blend control with professional training and certification, and it’ll mean that you can work them in on your own time so that progress doesn’t mean a loss in pay or free time.

Only Consider Ones that are Backed-up or Recognized in Your Industry

When you are considering why to get professional certifications from one place or another, remember that quality is really important. You only want to go with choices that have the professional statistics that you need, whether that be licenses or approvals, etc.

Whatever you are looking for in your institution, make sure that it’s all legitimate one that is based on helping you achieve success.

Focus on Where You Want to go With Your Professional Certification,

Remember that our professional certification isn’t about where you are right now. IT’s about where you want to go. If you’re apprehensive about spending the money, it makes total sense. But getting ahead of the competition and furthering your education specific to your future in the oil and gas industry means that you need to keep your sights trained on where you want to be in 5 years.

The details matter

When it comes to everything from the teaching method to the professionalism, to what they mean for the future, getting the details right on all of these is going to be one of the best ways for you to make sure that you are focusing on the right certification. Whatever it may end up being for your part in the industry, and what you end up looking to achieve, remember to factor in all of these important details.

Making your way to the top of the ladder within the gas and oil industry is going to be as much about focusing on the little details, as it is about the big ones. You don’t need to spend the big bucks in order to impress those that are around you. Just enroll smart and carefully, and it’ll mean that you’ll have all of the same opportunities.

RELATED ARTICLES

THE 4 POPULAR COURSES AFTER MECHANICAL ENGINEERING

CAREER IN OIL AND GAS INDUSTRY

Picking the Best Skill Development Courses

RELEVANT CERTIFICATION COURSES

Thermal Insulation Courses

Passive Fireproofing Courses

Protective Coating Courses

#professional#certification#development#career#training#course#online course#institute#oil and gas#qaqc#quality#quality control#quality inspector#quality control inspector#skills#skill development#Professional Development#education#online learning#learning#training courses#qa#qc#testing#inspection

0 notes

Text

Picking the Best Skill Development Courses

When you want to make sure that you succeed in your career, the skills that you choose to focus on or the courses that you take up for your skill development are going to determine just how successful that you are or you will be. The tricky thing can be figuring out which skills you should be looking at to make sure that you are successful at the end of the journey. If you need some help, here are some top consideration points to help you make those choices a little easier.

Online vs Offline Courses for Skill Development

Firstly, let’s tackle the offline and online debates. You will find skill development courses online that are going to meet your every need with the convenience of being entirely online.

Offline courses are courses that require you to travel to a particular location on a specific date and time, and will not give you many advantages to the online versions now.

It may seem strange when you think about how different it seems. But the online courses focus on education rather than on physical appearance.

Is the Skill that You Get or a Skill Development Course that You Take up Going to Mean a Pay Raise?

It is important to think about when looking at your budget for the course. Then what actual skill you are going to get with the budget you have. One of the best industries you should look to work on or for your career development is oil and gas.

Since the oil and gas industry is often rich with competition, you’ll want to make sure that you are learning a skill to help you scale the ladder.

Forget Taking General Courses for Skill Development and Just Focus on Your Industry

The reason that there are skill development courses for the oil and gas industry is that this is a very specific niche that requires equally specific skills. Don’t waste your time learning general management or other non-industry options. Focus on what you need to know for your role.

What comes next?

A lot of people will take a look at skill development courses after engineering or similar education. This is a great place to really get a sense of how you want your career to go.

The courses that you choose will determine where you end up in a few years’ time, making you want to think about where you wish to be so that you can choose the right courses to help you get there.

YOU DESERVE THE BEST

There are a lot of skill development training courses or training programs out there that will offer some of what you need, but make sure that you focus your attention on a skill development course or program that is going to offer you exactly what you need.

you should focus specifically on the skill development courses relevant to your industry like the gas and oil industry. and the like.

It’s automatically tailored to help you enjoy great progress within your industry, offering you the best chance at moving forward without having to cherry-pick here and there in other kinds of general focus products.

You can do a lot of good by simply getting your priorities straightened out so that you’ll be able to focus your attention on those locations and tasks that most require you to prioritize them for a more successful career.

FOCUS ON YOUR GOAL

Never deviate from the goal of doing what you have to do to be more successful in your chosen career path. That’s what this is all about. Everything should help you achieve it easier and faster.

RELEVANT ARTICLES

PROFESSIONAL COURSES AFTER ENGINEERING OR DIPLOMA

THE 4 POPULAR COURSES AFTER MECHANICAL ENGINEERING

CAREER IN THE OIL AND GAS INDUSTRY

RELEVANT TRAINING COURSES

QUALITY CONTROL COURSES

THERMAL INSULATION COURSES

PASSIVE FIREPROOFING COURSES

PROTECTIVE COATING COURSES

#career#course#institute#oil and gas#Refinery#skills#skill development#Professional Development#course institute#education#industry#quality#quality control#qaqc#Quality Controller#training#qc controlar#quality control inspector#online learning#online course#fiberglass#foamglass#intumescent#cementitious#Rockwool#virtual training#zoom#zoom training#distance learning#petroleam

0 notes

Text

This is How You Can Develop Your Career or Start a New Career

Career development is important in any industry around the world. With many professionals entering the field like oil and gas and looking to settle down into worthwhile careers that will keep them earning for a long time to come, everyone is suddenly on an even playing field.

What’s going to help you get ahead of the competition, then? Your education and skills, of course.

Online learning to develop your skills is one of the best options that you can choose on for advancing your career continuously from anywhere and at any place and time. All geared toward career development from genuine viewpoints.

The 3 ladders that you would need for a better career

The following three things that you would be needed to keep moving ahead to your career or starting a new career in any industry are;

Basic Education

A vision

Necessary skills

Basic Education

The basic education is the one that you get from your school or college. Basic education can be a degree or diploma that you get from a university after studying for a 2 or 4 years period.

Vision

Once you achieve your basic education, you then have to decide and make a vision to start your career in an industry that can pay you what you deserve.

Necessary Skills

No industry will hire you just because you hold a degree or diploma, or you won’t get a well-paid job without adding the necessary skills to your curriculum. Gaining the necessary skills is a must in today’s crowded job market.

The skills that you get can set you apart from the crowd and help make you more valuable to your employer.

To get the right skills, read out the below tips and make sure you get the new skills or upgrade the current one continuously for your career development or continuous professional development (CPD).

Remember these tips to help you succeed or in you career development

When considering an oil and gas institution like IOGS, as well as other ones that may appeal to you, keep all of these focus points in mind to give you the best results.

Choose from the right courses for your career development

If the skill development courses aren’t oriented towards helping you succeed in your educational position, then what good are they? Make sure that you remember what your goal is when picking the certifications and courses that are offered.

You can take anything you want to, of course, but you’ll want to make sure that it’s getting you to where you want to go, too.

Focus on the skills and certifications you need

Before you choose a random online study class, focus on learning about what your next position needs. Does it require certain certificates? Are there a certain amount of hours that you must complete before being considered?

If so, you’ll need to remember this when looking at course loads. Get the skills and certifications that you are lacking to help you look like the best candidate for the job.

Constantly keep learning and adjusting for your career development

No matter what, you’ll love the idea that online education helps you to keep on learning, adjusting, shifting, and more.

Since the industry like oil and gas can change quickly, this is the best way to stay current on all of the most recent updates and upgrades that are waiting for you.

Look for online options

No one has time or energy for classic educational models anymore. Put yourself on the path to easy education by focusing on online learning methods. There are endless options to look at that are exclusively online, so you won’t be hemmed in by course choices or timings.

It’ll help you stay on the job and still further develop your skills or your education in a way that is going to be simple and convenient. What more could you ask for?

Do what you can to find success for your career development

At the end of the day, whoever can do the job better is going to win the job being offered. When you want to land a job, and then accelerate through the positions to get you to your dream position, you need to have the proper training or get trained and gather all the necessary skills that can set you apart.

Online learning is going to help you get that but still, make sure that you’re always looking at the idea of advancing when you have to do so.

Don’t take away from your career

Ideally, advancing in your career shouldn’t take away from your career itself. That’s what makes the online study so exciting when looking at career development! It blends convenience with proper, up-to-date information that will make the difference that you seek.

RELATED ARTICLES

Know What Petroleum Engineering Industry Really is? Career Wise!

Career in Oil and Gas Industry

5 Common Rules of Deciding to Take the Professional Courses

3 POPULAR WORK FIELDS FOR DEVELOPING YOUR SKILLS OR STARTING A CAREER

Thermal Insulation

Passive Fireproofing

Protective Coating

ONLINE COURSES FOR SKILL AND CAREER DEVELOPMENT

Insulation Inspector Level 2

Coating Inspector Level 2

Fireproofing Inspector Level 2

ONLINE EDUCATION – A GREAT WAY OF CAREER DEVELOPMENT

https://www.youtube.com/watch?v=g580bYk6A60&t=5s

#career#course#oilandgas#inspection#institute#Refinery#skills#skill development#professional#Professional Development#iogs institute#education#industry#quality#quality control#qaqc#training#online course#online learning

0 notes

Text

Understand the INSULATION Before You Decide Using it For Your Project

Are you interested in working for or already working in the thermal insulation field of an oil refinery or industrial processing plant? If so, you’ve come to the right place to learn more about thermal insulation. Here, we answer some of the most frequently asked questions about insulation and its use.

What is Insulation?

Essentially, it is any material or system used to resist or restrict the transfer of thermal energy or sound. Insulation material can reduce the flow of heat energy by reflection, absorption, or both.

A common misconception is that insulation keeps the cold out, when in fact the function of insulation is to reduce the transfer of heat, which means it keeps heat in. Heat energy will transfer to nearby objects of lower temperatures.

What is so special about insulation’s ability to prevent the loss of heat?

Thermal insulation material contains voids or hollow spaces that help resist heat transfer. Heat flows naturally from warmer areas to cooler ones. Insulation works by slowing that movement of heat from a hot space to a cooler space or vice versa.

What are the Different Categories of Insulation?

Insulating materials are divided into the following 4 categories:

Fibrous

Granular

Cellular

Reflective

The materials in each category have both pros and cons. It is your responsibility to understand them before you select a material for use in your project.

For example, insulation materials made of fiber are not suitable for resisting cold temperatures, but cellular materials have limitations for use at temperatures above ambient.

The insulation materials’ temperature ranges and their properties can be found in the product datasheet you receive from the insulation manufacturer.

How to Choose the Best Insulating Material?

Before choosing an insulating material for your project, be sure to answer the following commonly asked questions:

What item requires insulation?

- Temperature limit

- Size or area

- Type of substrate to be insulated (i.e., metallic or non-metallic)

What is the geographical location/environmental condition?

What is the purpose of the insulation?

- Heat or cold conservation

- Sound prevention

- Personal protection

Decide the Right Insulating Material

Based on the answers to the above questions, you must decide the type of insulating material, thickness, and whether the installed insulation requires further protection from its surrounding environment.

Next, contact the insulation manufacturer to identify the insulation materials to best suit your requirements and/or review the material’s product datasheet to check which materials meet your requirement.

Finally, you must decide whether to use the accessories materials (i.e., fixing or fastening materials) to help keep the insulation in place around the insulating item. You must also ensure that all the fixing materials you use are compatible with the insulation, jacketing, substrate, and other fixing materials.

Write a Specification for the Insulation Work

Before commencing the insulation work, you must write a specification that details the material(s), their properties, and how the work will be carried for your project.

Next, find a contractor with a proven track record to carry out the insulation work for your project following the instructions and guidelines set forth in the specification and/or recommended by the insulation manufacturer.

What are the Different Types of Insulation Material?

There are several types of thermal insulation materials to choose from, including:

Mineral wool

A fibrous insulation material made of rock or stone, used to resist high temperatures, also protect the environment from excessive noise.

Calcium silicate

A granular insulation material. This white-colored insulation, used to resist high temperatures.

Cellular or foam glass

Cellular glass and foam glass are the two different names of the same material. Made of recycled glass and is cellular or closed-cell insulation. The foam glass insulation is primarily used to resist cold temperatures; however, it can also be used for hot services up to 400˚C temperatures.

PIR

A cellular type of insulation, also known as polyisocyanurate insulation, is commonly used for cold surfaces because it has temperature limitations when used for hot ones.

Ceramic fiber

This fibrous insulation material is also known as high-temperature insulation wool (HTIW) and is often used for lining furnaces.

The 4 common properties of an insulation material

Thermal conductivity

Thermal Resistance

Density

Combustibility

Thermal conductivity, also known as the K value of the insulating material decides if a material is a good insulator or not. The lower the K value the better the insulation material is. The thermal resistance or R-value state how well an insulating material can resist the heat, R-value is opposite to the K-value, i.e. good insulation must have a higher R-value.

The density is mass per unit volume of a material. Combustibility means if a material will catch fire or not, non-combustible type material is a must in an area prone to fire.

Where will the Insulation be Used?

Insulation is used everywhere whether it is a home, office, appliances you use, or oil refinery or industrial process plant. some of the areas where you would find insulation are listed below:

INDUSTRIAL

Piping: When looking around a refinery or industrial processing plant, you will find yourself surrounded by insulated items. One such insulated item is piping. Approx. 75% (or more) of the piping used is insulated for a variety of reasons like hot or cold conservation, process control, personal protection, etc. A medium-sized oil refinery contains 475 miles of insulated piping.

Equipment: Equipment such as heat exchangers, boilers, columns, pressure vessels, storage tanks, pumps, and compressors, are all insulated for heat conservation, cold conservation, acoustic attenuation, or any other oil refinery or industrial processing plant purpose.

For your information, a medium-sized oil refinery contains 1.8 million square feet of insulated equipment.

DOMESTIC

Wall insulation: Walls are a major source of energy loss in homes, it is a must to reduce heat loss through the cavity wall by filling the air gap with material that interferes with heat transfer, trapping air in the cavity, thereby preventing heat loss and reducing heating costs.

Basement Insulation: The basement is another area of a home where there is a need for insulation installation. Basement walls are insulated with non-water sensitive insulation that prevents interior air from contacting cold basement surfaces.

Crawl space insulation: This space is often forgotten because not everyone uses their crawl space regularly; however, it can help prevent heat from leaking into or escaping from your home. The best insulation material for crawl spaces is a rigid foam insulation board.

Domestic appliances; Air-conditioning, refrigerator, water cooler, and the like are all insulated to prevent the movement of heat into or out of them.

#insulation#thermal insulation#cold insulation#Insulation Inspector#pir#quality inspector#quality control#quality control inspector#quality management system#fiberglass#cellular cellular#spray#spray of insulation#reduce#heat#heat metal#insuation work#career#online course#iogs institute#skills#skill development#quality#qaqc#training#online learning#online courses

1 note

·

View note

Text

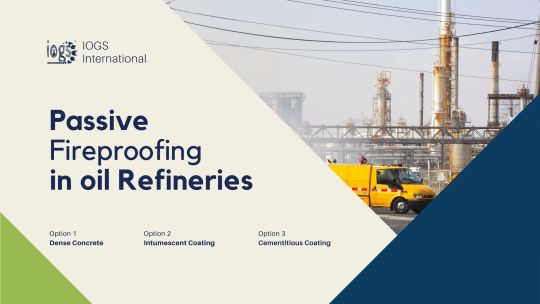

4 Reasons Why Fireproofing is Used for the Fire Protection

Fireproofing, also known as passive fire protection, refers to the process of increasing the fire resistance of structures or materials. The term fireproofing does not necessarily mean that the fire won't affect the fireproofed item or the fireproofed item cannot ever burn. When an item is fireproofed, it means that the item gets protection from the fire to a certain time or duration based on the measured performance of the fireproofing material under certain tests and evaluation.

Fireproofing is divided into two disciplines, that are active fire protection and passive fire protection. Passive fire protection is used in oil refineries or industrial process plants to minimize the escalation of fire that could result from structural failure and overheating of pressure vessels. Damage that the fire could do too soon can add significant fuel to the fire.The traditional fireproofing method used earlier was to pour the concrete or gunite in place around the item to be fireproofed. Such fireproofing systems are too heavy and make life difficult to install at higher elevations or areas where heavyweight are not allowed (e.g. offshore). the fireproofing industry has come up with a solution by discovering the fireproofing system based on vermiculite and epoxy instead of concrete.

The vermiculite-based fireproofing systems are lighter in weight and are installed at all elevations, however, they are not so strong as the concrete-based fireproofing, and are prohibited to use at lower elevations or areas prone to mechanical abuse. There is a trend of using concrete-based fireproofing from the ground to 1 meter followed by vermiculite-based fireproofing to the rest parts of the structures.

The purpose of Fireproofing

Basically, fireproofing is used to protect the structural steel that carries risky or valuable equipment. The breakpoint of steel is commonly referred to as 535˚C, as this is the point at which the steel loses approximately half (i.e. 50%) of its strength. So the goal is to keep the steel from reaching 535˚C for a certain period of time. The time we buy or want the fireproofing to maintain the integrity of the steel in the event of a fire is between 15minutes to 240 minutes. The time period that a fireproofing gets after certain testing in an independent laboratory is known as the time rating or fire resistance period (FRP).

Over time, the fireproofing may degrade or get damaged from the element's in daily plant life so it is at most important to protect and maintain the fireproofing so that in the event of a fire, the fire resistance properties remain constant in order to fulfill the intended functions.

Daily exposure in the plant includes but is not limited to the following;

Mechanical abuse

Contact with oils, solvents, chemicals, etc.

Risk-Based Analysis

The term fireproofing may mislead many people because no material is completely fireproofed. All materials used in the construction are susceptible to fire. What we mean when we say fireproofing is the fire-resistance, which means, we try to withstand potential fire situations over a period of time. The goal of fireproofing is to minimize the overall damage caused by the fire. The fireproofing enables us to take action, while we are in the fire resistance period. The fire resistance period gives us time to extinguish the fire, turn off the fuel supply to the fire and try all possible ways to evacuate the personnel and to stop the process (fire).

The decision to make the industrial process plant fireproof is made on the basis of risk analysis. First, consider the type of fire and then evaluate the required fire life for a variety of equipment including structural steel, pressure vessels, exchangers, pipes, and the like. The location of certain equipment in a process plant is just as important as the location of the plant in relation to neighboring facilities.

The fire resistance period and test methods

No single fire test method is representative of an actual fire situation and therefore there is no best or accurate test method available. Standardized tests simply provide a basis for relative comparisons of fire-resistant materials and structures.

When fire protection is required, the degree of fire resistance depends on the application in the process plant. Typical requirements for the protection of an oil refinery or process plant may be as follows;

For structural steel, installation may require a 2 to 3 hours fire resistance period (FRP). A thickness between 50mm to 75mm may be appropriate to achieve the said FRP. Lightweight cementitious (vermiculite based), or Epoxy-based intumescent are common materials for use, however, the traditional fireproofing material based on concrete may also be an option.

Equipment may require 1 to 2 hours FRP with 40mm to 50mm fireproofing thickness. The fireproofing materials that provide the equivalent fire resistance period may be used to protect the equipment from fire.

Plates and frame heat exchangers are of particular interest because of the rubber gasket material used between the plates. These heat exchangers are equipped with a protective cover designed to prevent the maximum operating temperature of the heat exchanger from exceeding approximately 1 hour. The maximum operating temperature is the temperature specified by the equipment manufacturer (or vendor) and is common at <150˚C.

Fireproofing Materials

Passive fire protection generally falls into the following three categories:

Dense concrete

Lightweight cementitious based on exfoliated vermiculite

Intumescent based on epoxy or acrylic

DENSE CONCRETE

The potential of concrete as a fireproofing material has long been recognized. Many refineries built before World War II used dense concrete extensively as fire protection. This material is inexpensive and is known to withstand extreme temperatures. However, problems quickly arose: the concrete was heavy, resulting in excessive demands on the steel structures; This also means high labor costs, since forming concrete around the steel is a laborious, and multi-step process.

It has also been found that rapid cooling after a fire causes the concrete to crack and in some cases severely compromises the structural integrity of the material. This damage is sometimes difficult to detect and can be hazardous to those working on site. Dense concrete as fire protection has been largely abandoned in favor of new methods that provide superior performance and less inconvenience.

LIGHTWEIGHT CEMENTITIOUS

The lightweight cementitious fireproofing retains the advantages of being based on inexpensive raw materials (vermiculite) and not having the problem of being overweight. As the name suggests, the material is considerably lighter than concrete and therefore does not require excessive design specification However, lightweight fireproofing retains the high labor costs.

The major disadvantage with lightweight cementitious fireproofing is it tends to crack if inappropriately applied, and may create an inevitable space between the fireproofing and the substrate it was applied to. This space tends to collect moisture, which in turn causes corrosion under the fireproofing.

INTUMESCENT FIREPROOFING

Intumesce means swell, so the fireproofing tends to expand in its thickness to several times in the presence of extreme heat generated by the fire, thus, an increase in volume and a decrease in density slow down the heating of the substrate, which increase the time before the steel loses its load-bearing strength or melts. The expansion, which is also known as the char, basically creates a larger barrier between the fire and steel.

The epoxy intumescent fireproofing tends to create the char up to 5 times the actual fireproofing thickness, and the acrylic-based intumescent fireproofing swells up to 50 times to its original thickness. The thickness of the char and the time that the fireproofing char remain in its place decides the fire resistance period.

The advantage of the intumescent fireproofing is that the fireproofing is lighter in weight among all and may fight corrosion in much the same way as traditional protective coatings.

APPLICABLE STANDARDS

While there are several standards available to use for the fireproofing work, some of the common standards that you may find helpful are listed here;

UL 1709

UL 263

BS 410

API RP 2218

API RP 2001

DNV GS D301

ASTM E1529

RELEVANT ARTICLES

Cold and Cryogenic Insulation

Protective Coating or Painting

RELEVANT TRAINING COURSES

Fireproofing Inspector Level 2

Fireproofing Inspector Level 3

Diploma in Passive Fireproofing

0 notes

Text

Why is Abrasive Conductivity Test So Important to Perform - ASTM D4940

Corrosion, also known as rust, is a significant problem for any metal. It occurs throughout the world in residential, commercial, and industrial environments. Any time metal is used, corrosion can occur on the metal’s surface.

The corrosion rate depends on several factors that the metal is exposed to, for example, metal in a residential or commercial environment will have a lower corrosion rate than metal in an industrial environment.

Soluble salt, if present within an environment, is a corrosion accelerator. Project specifications often limit soluble salt levels before applying the coating for corrosion protection.

Soluble salt can deposit on a steel surface in many ways. One such way is with abrasives during blast cleaning operations.

The abrasive conductivity test determines the presence of soluble salt, this article will explain everything about the abrasive conductivity test.

Use of Abrasive

Abrasives are widely used during blast cleaning to get clean, rough surfaces for coating applications. The abrasive is made of slag, cooled by air and water.

Slag cooled by seawater or other contaminated or salty water, contains many ionic substances. Ion (salt) contamination from abrasives then transfers to the steel surface. This accelerates the corrosion rate. Failure to remove the salt before coating can cause premature coating failure.

Project coating specifications usually set the upper limit of acceptable abrasive contamination, as well as asks for performing abrasive conductivity tests to ensure compliance.

Abrasive Conductivity Test Frequency

The specification also provides the test frequency; though conductivity tests are performed on the abrasive each time a new batch arrives at the construction site.

Abrasive Conductivity Test Apparatus

The test apparatus includes the following:

Conductivity meter

Electrode cleaner

Calibration solution

Pure distilled water

Glass beakers (600mL and 100mL)

Plastic measuring beaker

Funnel

Stirring rod

Filter paper

Timer

Conductivity Meter Accuracy

Before starting the test, the equipment’s accuracy is evaluated using cleaning and calibration solutions. This procedure varies depending on the type of conductivity meter used for the test.

For more information, refer to the instrument’s operating instructions. The following procedures apply to conductivity meters in the image

Conductivity Meter Calibration Check

Press the ON/OFF button to turn on the conductivity meter, and then press the CAL button until the display shows CAL.

Open the electrode cover and wash the instrument’s electrode with the cleaning agent. Be sure to apply an appropriate amount of calibration solution to the electrode.

When finished cleaning, close the electrode cover. Press and hold the CAL button for more than 2 seconds.

If the instrument accuracy is correct, the reading displayed on the screen will match the specified reading after the time-lapse. If the measured value does not match the solution’s target value, recalibrate/adjust the device per the manufacturer's recommendations.

Clean the electrode with tap water and shake it off to remove moisture. Press the MEA button on the instrument to put it in measurement mode.

Now that we have the instrument’s calibration, let's proceed with the sampling procedure.

SAMPLING PROCEDURE

Select a random bag of abrasives for sampling.

Measure 300 ml of abrasive and pour into the 600 ml beaker, then add 300 ml of water.

Start the timer and stir the solution with the stir bar for one minute.

Let the solution sit for 8 minutes, then stir again for 1 minute.

Place filter paper in the funnel to get enough solution into the 100 ml beaker.

Discard the first 10mL of filtrate.

It is time to check the sample’s conductivity using the conductivity meter. Following the steps below.

Abrasive Conductivity Measurement

Turn on the conductivity meter.

Rinse the electrode with clean water until the display shows that the water conductivity is equal to or less than 5 µS/cm.

Immerse the electrode in the sample in a 100 ml beaker.

Mix gently for 2-3 minutes.

Read and record the conductivity value of the sample on the screen.

You can now check the specification compliance using the abrasive’s conductivity value you recorded.

SPECIFICATION COMPLIANCE

Use the project’s coating specification to verify that the recorded value is below the upper value set by the specification.

If it does not meet the specifications, use other abrasive bags for additional measurements before taking corrective and preventive measures.

APPLICABLE STANDARDS

Project coating specifications often state the ASTM D4940 needed to carry out the abrasive conductivity test.

CONCLUSION

The conductivity test determines soluble salt or invisible contaminant, presence in abrasives. This test ensures that abrasives will not contaminate surfaces after sandblasting, because the salt contained in steel increases the corrosion rate and makes the coating prematurely deteriorate, making it almost impossible to achieve the ideal service life.

A coating project assigns paint coating inspectors to carry out the abrasive conductivity test. The inspectors get certified by attending paint coating inspection and quality control training to perform such a task.

Videos about protective coating are available on YouTube. You can also find protective coating training courses at the following website: www.iogs.org.

The Institute for Oil and Gas Sector provides the following comprehensive coating inspector courses. Getting into the coating inspection and quality control field you require completion of one of these courses:

Coating Inspector Level 2

Coating Inspector Level 3

Related Articles;

9 Simple (But Important) Things to Remember About Corrosion Under Insulation

Everything You Need To Know About Salt Test Before Paint Coating Application

Enhance Your Cold Insulation Skills

#corrosion#corrosion protection#cui#quality#quality control#quality control inspector#quality inspector#insulation#Insulation Inspector#painting#painting inspection#painting inspector#corrosion control#skills#new skills#online course#Refinery#oil and gas#oil and gas industry

0 notes

Text

Know What Petroleum Engineering Industry Really is? Career Wise!

Are you someone who is looking to find out more about petroleum engineering? Do you want to know about petrochemical engineering and how it works? If you said yes to both these questions then keep scrolling down because we have just what you have been looking for.

What do petroleum engineers do?

Petroleum engineers play a vital role in maintaining the world economy. They ensure that the extraction of oil and gas is safely done. They make sure that the entire process is done efficiently so that the product is more affordable to the customers.

If we talk about the involvement of the petroleum engineers in the oil and gas fields then it is important to bring to attention that they are actively part of the entire process.

Types of petroleum engineer

Here is a list of categories in which petroleum engineers are divided into:

Petroleum geologists

Petroleum geologists make sure that they find hydrocarbons. They analyse subsurface structures. They do this with the help of geological and geophysical methods.

Reservoir engineers

Reservoir engineers help in the optimisation of the production of oil and gas. The optimisation process is only possible with the help of proper placement, production levels and enhanced oil recovery techniques. The Reservoir engineers use various computer simulations to identify the risks associated with the process. They also use the same method to make forecasts on reservoir potential.

Production engineers

Production engineers are known for managing the interface. They make sure the interface between the reservoir and the well through tasks is done properly. The tasks include perforations, sand control, artificial lift, downhole flow control and monitoring equipment. Production engineers select the surface equipment to separate the fluids that are being produced. These fluids include oil, natural gas and water.

Drilling engineers

Drilling engineers deal with the technical aspects. They look after both the production and injection wells. Drilling engineers work in multidisciplinary teams. Their teams include engineers from different backgrounds, scientists and contractors.

Quality engineer

Quality engineers or QA/QC Engineers make sure that the work gets done in a specified time, following the guidelines given to them by the company. They govern different regulations, prepare and document reports related to the quality of the entire process.

Safety engineers

Safety engineers are there to enforce the safety rules and regulations. They make sure that everything is done following the health and safety requirements.

Responsibilities of an Engineer in Petroleum Industry

The responsibilities of every engineer vary from the other; depending on the role, they have been assigned.

Here is a list of responsibilities that engineers might be asked to perform:

One of the major responsibilities of engineers includes liaising with geoscientists

They also look after the production

Some engineers have to liaison with commercial managers to interpret the good logging results

They also predict the potential of the production

Another important responsibility of engineers is to compile a detailed development plan of the reservoir performance

They do this using different mathematical methods

Engineers are also responsible for selecting an optimal tube size

They look after suitable equipment to make sure different functions are performed properly

They design the complete process which is the main part of the well that helps in communicating with the reservoir fluids

Engineers design different systems to make sure that the well flows properly

Engineers manage problems about the fluid behaviour

They also deal with the problems of the production chemistry

One responsibility is to evaluate and recommend the rate of flow by enhancing the hydraulic fracture

They force fluid into a well for fracturing the rock

They look after the acid treatment so that they can keep a lookout when the rock erodes and can help improve the flow path

Engineers help to manage and control both horizontal and multilateral wells that have branches underneath

They use well and reservoirs with the help of remote sensing technology

They also deal with surveillance data that helps in managing the value of the reservoir

They are responsible for deciding on an appropriate engineering intervention

They understand and then manage how a set of wells interact with each other

They are responsible for dealing with contractor relationships

Engineers look at the health, safety and environmental protocols

They supervise well site operations

They also train and supervise different crew members

They ensure that everyone around them is working as a team

They also ensure that deadlines are met and the clients are satisfied

They liaison with different departments to ensure the progress of the multiple on-going projects

They are responsible for the maintenance of the equipment

Engineers liaison with different clients to keep them in the loop

Petroleum Engineer Salary

The salaries of engineers vary, depending on the nature of their job.

Here is what you can expect to get if you are applying for the position of petroleum engineer:

In this region, if you are only starting, you should be prepared to get something from £25,000 to £35,000

If you have a relevant PhD in the field, you can expect something more

The starting off salary figures are for those who are applying to international oil companies

A similar salary range is for graduates who get into training programs before signing up for a full-time job

If you are applying in a comparatively new company, you should expect something lower in terms of the salary

If you are an experienced petroleum engineer then you should expect something from £55,000 to £95,000

If the demand is higher, an experienced freelance engineer may even earn over £1,000/day

Working hours in Petroleum Industry

If we talk about the work hours in the field of petroleum engineering then they are the typical 8 hours of the day.

It means that if you are thinking of getting into the field, you should keep in mind that your normal workday would start at 9 am and end at 5 pm. However, like any other profession, there might be days when you would be required to put in extra hours.

If you were working for a big company, you would know that they usually have flexible working hours. There is a routine of working in shifts so that no one person is overburdened with work. If you were on an offshore assignment, you would be required to work for 12 hours straight. This could go on for at least two weeks. One plus point is that the petroleum engineers also get a two-week break to make it up for their thought schedule.

What to expect in Petroleum Industry?

Here is what you should expect from your life when working in the petroleum engineering field:

If you are a beginner, you should expect the first three years of your professional career in the rig site

When the engineers gain experience and put in their time and effort, they start working in the office

Once engineers start working in the office, they closely work with geologists on the oil field

The senior geologists are located onshore

With the help of remote sensing technology, engineers should expect to work with high bandwidth that works with global networks and visualisation systems

Once you reach a position where you can make decisions, you must expect to work with fewer people in the field and make more decisions in the office

You can also expect to be self-employed or do freelance work in the future

Through outsourcing, there have been many opportunities that have been created for engineers with more than five years of professional experience

If you want to sign a contract, you should do that by first determining the project status and going through the oil prices

More women are being recruited in this profession with the help of awareness about this field of work

When you start working in the oil field, you will see a mix of different cultures

If you are on an offshore assignment, you will have to start living in a communal system

If you are working in the field, you might have to make do with inhospitable living conditions

You should be mentally and physically prepared for the job

The onshore and offshore routine can get a little overwhelming for some people

You should be ready to compromise on your social life

You would sometimes be required to travel within a day or two

You would not always be present at home with your family

Overseas travel is another feature that is part and parcel of this profession

You should be prepared to change your location on a short notice

Qualifications to Work for Petroleum Industry

Like any other profession, prior qualification is a prerequisite for petroleum engineering as well. If you have applied for a job at a reputable company, your employer would first check for your qualifications in the relevant field.

Here is a list of qualifications that employers look for when hiring engineers at the job:

Aeronautical engineering

Astrophysics

Chemical engineering

Civil engineering

Earth sciences

Mathematics

Mechanical engineering

Petroleum engineering

Skills Required to Grab Jobs in Petroleum Industry

If you aim to work in petroleum engineering or the petrochemical engineering field then you need a skill set.

Here is a list of skills that you should possess if your goal is to become an engineer:

Technical capabilities

Business awareness

Analytical skills

Creative skills

Managerial potential

Self-motivated

Ability to work internationally

Ability to work in offshore environments

Team skills

Self-driven

Enthusiasm

Problem solver

Willingness to tackle challenges

Flexibility

Multitasker

Computer literate

Relevant training

Different certifications

Do I Need any Work Experience Before Applying for a Job?

If you are only starting, you should have a good qualification and a skill set that shows in your work. If you are someone who wants to switch jobs then you should know that there is a lot of competition in the market. Yes, you read that correctly. You can look for different opportunities based on your years of experience and area of expertise.

Employers

If you want to work with prestigious companies then you should be ready to relocate. Most of the oil and gas explorations are based overseas.

If you are good at what you do then the field of petroleum engineering and petrochemical engineering can take you places you had only thought of going to.

Here is a list of settings where you would find the right kind of employment:

You should look up operating companies

You can also look for production companies, mostly the ones that are international oil companies to get a better job

Apply to engineering consultancies

Send your resume to integrated service providers

Apply for a position at a specialist plant construction

Professional Development Institutions

If you are aiming to apply to a multinational corporation, you need to keep in mind certain aspects such as your personal and professional development as an individual.

When applying to a reputable company, make sure you have already taken oil and gas courses as part of your professional development.

Here is a list of the relevant professional engineering institutions you can take up the oil and gas courses from:

The Institute for Oil & Gas Sector (IOGS)

American Petroleum Institute (API)

You can also check the below listed for further training:

OPITO

IOGS

Career Prospects and Skill Development Courses

Considering the current world order, the engineering process will continue to rise. You must keep up the hard work and trust yourself when applying for a job in the petroleum engineering field. Do not lose hope, keep applying!

There are several skill development courses that you should take up to make yourself apart from the crowd in the job market, the following 4 skill development work fields are most popular;

Protective Coating

Thermal Insulation

Passive Fireproofing

Corrosion Control

Did you find this article useful? Let us know in the comments below.

#qa qc#quality#quality inspector#quality management system#Insulation Inspector#inspection#skills#new skills#career#cui#professional#Quality Controller#coating#corrosion#corrosion protection#skill development

1 note

·

View note

Text

9 Simple (But Important) Things to Remember About Corrosion Under Insulation or CUI

Corrosion under insulation (CUI) is the external corrosion of outside equipment made from carbon-manganese, low-alloy, and austenitic stainless steel due to the absorption of water under the insulation.

It has been several decades since the CUI has been one of the major common problems across a wide range of industries worldwide. Still, we didn't find out a way to eliminate it completely, instead, we just rely on tools and techniques to minimize the issue.

This article will provide an understanding of the following:

What is Corrosion Under Insulation (CUI)?

Why Insulate?

CUI Causes

Corrosion Types

CUI Identification

Rate of CUI

CUI Maintenance Costs

CUI Temperature Ranges

Applicable Codes and Standards

What is Corrosion Under Insulation (CUI)?

Corrosion under insulation, also known as CUI, is a serious problem that affects thermally insulated mechanical components. It is known as the hidden enemy because its detection can be too late resulting in disastrous outcomes such as leakages, loss of containment, and even fire and explosion.

One study shows that the petrochemical industry spends approximately 10% of its maintenance and repair budget on piping systems and pressure vessels due to CUI.

To better understand CUI, you first need to understand the reasons for insulating piping and vessels.

Why Insulate?

Insulation, or more correctly thermal insulation, is a material or system used to reduce the movement of heat or sound. It is a critical feature in oil refineries and industrial process plants.

If you look closely at any industrial plant, you will see they are surrounded by insulated pipes, equipment, and vessels. These mechanical components can either receive hot, cold, or acoustic insulation systems.

To better visualize, an oil refinery contains about 73 miles of insulated pipes and 2.5 million square feet of insulated equipment. Many different types of insulations are used to insulate the mechanical components in an industrial plant.

There are several reasons for using insulation, including:

Energy conservation

Heat conservation

Process control

Cold conservation

Condensation control

Acoustic attenuation

Personal protection

Corrosion Under Insulation Causes

Water causes CUI when it enters an installed insulation system. Unfortunately, it’s not simple to design and install insulation systems because there are many different ways that water can seep into them. For example:

Insulation material gets wet during storage or installation.

Protective jacketing installed incorrectly or prove ineffective at preventing water ingress.

Protective jacketing become damaged after installation.

The protective coating/painting becomes damaged and/or not touched up (refurbished) appropriately before insulation work.

The protective coating can be ineffective as a barrier between the water, that ingresses under the insulation, and the metal.

Now that you know the cause of CUI, allow us to explain the type of corrosion that occurs under the insulation.

Types of Corrosion Under Insulation

Corrosion on carbon steel usually resembles a general or pitting appearance. On austenitic stainless steel, it almost always consists of chloride stress corrosion cracking (CLSCC).

Water that ingresses into the insulation system passes through the insulation material to reach the outer surface of the insulated item; however, when closed-cell insulations are used, the water cannot pass through it easily, but will still find ways to reach the surface (e.g., through joints or breaks).

Immediately upon reaching the steel through one or more breaks in the protective coating, water begins acting as an electrolyte to complete the corrosion cell triangle. The result is the general or pitting corrosion on the carbon steel substrate.

If the water contains chloride, it causes CLSCC on the stainless-steel surfaces. Where does the chloride come from? It’s important to know that water itself may contain chloride.

Additionally, water can also leach out chlorides from insulation and/or accessories material.

Now that we’ve discussed the types of corrosion that occur under the insulation, it's time to understand how you can identify such corrosion.

CUI Detection

CUI detection is difficult because insulation, by its very nature, creates a barrier between the insulating surface and the environment. Thus, finding it involves several steps, including:

Visual inspection

Non-destructive testing (NDT)

A visual inspection involves either partially or completely removing the insulation to check the integrity of the insulated surface. The problem with this approach is that removing the entire insulation, whether partially or fully, is costly and time-consuming. Insulation removal is often carried out during a plant shutdown.

Insulation removal methods are qualitative; therefore, they cannot directly measure the metal thickness loss due to CUI. The use of a pit depth gauge can quantify the metal loss due to corrosion.

NDT is another CUI detection method. While not as effective as insulation removal, it is common practice to use NDT when insulation removal is not a practical option.

The NDT techniques require detailed knowledge of the piping system or equipment layout, as well as the advantages and disadvantages of using a cost-to-benefit ratio. The following NDT techniques are common for CUI detection:

Moisture meter

Infrared thermography

Pulsed eddy current

Flash radiography

Now, let's determine the CUI range.

The Rate of Corrosion Under Insulation

Corrosion Under Insulation usually remains undetected until the protective jacketing and insulation are removed. removing insulation as soon as the water gets in, indicates less potential for CUI; however, CUI is more likely if it takes five or more years for the insulation removal.

The CUI rate depends on the water’s conductivity. If the infiltrating water contains soluble salts (e.g., sulphates and chlorides), it will accelerate the CUI rate.

The rate of CUI is about 20 times faster than atmospheric corrosion. The range of metal loss due to CUI is 1.5mm – 3mm annually.

For example, a pipe has a total wall thickness of 15mm (i.e., 10mm thickness and 5mm corrosion allowance). If we consider that the CUI rate where the pipe will be installed is 2.5mm/year, it may only take 2 years before the CUI eliminates the corrosion allowance making the pipe prone to leakage or breaking.

Temperature Ranges of CUI

Corrosion Under Insulation appears in temperature ranges between −4 °C (25 °F) and 175 °C (347 °F). While CUI problems have been reported outside this range; the majority are within the specified range.

Generally, the metal temperature is the same as the process operating temperature for insulated pipe/equipment. If the insulation is damaged and/or highly humid conditions exist, a process temperature significantly above 121 °C (250 °F) can result in metal temperatures low enough to cause CUI. As a result, the CUI range exceeds 175 °C (347 °F).

Additionally, CUI also takes place on equipment subject to cyclic temperatures or dead legs, which are outside the said CUI range,

Applicable Codes and Standards

There are several codes and standards are available to learn and mitigate the CUI, the 3 most popular standards are as follows:

ASTM STP 880 – Corrosion of Metals Under Thermal Insulation

NACE SP0198-2010 – Control of Corrosion Under Thermal Insulation and Fireproofing Materials

API RP 583 – Corrosion Under Insulation and Fireproofing

Thank you for taking the time to view this article. We hope we have provided you with sufficient knowledge of corrosion under insulation (CUI).

If you wish to learn more on this topic, you may visit www.iogs.org. Also, don’t forget to read the related articles outlined below or enroll in a course related to thermal insulation, inspection and quality control, or CUI.

Corrosion Under Insulation Video

https://www.youtube.com/watch?time_continue=22&v=m8oH4CydCLo&feature=emb_title

RELATED ARTICLE

Enhance Your Cold Insulation Skills

What is Corrosion? Why Metal Corrodes?

How to Make Career in Oil & Gas Industry

Reasons for Insulating Piping and Vessels of an Oil Refinery

RELEVANT COURSES

Corrosion Under Insulation

Coating Inspector Level 2

Insulation Inspector Level 2

Fireproofing Inspector Level 2

Coating Fundamentals

#coating#painting#insulation#Refinery#corrosion protection#corrosion#cui#quality#Coating Inspection#painting inspection#corrosion control#online course#skills#new skills#professional#professional development#education

0 notes

Text

How Quality Assurance Can Ease Your Business Pain

We all know how much quality assurance (QA) is necessary for successful businesses. Quality Assurance is a must if you want that only the best products to hit the shelves. But, how to actually ensure the best possible quality? Good quality assurance system is the only answer.

Basically, QA is a systematic process followed by associations and companies. The companies keep a thorough check on the items and services they give to clients and that guarantees quality and fulfillment. The process is vital and runs in a precise way, but, that doesn’t mean it gives an undeniable certainty of value!

QA Requires a Customer Service

We use customer service and products on an almost daily basis. However, what a number of us can ensure that whatever we are buying is of worth? The main thing that people now want these days is storage spaces and facilities.

So, you should make sure that the storage spaces offer quality help and save you from the situation that whatever you keep in these units gets ruined. Obviously! Nobody wants to endure a misfortune.

But, how can you avoid such circumstances? You should opt for the services that have quality assurance measures running in their units.

Standard Cycle of Quality Assurance

Just as the name suggests, a Quality assurance system is a standard cycle that guarantees the quality of products. Businesses and companies should give the best possible services to their clients and that involves testing items and administration from the very start.

Keeping your unused things in storage space requires some other measures and you should ensure that the facility your opted company provides is the best.

It should be completely lit.

No congested space.

Organized things and kept them appropriately.

Pest controlled and termite-free

Climate-controlled units

Essential Objectives of Quality Assurance

The essential objective of the quality affirmation measure is to keep up with the nature of items. The products that the businesses are putting out in the market, should meet the customer’s needs. This cycle or framework follows:

Calculation of data

Archiving data

Uncertainty estimation

Emission computation

Additionally, the framework intends to deal with many different things:

Gives normal checking administrations so that there is accuracy and fulfillment in services.

Brings out the blunders and addresses them for extra quality support.