#industrial robot

Text

industrial robots

#KUKA#robot#industrial robot#manufacturing#heavy industry#automotive#FIAT#Italy#Torino#Turin#FIAT 500

209 notes

·

View notes

Photo

🔩 A013 - KUKA KR 240 Industrial Robot... 7 axis

RTU Robot Transfer Unit... KL1500 Track 8 mts... Linear Motion Track

PositionTable Position Table

KRC2 Ed05 ... picture via EuroRobots

▸ TAEVision Engineering on Pinterest

Data A013 - Nov 03, 2022

#automation#robot#robotics#KUKA#KR 240#KUKA KR 240#industrial robot#7th axis#RTU#RTU Robot Transfer Unit#RTU Transfer Unit#RTU Assembly Robotics#TransferUnit#transfer unit#PositionTable#position table#linear motion track#EuroRobots

25 notes

·

View notes

Text

The impact of industrial robots in transforming industries

The manufacturing environment has changed dramatically due to industrial robots, altering production techniques across various industries. We examine how commercial robots have developed, the range of uses they have, and the significant influence they have on modern manufacturing.

The Rise of Industrial Robots

A Brief History

From the first programmable robotics in the 1950s to the latest superior robot structures, commercial robots have gone through substantial technological improvements. Early fashions have normally been used for repetitive obligations, but contemporary robots boast advanced capabilities and flexibility.

The Evolution of Technology

Advancements in robotics generation, along with synthetic intelligence, machine learning, and the sensor era, have enabled business robots to carry out complicated tasks with precision and efficiency. Today's robots are capable of tasks ranging from assembly and welding to inspection and packaging.

Applications Across Industries

Automotive Manufacturing

Industrial robots play an essential role in car production, wherein they're used for responsibilities along with welding vehicle bodies, painting, and assembly. Robots beautify efficiency, improve quality, and ensure consistency in manufacturing processes.

Electronics Industry

In the electronics enterprise, industrial robots are used for responsibilities that include soldering, thing placement, and checking out. Robots enable quicker production cycles, lessen errors, and enhance the precision required for complex digital components.

Industrial robots continue to pressure innovation, efficiency, and competitiveness in production industries worldwide. As the era advances and adoption rates boom, industrial robots will play an increasingly integral role in shaping the destiny of producing, driving productivity, and allowing new possibilities in industrial automation.

0 notes

Photo

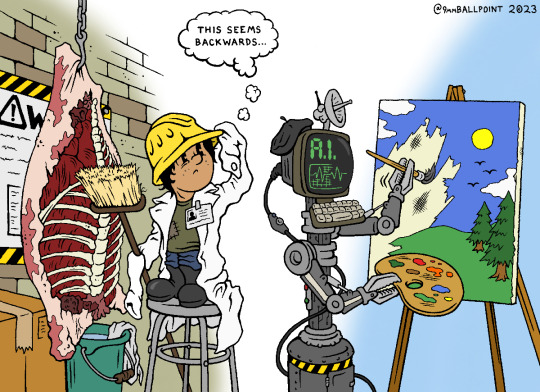

I'm not anti-technology, I just think there's something deeply sick about a society where robots make art and children work in factories.

54K notes

·

View notes

Text

Who are the top countries in PLC technology?

PLC technology, modernizing the industrial world, post World War II. The demand of the automobile industry and the auto world increased, leading to the need for more advanced technology for mass manufacturing.

However, a quick realization of the importance of PLC technology on a larger industrial scale led countries to conquer the technology to be a world provider.

Let’s look at a comparative…

View On WordPress

0 notes

Text

How are industrial robotic arm controlled ?

How are robotic arms are controlled? Do they need a separate CNC control? Are PLCs used to control robotic arms at all? Is the industry moving to an embedded control system at all?

Industrial robotic arms are typically controlled using a combination of hardware and software components. The control system for industrial robotic arms consists of the following key elements:

Robot Controller: The robot controller is the central component of the control system. It is a dedicated computer or embedded system that manages the overall operation of the robotic arm. The controller is responsible for receiving commands, processing them, and generating control signals for the arm’s actuators.

Programming and Command Input: To control the robotic arm, it needs to be programmed with specific instructions. This can be done through various methods, including:

Offline Programming: Robotic arm movements and tasks are programmed using specialized software on a computer. The program is then transferred to the robot controller.

Teach Pendant Programming: Operators manually move the robotic arm through the desired motions using a teach pendant or handheld device. The positions and actions are recorded and saved as a program.

Integrated Programming: Some robotic arms offer integrated programming interfaces, allowing operators to program the arm’s movements directly through intuitive user interfaces or by physically guiding the arm through the desired path.

Sensors and Feedback: Industrial robotic arms are equipped with various sensors to provide feedback and enable precise control. These sensors include:

Encoders: Measure the position and velocity of the arm’s joints, providing feedback on their actual positions.

Force/Torque Sensors: Measure forces and torques applied by the arm’s end effector, enabling it to react to external forces or maintain a specific force during tasks.

Vision Systems: Cameras and vision sensors allow the robotic arm to perceive and interact with its environment, detect objects, and perform tasks based on visual information.

Actuators and Motors: The robotic arm’s joints are actuated using motors, such as electric servo motors or hydraulic/pneumatic actuators. The control signals generated by the robot controller are sent to these actuators, enabling precise control of the arm’s movement and positioning.

Safety Systems: Industrial robotic arms are equipped with safety systems to ensure safe operation in collaboration with human operators. These may include emergency stop buttons, safety interlocks, proximity sensors, and software features that monitor and respond to potential collisions or hazardous situations.

Communication and Integration: Industrial robotic arms often need to communicate with other systems and devices in the manufacturing environment. This can involve integration with supervisory control systems, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other automation equipment to coordinate tasks and exchange data.

By combining these elements, the control system of an industrial robotic arm enables precise and efficient operation, executing programmed tasks with speed, accuracy, and safety.

About us :

GUANGDONG BORUNTE TECHNOLOGY CO.,LTD., is the distribution and wholesale of BORUNTE industrial robots, injection molding machine robots, die-casting robots and peripheral automation equipment with professional marketing, technology and after-sales automation. At present, the company has established long-term and stable cooperative relations with many terminals and agents at home and abroad. At the same time, we are sincerely welcome you join us who would like to be our agent around the world.

#marketing#branding#sales#industrial robot#industrial coating#industrial painting#automation#universal robots#welding robot arm#industrial robot arm

0 notes

Text

Industrial Robotics Market Insight & Future Assessment For The Period 2022 – 2029

Paradigm shifts and technological interventions have completely transformed the way industries operate, making a quantum leap toward automation. To this end, industrial robots are comprehensively being incorporated across food and beverage, metals and machinery, electronics, and semiconductors industries. Leveraging these industrial robots, organisations can efficiently automate mundane and repetitive tasks with great precision and accuracy. Against this backdrop, industrial robotics has gained considerable traction across diverse industrial applications including packaging and labelling, welding, assembly, painting, and product inspection. In addition, extensive use of industrial robotics in automotive and electronics manufacturing is poised to ameliorate the productivity of high-volume production lines. Such trends are setting the stage for the robust expansion of the global industrial robotics market.

For More Industry Insights Read: https://www.fairfieldmarketresearch.com/report/industrial-robotics-market

Miniaturisation, and Precision Robotics to Unlock New Avenues for Expansion of Industrial Robotics Market

Today, the periphery of robotics applications has expanded from being limited to heavy industries such as automobiles and energy. This can be attributed to the provided precision, optimal utilisation of resources, significant cost reductions, productivity enhancements, and better quality of outputs. In addition, the miniaturisation of robots & advent of nanorobotics has further tapped into new markets including instrumentation, electronics, and healthcare. With such a vast application base, industrial robotics has succeeded in accentuating its position in small and medium-sized enterprises (SMEs). Considering the aforementioned factors, the global industrial robotics market is anticipated to witness substantial growth in the years to come.

Ascending Demand for Collaborative Robots to Steepen Growth Curve of Industrial Robotics Market

Collaborative robots, also known as cobots, have been experiencing sharp spikes in demand across various industries. These cobots are designed in a way to interact and work in complete harmony with humans in the common workplace. Likewise, employing these cobots and automating tasks is plain sailing. Cobots can assist enterprises in packaging, screwing, pick-and-place, laboratory testing, assembly, and quality inspection. Moreover, the cobots are highly capable of performing repetitive tasks with great speed and accuracy, ensuring a safer environment for workers and production. Acknowledging these benefits and applications, various retailers, healthcare providers, and automotive manufacturers are rapidly advancing towards the adoption of collaborative robots. The steadily rising demand for industrial robotics is, in a way, paving pathways for the industrial robotics market expansion.

Asia Pacific to Slate Dominance in Industrial Robotic Market Owing to Rising Labour Costs

With consistently surging labour costs, the manufacturers in the Asia Pacific are opting for automation technologies, such as industrial robotics, to curtail the overall cost of production. Moreover, economies such as China are rebounding their production lines after undergoing a period of stark stagnation. In addition, Thailand and Taiwan are also propelling the adoption of automation technologies. Other macro factors such as a rise in disposable income, demand for consumer goods, population, and production capacity are instrumentally elevating the demand for industrial robots in the Asia Pacific.

Major Market Players

Some of the most prominent players consolidating stronghold positions in the global industrial robotics market include Bosch Rexroth (Germany), FANUC (Japan), ABB (Switzerland), ICR Services (US), KUKA (Germany), Mitsubishi Electric (Japan), YASKAWA (Japan), Denso Corporation (Japan), NACHI-FUJIKOSHI (Japan), Seiko Epson (Japan), Kawasaki Heavy Industries (Japan), Universal Robots (Denmark), DÜrr (Germany), Comau (Italy), Stäubli (Switzerland), IRS Robotics (Netherlands), B+M SURFACE SYSTEMS (Germany), Siasun Robotics (China), RobotWorx (US), Hyundai Robotics (South Korea), Rethink Robotics (Germany), Techman Robot (Taiwan), F&P Robotics (Switzerland), and FrankaEmika (Germany).

For More Information Visit: https://www.fairfieldmarketresearch.com/report/industrial-robotics-market

About Us

Fairfield Market Research is a UK-based market research provider. Fairfield offers a wide spectrum of services, ranging from customized reports to consulting solutions. With a strong European footprint, Fairfield operates globally and helps businesses navigate through business cycles, with quick responses and multi-pronged approaches. The company values an eye for insightful take on global matters, ably backed by a team of exceptionally experienced researchers. With a strong repository of syndicated market research reports that are continuously published & updated to ensure the ever-changing needs of customers are met with absolute promptness.

#industrial robotics#industrial robotics market#industrial robotics market size#industrial robotics market share#industrial robotics market trends#industrial robotics market demand#industrial robotics market growth#industrial robotics market forecast#industrial robotics market analysis#industrial robotics market scope#robotics market#industrial robot#fairfield market research

0 notes

Text

Industrial Robot Market risks and challenges that the industry is facing

Industrial Robot Market risks and challenges that the industry is facing

The Industrial Robot Market research report 2022-2030 provides an in-depth analysis of the changing trends, opportunities, and challenges influencing the growth over the next decade. The study includes a detailed summary of each market along with data related to demand, supply and distribution. The report examines Industrial Robot market growth strategies adopted by leading manufacturers which…

View On WordPress

#Covid-19 Impact Analysis#Industrial Robot#Industrial Robot forecast#Industrial Robot Industry#Industrial Robot Market#Industrial Robot price#Industrial Robot report#Industrial Robot research#Industrial Robot share#Industrial Robot trends

0 notes

Text

DO YOU UNDERSTAND.

#this idea came to me while sitting in my cyborgs film class. professor showed this graph and my first thought was#‘industrial robot is objectively cooler than hyper realistic humanoid robot’#a talking lizard#cookiebytes#im not objectum but I believe in their beliefs

976 notes

·

View notes

Photo

🔩 A013 - KUKA KR 240 Industrial Robot... 7 axis

RTU Robot Transfer Unit... KL1500 Track 8 mts... Linear Motion Track

PositionTable Position Table

KRC2 Ed05 ... via EuroRobots

▸ TAEVision Engineering on Pinterest

Data A013 - Oct 02, 2022

#automation#robot#robotics#KUKA#KUKA KR 240#industrial robot#7th axis transfer unit#RTU#RTU Robot Transfer Unit#RTU Transfer Unit#RTU Assembly Robotics#TransferUnit#transfer unit#PositionTable#position table#EuroRobots

2 notes

·

View notes

Text

Revolutionizing Manufacturing: Exploring Industrial Robots

Industrial robots are transforming the manufacturing landscape, revolutionizing manufacturing processes, and using performance and innovation. Let's delve into the arena of commercial robots and discover their effect on present-day production.

The Evolution of Industrial Robotics

From Assembly lines to Automation

Industrial robots have come a long way since their inception, evolving from simple assembly line equipment to sophisticated automation systems. Today, they perform a wide variety of tasks, from welding and painting to fabric management and first-rate control.

Integration of Advanced Technologies

Modern commercial robots are equipped with superior technologies, including artificial intelligence, system learning, and sensor systems. These technologies allow robots to evolve to converting environments, research from experience, and perform complicated tasks with precision and efficiency.

Benefits of Industrial Robotics

Increased Efficiency and Productivity

Industrial robots streamline production procedures, leading to accelerated efficiency and productivity. They can work around the clock without fatigue, resulting in quicker production cycles and better output degrees.

Improved Safety and Ergonomics

By taking on risky, repetitive, or physically traumatic duties, industrial robots help enhance administrative center protection and ergonomics. They reduce the chance of accidents and permit human employees to focus on more professional and value-delivered activities.

Conclusion:

Industrial robots have grown to be necessary belongings in modern production, driving performance, productivity, and innovation. By embracing automation and the robotics era, groups can stay competitive in a hastily evolving worldwide marketplace and release new opportunities for growth and achievement.

1 note

·

View note

Video

[TURN SOUND ON]

In Chai’s own words; What a fight!

I mean, if your game doesn’t let me fight a giant mecha werewolf with a guitar inside Scrooge McDuck’s vault, then honestly what’s even the point?

#Sometimes I remember I'm supposed to be a game developer and can make stuff that's industry standard#then I laugh and go right back to shitposting#hi fi rush#hi-fi rush robot#hi-fi rush fanart#hi fi rush fanart#hi fi rush roquefort#hi fi rush chai#hi-fi rush chai#hi-fi rush comic#hi fi rush 808#hi fi rush cat#speedpaint#animated speedpaint#animation#spine animation#2Dspine#werewolf#mecha#DO YOU HAVE ANY IDEA HOW LONG THIS TOOK TO MAKE

2K notes

·

View notes