#conveyor rollers

Text

Conveyor Roller Systems | Damon

In the bustling world of manufacturing and logistics, efficiency is the name of the game. Every minute counts, every movement matters. It’s in this environment that conveyor roller systems emerge as unsung heroes, silently but efficiently carrying out the heavy lifting of material handling. Let’s delve into how these unassuming systems play a crucial role in enhancing productivity across various industries.

Streamlined Material Flow: Picture a bustling warehouse or a manufacturing floor. Without conveyor roller systems, the scene would be chaotic, with workers constantly shuttling between stations, carrying loads of materials. But with these systems in place, materials move seamlessly from one point to another, eliminating bottlenecks and streamlining the entire process.

Reduced Manual Labor: Gone are the days of back-breaking manual labor. Conveyor roller systems automate the tedious task of moving materials, freeing up human resources for more skilled and value-added tasks. This not only improves worker morale but also reduces the risk of injuries associated with manual handling.

Optimized Space Utilization: In today’s world where real estate comes at a premium, every square inch counts. Conveyor roller systems are designed to make the most out of available space by facilitating vertical integration and efficient layout designs. This optimization leads to higher storage capacity and better utilization of floor space.

Flexibility and Customization: One size does not fit all, especially in the world of manufacturing. Conveyor roller systems offer a high degree of flexibility and customization, allowing businesses to tailor solutions according to their specific needs. Whether it’s adjusting speed, accommodating different types of materials, or integrating with existing machinery, these systems can be fine-tuned to meet diverse requirements.

Enhanced Safety: Safety is paramount in any workplace. Conveyor roller systems are equipped with various safety features such as emergency stop buttons, guardrails, and sensors to prevent accidents and ensure a secure working environment for all personnel involved.

In essence, Conveyor Roller Systems are the unsung heroes of the manufacturing and logistics world, quietly but effectively driving efficiency, productivity, and safety across industries. As technology continues to evolve, these systems will undoubtedly play an even more integral role in shaping the future of material handling.

More Info Contact Us

Website https://www.damon-group.com.au/

Facebook https://www.facebook.com/damon.australia/

Youtube video Urlhttps://www.youtube.com/channel/UClI-8HJ0s314pTINMVICTjA

Ph: 3 9333 7034

Mail id: [email protected]

Working Time: Monday to FRiday 9.00 am - 6.00 pm.

0 notes

Text

0 notes

Text

Steel vs Plastic Conveyor Rollers

The traditional way of manufacturing involves a lot of heavy machinery and raw materials. The days of factories being situated in one place are long gone, thanks to the power of technology.

One such example is the production process for steel and plastic conveyor rollers. In this article, we will explore the benefits and drawbacks of both materials, and help you decide which is better for your particular manufacturing needs.

What is a steel roller?

A steel roller is made of a strong metal that is coated with metal oxide. This creates a smooth surface that can move large amounts of material quickly and easily.

What is a plastic roller?

A plastic roller is a conveyor belt moving products through a manufacturing or processing plant. It is made from durable plastic and typically has several rows of small, smooth wheels. These wheels help the roller move products along the conveyor belt at a steady pace.

The benefits of using steel rollers

There are many reasons to choose steel rollers for your conveyor system. Here are some of the benefits: -Steel is more durable and less likely to wear down over time.

-Steel rollers can handle heavier loads with ease, making them a better choice for high-volume applications. -They're also less noisy than plastic rollers, which can be considered in areas with sensitive noise levels.

The benefits of using plastic rollers

There are many benefits to using plastic conveyor rollers over metal ones.

- Plastic rollers are much lighter, making them easier to move and handle.

-They also have a longer lifespan, meaning they will not rust or corrode as metal rollers can.

-Additionally, plastic conveyor rollers are typically quieter than metal ones, which can help keep your facility quiet and organized.

Which type of roller should you buy?

When choosing between steel and plastic conveyor rollers, the answer is that it depends on the specific application. Generally speaking, steel roller conveyors are more expensive than their plastic counterparts, but they offer a number of benefits.

For one, they're stronger and last longer than their plastic counterparts. They're also less likely to wear down over time, so they can handle more abuse without faltering.

On the other hand, Plastic roller conveyors are cheaper to buy and maintain, but they don't always offer the same level of performance as steel models. Additionally, they can be difficult to clean if debris is clogged.

Ultimately, choosing a roller conveyor is important based on its intended use. If you have questions about which type of roller conveyor is best for your project, please get in touch with us at [contact info].

Which is Better for Your Business?

When choosing the best conveyor roller for your business, it’s important to consider a few things. First and foremost, what type of material will your conveyor be moving? If your conveyor is moving steel, then you’ll want to choose a steel roller.

However, if your conveyor is moving plastic materials, a plastic roller is likely the better option. Also, consider how often the roller will need to be replaced. If your roller is going to be used heavily, you'll likely want to choose a stronger Roller.

Finally, think about how easy it will be to maintain and operate. If the roller is difficult to keep clean or requires frequent maintenance, it may not be the best choice for your business.

Conclusion

Conveyor rollers are an important part of any manufacturing process, and choosing the right type for the job is important.

For example, steel conveyor rollers are better for heavy loads, while plastic conveyor rollers are better for delicate tasks. Ultimately, it's crucial to test a roller in advance of using it in order to ensure that it will meet your specific needs.

"Don't let the decision of choosing the right conveyor roller for your business stress you out. Take a look at our article on Steel vs Plastic Conveyor Rollers to learn about the benefits and drawbacks of both materials.

Still have questions? Contact us at +91 9168514741 and our team will be happy to assist you in finding the perfect conveyor roller for your specific needs.

Visit our website at https://polestarpolymers.com/ for more information."

0 notes

Text

Upgrade your industrial operations with top-quality conveyor belts from Prakash Engineering & Gear Co, the most trusted manufacturers.

Shop now and optimize your efficiency: https://www.prakashgear.in/nu-gearbox-manufacturers.php

#conveyor belt manufacturers in india#conveyor#conveyor belts#conveyor rollers#conveyor belt manufacturer

1 note

·

View note

Text

Heinrich Brothers is one of the trusted heavy duty conveyor rollers suppliers in USA. You can get the comfortable rollers with a great price. Contact today or visit website to get a quote!

0 notes

Text

figure status update - real world task | source

#talos gifs#stim gifs#stim#robot stim#robotics#robotcore#robotkin#metallic#metal#mechanical#technology#silver#white#black#grey#gray#blue#plastic#crates#roller conveyor#im pertty sure thats what thats called#gif ids#id in alt

45 notes

·

View notes

Text

Conveyor rollers for airport baggage handling, commonly known as Conveline rollers, are integral components of modern airport infrastructure, ensuring smooth and efficient transportation of luggage. These rollers are meticulously designed to withstand the demanding environment of airport terminals, offering reliability and durability in high-volume operations. For More Info : https://www.convelinerollers.com/rollers-uses-in-airport

0 notes

Text

Ultimate Guide to Selecting Conveyor Rollers for Efficiency

Whether you're upgrading an existing conveyor system or starting from scratch, selecting the right conveyor rollers is crucial for maximising productivity and minimising downtime. In this ultimate guide, we'll walk you through everything you need to know to choose the perfect conveyor rollers for your application.

Understanding the Basics

Before diving into the specifics of selecting conveyor rollers for sale, it's essential to grasp the fundamentals of how they function within a conveyor system.

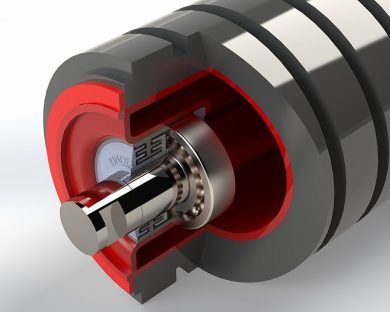

Conveyor rollers are cylindrical tubes or shafts that support and guide conveyor belts, allowing them to move items from one point to another with minimal friction. These rollers come in various sizes, materials, and designs, each tailored to specific applications.

Types of Conveyor Rollers

When it comes to selecting conveyor rollers, one size does not fit all. Different types of rollers are available, each offering unique benefits depending on the application. Some common types include:

Gravity Rollers

Conveyor rollers often include gravity rollers, which rely on the force of gravity to move items along the conveyor line. These rollers are ideal for transporting lightweight packages or products with a smooth, flat bottom.

Powered Rollers

Powered rollers, on the other hand, are driven by motors or other power sources, providing greater control over the movement of goods. They're suitable for heavier loads or applications that require precise speed and positioning.

Tapered Rollers

Tapered rollers are designed to help facilitate the movement of curved or irregularly shaped items along the conveyor line. They feature a conical shape that allows for smoother transitions between sections of the conveyor system.

Idler Rollers

Idler rollers are non-powered rollers that support the weight of the conveyor belt and the items being transported. They're essential for maintaining proper tension and alignment within the conveyor system.

Factors to Consider

Choosing the right conveyor rollers for sale involves considering several key factors to ensure optimal performance and longevity. Here are some essential considerations:

Load Capacity

One of the most critical factors to consider is the weight of the items being transported. Select conveyor rollers that can support the anticipated load without compromising efficiency or safety.

Material Compatibility

The material composition of the conveyor rollers should be compatible with the items being transported. For example, corrosive or abrasive materials may require rollers made from durable materials such as stainless steel or polyurethane.

Environmental Conditions

Take into account the operating environment of your conveyor system. Factors such as temperature extremes, humidity, dust, and exposure to chemicals can affect the performance and lifespan of conveyor rollers.

Maintenance Requirements

Consider the maintenance needs of the conveyor rollers. Choose rollers that are easy to clean and maintain to minimise downtime and prolong the life of your conveyor system.

Making the Right Choice

With so many options available, selecting the right conveyor rollers can seem like a daunting task. However, by carefully considering your specific needs and requirements, you can make an informed decision that maximises efficiency and productivity.

Whether you're in the market for gravity rollers, powered rollers, tapered rollers, or idler rollers, there are conveyor rollers for sale to suit every application and budget.

Conclusion

Conveyor rollers are the backbone of any conveyor system, playing a crucial role in ensuring smooth and efficient transportation of goods and materials. By understanding the different types of rollers available and considering factors such as load capacity, material compatibility, environmental conditions, and maintenance requirements, you can select the perfect rollers for your application.

With the right conveyor rollers in place, you can streamline your operations, improve productivity, and ultimately, boost your bottom line.

0 notes

Text

#Construction Equipment Market#Construction Equipment#Forklifts#Cranes#Conveyors#Hoists#Concrete Mixer & Pavers#Construction Pumps#Road Rollers#Backhoe Loaders#Skid Steer Loaders#Crawler/Track Loaders#Wheeled Loaders#Motor Graders#Bulldozers#Trencher#Motor Scrappers#Earth Moving Equipment#Concrete and Road Construction Equipment#Material Handling Equipment

0 notes

Text

conveyors

#trying to remember if i ever got on a moving conveyor or if its just something i really wanted to do and everyone said i couldnt#it wouldve been fine i think. pallet conveyors can handle more weight than i am. just put me on a psb and ill get off before the cranes#ive stood (crouched) on a stopped conveyor at least. im looking at the selfie right now. it was a roller conveyor its fine#well whatever it wouldnt be that fun anyway. conveyors dont go that fast <- cope from someone who still wants to ride a conveyor

0 notes

Text

Efficient Material Handling Solutions: Roller, Chain, and Slat Conveyors by Delta Stark

Delta Stark offers a comprehensive range of material handling solutions, including roller conveyors, chain conveyors, and slat conveyors, designed to optimize productivity and streamline operations across various industries.

Roller conveyors provide a cost-effective and efficient way to transport goods, utilizing a series of rollers to move items along a predetermined path. Ideal for both light and heavy-duty applications, roller conveyors are versatile and reliable, ensuring smooth and consistent material flow.

Chain conveyors are well-suited for transporting heavy loads or products with irregular shapes. Utilizing durable chains and sprockets, these conveyors offer robust performance and can handle demanding environments with ease. With customizable configurations, chain conveyors can be tailored to fit specific layout requirements.

Slat conveyors feature slats or plates attached to a chain, providing a sturdy platform for transporting items. These conveyors are suitable for conveying bulky or irregularly shaped materials, offering excellent stability and reliability. Slat conveyors are often used in assembly lines, manufacturing facilities, and warehouses.

At Delta Stark, we understand the importance of efficient material handling for optimizing workflow and increasing productivity. Our roller, chain, and slat conveyors are designed with durability, reliability, and versatility in mind, ensuring they meet the unique needs of our clients' operations.

With our expertise in conveyor system design and engineering, we work closely with clients to develop tailored solutions that maximize efficiency and throughput. Whether you need to move packages, components, or heavy equipment, Delta Stark's conveyor systems are built to deliver reliable performance and streamline your material handling processes.

Choose Delta Stark for all your material handling needs and experience the difference our roller, chain, and slat conveyors can make in optimizing your operations.

0 notes

Text

Conveyor Roller Systems | Damon

In industries ranging from manufacturing and logistics to warehousing and distribution, the efficiency of material handling processes is essential for maximizing productivity and reducing operational costs. Conveyor roller systems play a pivotal role in streamlining these operations, offering a reliable and efficient method for transporting goods and materials throughout facilities with ease.

Conveyor roller systems consist of a series of rollers mounted on a frame, which are powered by belts, chains, or gravity to move items along a predetermined path. These systems are designed to handle a wide range of loads, from lightweight parcels to heavy-duty pallets, making them versatile solutions for a variety of applications.

One of the primary advantages of conveyor roller systems is their ability to automate material handling tasks, reducing the need for manual labor and minimizing the risk of injuries associated with lifting and carrying heavy loads. By providing a continuous flow of materials, these systems help businesses increase throughput and meet production targets more efficiently.

Moreover, conveyor roller systems offer flexibility and scalability to accommodate changing operational needs. With modular components and customizable configurations, these systems can be easily adapted to fit different layouts and workflows, allowing businesses to optimize space utilization and improve workflow efficiency.

In addition to their efficiency and flexibility, conveyor roller systems also contribute to improved safety in the workplace. By reducing the need for manual handling and minimizing the risk of accidents such as slips, trips, and falls, these systems create a safer working environment for employees, enhancing overall job satisfaction and morale.

Furthermore, conveyor roller systems support sustainability initiatives by reducing energy consumption and minimizing material wastage. By optimizing material flow and reducing idle time, these systems help businesses operate more efficiently, leading to lower energy costs and reduced environmental impact.

In conclusion, Conveyor Roller Systems play a crucial role in enhancing efficiency, productivity, and safety in various industries. Their versatility, scalability, and sustainability make them indispensable tools for businesses seeking to streamline their material handling processes and stay competitive in today's fast-paced market.

More Info Contact Us

Website https://www.damon-group.com.au/

Facebook https://www.facebook.com/damon.australia

Youtube https://www.youtube.com/channel/UClI-8HJ0s314pTINMVICTjA

Linkedin: https://www.linkedin.com/company/damon-australia-pty-ltd/?viewAsMember=true

Ph: 3 9333 7034

Mail id: [email protected]

Working Time: Monday to FRiday 9.00 am - 6.00 pm.

0 notes

Text

Gravity Roller Conveyor Manufacturer – Conveline

Conveline Systems Pvt Ltd is a leading manufacturer of high-quality gravity roller conveyors in Ahmedabad, India. We understand the importance of efficient material handling in today's fast-paced work environment. Gravity roller conveyors give a simple yet effective way to speed up your processes without breaking a budget. Contact us today to discuss your specific needs and find the perfect conveyor system to streamline your industries. We offers a wide range of gravity roller conveyor options to suit your specific needs. Our team of experts can design and implement the perfect conveyor system for your industry. Visit our Site: https://www.conveline.com/product/gravity-rollers/gravity-rollers or Contact Us: +919081915912

#Gravity Roller Conveyor#Gravity Conveyor Systems#Industrial Roller Conveyor#Gravity Rollers For Sale#Gravity Roller Conveyor Manufacturer#Roller Conveyor Manufacturer In India

0 notes

Text

Polyurethane conveyor roller

View On WordPress

0 notes

Text

Best Conveyor Roller Manufacturer In India

Conveyor rollers are also known as idler rollers that run under the conveyor belt. Prakash Engineering & Gear Co is a leading conveyor rollers Manufacturer. We offer different types of idler rollers with varying functions. Contact us today to get the best conveyor roller!

1 note

·

View note

Text

Belt Conveyor System: A Comprehensive Guide to Its Uses and Benefits

Belt conveyor systems are ubiquitous in modern manufacturing and transportation industries. These systems are designed to transport materials from one location to another, typically over long distances and across various terrains. Belt conveyor systems are used in a wide range of applications, including mining, agriculture, food processing, and packaging.

The basic design of a belt conveyor…

View On WordPress

#agriculture and food processing#airport baggage handling#Belt conveyor system#belt materials#conveyor structure#manufacturing and packaging#mining and quarrying#pulley#roller#tensioning mechanisms

0 notes