#Machinary

Text

Tony is back out on the fields again today.

Rolling on into the evening...

8 notes

·

View notes

Text

i fucking love robots i love you body horror but the insides are made of wires and hardware i love you mechanical divinity i love you man-made objects that feel alive i love you "the machine is breathing" i love you i love you i love you

#rana thoughts#machinary#robots#deus ex machina#yes this is about GlaDOS#but also all the living breathing machines we know and love both in fiction and real life#body horror kinda

29 notes

·

View notes

Note

kicks my feet. ive never done the titles things before but. titles relating to machinery and mechanical hands/arms?

🪦 ⌕ mechanical hands/arms themed titles 。。。

the one whose arms are mechanical , the one whose hands are mechanical , the one with mechanical arms , the one with mechanical hands , the one of metal arms , the one of metal hands , the one whose arms whirr when (pronoun) moves them , the one whose hands whirr when (pronoun) moves them

🩸 ⌕ note 。。。 robot themed titles can be found here. i mainli think of robots when i think of machineri so the titles i would provide would probabli be veri similar. sorri that there’s not a lot tho (there and here…i wasn’t realli sure how to tackle this prompt…whoops (not your fault tho)) </3 aniways. i am kicking my feet back at you. kicking feet buddies!!! hope we don’t get into a feet kicking fight….. /silli

6 notes

·

View notes

Text

Transformer Trade

Transformer: A device that steps up or steps down the voltage as it transmits electrical energy from one alternating-current circuit to one or more other circuits. Transformers are used for a wide range of functions, including raising the voltage from electric generators to enable long-distance transmission of electricity and lowering the voltage of conventional power circuits to run low-voltage devices like doorbells and toy electric trains.

Transformers work by inducing current in a second coil known as the secondary as the magnetic lines of force (flux lines) build up and contract in response to variations in current flowing through the primary coil. The number of turns in the secondary coil divided by the number of turns in the primary coil, known as the turns ratio, is multiplied by the primary voltage to determine the secondary voltage.

The currents used for radio transmission are transferred by air-core transformers, which are made of two or more coils coiled around a solid insulating material or on an insulating coil shape. Similar duties are performed by iron-core transformers in the audio frequency range.

Transformer On Rent

Perennial Technologies provide a transformer for hire in monthly basis.

2 notes

·

View notes

Text

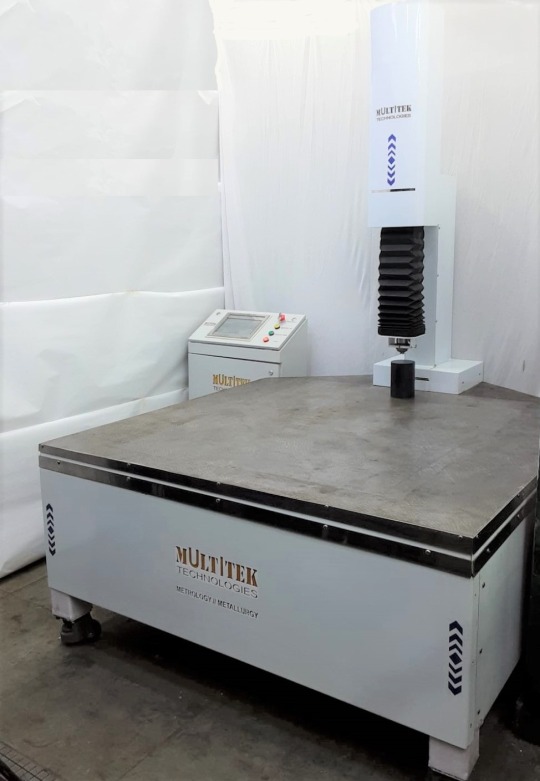

Rockwell Hardness Tester: A Comprehensive Guide by Multitek Technologies

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the knowledgebase on Rockwell Hardness Tester. In the world of material science and engineering, understanding the mechanical properties of materials is crucial for ensuring their quality and reliability in various applications. One of the key properties that engineers and manufacturers often need to measure is hardness. Hardness is defined as the resistance of a material to deformation, indentation, or scratching, and it plays a significant role in determining a material's suitability for specific uses.

Hardness testing is a widely used method for quantifying the hardness of materials. It involves applying a controlled force or pressure to the surface of a material and measuring the resulting indentation or penetration. There are several methods of hardness testing available, each with its own advantages and limitations. One of the most popular and widely used methods is the Rockwell hardness test.

Why Rockwell Hardness Tester?

The Rockwell hardness test is a non-destructive testing method used to measure the hardness of metallic materials. It is based on the depth of penetration of an indenter into the material under a specific load. The test is named after its inventor, Stanley P. Rockwell, who developed the method in the early 20th century.

The Rockwell hardness test is known for its simplicity, speed, and accuracy, making it suitable for a wide range of applications across various industries. It is particularly well-suited for quality control and materials testing in manufacturing environments.

What are the Principles of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of measuring the depth of penetration of an indenter into the material under two loads: a minor load to establish a reference position (preliminary load), and a major load to complete the test (additional load). The difference in indentation depths between the two loads is used to calculate the Rockwell hardness number.

The Rockwell hardness scale is defined by a combination of the indenter type (diamond or ball) and the applied load. There are several Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell hardness tester consists of several key components:

Indenter: The indenter is the tool that is pressed into the material to create the indentation. In Rockwell testing, the indenter can be either a diamond cone or a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil provides a stable surface against which the material being tested is placed. It ensures that the material is properly supported and prevents any deflection during the test.

Load Application System: The load application system applies the predetermined loads to the indenter. It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads. Feel Free to Navigate about Multitek’s Other Products/Machines

Depth Measurement System: The depth measurement system accurately measures the depth of penetration of the indenter into the material under the applied loads. This measurement is crucial for calculating the Rockwell hardness number.

Display and Readout: The display and readout system provides the results of the hardness test in the form of Rockwell hardness numbers. It may include analog or digital indicators, depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell hardness test involves the following steps:

Prepare the Specimen: Ensure that the surface of the specimen is clean, flat, and free from any contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter and Scale: Choose the appropriate type of indenter (diamond or ball) and the Rockwell scale based on the material being tested and the expected hardness range.

Apply the Preliminary Load: Apply the minor load to the indenter, which establishes a reference position on the specimen surface.

Apply the Additional Load: Apply the major load to the indenter, which creates the indentation on the specimen surface.

Release the Load: Release the major load while maintaining the minor load, allowing the indenter to partially retract from the specimen surface.

Measure the Depth of Penetration: Use the depth measurement system to accurately measure the depth of penetration of the indenter into the material.

Calculate the Rockwell Hardness Number: Calculate the Rockwell hardness number using the formula specified for the selected Rockwell scale.

Record the Results: Record the Rockwell hardness number along with relevant details such as the test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

Micro Vickers or Universal Hardness Tester

Brinell hardness Testing (BHN & LCB)

Rockwell Hardness Testing (RMT-AL & RHT-LC1500-1A)

Rubber Hardness Testing Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness test offers several advantages over other hardness testing methods:

Versatility: The Rockwell hardness test can be used to measure the hardness of a wide range of metallic materials, including ferrous and non-ferrous metals.

Speed: The test is relatively quick to perform, allowing for high throughput in quality control and production environments.

Accuracy: The Rockwell hardness test provides accurate and repeatable results, making it suitable for precise materials testing and characterization.

Non-Destructive: Unlike some other hardness testing methods, such as the Brinell test, the Rockwell test is non-destructive, meaning it does not significantly alter the specimen's properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications across various industries, including:

Manufacturing: The test is commonly used for quality control and materials testing in manufacturing processes, such as automotive, aerospace, and machinery production.

Metalworking: The test is used to assess the hardness of metal components, including forgings, castings, and heat-treated parts.

Engineering: The test helps engineers and designers select materials with suitable hardness properties for specific applications, such as tooling, dies, and machine components.

Construction: The test is used to evaluate the hardness of construction materials, such as steel beams, structural components, and concrete.

Research and Development: The test is employed in research and development activities to characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell Hardness Test Machines

According to Multitek Technologies the Rockwell hardness test is a versatile, accurate, and widely used method for measuring the hardness of metallic materials. Its simplicity, speed, and non-destructive nature make it an invaluable tool for quality control, materials testing, and engineering applications across various industries.

By understanding the principles, procedures, and applications of the Rockwell hardness test, engineers and manufacturers can ensure the quality, reliability, and performance of their products and components. Feel Free to Contact Us, if you have any question related to Rockwell Hardness Tester!

#rockwell hardness tester#rockwell tester#metallurgy#metrology#metalography#Metal Hardness Tester#Automotive Services#Multitek#Technologies#Delhi#India#engineering#mechanical#equipment#industrial#Machinary#Machine

0 notes

Text

youtube

#machine#machinary#business#business at home#home business#paper plate making machine#cup making machine#candle making#shoe making#management#trendingnow#viral trends#youtube#tamilnadu#trends#branding#wholesale#electronic#viral video#Youtube

0 notes

Text

Piotex deals with the Textile Weaving Machines and it is used for combining warp and weft components to make a woven structure and to hold the warp threads.

https://piotex.in/products/textile-weaving-machines/

1 note

·

View note

Photo

Merry Christmas All! This morning while stopping to get coffee before my workout I meet Steve. We are still here and going at it. This was supposed to BE (happen). So many gems of truth coming out of this conversation. Truly “Iron sharpens Iron.” Have you ever had one of those divine appointments that keep you stayed longer than usual? Those are God moments that are to be valued and cherished. We are are educating and equipping ourselves for kingdom influence for the upcoming year. I’ll get back to the gym later but first things first. “Seek First Heaven’s Design and Machinery and Everything else will fall in place.” Got it? May 2023 be even brighter. “The path of the righteous is like the morning sun, shining ever brighter till the full light of day. “ (Prov. 4:18). #purposeman #identity #plans #machinary #leaderdhipdevelopment #selfdiscoveryjourney (at West Palm Beach, Florida) https://www.instagram.com/p/CmjuZqarbdR/?igshid=NGJjMDIxMWI=

1 note

·

View note

Text

What Are the Types of Conveyors Used in Industrial Applications?

Manufacturers use conveyor frameworks in light of multiple factors. Most conveyors help laborers with moving massive or copious item materials. Conveyors' capacity to take responsibilities off representatives increment working environment efficiency and wellbeing. These powerful machines upgrade office space and further develop project stream.

Here are a few basic types of conveyors:

Bucket Conveyor

Bucket Elevators, which we discussed here, fall under this class. Bucket conveyor frameworks are used to move material in an upward direction, by scooping it with a progression of buckets connected to a belt, chain, or link. The conveyor moves the buckets up, gathering up the material, and conveying it to the top prior to unloading it out.

Gravity Roller Conveyor

The gravity roller conveyor is likewise one of the easiest kinds of conveyor frameworks and is additionally very reasonable. A progression of rollers are mounted on a side casing that gives the moving surface.

Chain Conveyors

Chain conveyors are useful for heavier items. Chains give thing versatility as they convey conveyor materials forward. Ordinarily, chain conveyors convey beds and enormous industrial holders. Because of their hard core use, these kinds of conveyors are regularly more slow.

Vibratory Conveyors

This conveyor vibrates marginally to move mass material along it. It tends to be a cylinder, a level top, or a box.

Powered Roller Conveyor

This resembles a gravity roller conveyor with the exception of a chain or belt is used to make the rollers turn all alone, so they don't need to be based on a decay. Once in a while they might in fact go uphill.

Salt Conveyors

One of the greatest benefits of using a Salt conveyor is its smooth surface. The design of brace conveyors permits items to be fixed and held set up during the migration. Salt conveyors have a two-strand chain framework with supports associated with the chain. The supports are then educated by a directing framework to guarantee the ideal situating.

Belt Conveyor

These conveyors are likewise named Conveyor belts by the vast majority and are really alluded to as the belting material wherein a belt framework is one of the least difficult conveyor types and moves parts from one spot to the next place by decreasing human endeavors.

Screw Conveyors

This is a cylinder with a screw-molded gadget inside that goes to move material. It's likewise alluded to as a drill conveyor.

In the event that you want assistance picking a conveyor framework, let us know. GWInnovation have more than 10 years of involvement dealing with projects huge (up to $30 million) and little. Contact Us.

1 note

·

View note

Text

Tony is muck spreading today 🚜

4 notes

·

View notes

Text

youtube

it be finished

i should make a playlist of my walkers

1 note

·

View note

Text

forever thinking about the tears on the cybermen suits

doctor who costume designers i love you

#cybermen best doctor who villian im RIGHT#the trope of trying to “elevate” the human race as metaphor for eugenics and comformity#THE TRYING TO ESCAPE DEATH VIA ESCAPING HUMANITY AND IN RETURN CREATING SOMETHING HORRIBLE TROPE#the inherent horror in all their episodes#like the cybermen episodes are so disturbing even as someone whos a Seasoned Horror Enjoyer and has watched them before#fucking amazing.#AND OHMYGOD HOW THEY DEAL WITH THE LOSS OF EMOTIONS AND THEREFORE HUMANITY#and the cautionary tale of replacing people with machinary#its just. perfect.#i could go on but i wont bc i reaalllyy need to write my essay... may elaborate on this later. may not. idk.#anyways. fuckin love the cyberman thank you for coming to my ted talk#doctor who#cybermen

42 notes

·

View notes

Note

What is the wildest piece of trivia from the game you know?

Coming from a wiki editor, I'm a behind the scenes historian. Some few examples include:

The fact the key promotional artist was semi-viral in the Spanish JoJo community.

The fact Jacksepticeye played a prior project from Genow (Robin is the game in question).

The fact Maki was the first character created in general.

The cut cutscenes between Vanessa & Hoaxe.

Being indirectly responsible for leaking new info about the game because I copied & pasted something from the discord server.

And the funniest one.

Genow accidentally liking a NSFW artist's SFW Kabbu fanart and being unaware on the content that person draws.

bold of you to assume i know any cool trivia that i didn't learn from the wiki lmao. EVERYTHING you just said is new information to me

like, some background lore i know is the "you shouldnt be able to use the compass in the beehive" argument, leif used to a lady named cerise, some of the characters came from an earlier version where the game was about sea creatures instead of bugs.

but yeah most of the trivia i know is throw away lines from having team snakemouth chit chat/talk to npcs that mean absolutely nothing to the overall game but mean everything to me <3

#fun facts from such throwaway lines#vi is Very Bad with machinary#she also wants own a shop#Leif is older than the invention of glasses#leif HATES “termite pop”#leif thinks that running something like the coliseum would be fun#kabbu is scared on the bridge from the hive to the tree#but he thinks that the bounce mushrooms are a lot of fun#he also wanted desperately to roll down the sand dunes for fun but leif and vi wouldnt do it cause they didnt want sand in their fur#the bees that work in the factory work several day shifts#iirc the bee in the hive running the shop. it was like literally her first day or something lol#when talking to the stickbug someone comments to leif 'not used to seeing someone taller than you huh?'#which is where ALL my tall leif proof comes from fuck the sprites i am correct#kabbu is incredibly curious and wants to buy everything from the junk seller on metal island#he sees a crack in the wall and he HAS to find out whats on the other side#i dont remember any more off the top of my head lol#ask#chit chat#aged-string

31 notes

·

View notes

Text

fun technology my universe has for handwaving physics purposes

a stellar sustainer, a device powered by a muno crystal [basically magic] which can make a star last billions of years longer than it should have [specifically for drekols home star which has a maximum natural lifespan of one billion years]

habitation/EC suit, a suit that can be either designed for a specific species or adaptive for any species which lets carbon based life survive in boron compatible environments and vice versa

planetary EC, a large satellite like machine which in 48 hours of charging can adjust the compatibility of a planet

planetary sustainer, a device which can keep a planets core from cooling down [specifically for ath which is a rogue planet]

A-speed engine, a device which turns light years travel distance into a few minutes to days

quasi-glass, a sheet of a semi-solid glass like substance which appears to make a "hologram" screen possible

#speculative biology#spec bio#speculative machinary#spec machines#exobiology#speculative world#ngiu◗#ath#lotred#◗ta#ap#drekol#fictional technology

12 notes

·

View notes

Text

I think if I was Wendell and lost my scholarship meaning I would have to work on busses i would literally die

#wendell bray#i am at work rn#i do not work i busses#but i work on machinary#i am going to literally die#poor wendell#this is very stupid lol

3 notes

·

View notes

Text

Avi Some Desperate Glory and Nirai Jujen would get along really well I think.

By which I mean one of them would kill the other by the end of the week. But like, before then.

2 notes

·

View notes