#nitrile chemical resistant gloves

Text

BIS Certified Nitrile Hand Gloves For Industrial Safety

Mallcom India is a leading manufacturer of EN and BIS-certified industrial safety hand gloves to protect your hands from hazards. Available in many styles and sizes.

#mallcom nitrile gloves#black nitrile gloves#nitrile coated gloves#nitrile gloves manufacturer in india#nitrile chemical resistant gloves#mallcom safety gloves#cut resistant hand gloves#hand protection gloves

0 notes

Text

*twirls my helmet visor around my finger*

W-woah, nice PPE bro, it looks so protective and within workplace standards 🥵

#they look so safe from chemicals#nothing is sexier than a tight pair of nitrile gloves and splash resistant apron

1 note

·

View note

Text

Black Mamba Nitrile Gloves

Our Black Mamba super strong Nitrile Gloves serve as a barrier between the wearer's hands and potentially dangerous petroleum products, such as oils, fuels and greases. Our Mamba gloves Feature our grip rite finish for secure handling and dexterity even when working with fine objects. This high level of protection makes nitrile gloves a popular choice for automotive, manufacturing and industrial use. With black mamba 100 gloves pack you now no longer need to change your gloves multiple times due to ripping or tearing. For gloves built for your tough tasks...it must be Black Mamba! Visit : https://amzn.to/3QdzXCZ

0 notes

Text

PPE: Hand Protection

Most work in the laboratory involves the use of hands and gloves are mandatory in many environments and organizations, but the choice of hand protection is crucial. While thicker gloves may offer more protection, they can reduce dexterity and create more risks when doing tasks that require finesse. They length of time the gloves will be worn should also be considered. When dealing with chemicals, it is important to consult proper sources, as different chemicals react differently to different glove materials.

Nitrile, disposable, gloves are among the most commonly used when working with chemicals, but most other gloves are non-disposable. Cut resistant gloves can be used when working with sharps, and flame resistant gloves should be used during hot work. There are also rubber gloves for more reactive chemicals and cryogenic gloves for working with liquid nitrogen and similar materials. As with any PPE, maintenance is key: gloves with holes or rips should not be used and disposal gloves should be removed and replaced if they come in contact with chemicals. Some situations may require the use of more than one kind of glove, or double gloving.

Sources/Further Reading: (Image source - Eastern Washington University) (UC Berkeley) (MSC) (Tameson)

18 notes

·

View notes

Note

are you actually a scientist??? i need to know its been driving me crazy for monthes now i cant tell

My biweekly paycheck tells me I am, hahaha

But for real, yes, I'm an environmental scientist. I keep many details of my job private for anonymity's sake, but I collect samples, receive samples, and conduct routine tests on those samples - all while wearing a fancy schmancy chemical-resistant lab coat, protective glasses, and nitrile gloves.

My childhood dream was to become a scientist, so it's really been a dream come true the past couple years :)

18 notes

·

View notes

Text

Outdoor Gloves Guide

Outdoor Gloves Guide

When it comes to outdoor tasks that demand durability, protection, and a reliable grip, nitrile-coated outdoor gloves are a must. Designed to withstand rough surfaces, sharp objects, and varying weather conditions, these gloves are essential for any outdoor enthusiast, gardener, construction worker, or DIY hobbyist. Here, we'll explore some of the best nitrile-coated outdoor gloves with grip, highlighting their unique features and benefits.

youtube

What Goes into a Good Outdoor Glove?

When it comes to outdoor tasks, having the right gear can make a significant difference in your performance, safety, and overall enjoyment. Nitrile coated outdoor gloves with grip are essential tools that provide protection, durability, and excellent traction for a wide range of activities. To ensure you invest in the best pair of gloves for your needs, follow this comprehensive guide to buying the perfect nitrile coated outdoor gloves with grip.

Consider Your Outdoor Activities

Start by identifying the specific outdoor activities you'll be engaging in regularly. Are you an avid gardener, a construction professional, or do you enjoy DIY projects? Different activities may require gloves with varying levels of protection, grip, and flexibility. By understanding your needs, you can narrow down your options and find gloves tailored to your preferred tasks.

Safer Grip Gloves by OPNBar

10053 Whittwood Dr, Suite 11284 Whittier,

CA 90603 USA

657-667-6227

Grip Technology

The primary feature that sets nitrile coated gloves apart is their enhanced grip. Look for gloves with a textured nitrile coating that offers excellent traction even in wet or oily conditions. The grip should allow you to maintain control over tools and materials, preventing accidents and improving efficiency. Prioritize gloves with multiple grip zones for added versatility and adaptability to different tasks.

Material Quality and Durability

Check the quality of the base material and the thickness of the nitrile coating. Opt for gloves made from high-quality nylon, polyester, or other durable materials that can withstand regular wear and tear. The nitrile coating should be thick enough to provide ample protection against cuts, scrapes, and punctures. Investing in gloves with reinforced fingertips and palms can further enhance their longevity and resistance to abrasion.

Size and Fit

A proper fit is crucial for comfort and dexterity during outdoor tasks. Choose gloves that are available in various sizes to ensure you find the one that fits your hands perfectly. A snug fit prevents the gloves from slipping off during use while allowing your hands to move freely. Be sure to consult the sizing chart provided by the manufacturer to find the most appropriate size for your hands.

Comfort and Flexibility

Outdoor tasks can be physically demanding, so prioritize gloves that offer comfort and flexibility. Look for gloves with a breathable design that allows air circulation and prevents excessive sweating. A flexible base material enables better hand movement and reduces hand fatigue, especially during extended use.

Water and Chemical Resistance

Depending on your activities, you may need gloves that are water-resistant or offer protection against specific chemicals. Consider the environments in which you'll be using the gloves and choose a pair that meets those requirements. Some gloves have specialized coatings that repel water and oils, ensuring a secure grip even in wet conditions.

Eco-Friendly Options

If environmental sustainability is a priority for you, consider opting for eco-friendly nitrile coated gloves made from sustainable materials and manufactured using environmentally conscious processes. Several brands are now offering eco-friendly options that reduce their impact on the environment.

Read Reviews and Recommendations

Before making a final decision, read reviews and seek recommendations from other users. Online reviews provide valuable insights into the performance and durability of the gloves, helping you make an informed choice.

Choosing the best nitrile coated outdoor gloves with grip involves considering your specific outdoor activities, grip technology, material quality, size and fit, comfort, water and chemical resistance, and eco-friendliness. By following this guide, you can confidently select a pair of gloves that will serve as a reliable companion for all your outdoor adventures, providing the protection, durability, and grip you need to excel in every task.

Materials that Enhance Grip

Various materials and technologies contribute to the grip-enhancing properties of hiking gloves. Some of the most popular choices include:

Silicone patterns: Many high-quality gloves incorporate silicone patterns on the palms and fingers, offering an impressive grip on multiple surfaces.

Textured synthetic materials: Gloves made with textured synthetic materials, such as polyurethane or rubber, provide an excellent balance between grip and durability.

Innovative grip technologies: Some gloves utilize cutting-edge technologies to enhance their grip capabilities, such as strategically placed padding, ergonomic design, or moisture-wicking materials.

Benefits of Hiking Gloves with Grip

Hiking gloves with superior grip features offer numerous advantages, including:

Safety: A firm grip helps prevent accidents and injuries resulting from slips or loss of balance.

Versatility: Gripping gloves enable secure handling of various gear and equipment, making them suitable for different outdoor activities.

Comfort: Gloves with exceptional grip often boast ergonomic designs and materials, providing comfort during extended hikes.

Improved performance: Enhanced grip contributes to better control and dexterity, allowing hikers to tackle challenging trails with confidence.

Investing in hiking gloves with outstanding grip capabilities is a game-changer for outdoor enthusiasts. These gloves provide safety, versatility, and comfort while enhancing your overall performance on the trail. Before embarking on your next adventure, consider upgrading to gripping hiking gloves for a more enjoyable and secure experience.

Grip gloves are specialized gloves designed to provide an enhanced grip when handling objects. They are widely used in various industries, including construction, manufacturing, and automotive, to improve productivity and reduce the risk of accidents. In this article, we will discuss the benefits of using grip gloves and explore the different types of grip gloves available in the market.

Types of Grip Gloves

Latex Grip Gloves: Latex grip gloves are made of a latex coating over a knit or woven base material. They are lightweight and offer excellent grip in wet or dry conditions. Latex grip gloves are commonly used in the healthcare industry, where they provide protection against infectious materials.

Nitrile Grip Gloves: Nitrile grip gloves are made of a synthetic rubber material that is resistant to punctures, cuts, and chemicals. They offer excellent grip in wet or oily conditions and are commonly used in the automotive and manufacturing industries.

PVC Grip Gloves: PVC grip gloves are made of a PVC coating over a knit or woven base material. They are lightweight and offer good grip in wet or oily conditions. PVC grip gloves are commonly used in the food processing and janitorial industries.

Leather Grip Gloves: Leather grip gloves are made of high-quality leather and offer superior grip and durability. They are commonly used in the construction and landscaping industries, where workers need to handle heavy tools and materials.

Cut-Resistant Grip Gloves: Cut-resistant grip gloves are made of specialized materials that offer protection against cuts and abrasions. They are commonly used in industries where workers handle sharp tools and materials, such as the construction and manufacturing industries.

Choosing the Right Grip Gloves:

When choosing grip gloves, there are several factors to consider, including the type of work being performed, the level of grip required, and the potential hazards present in the workplace. Some important factors to consider include:

Material: The material of the gloves should be chosen based on the type of work being performed. For instance, latex grip gloves are suitable for healthcare workers, while nitrile grip gloves are better for automotive and manufacturing workers.

Grip: The level of grip required will depend on the nature of the work being performed. Workers who handle heavy or slippery objects may require gloves with a stronger grip, while those who handle smaller components may require gloves with a more delicate grip.

Size: The gloves should fit snugly to ensure maximum grip and protection. It is essential to choose gloves that fit properly to avoid slipping or sliding while working.

Durability: The durability of the gloves should be considered when choosing grip gloves. Workers who handle sharp or abrasive materials may require gloves that are more durable to prevent punctures or tears.

Employee Safety

Employee safety should be a top priority in any company. Apart from the obvious pain and suffering with worker deaths and injuries, workers who are injured on the job could sue a company for financial damages. Injuries may make them less productive when they return to work. It is important that employers effectively communicate safety standards to every employee, and train them properly.

Safer Grip Gloves by OPNBar™️ are ideal work grip gloves for all-day use for light manufacturing, warehouse operators, and for use in maintenance areas.

Our new and improved Safer Grip nitrile coated grip gloves by OPNBar are ideal multi-purpose work grip gloves for various applications like trucking and delivery, warehouses, maintenance areas, light manufacturing and carpentry. They are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Coated Grip Gloves

Safer Grip nitrile coated gloves are made of 15-Gauge nylon polyester engineered yarn. The glove conforms to the operator’s hand and offers maximum flexibility and comfort. Safer Grip spandex nylon glove palms are coated in micro-foam nitrile, and are quite flexible, making Safer Grip nitrile coated grip gloves the perfect nitrile foam gloves for working with tools and protecting your hands and products. The latest glove offers a durable thumb crotch for extra grip and protection.

Coated foam grip gloves are extremely popular, primarily because they have a good price point. They are effective and comfortable, provide great dexterity, and protect operator hands from hazards, as well as protect products from workers’ hands.

Foam coatings can be applied and used in wet, oily, cold, and normal situations. Safer Grip spandex gloves with a long lasting microfoam nitrile coating are breathable with a coarse surface that can suck up oil and liquid, and maintain grip and tactility even when wet.

Nitrile Foam Grip Gloves Coating

Safer Grip Gloves by OPNBar™️ grip gloves are dipped in a special longer lasting formula, with a durable nitrile foam coating that improves tactility and dexterity. The foam coating resists cuts, abrasions, and tears, and is also a good alternative for people with latex allergies or want an alternative to leather. Safer Grip gloves are dipped in an improved nitrile microfoam formula in a three-quarter palm dip. Micro-foam technology offers great breathability, making them cool and comfortable to wear, in any environment.

Lots of Features

15-Gauge Nylon/Spandex Liner

Tough Micro-Foam Nitrile Coating

Touchscreen Compatible Grip Gloves that Work with Phone

Superior Grip, Dexterity & Protection

Ultra Soft Fitting, Breathable

Abrasion Resistance: 40,000 cycles, EN388:4131X

Oeko-Tex Standard 100, Skin Friendly, Latex Free

Machine Washable

CE Compliance

Safer Grip nitrile coated grip gloves are CE Certified, EN388 4131 compliant, and have an abrasion resistance of 40,000 cycles. Safer Grip gloves are Oeko Tek Standard 100, are skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

STANDARD 100 by OEKO-TEX® is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety.

SAFER GRIP Gloves by OPNBAR™️ apparel carries the STANDARD 100 label. You can be certain that every component has been tested for harmful substances and are harmless for human health.

In the test, they take into account numerous regulated and non-regulated substances, which may be harmful to human health. In many cases, the limit values for the STANDARD 100 go beyond national and international requirements.

More Features of Safer Grip

Touchscreen Compatible Grip Gloves that Work with Phone

These work gloves are also touchscreen compatible on 4 fingers!

Ultra Soft Fitting, Breathable

These lightweight work gloves offer superior breathability and are quite form fitting.

Superior Grip, Dexterity & Protection

Nitrile coated work gloves offer versatile protection for many environments.

Reinforced Thumb Crotch

The thumb crotch on these work gloves provides a firm grip for these grip gloves.

Abrasion Resistance: 40,000 cycles, EN388:4131X

SAFER GRIP gloves are tested to have an abrasion resistance of 40,000 cycles!

Tough Micro-Foam Nitrile Coating

SAFER GRIP nitrile dipped work gloves and nitrile coated in a special, long lasting formula.

Versatile Weather Protection

These safety gloves can offer protection not only for your hands and products, but also weather elements as well.

Latex Free, Skin Friendly

Skin friendly, latex free, and guarantee a high level of protection, comfort, and durability.

Industrial Use Features of Safer Grip

Construction, Carpentry, Roofing

Woodworking/Carpentry Gloves

These construction gloves are also great for being woodworking gloves and roofing gloves.

Warehouse Gloves

These warehouse gloves also make great moving gloves or box handling gloves.

Mechanic Gloves

These mechanics gloves also make great shop gloves or gloves for home improvement.

Truck Driver Gloves

SAFER GRIP gloves are popular truck driver gloves for their versatility and comfort.

Versatile Outdoor Uses of Safer Grip Gloves

Gardening Gloves

SAFER Grip gloves make great outdoor gloves and gardening gloves.

Hiking Gloves

These are great for everyday use in the outdoors and also make excellent hiking gloves.

Boating Gloves

Nitrile coated gloves provide dexterity in wet environments making them great boating gloves and fishing gloves.

Biking and Outdoor Gloves

These firm grip gloves are also great as biking gloves or daily outdoor gloves.

Protecting your hands should be your top priority, and the best way is to use work gloves. Yes, these work gloves are great as they provide a layer of protection to the knit gloves and give a non-slippery experience.

Gloves can be made of nylon, cotton, and even polyester or engineered yards called Kevlar or Dyneema. This material is an excellent alternative for expensive leather gloves.

The palm-coated industrial work gloves are great for different use in the automotive industry, construction, or even in sampling and handling products, which offer a better, and anti-slip grip.

Glove Coatings

The dip coating is applied on the knit gloves to give a good layer of protection. However, the amount of coating can be customized as follows:

Full Dip

The full dip allows covering the whole hand including the lower wrist.

Palm Dip

The palm dip will cover the whole palm including the fingertips for a better shield.

¾ Dip

The ¾ dip protects the palm, knuckles, and fingers.

What’s Grip Gloves Do you Prefer?

These tough coatings will give a perfect experience for handling tough materials filled with grease and chemicals. These gloves will enhance durability, chemical resistance, and even cut protection.

Many coatings can be used on knit gloves which are as follows:

Nitrile Foam

Latex

PVC

Neoprene

Zed coat

Micropore Nitrile

Polyurethane (PU)

Now, let us have a brief look at all these types of coating.

Nitrile Foam Coated Gloves

Industrial environments of today carry many activities that have risks. Governments and businesses in many countries define guidelines that benefit the safety of their workers. Many industrial applications promote the use of nitrile foam grip gloves for industry workers as a means of safety.

For Those with Allergy Concerns

Nitrile foam grip gloves are a type of glove made from nylone and coated with synthetic rubber. Nitrile is a polymer compound with a production process similar to that of making rubber. Unlike rubber however, nitrile is a 100% synthetic substance and typically does not create any type of allergic reaction on the human body and as a result, is accepted and used in many businesses. Nitrile is the synthetic form of latex and is commonly chosen for its strength.

Nitrile Latex vs Rubber

Just like natural rubber, Nitrile latex does not contain latex proteins. Nitrile rubber provides excellent resistance to tears and punctures and is almost 3 times stronger than natural rubber. Nitrile stands up well to oil, and makes it is a good choice for handling small wet/oily parts.

Features of Nitrile Foam Gloves

The main feature of knit nylon gloves coated with nitrile is their good grip and dexterity. Nitrile coated palm and fingers provide protection from abrasion, excellent grip, are extremely thin and durable, are breathable, comfortable, cut resistant, have great dexterity, tactility, and sensitivity.

There are various types of Nitrile coated glove dips available, some of them which include Nitrile palm coated grip gloves, foam Nitrile coated gloves, and fully coated Nitrile gloves.

All-Weather Grip Gloves

Many businesses use nitrile work grip gloves for their workers and most of these companies, especially in cold weather areas of the world. Nitrile foam gloves can keep worker’s hands warm in cold weather conditions and allow them to move their hands freely and easily even in cold conditions as well as protect their hands from harmful substances, cuts, and abrasion.

Works Well with Wet Conditions and Oil

Nitrile foam gloves withstand oils and have tactility even when wet. Nitrile coatings protect hands by preventing oil from penetrating through the gloves. Some applications include working with small or oily parts, as nitrile coating provides a secure grip.

Durable and Long Lasting

Nitrile foam gloves do not easily break down, delaminate or blister-like other coating materials in the presence of oils and in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Other Information on Nitrile Foam Gloves

Nitrile foam gloves are perfect for general work because of their durability and robustness. The nitrile coating will prevent cuts, tears, and even abrasions. These grip gloves work well between -25 F and 350 F.

Nitrile foam gloves are durable, but they will not provide a robust grip in oily and wet conditions compared to micropore nitrile gloves.

Nitrile foam coating may not be ideal for liquids and adhesives because they may seep inside the gloves.

Latex Coated Gloves

Latex-coated gloves are soft and flexible. These soft gloves give a perfect grip and an anti-slip experience. Latex-coated gloves work well in all circumstances and temperatures, and they are a perfect choice for high temperatures too.

Latex gloves fall in the category of the most durable gloves, but you may experience low abrasion and oil resistance. Latex gloves can resist the use of alcohol and some categories of ketones, but they won’t work well for organic solvents and hydrocarbons.

Latex gloves are perfect to use in construction, masonry, and even landscaping.

Micropore Nitrile Gloves

Micropore nitrile gloves work best for oily grip. These gloves consist of different suction cups which absorb all the oil and liquid providing a firm grip.

This coating doesn’t work well with adhesives, but the outcome is highly abrasion-resistant.

Polyurethane Coated Gloves

Polyurethane-coated gloves come with the best stretch and flexibility. These gloves work well for delicate applications, and the coating offers flexibility.

Polyurethane-coated gloves are resistant to all kinds of liquids, including oil. It is also heat resistant, but these gloves are not recommended to use above 79 degrees celsius. These polyurethane gloves work perfectly well for aerospace, fine part handling, and even with assembly and inspection.

PVC Gloves

PVC gloves work the best with adhesives, and they are abrasion-resistant. The adhesives won’t stick on the gloves so that you can work without any hassle. These gloves are best when working with furniture, automotive assembly, and trim applications.

These PVC gloves are perfect to use within cold conditions, and these PVC gloves are flexible but not tactile with rubber products.

Neoprene Coating Gloves

Neoprene coating gloves are synthetic rubber that also comes with chemical stability and heat resistance. These gloves are suitable for chemical-resistant and fire-retardant installations.

Neoprene coating will provide a dry, oily, and wet grip, but it has low resistance towards abrasion.

Final Verdict!

Nitrile foam grip gloves are more versatile do not easily break down, delaminate or blister-like other coating materials in general. This makes nitrile foam gloves a choice for jobs that require a high degree of sensitivity and dexterity, especially when grip is important such as assembly, construction, painting, working on automotive, handling small oily parts and components, gardening, machining, maintenance, warehouses, and trucking. Recreationally, they are also great for gardening, and various outdoor activities that require grip in wet conditions, like boating, fishing, hiking, and biking.

Looking for comfortable grip gloves should be your topmost priority so that there is no chance of removing these grip gloves and damaging your skin and hands.

Nitrile foam grip gloves will become your new favorite with a long-lasting experience.

2 notes

·

View notes

Text

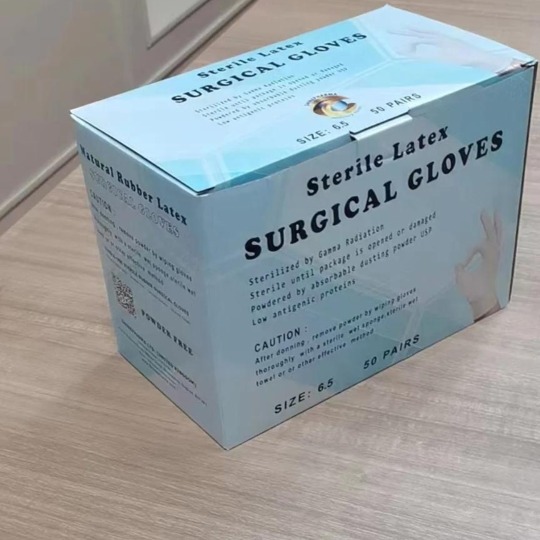

Surgical Gloves: The Importance of Choosing the Right Ones for Your Practice

Any medical procedure requires the use of surgical gloves. In addition to shielding the user from damage, they help stop the spread of illness to other patients. It might be difficult to determine which surgical gloves are appropriate for your needs given the huge range on the market. In this post, we'll look at the various categories of surgical gloves and discuss how to pick the best ones for your clinic.

Types of Surgical Gloves

The most popular type of surgical gloves are latex ones. They are cozy to wear and provide great defense against bloodborne infections. But, some people may experience allergic responses, so it's crucial to have substitutes on hand.

Gloves made of nitrile - They are a great substitute for latex gloves. They are made of a synthetic material that has great chemical and puncture resistance, is hypoallergenic, and is hypoallergenic. Moreover, they provide exceptional tactile sensitivity and are pleasant to wear.

Vinyl Gloves - The least priced alternative, these gloves provide effective pathogen defense. They can't be used in high-risk circumstances since they are not as reliable as latex or nitrile gloves.

Choosing the Right Surgical Gloves for Your Practice

The kind of treatment, the level of danger, and the wearer's comfort are all things to keep in mind when selecting surgical gloves for your business.

Process Type - The degree of protection necessary will depend on the kind of procedure being done. It is advised to use gloves with a higher level of protection, such as nitrile gloves, during high-risk procedures like surgery.

Risk Level - The kind of gloves required will depend on the degree of danger associated with the procedure. When handling blood or other bodily fluids, for instance, it's imperative to wear gloves that provide the highest level of pathogen protection.

Comfort - Another important aspect to take into account is the gloves' level of comfort. Uncomfortable gloves that are excessively tight or too loose can impair the wearer's dexterity and cause errors during the procedure. It's crucial to pick gloves that fit well and give the user enough flexibility.

Conclusion

Surgical gloves are a crucial component of any medical procedure, to sum up. They shield the wearer from injury and stop patients from getting sick. It's crucial to take the type of procedure, the level of danger, and the wearer's comfort into account while selecting surgical gloves. By taking these aspects into account, you can guarantee that you are utilizing the correct gloves for your practice and giving the best possible treatment to your patients.

3 notes

·

View notes

Text

Gorilla Chem II

Nitrile rubber glove, Washed, Comfortable, Reusable Fingertip precision, Good dexterity Good grip - Reverse Lozenge grip pattern Flocked for ease in donning and doffing and comfort during use Good solvent resistance Reduced risk of allergic reactions Free of extractable proteins, Silicon free Formulation Ingredients compliant with FDA/EU Regulations for use in repeated contact with foods.

Origin: Sri Lanka

Application:

Exposure to chemicals/solvents/ petroleum chemicals/petroleum hydrocarbons Printing industry, Petrochemical industry Metal fabrication, Chemical processing/Oil refining Cleaning and degreasing Chemical plants and transportation Surface coating, Aerospace workshop Food processing/food handling Automotive workshop, Laboratories Janitorial and maintenance work.

2 notes

·

View notes

Text

NitrileGloves

Check out our variety of nitrile gloves. These chemical-resistant disposable gloves are perfect for food preparation or chemical handling & even dentists. For #NitrileGloves, visit: https://www.adamdental.com.au/infection-control/gloves

0 notes

Text

Is nitrile rubber abrasion resistant?

Nitrile rubber is valued for its toughness, oil, fuel, and chemical resistance, as well as its high abrasion resistance. Its temperature flexibility and wear resistance make it ideal for a wide range of applications. However, when selecting abrasion-resistant materials, consider abrasion type, chemicals, temperature, and environment. The abrasion resistance of nitrile rubber is influenced by its quality and formulation, emphasizing the importance of selecting the appropriate grade for optimal performance.

Check the best Cut-resistant Gloves here: https://www.wholesaleworkwearsupply.com/index.php?route=product/category&path=19047_19048_19050

#wholesaleonlinegroup#wholesaleworkwearsupply#wholesalesafetysupply#wholesale#wholesalevendors#workwear#safetywear#safetysupply#shopnow

0 notes

Text

Comprehensive Analysis: The Persistent Issue of Substandard Rubber Gloves and Strategic Improvements

Rubber gloves are indispensable in many sectors, including healthcare, food processing, and cleaning. They act as a critical barrier against contamination and facilitate adherence to hygiene protocols. Despite their crucial role, there is a widespread issue with the quality of these gloves: they frequently fail, tearing or breaking during use. This not only poses safety risks but also leads to inefficiency and increased costs due to frequent replacements.

Unpacking the Issue: Why Do Rubber Gloves Fail?

The core problem with rubber gloves often boils down to their production and material composition. Most are crafted from materials like latex, nitrile, or vinyl, which vary in terms of strength and elasticity. To cut costs, manufacturers might opt for cheaper materials or thinner designs, which, while economical, compromise the glove's integrity and functionality.

Environmental factors also play a role. For instance, rubber gloves are sensitive to conditions such as extreme temperatures and exposure to UV light, which can degrade the material properties and lead to quicker deterioration. Moreover, the standard practice of mass-producing gloves in limited sizes can result in a poor fit for many users, exacerbating the likelihood of tearing.

Strategies for Enhancing Glove Quality

The solution to this pervasive issue lies in revamping the manufacturing approach. Investing in high-quality materials and adopting advanced technologies in glove production can lead to stronger, more resilient products. For example, integrating double-dipping techniques in the production of nitrile gloves can enhance their puncture and chemical resistance.

Additionally, manufacturers should consider expanding their size range to provide a better fit, which would reduce stress on the material at critical points and decrease the risk of breakage. Implementing stringent quality assurance processes to monitor every batch of gloves for defects before they hit the market is equally important.

Optimal Solution: The Forpro Website's Dedication to Quality

For individuals and businesses in search of dependable rubber gloves, the Forpro website represents a prime resource. Forpro specializes in offering superior-quality gloves that are engineered to withstand rigorous use without losing their integrity. The selection available through the Forpro website includes options that are meticulously tested to meet high durability standards.

The Forpro website also takes a dual approach to customer engagement, ensuring that each visitor has a seamless experience. From detailed product descriptions and authentic user reviews to interactive guides that help with sizing and material selection, the Forpro website makes it easier for customers to find gloves that suit their specific needs. Moreover, the Forpro website is committed to customer satisfaction, providing exceptional support to assist with inquiries and facilitate a hassle-free shopping experience.

In Conclusion

The frequent failure of rubber gloves is a significant challenge that affects safety and operational efficiency across various industries. This problem necessitates a shift towards better manufacturing practices and the use of advanced materials. Platforms like the Forpro website play a crucial role by offering high-quality alternatives that meet the needs of discerning buyers. By choosing better-quality products, users can enhance their safety protocols and reduce the overall cost associated with glove replacements. The future of rubber gloves lies in the hands of both manufacturers, who must elevate standards, and consumers, who should demand and choose quality and reliability over mere cost savings.

0 notes

Text

Nitrile Butadiene Rubber Market Report: Trends, Analysis, and Projections

Nitrile Butadiene Rubber (NBR) is a synthetic rubber with excellent oil and chemical resistance, making it indispensable across various industries. This blog explores the dynamics of the global NBR market, analyzing key drivers, applications, emerging trends, and future growth prospects.

Understanding the NBR Market:

Nitrile Butadiene Rubber (NBR) Also known as Buna-N or Nitrile Rubber, is a versatile elastomer synthesized from butadiene and acrylonitrile monomers. Its unique properties such as oil resistance, heat resistance, and durability make it a preferred material in automotive, oil and gas, aerospace, healthcare, and industrial applications.

Market Dynamics:

Automotive Sector: NBR is extensively used in automotive applications such as seals, gaskets, hoses, O-rings, and fuel system components due to its resilience to oils, fuels, and harsh environments, contributing to vehicle performance and reliability.

Oil and Gas Industry: NBR seals, gaskets, and O-rings are vital in oil and gas equipment, pipelines, and offshore installations, providing sealing solutions that withstand hydrocarbons, chemicals, and extreme temperatures.

Medical and Healthcare: NBR's compatibility with a wide range of fluids and sterilization methods makes it ideal for medical gloves, seals in medical devices, tubing, and pharmaceutical packaging, ensuring safety, hygiene, and product integrity.

Industrial Applications: NBR finds applications in industrial machinery, pumps, hydraulic systems, conveyor belts, seals for industrial equipment, and vibration isolation mounts due to its resilience and mechanical properties.

Applications Across Industries:

Automotive: Seals, gaskets, hoses, O-rings.

Oil and Gas: Seals, gaskets, O-rings, hoses.

Medical: Gloves, seals, tubing, pharmaceutical packaging.

Industrial: Seals, conveyor belts, vibration mounts.

Market Trends:

High-Performance Grades: Increasing demand for high-performance NBR grades with enhanced oil resistance, heat resistance, low-temperature flexibility, and compatibility with various fluids, meeting stringent industry standards and performance requirements.

Bio-Based NBR: Growing interest in bio-based and sustainable rubber materials drives research and development efforts towards bio-based NBR formulations, aligning with environmental sustainability goals and reducing dependency on fossil fuels.

Advanced Manufacturing Processes: Innovations in NBR production processes, compounding techniques, and polymer additives improve material properties, processing efficiency, and cost-effectiveness, driving market competitiveness.

Future Prospects:

The global NBR market is poised for steady growth, driven by the expanding demand from key industries, technological advancements, and sustainability initiatives. Investments in research, product development, and market expansion strategies will shape the market's trajectory and unlock new opportunities for stakeholders.

Conclusion:

Nitrile Butadiene Rubber (NBR) continues to be a critical material in various industries due to its unique properties and versatile applications. Understanding market trends, technological innovations, and sustainability imperatives is essential for stakeholders in the NBR market to capitalize on growth opportunities and address evolving industry needs effectively. With a focus on performance, sustainability, and application diversification, the NBR market presents promising prospects for continued growth and innovation in the global rubber and elastomer industry landscape.

0 notes

Text

Disposable Medical Gloves Market Analysis, Growth by Top Companies, Trends by Types and Application, Forecast to 2031

The global Disposable Medical Gloves Market has been witnessing steady growth, driven by a combination of factors such as increasing awareness regarding hygiene standards, rising healthcare expenditure, and the ongoing COVID-19 pandemic. According to recent market analysis, the market was valued at USD 12,290 million in 2022 and is projected to reach USD 16,309 million by 2030, with a CAGR of 3.6% during the forecasted period of 2023-2030.

Report Scope and Market Analysis

The report encompasses a comprehensive analysis of the disposable medical gloves market, including market size, growth drivers, challenges, and opportunities. It delves into various segments such as material type (latex, nitrile, vinyl, and others), application (surgical gloves, examination gloves), end-user (hospitals, clinics, ambulatory surgical centers, diagnostic centers), and geography.

The market analysis reveals a growing demand for nitrile gloves, attributed to their superior puncture resistance, chemical resistance, and allergen-free properties compared to latex gloves. Additionally, the surge in healthcare-associated infections (HAIs) and the need for stringent infection control measures have propelled the adoption of disposable medical gloves across healthcare facilities worldwide.

Download Free Sample Report: https://www.snsinsider.com/sample-request/2899

Impact of the Russia-Ukraine Conflict

The recent Russia-Ukraine conflict has had significant implications for the disposable medical gloves market. The conflict has disrupted the supply chains of raw materials used in glove manufacturing, leading to shortages and price fluctuations. Countries heavily reliant on imports for raw materials, such as nitrile butadiene rubber (NBR), have experienced supply constraints, impacting glove production and distribution globally. As geopolitical tensions persist, the market may continue to face challenges in raw material sourcing and pricing stability.

The Impact of Economic Slowdown

The disposable medical gloves market has also been affected by the broader economic slowdown induced by the COVID-19 pandemic. Economic uncertainties, supply chain disruptions, and fluctuating demand have influenced market dynamics. While the pandemic initially fueled demand for disposable medical gloves due to heightened hygiene protocols and increased healthcare activities, the economic slowdown in certain regions has dampened market growth to some extent. However, the long-term outlook remains positive, driven by sustained demand from healthcare facilities and growing awareness of infection control measures.

Regional Analysis

Regionally, North America dominates the disposable medical gloves market, driven by the presence of a well-established healthcare infrastructure, stringent regulatory standards, and high awareness regarding infection control practices. Asia-Pacific is poised to witness significant growth, fueled by rising healthcare expenditure, increasing prevalence of infectious diseases, and expanding healthcare infrastructure in countries like China, India, and Southeast Asian nations.

Key Takeaways and Recent Developments

Key takeaways from the disposable medical gloves market include the growing emphasis on quality and compliance with regulatory standards, increasing adoption of synthetic gloves over latex due to allergy concerns, and strategic initiatives by market players to expand their product portfolios and geographical presence through mergers, acquisitions, and partnerships.

Recent developments in the market include innovations in glove technology to enhance comfort, dexterity, and durability, as well as efforts to address sustainability concerns through the development of eco-friendly glove materials and recycling initiatives.

In conclusion, the disposable medical gloves market continues to evolve in response to changing healthcare needs, regulatory requirements, and global events such as the Russia-Ukraine conflict and the COVID-19 pandemic. Despite short-term challenges, the market is poised for steady growth driven by increasing hygiene awareness, rising healthcare expenditure, and ongoing efforts to combat infectious diseases.

0 notes

Text

A Guide To Choosing The Right Safety Gloves

Medical gloves are plentiful, but identifying the right one is complicated and crucial. The various options include powdered, non-powdered, latex, nitrile and much more. While choosing medical gloves you may have choices between different materials. Latex, nitrile, and vinyl are the basic options opted generally.

Before choosing any infection control products especially gloves, analyze its purpose. Trusta provides high quality Gloves and it is the best Infection Control Products Manufacturers in Oman, which includes other infection control products such as Face Masks, Respirators, Gloves, Disinfectants, Sterilization Products, Barrier Products and Disposables.

The thing that you have to take care of is that the gloves must not split or tear. Nitrile and latex medical gloves are more tough and it seems hard enough to get torn compared to vinyl gloves. Trusta Provides the Best Latex Medical Examination Gloves in Oman, which guarantees high durability and efficiency throughout the procedure. Therefore choose only the right materials which are strong and resilient.

For medical purposes such as handling instruments or feeling for a vein then you require sensitivity. Close fitting and stretchy latex gloves are the best choice for this type of use. Thin nitrile medical gloves can also perform efficiently but they are less sensitive than latex gloves. Vinyl gloves are not at all good for these tasks. Therefore check the sensitivity that the gloves offer while you choose.

A glove that suits well without loose and also stretches would provide a good balance. Latex is the best material to manipulate the fingers. A latex medical glove offers flexibility in sizing too as the glove will stretch to fit even when a smaller glove is really required. Hence, make sure you buy a stretchable one for your needs.

If the gloves you choose are not that stretchable it might go tearing. Latex and nitrile are tear resistant especially across the cuff. If they are prone to a risk of puncture , it would start splitting. Choose your gloves which are highly resistant to tearing and splitting.

Different tasks that use instruments and small objects like tools would require different gripping capability. In addition there are tasks that involve moving patients and it’s important to keep them comfortable as well. Therefore too much grip would hurt them and we do not require too much grip capability.

It is rare to require resistance to corrosive chemicals in a medical field. Latex, nitrile and vinyl gloves are not made with this property. Nitrile gloves have some resistance to a wide range of chemicals but latex have poor resistance to oil-based chemicals. Hence, ensure the chemical resistance too.

Apart from all these some gloves such as Latex gloves might cause allergies to some people. It can be mild to severe. The reaction can be due to the direct touch with the glove or through the powder in it. For that reason, choose your gloves carefully which do not cause such allergic reactions.

However protection is the primary goal of wearing gloves but every glove could not promise the equal level of safety and protection, Latex and nitrile gloves are excellent in pretending. As Vinyl gloves provide less protection it has been used in lower medical risk . Therefore keep in mind that the resilience, strength, and resistance to tearing and splitting are all relevant here.

For the best quality gloves visit our website or contact our crew for further assistance.

0 notes

Text

Hand in Glove: Exploring the Protective Gloves Market

Protective gloves serve as a vital line of defense for workers across various industries, shielding their hands from a myriad of hazards including chemicals, cuts, abrasions, and punctures. From construction sites to healthcare facilities, the protective gloves market plays a crucial role in ensuring the safety and well-being of workers worldwide. In this article, we delve into the dynamics of the protective gloves market, examining key trends, innovations, and considerations shaping the industry.

The protective gloves market encompasses a wide array of gloves designed to provide specific levels of protection against different types of hazards. These include disposable gloves made from materials such as latex, nitrile, and vinyl, which are commonly used in healthcare, food handling, and laboratory settings to prevent cross-contamination and ensure hygiene. Additionally, there are heavy-duty gloves crafted from leather, synthetic fibers, and specialized coatings, which are utilized in construction, manufacturing, and industrial environments to safeguard against mechanical, chemical, and thermal risks.

One of the notable trends in the protective gloves market is the increasing emphasis on comfort, dexterity, and ergonomic design. Traditionally, protective gloves were often bulky and restrictive, impeding manual dexterity and causing discomfort for users. However, advancements in materials science and manufacturing techniques have led to the development of thinner, lighter, and more flexible gloves that offer enhanced tactile sensitivity and maneuverability without compromising on protection. This trend towards comfort-driven design is particularly evident in industries where workers must perform delicate or precision tasks for extended periods, such as assembly, electronics, and healthcare.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS22125

Moreover, there is a growing demand for protective gloves that provide multi-hazard protection, addressing the diverse needs and challenges faced by workers in high-risk environments. Multi-purpose gloves with versatile features such as impact resistance, chemical resistance, and cut resistance offer comprehensive protection against a wide range of workplace hazards, reducing the need for workers to switch between different types of gloves for different tasks. Additionally, the integration of innovative technologies such as nanomaterials, microencapsulation, and smart textiles is enabling the development of next-generation gloves with enhanced performance and durability.

Another key trend driving the protective gloves market is the focus on sustainability and eco-friendliness. As awareness of environmental issues continues to grow, there is a rising demand for gloves made from renewable, biodegradable, and recycled materials, as well as those manufactured using eco-friendly production processes and practices. Additionally, initiatives to reduce waste and improve recycling rates for disposable gloves are gaining traction, with manufacturers exploring innovative solutions such as biodegradable gloves, reusable glove systems, and closed-loop recycling programs.

Furthermore, the COVID-19 pandemic has had a significant impact on the protective gloves market, driving increased demand for disposable gloves in healthcare, sanitation, and personal protective equipment (PPE) applications. However, the pandemic has also highlighted challenges related to supply chain disruptions, price volatility, and quality control issues within the global gloves industry, prompting calls for greater transparency, accountability, and resilience in the supply chain.

In conclusion, the protective gloves market continues to evolve in response to changing workplace dynamics, regulatory requirements, and societal expectations. With a growing emphasis on comfort, versatility, sustainability, and safety, manufacturers are innovating and diversifying their product offerings to meet the evolving needs of workers and industries worldwide. As the importance of hand protection remains paramount in ensuring workplace safety and productivity, the protective gloves market will continue to play a crucial role in safeguarding the health and well-being of workers across diverse sectors.

0 notes