#rockwell tester

Text

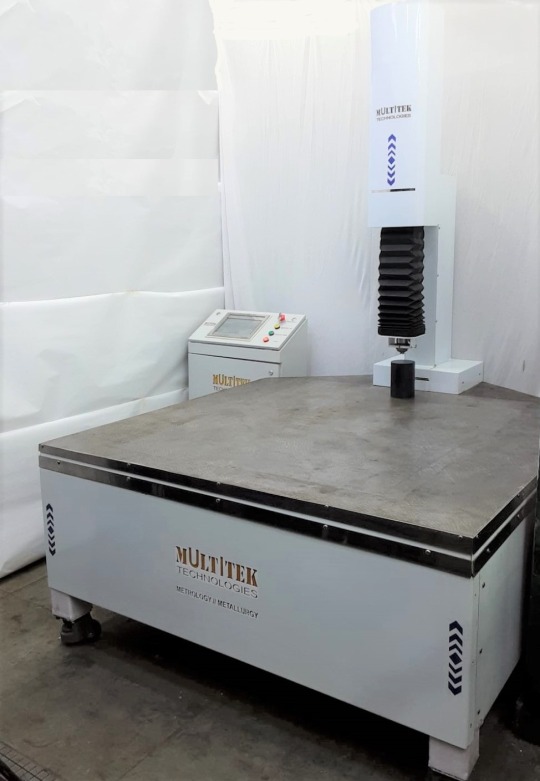

Rockwell Hardness Tester: A Comprehensive Guide by Multitek Technologies

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the knowledgebase on Rockwell Hardness Tester. In the world of material science and engineering, understanding the mechanical properties of materials is crucial for ensuring their quality and reliability in various applications. One of the key properties that engineers and manufacturers often need to measure is hardness. Hardness is defined as the resistance of a material to deformation, indentation, or scratching, and it plays a significant role in determining a material's suitability for specific uses.

Hardness testing is a widely used method for quantifying the hardness of materials. It involves applying a controlled force or pressure to the surface of a material and measuring the resulting indentation or penetration. There are several methods of hardness testing available, each with its own advantages and limitations. One of the most popular and widely used methods is the Rockwell hardness test.

Why Rockwell Hardness Tester?

The Rockwell hardness test is a non-destructive testing method used to measure the hardness of metallic materials. It is based on the depth of penetration of an indenter into the material under a specific load. The test is named after its inventor, Stanley P. Rockwell, who developed the method in the early 20th century.

The Rockwell hardness test is known for its simplicity, speed, and accuracy, making it suitable for a wide range of applications across various industries. It is particularly well-suited for quality control and materials testing in manufacturing environments.

What are the Principles of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of measuring the depth of penetration of an indenter into the material under two loads: a minor load to establish a reference position (preliminary load), and a major load to complete the test (additional load). The difference in indentation depths between the two loads is used to calculate the Rockwell hardness number.

The Rockwell hardness scale is defined by a combination of the indenter type (diamond or ball) and the applied load. There are several Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell hardness tester consists of several key components:

Indenter: The indenter is the tool that is pressed into the material to create the indentation. In Rockwell testing, the indenter can be either a diamond cone or a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil provides a stable surface against which the material being tested is placed. It ensures that the material is properly supported and prevents any deflection during the test.

Load Application System: The load application system applies the predetermined loads to the indenter. It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads. Feel Free to Navigate about Multitek’s Other Products/Machines

Depth Measurement System: The depth measurement system accurately measures the depth of penetration of the indenter into the material under the applied loads. This measurement is crucial for calculating the Rockwell hardness number.

Display and Readout: The display and readout system provides the results of the hardness test in the form of Rockwell hardness numbers. It may include analog or digital indicators, depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell hardness test involves the following steps:

Prepare the Specimen: Ensure that the surface of the specimen is clean, flat, and free from any contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter and Scale: Choose the appropriate type of indenter (diamond or ball) and the Rockwell scale based on the material being tested and the expected hardness range.

Apply the Preliminary Load: Apply the minor load to the indenter, which establishes a reference position on the specimen surface.

Apply the Additional Load: Apply the major load to the indenter, which creates the indentation on the specimen surface.

Release the Load: Release the major load while maintaining the minor load, allowing the indenter to partially retract from the specimen surface.

Measure the Depth of Penetration: Use the depth measurement system to accurately measure the depth of penetration of the indenter into the material.

Calculate the Rockwell Hardness Number: Calculate the Rockwell hardness number using the formula specified for the selected Rockwell scale.

Record the Results: Record the Rockwell hardness number along with relevant details such as the test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

Micro Vickers or Universal Hardness Tester

Brinell hardness Testing (BHN & LCB)

Rockwell Hardness Testing (RMT-AL & RHT-LC1500-1A)

Rubber Hardness Testing Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness test offers several advantages over other hardness testing methods:

Versatility: The Rockwell hardness test can be used to measure the hardness of a wide range of metallic materials, including ferrous and non-ferrous metals.

Speed: The test is relatively quick to perform, allowing for high throughput in quality control and production environments.

Accuracy: The Rockwell hardness test provides accurate and repeatable results, making it suitable for precise materials testing and characterization.

Non-Destructive: Unlike some other hardness testing methods, such as the Brinell test, the Rockwell test is non-destructive, meaning it does not significantly alter the specimen's properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications across various industries, including:

Manufacturing: The test is commonly used for quality control and materials testing in manufacturing processes, such as automotive, aerospace, and machinery production.

Metalworking: The test is used to assess the hardness of metal components, including forgings, castings, and heat-treated parts.

Engineering: The test helps engineers and designers select materials with suitable hardness properties for specific applications, such as tooling, dies, and machine components.

Construction: The test is used to evaluate the hardness of construction materials, such as steel beams, structural components, and concrete.

Research and Development: The test is employed in research and development activities to characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell Hardness Test Machines

According to Multitek Technologies the Rockwell hardness test is a versatile, accurate, and widely used method for measuring the hardness of metallic materials. Its simplicity, speed, and non-destructive nature make it an invaluable tool for quality control, materials testing, and engineering applications across various industries.

By understanding the principles, procedures, and applications of the Rockwell hardness test, engineers and manufacturers can ensure the quality, reliability, and performance of their products and components. Feel Free to Contact Us, if you have any question related to Rockwell Hardness Tester!

#rockwell hardness tester#rockwell tester#metallurgy#metrology#metalography#Metal Hardness Tester#Automotive Services#Multitek#Technologies#Delhi#India#engineering#mechanical#equipment#industrial#Machinary#Machine

0 notes

Text

The Importance of a Hardness Tester in Materials Production – Multitek Technologies

The hardness of a material is the property that enables it to resist deformation, bending, scratching, abrasion, or cutting. If you work in materials manufacturing, you probably already know that a hardness test is a crucial step in the production process for your products and the products you receive from third-party suppliers. You need to set baseline measurements and ensure that your products meet specific standards for strength. But if you’re not a materials engineer, you may be surprised to know that the hardness of any material is not an intrinsic property dictated by precise definitions and fundamental units of mass, length, or time. Instead, the value of a material’s hardness is the result of a specific measurement procedure.

For most materials of the modern age, a hardness test has usually been performed through a device that measures depth of an indentation left by a point of a specific shape, with a specific force, and for a specific amount of time. The most Knoop/Vickers Automated Hardness Testercommon hardness tests that measure the relationship between hardness and the size of the impression left by the test are the Rockwell, Brinell, and Vickers hardness tests.

Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the hardness of metals, alloys, and plastics, when compared to other methods. In the test, a diamond cone or hardened steel ball indenter is forced into the material being tested with a preliminary force that is usally 10 kgf. After equilibrium is reached, an additional load is applied which causes greater penetration of the material. Once equilibrium is reached again, the additional load is removed and the material rebounds slightly. The permanent depth of the indentation that remains is then used to calculate the Rockwell hardness number.

We at Multitek Technologies offer many testers which are used to measure not only Rockwell hardness, but also Brinell, Vickers, and Knoop tests. Give us a call or use our convenient online ordering to get the tester you need today. Browse our entire selection of hardness testers.

0 notes

Text

Rockwell, Analogue Hardness Testing Machine, Export type Rockwell Cum Brinell Hardness Tester, Special purpose Rockwell Hardness testing machine supplier, Manufacturer, Wholesaler in India, UAE, Saudi Arabia, Kuwait, Oman, Bahrain

0 notes

Text

Digital Touch Screen Rockwell

Digital Touch Screen Rockwell Hardness Tester is an advanced hardness testing instrument that incorporates digital technology and features a touch screen interface for conducting Rockwell hardness tests on various materials. It offers precise measurement capabilities, ease of use, and data management features. The touch screen interface provides a user-friendly and intuitive platform for operators to navigate through different settings, select test parameters, and view test results. The high-resolution touch screen display offers clear and detailed information, ensuring accurate and reliable readings.

#manufacture#industrial equipment#manufacturer#testing#metallographicequipments#metallurgical#rockwell hardness testing#hardness testing#rockwell hardness tester#hardness tester#hardness#hardness testing machine#rockwell hardness tester machine#digital touch screen rockwell hardness tester#rockwell hardness tester supplier#rockwell hardness tester manufacturer#rockwell hardness tester supplier in india#rockwell hardness tester manufacture in india#rockwell hardness tester supplier in uttar pradesh#rockwell hardness tester manufacture in uttar pradesh#rockwell hardness tester supplier in delhi#rockwell harness tester manufacture in delhi

1 note

·

View note

Link

If you're looking for a reliable, easy-to-use, and accurate hardness tester, this is the perfect tester for measuring the hardness of a material. It requires no preliminary calibration and measures a wide range of materials including non-ferrous and ferrous metals. This device features a motorized probe to eliminate human error and can measure hardness of even the thinnest of items.

0 notes

Text

App Dummy

*PING!*

Pulling the phone from his pocket, Mark smirked as he scrolled through his recent notifications. After months of tweaking and reconfiguring, the official CrissBaby Diaper App appeared fully operational. What better way to provide ease of control over CrissBaby’s entire product library than by allowing them to sync with mobile devices? No more fiddling around with a half-dozen remotes. Soon, control of all CrissBaby vibrators, robotic nursery aids, auto-locking fetish gear, and more would be paired with the convenience of a smartphone.

However, perhaps the feature that Mark was more proud of was the update he was allowed to make to every line of CrissBaby-branded diapers. Each and every nappy, from the thinnest of CrissBaby Pull-ups to the bulky might of the Super Absorber XXX, would soon house an array of microsensors capable of detecting all forms of diaper usage. Those pesky Littles won’t be able to hide those accidents anymore.

And which of those aforementioned pesky Littles would get to test out Mark’s latest and greatest innovation? Why, it would be none other than his darling baby girl and dutiful product tester, Shelby “Rocky” Rockwell. All it took was swapping out her usual CrissBaby padding for one with the microsensors embedded and voila! Now, he could keep track of how much of a good girl Rocky was being anytime, anywhere!

“Uh, Mark? Everything good?” said Rocky, catching a glimpse of Mark’s gleefully sadistic expression. It was a look she was all too familiar with. He was up to something, spiking both her anxiety and arousal simultaneously. Not wanting to masturbate to quell her rising lust for a second time today, she pushed on her bladder to stem her stimulation.

*PING!*

Mark’s phone once again, this time catching Rocky’s attention. “What do you keep giggling at on your phone?” she said, raising an eyebrow at how intently he was staring at his phone screen.

“Oh, nothing important,” replied Mark, snickering softly as a new “WET” alert popped up along the bottom of his screen. Rocky would surely be upsetti spaghetti once she found out the truth but for now, this new invention would be his kinky, little secret.

💜 Artwork By CodiBaby 💜

💕 Story By CrissieBaby 💕

For more of Rocky and Mark's ABDL antics, check out the full gallery of Test Dummy stories at https://www.deviantart.com/crissiebaby/gallery/78640127/test-dummy-series!

SubscribeStar: subscribestar.adult/crissiebaby

pixivFANBOX: crissiebaby.fanbox.cc

All CB Links: linktr.ee/crissiebaby

-------------------------------------------------------------

Special Thanks to Our CrissBaby Diaper Company Investors:

BlushyBen

DD

Gun1242

JFN

Joshy

LittlePissy

PrincessKittenLizzi

SissyDina

Strawberry

Sweetsamantharebecca

& Three Anonymous Investors

#diaper art#diaper stories#crissiebaby#little space#ab/dl#ab/dl stories#ab/dl art#diaper humiliation#crissbabydiaperco#ab/dl girl#codibaby#ab/dl caption#diaper captions#humiliation sissy#wetting diaper#dirty diaper#diaper messy#agepl@y#ab/dl community#ab/dl babygirl#dd lg babygirl#dd lg kink

89 notes

·

View notes

Text

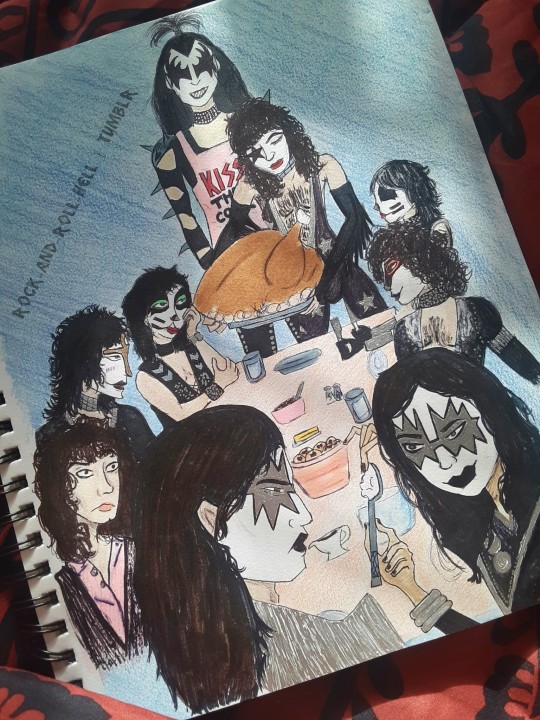

🦃 Happy Thursday! 🦃

This isnt as good as i imagined it lol.

I tried to do realistic at first but I couldn't get anyone but Tommy to look right so I just gave up and went cartoony. Tommy looks the best, ngl. I gave up when it came to Peter sadly.

Ace is going to fling potatoes at Tommy; bruce is concerned a food fight is going to start; My sister said it looks like Vinnie is giving eric 'bedroom eyes' which is not what I meant to do lol - him and eric are playing footsie under the table and Eric is the one flirting with him but 🤷🏻♀️😂; Eric Singer is adoringly gazing at Paul or gene; Paul is proud of the turkey he made; Gene is proud because he helped (he was Paul's taste tester); and peter is just hungry.

It's heavily based on a marvel parody of Freedom from Want, (also known as The Thanksgiving Picture) by Norman Rockwell I saw on pinterest.

#kiss#kiss fanart#kiss band#kiss army#art#Eric carr#ace frehley#vinnie vincent#bruce kulick#eric singer#paul stanley#peter criss#tommy thayer#gene simmons#the fox#the ankh warrior#the spaceman#the catman#the starchild#the demon#Thanksgiving

99 notes

·

View notes

Text

Rockwell Hardness Tester

A Rockwell Hardness Tester is a specialized instrument used to measure the hardness of materials, particularly metals. It operates on the principle of determining the depth of penetration of an indenter into the material under a specified load. The Rockwell hardness scale provides a numerical value that indicates the material's resistance to indentation or deformation. This type of tester is commonly employed in manufacturing, engineering, and quality control processes to assess the hardness properties of metal components, allowing for precise material selection and quality assurance. It typically features a dial or digital display for easy reading of hardness values and comes in various models suitable for different materials and testing requirements.

0 notes

Text

Ensuring Material Integrity: Best Practices for Fastener Material Testing

Manufacturer of Fasteners

Introduction:

Material testing is a critical aspect of fastener manufacturing, ensuring the integrity and quality of raw materials used in production. This article explores the best practices for material testing in fastener manufacturing, including methods, standards, and quality control protocols.

Objective:

This article aims to elucidate the importance of material testing in fastener manufacturing and highlight the best practices employed by manufacturers to ensure the quality and integrity of raw materials.

Stud Bolts and Nuts

Brief:

Material testing in fastener manufacturing involves the assessment of raw material properties such as chemical composition, mechanical properties, and microstructure. Various testing methods and standards are employed to verify material integrity and compliance with industry specifications.

Application:

Fastener manufacturers conduct material testing using advanced equipment such as spectrometers, hardness testers, and metallographic microscopes. Spectrometers analyze the chemical composition of raw materials to ensure they meet specified requirements for alloy composition and impurity levels. Carbon Steel Fasteners

Hardness testing is performed to assess the hardness of raw materials, which is a critical factor in determining the strength and durability of fasteners. Common hardness testing methods include Rockwell, Brinell, and Vickers hardness tests, which provide valuable insights into material hardness and mechanical properties.

Metallographic analysis involves examining the microstructure of raw materials to assess factors such as grain size, inclusion content, and phase distribution. This helps identify any defects or irregularities that may affect material performance and integrity.

Stainless Steel Bolt and Nut Manufacturers in India

Conclusion:

In conclusion, material testing is a critical aspect of fastener manufacturing, ensuring the integrity and quality of raw materials used in production. By employing best practices for material testing, including advanced testing methods, standards compliance, and quality control protocols, fastener manufacturers can uphold high standards of material integrity and deliver reliable and durable fastening solutions.

0 notes

Text

SPRING STEEL WIRES MANUFACTURERS IN DELHI

Joneja Steels Group (JSG) is diversified group of companies having 6 manufacturing plants in Faridabad (NCR Delhi Region), India with expertise in manufacturing different engineering products such as Bright Steel Bars, Steel Wires, Hydraulic Cylinders, and Precision Auto Components.

Joneja steel is one of the leading Spring Steel wires Manufacturers in Delhi as it is one reputed name in the field of steel industry. Being in the market for more than 35 years makes Joneja steel more trust worthy.

Joneja Steels Group (JSG) is diversified group of companies having 6 manufacturing plants in Faridabad (NCR Delhi Region), India with expertise in manufacturing different engineering products such as Bright Steel Bars, Steel Wires, Hydraulic Cylinders, and Precision Auto Components.

JSG originated in 1987 as Joneja Bright Steel Private Limited (JBSPL)it had dedicated manufacturing plants with advanced equipment, Automated Combined Drawing Machines, Draw Benches, Wire Drums, Inverted Bull Blocks, Peeling & Grinding Lines and Bell Annealing Furnaces. Over the years, JBSPL has grown to be the one-stop shop for most requirements of General Engineering Wires, Spring Steel Wires, Hard Bright (HB) Wires, Half Hard Bright (HHB) Wires, Wires for Spring Washers, Circlips, Cold Heading Quality Wires (CHQ) &Profiles, Shaped Bars, Cold Drawn Bars, Centre-less Peeled Bars and Ground Bars.

In 2020 under Prime Minister of India, Atmanirbhar Bharat (Made in India) initiative JSG established world class technology plant, Joneja Hydraulic Private Limited (JHPL)for manufacturing of Hydraulic Cylinders catering to all type of Construction Equipment, Fram Track and off Highway Vehicles. It has up to date CNC &VMC Machines, Welding SPMs, Automated Assembly, Washing and Paint Lines.

In 2021, JSG acquired and upgraded 100% Export Oriented Company, Greiner Engineering Products (GEP)with State of Art Technology CNCs and other Machineries for manufacturing of Precision Auto Components for Trucks & Trailers, 4 Wheelers, Cars and others.

JSG has its own Independent Testing Laboratory Unit Accreted by NABL having Spectrometer for chemical analysis, Tensile Testing Machines, Rockwell Hardness Testers, Micro scope image analyzer, salt spray and all related testing equipment’s required for Mechanical Properties Testing.

JSG boasts a team of qualified professionals dedicated to produce high-quality products with precision and adherence to quality systems Joneja Steels Group is a well established and technologically advance company with a strong focus on quality, innovation and diversification in its product offerings. The Strategic initiatives align with the make in India and self –reliance goal set by the Indian Government.

0 notes

Text

Tailoring the Rockwell Hardness Tester to Your Specific Needs: Customizable Options from Multitek Technologies

Multitek Technologies offers customizable options to tailor the Rockwell Hardness Tester to specific needs, making it an excellent choice for those who require a customized solution

The company understands that every customer has unique requirements and offers customizable solutions to meet those needs

Customized Rockwell Hardness Testers from Multitek Technologies offer a range of benefits, including greater accuracy and reliability, improved efficiency, and reduced costs

Multitek Technologies can help customers customize their Rockwell Hardness Tester to meet their specific requirements, providing excellent support throughout the process

Also offer AMC services for all machines that developed at multitek Lab.

For more information or to place an order, feel free to navigation our website at https://www.multitek.in or give us a call at +91-7836009888 or direct drop an email at [email protected]

Learn more how Rockwell Hardness Tester Work : https://www.youtube.com/watch?v=tOTuNt141Kc&t=30s

Subscribe our YouTube Channel for getting updates: https://www.youtube.com/@multitektechnologies

#Rockwell #HardnessTester #IndustrialEquipment #MultitekTechnologies #HardnessTesterMachine #MechenicalEngineering #Metallurgy #Metrology #MetalEngineering #RockwellTester #MetalTesting #MetalHardnessTester #AutomotiveIndustry #Automobile #Forging

#Rockwell Hardness#Hardness Tester#Digital Rockwell#Hardness Tester Machine#Metallurgical Hardness Tester#Mechenical Equipment#Industrial Equipment

1 note

·

View note

Text

Material testing machines Manufacturer, Suppliers and Exporter in India

Material testing machines are used to measure the physical properties of materials, such as their strength, hardness, and ductility. These machines are used in a variety of industries, including construction, aerospace, and automotive.

There are many different types of material testing machines, each designed to test a specific property of a material. Some of the most common types of material testing machines include:

1.Tensile testing machines: These machines are used to measure the strength of a material under tension. They are used to test a wide variety of materials, including metals, plastics, and rubber.

2.Compression testing machines: These machines are used to measure the strength of a material under compression. They are used to test a wide variety of materials, including concrete, wood, and composites.

3.Impact testing machines: These machines are used to measure the toughness of a material. They are used to test a wide variety of materials, including metals, plastics, and ceramics.

4.Hardness testing machines: These machines are used to measure the hardness of a material. They are used to test a wide variety of materials, including metals, plastics, and ceramics.

Material testing machines are an essential tool for ensuring the quality and safety of materials. They are used to test materials for a variety of purposes, including:

Product development: Material testing machines are used to test new materials during the product development process. This helps to ensure that the materials are strong, durable, and safe for use.

Quality control: Material testing machines are used to test materials during the manufacturing process.

Failure analysis: Material testing machines are used to investigate the cause of material failures. This helps to prevent future failures and improve the quality of materials.

Material testing machines are a valuable tool for a wide range of industries. They help to ensure the quality and safety of materials, and they play an important role in product development, quality control, and failure analysis.

Here is a list of material testing machines commonly used in school and college laboratories:

1.Universal Testing Machine (UTM):

Tensile testing machine

Compression testing machine

Flexural testing machine

2.Hardness Testing Machine:

Rockwell hardness tester

Vickers hardness tester

Brinell hardness tester

3.Impact Testing Machine:

Charpy impact tester

Izod impact tester

4.Fatigue Testing Machine:

Rotating beam fatigue tester

Axial fatigue tester

5. Torsion Testing Machine:

Torsion tester for metal specimens

Creep Testing Machine:

Constant load creep tester

6. Bending Testing Machine:

Three-point bending tester

Four-point bending tester

7. Shear Testing Machine:

Direct shear testing machine

8. Abrasion Testing Machine:

Abrasion tester for wear resistance

9. Tear Testing Machine:

Elmendorf tear tester

10.Melt Flow Index Tester:

Used for measuring the flow properties of molten plastics

11.Non-Destructive Testing (NDT) Equipment:

Ultrasonic testing machine

X-ray testing machine

12. Moisture Content Testing Machine:

Moisture analyzer for determining moisture levels in materials

13.Vibration Testing Machine:

Used for assessing material response to vibrations

14.Thermal Conductivity Tester:

Determines the ability of a material to conduct heat

15. Gas Permeability Tester:

Measures the permeability of gases through materials

16. Electrical Conductivity Tester:

Evaluates the electrical conductivity of materials

17.Viscosity Testing Machine:

Measures the resistance of a fluid to flow

18. Particle Size Analyzer:

Determines the particle size distribution of powders and granular materials

19.Density Testing Machine:

Measures the density of materials

0 notes

Text

Standard Rockwell Hardness Tester

Standard Rockwell Hardness Tester is a widely used instrument for measuring the hardness of materials. It operates based on the Rockwell hardness testing principle, which involves measuring the depth of penetration of an indenter into the material under a specific load. The Rockwell hardness scale provides a numerical value that represents the material’s resistance to indentation. Standard Rockwell hardness testing is commonly employed in industries such as manufacturing, metallurgy, and quality control to assess the hardness and mechanical properties of materials. The test results obtained from the Standard Rockwell Hardness Tester can help in material selection, process control, and product evaluation.

Rockwell hardness test, Rockwell hardness tester, Hardness measurement, Material hardness testing, Indentation hardness test

#manufacture#industrial equipment#metallurgical#manufacturer#metallographicequipments#hardness#hardness tester#hardness testing#rockwell hardness tester#rockwell hardness testing#rockwell hardness test#Indentation hardness test#Material hardness testing#Hardness measurement#rockwell hardness tester manufacturer#rockwell hardness tester supplier#rockwell hardness tester manufacture in india#rockwell hardness tester supplier in india#rockwell hardness tester supplier in uttar pradesh#rockwell hardness tester manufacturer in uttar pradesh

1 note

·

View note

Text

Hardness Testing Machines, Vickers Hardness Testers, Manufacturer<

Hardness Testing Machines, Vickers Hardness Testers, Manufacture

Hardness Testing Machine, Vickers Hardness Tester, Brinell Hardness Testing Machines, Rockwell and Combined Hardness Tester, Manufacturer, India.

0 notes

Text

Rockwell hardness tester

Link: https://www.autocontrolcable.com/factory/

0 notes

Text

what is injection molding

Established in 2011, Prototool is a prominent manufacturing and processing enterprise in China, holding ISO9001 and IATF16949 certifications.

Our specialization encompasses a range of advanced processes including non-standard mechanical component processing, milling-turning compound processing, precision CNC machining, custom injection molding, mold manufacturing, high-volume metal die-casting, and 3D printing rapid prototyping.

Prototool boasts extensive experience in industries such as new energy, automotive, telecommunications, automation equipment, consumer goods, aviation, and medical devices. Over years of development, we have evolved into an innovative technology company that seamlessly integrates research and development, production, and sales.prototype injection molding

Our facilities comprise hundreds of high-precision machining centers, high-speed lathes, milling machines, combined milling-turning machines imported from Japan, the United States, and Europe. We also possess precision injection molding machines, dual-color injection molding machines, all-electric injection molding machines, and a comprehensive array of quality inspection instruments.

The highest precision of our 5-axis machining center reaches 0.05mm, while the precision of our high-precision milling-turning machines reaches 0.005mm. Our monthly production capacity can exceed 2 million units.

Our machinery includes a 5-axis automatic coordinate measuring machine (CMM), automated optical projector, surface roughness tester, and Rockwell hardness tester.

Prototool has amassed a wealth of experience in the manufacturing industry and serves distinguished clients like Tesla, Porsche, BYD, and other renowned enterprises.

1 note

·

View note