#3E-Manufacturing Industry

Text

#INDUSTRIES#3E-Offshore Oil and Gas Industry#3E-Renewable Energy Industry#3E-Wind Energy Industry#3E-Environmental Agency Industry#3E-Construction Industry#3E-Gas and Electric Utilities Industry#3E-Politics and Policy Making Industry#3E-Manufacturing Industry#3E-Real Estate Industry.#VALUES#3E-Honest communication#3E-Accountability#3E-Responsible decision making#3E-Respect for stakeholders#3E-Transparency#3E-Objectivity#3E-Compassion.#TRAITS#3E-Analytical#3E-Objective#3E-Perceptive#3E-Thorough#3E-Curious#3E-Resourceful#3E-Knowledgeable#3E-Persuasive#3E-Logical#3E-Insightful.#TENSIONS

0 notes

Text

#INDUSTRIES#3E-Retail#3E-Food and Beverage Industry#3E-Manufacturing#3E-Environmental Services#3E-Construction#3E-Transportation#3E-Energy#3E-Technology. . VALUES#3E-Environmental Responsibility#3E-Sustainability#3E-Community Building#3E-Political Awareness#3E-Social Sensitivity#3E-Reducing Consumption#3E-Growth of Greener Habits / TRAITS#3E-Commitment#3E-Compassion#3E-Collaboration#3E-Creativity#3E-Forward-Thinking#3E-Hope#3E-Problem-Solving#3E-Positivity#3E-Resourcefulness#3E-Responsibility#3E-Selflessness TENSIONS#3E-Environmental effects of plastic#3E-The case for systemic environmental change#3E-Personal lifestyle changes as a component of green activism

0 notes

Text

Thoughts on crafting systems

I have ranted a few times about how RPG (and CRPG) crafting systems fail in various ways. I want to offer a tongue-in-cheek universal crafting system for use in any game, then make some observations from various games and try to form a bit of general theory and positive suggestions.

The universal crafting system is this: "It takes twice as long and costs twice as much for your player character to make it, because your player character has specialized in Swords&Spells, not specialized in Anvils&Tannins."

Professional artificer NPCs with a costly immobile workshop, established contacts, years of experience, pounds of reagents, specialized tools, et cetera, et cetera, are almost certainly going to do a faster and better job than your wandering murderhobo PC. This goes double for any games in industrial, cyberpunk, space age, or similar settings, where your products are likely coming out of an assembly line that vastly outdoes anything an individual worker can do, even if that individual knows Haste. You can buy an assembly line factory with the gold you got from the dragon's hoard, but the manufacturing process is still not you doing it.

Now let me gesture at when this argument does and doesn't apply.

For D&D, it applies because while your party's druid might brew their own potions, it's almost certain your party is not going to brew potions and write scrolls and forge swords and enchant armor and learn the five different spells required to craft the Ring of Stars and muck around with extradimensional space to create a Bag of Holding and muck around with planar energies to create the Greater Chasuble of Frobblebrotz. D&D has a lot of magic items to craft and wear ('christmas tree syndrome') and you're going to be depending on NPCs for most if not all of them.

For M&M, it doesn't apply because your protagonist is plausibly the only one in the world who knows how to create his super-science invention, and/or the only one with access to the materials required to build it. There are few or no NPCs that the work can be farmed out to. Also, owning a workshop in M&M is much cheaper (1/5th of a build point), and its immobility is less restrictive when you can own a private jet.

For Shadowrun, it applies because Ares Macrotechnology makes your gun and Ares Macrotechnology makes your accessories. You get a bit of choice in which six of the bazillion tactical operator accessories you want to put on the gun. This customization is not crafting in the sense I'm talking about here.

For various "stranded on a [desert island/space station/arctic outpost/hell dimension]" games, it doesn't apply because there are few or no NPCs at all, artificers or not.

Exalted provides an interesting edge case, because on one hand your protagonist is an omnicompetent superhero (or supervillain) similar to M&M, on the other hand there's the Realm of the Scarlet Empress populated with another ten thousand of those. Also the Exalted 3e crafting system is unusually terrible even by the standards of crafting systems.

So... what is up with D&D? Why does it have a crafting system for magic items? Well, in a sense it doesn't. (I'm specifically referring to D&D 3e here because of its convenient public SRD rules.) What D&D 3e has is effectively a conversion system for turning Experience Points into Gold Pieces at a fixed rate. If you want a +1 Flaming Longsword, you could go to the magic items store and pay eight thousand gold, or you could pay four thousand gold and 320 experience points to enchant a longsword. The enchanted longsword can then help you recover the XP by stabbing trolls. Unlike the crafting systems of every other game mentioned above, this D&D process doesn't have a roll. There is no failure chance. There is no skill check. There's also no mention of tools or ingredients required, only "prerequisites" of being a level X caster who knows spell Y and feat Z.

D&D 3e's bizarre "crafting" conversion system also works in another way that I think was partly accidental: The ingredient cost of item enchantment is simply calculated as half the item's [marginal] retail price.

Retail price is in turn calculated by out-of-universe authors who are operating primarily on a system of "how beneficial is this magic item to PCs?" without regard for whether there's market demand or NPC interest. This makes for bizarre economics, but functional PC-centered gameplay. It's also without regard for intuitive notions of "how much magic" might be involved. For example, the Unguent of Timelessness.

When applied to any matter that was once alive this ointment allows that substance to resist the passage of time. Each year of actual time affects the substance as if only a day had passed.

It costs 150gp for one flask that can coat eight Medium-sized (i.e. human-sized) items. It never wears off. It even provides minor resistance to hostile magic.

By contrast, it costs 250gp for a flask of Silversheen that can coat one melee weapon, lasting one hour to make it "counts as silver" for assistance in stabbing werewolves and vampires.

Silversheen is more relevant and useful to freelance facepunchers, therefore Silversheen costs more gold, therefore Silversheen requires more expensive magical ingredients to create.

This is hilariously unrealistic and didn't catch on with other games, but in retrospect it worked out fine for D&D while just about every other game had a case of "the crafting system is terrible". I don't really mean to praise D&D 3e's crafting system here, either, but it's at least tolerable in play if occasionally absurd.

By contrast, the other systems mentioned...

M&M is quite rules-light: dispense with the notion of monetary cost, permanent items cost abstract character build points, temporary items only need time and skill checks.

Shadowrun 5e is rules-light for mundane items but overly complicated and imbalanced for magical items, with splatbook rules accidentally breaking the process wide open and letting characters turn a 20x profit. (Forbidden Arcana lets you spend refined reagents to raise the Limit by 5 on all Magic tests. The Force of a Focus is determined by a roll using Artificing+Magic [Formula Force] that says you can't spend Edge.)

Exalted 2e involved HUGE TIMEFRAMES to craft artifacts and HUGE SPEEDUP powers that gave speed multipliers from 2x to 15x, so buying several of these powers was effectively a tax on making daiklaves in less than a year. In theory there were 5 Craft subskills by elements, but in practice you took Craft (Fire) which covered the forge, almost anything metal can be fluffed as made with a forge.

Exalted 3e kept the HUGE TIMEFRAMES but also required you to spend time collecting ten rat tails, I mean crafting five mundane swords to get psyched up for crafting an artifact sword, then four more mundane swords before you could craft a second artifact sword. And it introduced multiple abstract crafting subsystem resources representing inspiration or something, idk. Resources were partly gained by crafting and partly at the end of each "story arc", also "per day but not if you timeskip", which mixed levels of abstraction to create an annoying incentive structure. You could spend subsystem resources instead of XP on raising the Craft skills, partly compensating for the fact that Exalted 3e is a game where "Melee" is a single skill for sword, club, dagger, glaive, guisarme, and flail, but "Crafts" are now many skills as finely divided as tailoring from tapestry-weaving. Also it introduced the "terminus" mechanic - if you try to make an artifact sword you must complete the project in X rolls, or else it permanently fails and you are forbidden to ever attempt that artifact again.

Lessons from Exalted 3e: don't do that.

What should you do? IMO,

1. Crafting should be rules-light.

Most RPGs are not detailed simulations of shopkeeping nor chemistry nor the economics of market supply and demand, and should not try to pretend they are. It distracts from the goblinslaying and princesssaving.

That is what D&D 3e has to say about Crafting Wands. By contrast, the SR 5e rules for Crafting Talismans take up a full page, and they're worse.

2. Ditch entire subsystems.

This is a separate point because a lot of good judgment could go into when to have a short subsystem vs. when to have no subsystem. But most RPGs get by fine with no skill dedicated to Craft (gemcutting), to take an Exalted example.

3. Design around player characters.

Immunity to Aging costs 1 build point in M&M, where characters usually have 150 to spend. To a normal person this is far more valuable than a laser gun, but the laser gun costs more points and is harder to craft as well as taking more time to build because it's more valuable to the League of Righteous Face Shooters.

Matters of "what if the heroes went around creating immortality wristwatches en masse" can be left to the DM's decision to run such a game or not, instead of trying to fix a fair price in the rules.

4. Be heavy-handed about costs.

If there are professional NPC crafters around, PCs shouldn't be able to outdo them by dabbling, usually not even be competitive. If there aren't professional NPC crafters around, you're probably playing a game where resource shortage is part of the point. Either way, crafting should not be very profitable. It might be very useful (going from having no weapon to an improvised spear) but it should be expensive enough that the PCs don't feel tempted to stop adventuring for a year and resume when they've all got +10 Godly Plate of the Whale. Calling back to 3, the PC economics should be a concern, even if the wider setting economics are not.

5. Say "No breaking the economy."

Saying this is like 1% of the effort and gets you 90% of the effect of trying to wrangle your crafting system into being sufficiently balanced to run a simulated economy. Perhaps, add a brief handwave about how offscreen NPCs don't use the crafting subsystem presented for PCs, so the rules don't generalize and can't be used to break the economy.

6. Make appropriate exceptions.

None of the previous rules are absolute, but exercise thought about why you're breaking them. Exalted, for instance, is a game about wielding massive power and suffering terrible consequences. Breaking the economy is totally up its alley.

5 notes

·

View notes

Text

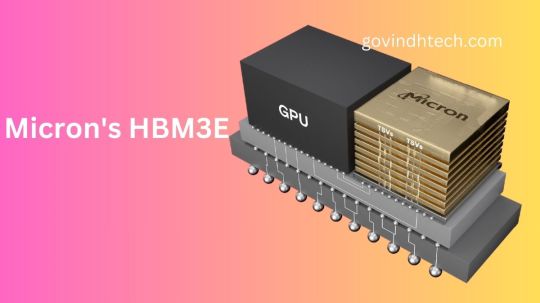

Micron Unleashes HBM3E Memory to Power AI Growth

Micron’s HBM3E Memory Accelerates AI Development

Global memory and storage leader Micron Technology has begun mass manufacture of High Bandwidth Memory 3E (HBM3E) devices. NVIDIA H200 Tensor Core GPUs, scheduled in Q2 2024, will use Micron’s 24GB 8H HBM3E Memory. Due to the HBM3E’s industry-leading performance and energy efficiency, Micron can dominate this market and provide AI solutions.

Micron HBM3E Memory uses 30% less power than rival HBM3E Memory chips, lowering data center running expenses.

HBM3E: Progressing the AI Revolution

Since the need for AI keeps growing, memory solutions become more and more important. Micron’s HBM3E Memory solution tackles this issue head-on by providing:

Outstanding Performance: AI accelerators, supercomputers, and data centers can access data at lightning-fast rates thanks to Micron’s HBM3E Memory , which reaches pin speeds of over 9.2 gigabits per second (Gb/s) and delivers over 1.2 terabytes per second (TB/s) of memory capacity.

Excellent Efficiency: Micron’s HBM3E Memory outperforms rival models in the market thanks to a 30% reduction in power consumption. In response to the increasing demand and use of AI, HBM3E Memory offers the most throughput at the lowest power consumption to improve crucial data center operational expense parameters.

Seamless Scalability: Data centers can easily expand their AI applications thanks to Micron’s HBM3E, which currently offers a capacity of 24 GB. Micron’s method provides the necessary memory capacity to expedite large-scale neural network training as well as inferencing tasks.

“Micron is accomplishing the triple threat through the HBM3E Memory milestone: speed to market management, best-in-class industry performance, and differentiated power efficiency,” said Micron Technology senior vice president and CBO Sumit Sadana. “Micron’s industry-leading HBM3E and HBM4 roadmap and memory bandwidth and capacity are excellent for AI applications, enabling significant growth in AI. with its comprehensive range of DRAM and NAND solutions for AI applications.”

Micron developed this industry-leading HBM3E architecture with its 1-beta technology, enhanced through-silicon via (TSV), and other innovations that enable a unique packaging solution. Micron is happy to support the advancement of semiconductor and system innovations going forward by joining TSMC’s 3DFabric Alliance. In the memory industry, Micron is credited with being a pioneer in 2.5D/3D stacking and cutting-edge packaging technology.

Furthermore, Micron is showcasing its leadership with the release of the 36GB 12-High HBM3E Memory sample, which is expected to surpass rival solutions in terms of energy efficiency and performance and generate over 1.2 TB/s by March 2024. As a sponsor of the global AI conference NVIDIA GTC, which begins on March 18, Micron will provide further details on its industry-leading AI memory portfolio and roadmaps.

With reference to Micron Technology

They are changing how the world uses information to enhance quality of life by setting the standard for cutting-edge memory and storage technologies. Micron and Crucial sell high-performance DRAM, NAND, and NOR memory and storage. The firm provides customers with cutting-edge technology, top-notch operations and production, and meticulous service. The data economy is propelled by human-generated breakthroughs that enable the development of 5G and AI applications. These innovations provide new opportunities for the client, mobile user experience, data center, and intelligent edge.

FAQS

What is HBM3E?

High-bandwidth memory 3E is HBM3E. Micron Technology’s new memory solution outperforms prior generations in performance and energy efficiency.

What makes HBM3E crucial for AI?

Large data sets and quick processing rates are often needed for AI applications. The quicker data flow between the CPU and memory made possible by HBM3E’s higher bandwidth may greatly enhance the performance of AI models. Its decreased power usage may also minimize operating expenses for data centers that handle AI applications.

Which characteristics make up the HBM3E from Micron?

Leading-edge results in the industry: provides more than 1.2 terabytes (TB/s) of memory bandwidth per second.

Outstanding efficiency: 30% less electricity is used compared with competitive systems.

Scalability: Currently available with a 24GB capacity, more capacities are planned for the future.

When is HBM3E going to be released?

The 24GB HBM3E was mass-produced by Micron in February 2024. The second-quarter 2024 H200 Tensor Core GPUs from NVIDIA will incorporate it.

What are HBM3E’s future plans?

Micron is creating a 36GB HBM3E with greater performance and economy. The March 2024 NVIDIA GTC conference will showcase their newest innovations.

Read more on Govindhtech.com

0 notes

Text

SPZI: JP 3E Holdings, Inc. Names Another Prominent Board Member - Daniel Lee

JP Energy Global, wholly owned subsidiary of JP 3E Holdings, Inc., formerly Spooz Inc., adds Daniel Lee to its BOD, current CEO of CIG International

Clearwater, FL., January 12, 2024 - JP Energy Global, PTE, LTD, a wholly owned subsidiary of JP 3E Holdings, Inc., formerly Spooz, Inc. (OTC: SPZI), is pleased to announce another additional member to the Board – Daniel Lee.

Daniel Lee is currently the CEO of CIG International. https://www.ciginter.com/ https://cigunited.com/ During Mr. Lee’s tenure as the CEO of CIG International, in 2018 CIG partnered with The US Regional Center Group, a premier EB-5 regional center organization, with projects worth over US $1.4 billion of EB-5 capital commitments, providing EB-5 investment services and expertise in key economic hubs within the United States. In 2021, CIG partnered with Keiretsu Forum Canada, a global angel investment group, which invests up to US $100M+ annually, to provide a platform for start-up venture investment and management. Since inception, CIG has raised over US $1 Billion investment funds through affiliated networks in the United States, Canada, China, Hong Kong, Vietnam, Taiwan, Indonesia, and Korea.

“Drawn to its incredible opportunities, I look forward to playing an instrumental role in bringing major high-valued EB-5 operations as wholly owned and majority owned subsidiaries to secure JP3E’s place in the market on a greater platform” said Daniel Lee, CEO of CIG International.

With CIG’s specialties in debt-based investment, private equity investment, and foreign investment facilitation, CIG provides unique alternative investment opportunities to its investors through CIG’s affiliated companies and professional networks in the United States. We are working on real estate development projects to build workers’ housings and other amenities in the surrounding area of EV battery plants in the United States. Related EV Battery Plants are under construction, which have received investments by Korean companies such as Samsung SDI, SK On, LG Energy Solutions, and the following US joint venture EV car manufacturers: Ford, GM, and Stellates. CIG has collaborated with various groups including city governments, real estate developers, and local communities to develop and build housing units, retail outlets, and common areas to house and support workers being recruited for EV battery plant sites being built by Samsung, SK, LG Energy Solution, and other Korean conglomerates. The EV battery plants that are currently under construction are located in Indiana, Kentucky, Tennessee, Michigan, and Georgia.

Local communities in these states are excited about the oncoming economic boom that accompanies such developments and recognize the need to address the housing shortages for accommodating thousands of workers coming from various neighboring cities. CIG’s involvement cultivated a unique opportunity for conventional investors as well as foreigners seeking an investment path towards immigrating to the U.S. under this EB-5 project, made possible by John K. Park’s facilitation of this opportunity for JP 3E Holdings, Inc.

Mr. Lee has over 25 years of experience as a business development & investment consultant in the US EB-5 and Canada Investor FIIP and QIIP industry. He has also represented investor programs in association with MCAN Capital (formerly known as MCAP), California Military Base (CMB) Regional Center, Laurentian Bank Securities, Inc. (LBS), and the US Regional Center Group (USRC). Through years of structuring, developing, and marketing investor program experience, Mr. Lee developed a keen understanding and knowledge for identifying, developing, and financing projects within the United States through a network of institutional investors as well as structuring regional centers for immigration investment funds.

“Adding Daniel Lee to our team will prove to be an invaluable addition as we are prepared to introduce our current and future growth initiatives that are currently transpiring right now with our EB-5 projects and operations” said John K. Park, Chairman and CEO of JP 3E Holdings, Inc., formerly Spooz, Inc.

About Spooz, Inc. (SPZI) now JP 3E Holdings, Inc.

Operating companies to supply the world with the vital needs of Eating, Energy, and Education (3E) which are essential needs for our everyday living and quality of life.

SAFE HARBOR ACT: Forward-looking statements are included within the meaning of Section 27A of the Securities Act of 1933 and Section 21E of the Securities Exchange Act of 1934, as amended. All statements regarding the Company’s expected future financial position, results of operations, cash flows, financing plans, business strategy, products and services, competitive positions, growth opportunities, plans and objectives of management for future operations or listing on an exchange — including words such as “anticipate,” “if,” “believe,” “plan,” “estimate,” “expect,” “intend,” “may,” “could,” “should,” “will” and other similar expressions — are forward-looking statements and involve risks, uncertainties and contingencies, many of which are beyond the Company’s control and may cause actual results, performance or achievements to differ materially from anticipated results, performance or achievements. The Company is under no obligation to (and expressly disclaims any such obligation to) update or alter its forward-looking statements, whether as a result of new information, future events or otherwise. No information in this press release should be construed in any manner whatsoever as an indication of the future performance of the Company’s revenues, financial condition or stock price.

Company Contact:

John K. Park, Chairman

Office: 727 216 6765

Websites: https://www.jp3e.com/

https://www.jp3eholdings.com/

Twitter: http://www.twitter.com/SpoozInc

Facebook: http://www.Facebook.com/SpoozInc

Email: [email protected]

SOURCE: Spooz, Inc.

#press release#prism mediawire#stock market#investing#otc markets#otc#prismdigitalmedia#prismmarketview#spooz#spzi

1 note

·

View note

Text

Top 7 best CNC machining manufactures

Top 7 best CNC machining manufactures

When it comes to the CNC machining manufacturing industry, finding reliable top-tier manufacturers is of utmost importance.

CNC (Computer Numerical Control) machining technology plays a vital role in modern manufacturing, providing designers and

engineers with highly precise and dependable production solutions. Globally, there are numerous renowned CNC machining

manufacturers, known for their excellent technology, high-quality finished products, and outstanding customer service.

In this article, we will focus on the top 7 CNC machining manufacturers that stand out in the field, showcasing their expertise and

innovative solutions that bring exceptional value to customers across various industries. Whether it's prototyping or low-volume

production, these CNC machining manufacturers excel with their performance and relentless pursuit of excellence in the industry.

Let's delve into these outstanding manufacturers, exploring their technical prowess and commitment to meeting customer needs.

1. 3ERPmold (3E Rapid Prototyping)

A 3ERP (3E Rapid Prototyping) mold is a type of mold used in rapid prototyping and low-volume production processes. It is a

cost-effective and time-efficient solution for creating parts and products that require limited quantities. The term "3ERP" stands for

"3E Rapid Prototyping," representing the three main aspects of the service: "Economical," "Efficient," and "Excellent."

Here's an introduction to 3ERP molds:

Economical: 3ERP molds are designed to be cost-effective, especially for low-volume production runs. Traditional injection molds

can be expensive and time-consuming to produce, making them less suitable for small quantities. In contrast, 3ERP molds can

significantly reduce tooling costs and allow for more affordable production of prototypes or limited batches.

Efficient: As the name suggests, 3ERP molds offer rapid prototyping capabilities, enabling quick turnaround times. This speed is

achieved through various manufacturing technologies, such as 3D printing, CNC machining, and vacuum casting. These methods

enable the creation of molds faster than conventional mold-making processes.

Excellent: Despite their rapid production, 3ERP molds maintain a high level of quality. The materials used in the process are carefully

selected to ensure the durability and accuracy of the molds, resulting in precise parts and prototypes.

Common applications of 3ERP molds include:

Prototype Development: Engineers and designers often use 3ERP molds to create prototypes for testing and validation before moving

on to mass production.

Low-Volume Production: When only a small quantity of parts is needed, 3ERP molds can be a cost-efficient solution compared to

traditional tooling methods.

Bridge Tooling: 3ERP molds can serve as bridge tooling, providing a temporary production solution while awaiting the development

of final production molds.

Custom Parts: Manufacturers can use 3ERP molds to produce custom parts that are not feasible or economical using other

manufacturing methods.

It's important to note that while 3ERP molds offer advantages in terms of speed and cost for low-volume production, they may not be

suitable for high-volume manufacturing due to their limited lifespan and potential limitations in material selection. For larger

production runs, traditional injection molding or other mass production methods are generally more appropriate.

As technology advances, the capabilities and applications of 3ERP molds may expand, providing an even more versatile solution

for rapid prototyping and low-volume production needs.

2. REGO MOULD

REGO MOULD is a professional Rapid prototyping companies that has been serving customers since 2008. Our focus is on providing

top-quality services such as mold design, mold fabrication, plastic injection molding, CNC machining, rapid prototyping, and much more.

specialize in the mould manufacturing for aerospace, automotive, robots & automation, telecommunications, consumer electronics,

home appliance, and other industries.Our factory is over 5000 square meters in size and is closed to convenient transportation.

At present, Rego has over 100 employees, Equipment is mostly imported from Switzerland and Taiwan.We have 5 sets of 5-axis CNC

milling, 30 CNC machines, 15 EDM machine, We have the capacity to produce 50-60 injection moulds per month.

If you are looking for information on Rego Mould or mold-making companies, I can provide you with a generic introduction to Rego Mould:

Rego Mould specialize in the design, fabrication, and production of molds used in various manufacturing processes, such as injection

molding, blow molding, die casting, and more. Molds are crucial tools that shape and form raw materials into specific shapes or products

during the manufacturing process.

Here are some key points about Rego Mould:

Expertise: Rego Mould typically have a team of skilled engineers and designers with expertise in mold design and fabrication. They use

specialized software and equipment to create precise and customized molds based on client requirements.

Materials: Molds can be made from different materials, depending on the manufacturing process and the material being molded.

Common materials used for mold fabrication include steel, aluminum, and various alloys.

Prototyping: Rego Mould often provide prototyping services to help clients validate their designs and ensure that the molds meet the

required specifications before full-scale production.

Customization: Rego Mould can create molds tailored to the specific needs of their clients. They can produce molds for a wide range

of products, from simple components to complex and intricate parts.

Quality Control: Quality is critical in Rego to ensure the accuracy and consistency of the molded products. Reputable mold manufacturers

have stringent quality control processes in place to deliver high-quality molds.

Lead Times: The time required to manufacture a mold can vary depending on its complexity and the manufacturing company's workload.

Some companies may offer expedited services for faster mold production.

Additional Services: In addition to mold manufacturing, some companies may offer related services, such as mold maintenance, repair,

and modification, to ensure the longevity and efficiency of the molds.

Remember, if you are specifically interested in "REGO MOULD," I recommend verifying the information through their official channels or

contacting them directly for accurate and up-to-date details about their services and capabilities.

https://jnrorwxhnlnlln5p.ldycdn.com/cloud/jpBpqKjkloSRrkiqqkoiio/weixintupian_202307271917232.png

3. Star Rapid

Star Rapid is a global rapid prototyping, rapid tooling, and low-volume manufacturing company that offers a wide range of services to

support product development and production needs. Headquartered in China, Star Rapid serves clients from various industries worldwide,

providing them with high-quality and cost-effective solutions for bringing their ideas to life.

Here's an introduction to Star Rapid and its services:

Rapid Prototyping: Star Rapid specializes in rapid prototyping services, which allow clients to quickly and iteratively create physical

prototypes of their designs. They offer various prototyping technologies, including 3D printing (SLA, SLS, FDM, etc.), CNC machining,

vacuum casting, and more. Rapid prototyping enables designers and engineers to validate their concepts, test product functionality,

and make design improvements before moving to production.

Rapid Tooling: The company also provides rapid tooling services, which bridge the gap between prototyping and full-scale production.

Rapid tooling techniques, such as aluminum tooling or soft tooling, enable faster and more cost-efficient production of low to medium

volumes of parts compared to traditional steel injection molds.

Low-Volume Manufacturing: Star Rapid specializes in low-volume manufacturing, catering to customers who need small to medium

quantities of parts. Their expertise in rapid prototyping and rapid tooling allows them to deliver production-grade parts in quantities

that may not be feasible or economical with mass production methods.

Materials and Finishing Options: Star Rapid offers a wide selection of materials to choose from, including various plastics, metals, and

elastomers. Additionally, they provide a range of finishing options, such as painting, plating, anodizing, and more, to meet specific product

requirements.

Design for Manufacturability (DFM) Support: The company's team of experienced engineers provides Design for Manufacturability (DFM)

support to optimize product designs for better manufacturability and cost-effectiveness. They work closely with clients to address potential

design issues and ensure smooth production processes.

Global Reach: While headquartered in China, Star Rapid has a global presence and serves customers from all over the world. They offer

international shipping and support, making it convenient for clients regardless of their location.

Quality Control: Star Rapid is committed to maintaining high-quality standards throughout their processes. They have a robust quality

control system in place to ensure that the parts they produce meet the required specifications and expectations.

As a company, Star Rapid focuses on customer satisfaction, providing fast turnaround times, competitive pricing, and excellent customer

service. They cater to a wide range of industries, including automotive, aerospace, medical, consumer electronics, and more, helping businesses

of all sizes turn their ideas into reality efficiently and effectively.

4. HLH Prototypes Co. Ltd

HLH Prototypes Co. Ltd is a prominent and well-established manufacturing company based in China that specializes in providing rapid

prototyping, rapid tooling, and low-volume manufacturing services. With extensive experience and a global client base, HLH Prototypes

is recognized for delivering high-quality products, quick turnaround times, and excellent customer service.

Here's an introduction to HLH Prototypes Co. Ltd:

Company Overview: HLH Prototypes was founded in 2001 and is headquartered in Shenzhen, China. Over the years, the company has

grown to become one of the leading rapid prototyping and manufacturing service providers in the industry.

Rapid Prototyping Services: HLH Prototypes offers a wide range of rapid prototyping technologies, including 3D printing (SLA, SLS,

FDM, etc.), CNC machining, vacuum casting, and more. These capabilities allow clients to quickly create physical prototypes for design

validation, testing, and evaluation purposes.

Rapid Tooling Services: In addition to prototyping, HLH Prototypes provides rapid tooling solutions. These methods, such as aluminum

tooling or soft tooling, enable the production of low to medium volumes of parts without the high costs associated with traditional steel

injection molds.

Low-Volume Manufacturing: HLH Prototypes specializes in low-volume manufacturing, catering to clients who require small to medium

quantities of parts. This service is ideal for bridging the gap between prototyping and full-scale production.

Material Selection: The company offers a wide range of materials to choose from, including various plastics, metals, resins, and composites.

This diversity allows clients to select the most suitable materials for their specific project requirements.

Design for Manufacturability (DFM) Support: HLH Prototypes has a team of experienced engineers who provide Design for Manufacturability

(DFM) assistance. They work closely with clients to optimize product designs for better manufacturability, cost-effectiveness, and overall

product quality.

Quality Assurance: HLH Prototypes places a strong emphasis on maintaining high-quality standards throughout their manufacturing

processes. They have a rigorous quality control system in place to ensure that the produced parts meet the required specifications and

quality requirements.

Global Reach: While based in China, HLH Prototypes serves clients from around the world. They offer international shipping and support,

making their services accessible to businesses and individuals regardless of their location.

Overall, HLH Prototypes Co. Ltd has built a reputation as a reliable and trusted partner for rapid prototyping and manufacturing needs.

Their commitment to excellence and customer satisfaction has made them a go-to choice for a wide range of industries, including

automotive, aerospace, medical, consumer electronics, and more.

5. 3D Hubs B.V.

3D Hubs B.V. was a well-known online platform that provided on-demand manufacturing services, including 3D printing, CNC machining,

injection molding, and sheet metal fabrication. It facilitated the connection between customers seeking to manufacture custom parts and

a network of manufacturing partners worldwide.

Here's an introduction to 3D Hubs B.V. based on the information available:

Company Overview: 3D Hubs B.V. was founded in 2013 and was headquartered in Amsterdam, Netherlands. It was one of the early

pioneers in the online manufacturing platform space, offering a streamlined and user-friendly process for customers to access various

manufacturing services.

Online Manufacturing Platform: 3D Hubs operated as an online manufacturing platform where customers could upload their 3D models

or CAD designs and receive instant quotes for the production of their parts. The platform provided a wide range of manufacturing

technologies, allowing customers to choose the most suitable method for their specific project requirements.

Manufacturing Technologies: The services offered by 3D Hubs included 3D printing, CNC machining (milling and turning), injection

molding, and sheet metal fabrication. This allowed customers to access a comprehensive range of manufacturing options for different

materials and part complexities.

Global Network of Manufacturing Partners: 3D Hubs had a vast network of manufacturing partners worldwide. These partners were

carefully vetted to ensure they met quality standards and could offer competitive pricing. When customers placed orders,

the manufacturing was handled by the most suitable partner within the network.

Fast Turnaround Times: The platform was known for providing relatively quick turnaround times for prototype and low-volume

production orders. This enabled customers to receive their parts promptly, facilitating faster product development cycles.

Materials and Finishing Options: 3D Hubs offered a variety of materials for 3D printing and machining processes. Additionally, they

provided finishing options such as painting, anodizing, and surface treatments to meet specific part requirements.

Quality Control: The platform had measures in place to ensure the quality of the manufactured parts. Customers could leave reviews

and ratings after receiving their orders, contributing to the platform's quality assurance process.

6. Quickparts

"Quickparts" was a division of 3D Systems, a leading provider of 3D printing and additive manufacturing solutions. While Quickparts

is primarily known for its rapid prototyping and low-volume production services, they also offer mold-making services as part of their

broader manufacturing capabilities.

Here's an introduction to Quickparts MOULD:

Mold-Making Services: Quickparts MOULD is a division of Quickparts that specializes in providing mold-making services. They design

and fabricate molds used in various manufacturing processes, such as injection molding, which is a widely used method for producing

plastic parts in large volumes.

Expertise in Mold Design: Quickparts MOULD has a team of skilled engineers and designers with expertise in mold design. They use

advanced software and tools to create precise and efficient molds that meet the specific requirements of their clients.

Materials for Molds: Molds can be made from various materials, with steel and aluminum being common choices. The material selection

depends on factors such as the type of manufacturing process, the expected production volume, and the properties of the molded material.

Customization: Quickparts MOULD offers customized mold solutions to cater to the specific needs of their clients. They work closely with

customers to understand their requirements and design molds that align with their product specifications.

Quality Control: As with all manufacturing processes, quality control is paramount in mold-making. Quickparts MOULD has stringent

quality assurance measures in place to ensure the accuracy, durability, and functionality of the molds they produce.

Rapid Prototyping and Low-Volume Production: In addition to mold-making services, Quickparts specializes in rapid prototyping and

low-volume production using various manufacturing technologies, including 3D printing and CNC machining. This comprehensive approach

allows clients to benefit from a wide range of manufacturing solutions under one roof.

Global Reach: Quickparts MOULD, being part of 3D Systems, has a global presence and serves clients from various industries worldwide.

Their international reach and manufacturing capabilities make them a preferred choice for businesses seeking rapid prototyping,

low-volume production, and mold-making services.

For the most current and detailed information, I recommend visiting their official website or contacting them directly to inquire about their

mold-making services and capabilities.

7. Xcentric Mold

Xcentric Mold & Engineering, commonly known as Xcentric, is a leading rapid manufacturing company based in the United States.

With over 25 years of experience, Xcentric specializes in providing rapid injection molding and CNC machining services, offering

high-quality, low-volume production solutions to a diverse range of industries.

Here's an introduction to Xcentric Mold & Engineering:

Expertise in Rapid Manufacturing: Xcentric is a pioneer in the field of rapid manufacturing. They are known for their expertise in rapid

injection molding and CNC machining, which enables them to produce functional prototypes and low-volume production parts quickly

and efficiently.

Injection Molding Services: Xcentric offers rapid injection molding services, which is a cost-effective method for producing plastic parts

in low volumes. They utilize advanced injection molding technology and materials to create high-quality parts that closely resemble the

final product.

CNC Machining Services: In addition to injection molding, Xcentric provides CNC machining services. They use state-of-the-art CNC

milling and turning equipment to produce precision parts from a wide range of materials, including metals and plastics.

Material Selection: Xcentric offers a comprehensive selection of materials for both injection molding and CNC machining processes.

This allows customers to choose the most suitable materials for their specific applications and requirements.

Design for Manufacturability (DFM) Support: Xcentric has a team of experienced engineers who provide Design for Manufacturability

(DFM) support. They work closely with clients to optimize their designs for better manufacturability, cost-effectiveness, and overall part quality.

Fast Turnaround Times: The company is known for its quick turnaround times, allowing customers to receive their prototypes or

low-volume production parts within days. This speed is achieved through streamlined processes and efficient manufacturing techniques.

Quality Assurance: Xcentric maintains a strong focus on quality control throughout their manufacturing processes. They have quality

inspection measures in place to ensure that the produced parts meet the required specifications and adhere to strict quality standards.

Online Quoting and Ordering: Xcentric operates an easy-to-use online platform where customers can upload their 3D models, receive

instant quotes, and place orders for their prototypes or production parts. This streamlined process simplifies and expedites the ordering process.

Global Reach: While based in the United States, Xcentric serves clients from around the world. They offer international shipping and

support, making their services accessible to businesses and individuals worldwide.

As an established and reputable rapid manufacturing company, Xcentric Mold & Engineering continues to be a reliable partner for

businesses seeking high-quality, rapid prototyping, and low-volume production solutions.

0 notes

Text

SOLUTION AT Academic Writers Bay Project Management Processes, Methodologies, and Economics Third Edition Avraham Shtub Faculty of Industrial Engineering and Management The Technion–Israel Institute of Technology Moshe Rosenwein Department of Industrial Engineering and Operations Research Columbia University Boston Columbus San Francisco New York Hoboken Indianapolis London Toronto Sydney Singapore Tokyo Dubai Madrid Hong Kong Mexico City Munich Paris Amsterdam Cape Town Montreal Vice President and Editorial Director, Engineering and Computer Science: Marcia J. Horton Editor in Chief: Julian Partridge Executive Editor: Holly Stark Editorial Assistant: Amanda Brands Field Marketing Manager: Demetrius Hall Marketing Assistant: Jon Bryant Managing Producer: Scott Disanno Content Producer: Erin Ault Operations Specialist: Maura Zaldivar-Garcia Manager, Rights and Permissions: Ben Ferrini Cover Designer: Black Horse Designs Cover Photo: Vladimir Liverts/Fotolia Printer/Binder: RRD/Crawfordsville Cover Printer: Phoenix Color/Hagerstown Full-Service Project Management: SPi Global Composition: SPi Global Typeface: Times Ten LT Std Roman 10/12 Copyright © 2017, 2005, 1994 Pearson Education, Inc. Hoboken, NJ 07030. All rights reserved. Manufactured in the United States of America. This publication is protected by copyright and permissions should be obtained from the publisher prior to any prohibited reproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise. For information regarding permissions, request forms and the appropriate contacts within the Pearson Education Global Rights & Permissions department, please visit www.pearsoned.com/permissions/. Many of the designations by manufacturers and seller to distinguish their products are claimed as trademarks. Where those designations appear in this book, and the publisher was aware of a trademark claim, the designations have been printed in initial caps or all caps. The author and publisher of this book have used their best efforts in preparing this book. These efforts include the development, research, and testing of theories and programs to determine their effectiveness. The author and publisher make no warranty of any kind, expressed or implied, with regard to these programs or the documentation contained in this book. The author and publisher shall not be liable in any event for incidental or consequential damages with, or arising out of, the furnishing, performance, or use of these programs. Library of Congress Cataloging-in-Publication Data Names: Shtub, Avraham, author. | Rosenwein, Moshe, author. Title: Project management : processes, methodologies, and economics / Avraham Shtub, Faculty of Industrial Engineering and Management, The Technion-Israel Institute of Technology, Moshe Rosenwein, Department of Industrial Engineering and Operations Research, Columbia University. Other titles: Project management (Boston, Mass.) Description: 3E. | Pearson | Includes bibliographical references and index. Identifiers: LCCN 2016030485 | ISBN 9780134478661 (pbk.) Subjects: LCSH: Engineering—Management. | Project management. Classification: LCC TA190 .S583 2017 | DDC 658.4/04—dc23 LC record available at https://lccn.loc.gov/2016030485 10 9 8 7 6 5 4 3 2 1 ISBN-10: 0-13-447866-5 ISBN-13: 978-0-13-447866-1 This book is dedicated to my grandchildren Zoey, Danielle, Adam, and Noam Shtub. This book is dedicated to my wife, Debbie; my three children, David, Hannah, and Benjamin; my late parents, Zvi and Blanche Rosenwein; and my in-laws, Dr. Herman and Irma Kaplan. Contents 1. Nomenclature xv 2. Preface xvii 3. What’s New in this Edition xxi 4. About the Authors xxiii 1. 1 Introduction 1 1. 1.1 Nature of Project Management 1 2. 1.2 Relationship Between Projects and Other Production Systems 2 3. 1.3 Characteristics of Projects 4 1. 1.3.1 Definitions and Issues 5 2. 1.3.2 Risk and Uncertainty 7 3. 1.3.3 Phases of a Project 9 4.

1.3.4 Organizing for a Project 11 4. 1.4 Project Manager 14 1. 1.4.1 Basic Functions 15 2. 1.4.2 Characteristics of Effective Project Managers 16 5. 1.5 Components, Concepts, and Terminology 16 6. 1.6 Movement to Project-Based Work 24 7. 1.7 Life Cycle of a Project: Strategic and Tactical Issues 26 8. 1.8 Factors that Affect the Success of a Project 29 9. 1.9 About the book: Purpose and Structure 31 1. Team Project 35 2. Discussion Questions 38 3. Exercises 39 4. Bibliography 41 5. Appendix 1A: Engineering Versus Management 43 6. 1A.1 Nature of Management 43 7. 1A.2 Differences between Engineering and Management 43 8. 1A.3 Transition from Engineer to Manager 45 9. Additional References 45 2. 2 Process Approach to Project Management 47 1. 2.1 Introduction 47 1. 2.1.1 Life-Cycle Models 48 2. 2.1.2 Example of a Project Life Cycle 51 3. 2.1.3 Application of the Waterfall Model for Software Development 51 2. 2.2 Project Management Processes 53 1. 2.2.1 Process Design 53 2. 2.2.2 PMBOK and Processes in the Project Life Cycle 54 3. 2.3 Project Integration Management 54 1. 2.3.1 Accompanying Processes 54 2. 2.3.2 Description 56 4. 2.4 Project Scope Management 60 1. 2.4.1 Accompanying Processes 60 2. 2.4.2 Description 60 5. 2.5 Project Time Management 61 1. 2.5.1 Accompanying Processes 61 2. 2.5.2 Description 62 6. 2.6 Project Cost Management 63 1. 2.6.1 Accompanying Processes 63 2. 2.6.2 Description 64 7. 2.7 Project Quality Management 64 1. 2.7.1 Accompanying Processes 64 2. 2.7.2 Description 65 8. 2.8 Project Human Resource Management 66 1. 2.8.1 Accompanying Processes 66 2. 2.8.2 Description 66 9. 2.9 Project Communications Management 67 1. 2.9.1 Accompanying Processes 67 2. 2.9.2 Description 68 10. 2.10 Project Risk Management 69 1. 2.10.1 Accompanying Processes 69 2. 2.10.2 Description 70 11. 2.11 Project Procurement Management 71 1. 2.11.1 Accompanying Processes 71 2. 2.11.2 Description 72 12. 2.12 Project Stakeholders Management 74 1. 2.12.1 Accompanying Processes 74 2. 2.12.2 Description 75 13. 2.13 The Learning Organization and Continuous Improvement 76 1. 2.13.1 Individual and Organizational Learning 76 2. 2.13.2 Workflow and Process Design as the Basis of Learning 76 1. Team Project 77 2. Discussion Questions 77 3. Exercises 78 4. Bibliography 78 3. 3 Engineering Economic Analysis 81 1. 3.1 Introduction 81 1. 3.1.1 Need for Economic Analysis 82 2. 3.1.2 Time Value of Money 82 3. 3.1.3 Discount Rate, Interest Rate, and Minimum Acceptable Rate of Return 83 2. 3.2 Compound Interest Formulas 84 1. 3.2.1 Present Worth, Future Worth, Uniform Series, and Gradient Series 86 2. 3.2.2 Nominal and Effective Interest Rates 89 3. 3.2.3 Inflation 90 4. 3.2.4 Treatment of Risk 92 3. 3.3 Comparison of Alternatives 92 1. 3.3.1 Defining Investment Alternatives 94 2. 3.3.2 Steps in the Analysis 96 4. 3.4 Equivalent Worth Methods 97 1. 3.4.1 Present Worth Method 97 2. 3.4.2 Annual Worth Method 98 3. 3.4.3 Future Worth Method 99 4. 3.4.4 Discussion of Present Worth, Annual Worth and Future Worth Methods 101 5. 3.4.5 Internal Rate of Return Method 102 6. 3.4.6 Payback Period Method 109 5. 3.5 Sensitivity and Breakeven Analysis 111 6. 3.6 Effect of Tax and Depreciation on Investment Decisions 114 1. 3.6.1 Capital Expansion Decision 116 2. 3.6.2 Replacement Decision 118 3. 3.6.3 Make-or-Buy Decision 123 4. 3.6.4 Lease-or-Buy Decision 124 7. 3.7 Utility Theory 125 1. 3.7.1 Expected Utility Maximization 126 2. 3.7.2 Bernoulli’s Principle 128 3. 3.7.3 Constructing the Utility Function 129 4. 3.7.4 Evaluating Alternatives 133 5. 3.7.5 Characteristics of the Utility Function 135 1. Team Project 137 2. Discussion Questions 141 3. Exercises 142 4. Bibliography 152 4. 4 Life-Cycle Costing 155 1. 4.1 Need for Life-Cycle Cost Analysis 155 2. 4.2 Uncertainties in Life-Cycle Cost Models 158 3. 4.3 Classification of Cost Components 161 4. 4.4 Developing the LCC Model 168 5. 4.5 Using the Life-Cycle Cost Model 175 1. Team Project 176 2. Discussion Questions 176 3.

Exercises 177 4. Bibliography 179 5. 5 Portfolio Management—Project Screening and Selection 181 1. 5.1 Components of the Evaluation Process 181 2. 5.2 Dynamics of Project Selection 183 3. 5.3 Checklists and Scoring Models 184 4. 5.4 Benefit-Cost Analysis 187 1. 5.4.1 Step-By-Step Approach 193 2. 5.4.2 Using the Methodology 193 3. 5.4.3 Classes of Benefits and Costs 193 4. 5.4.4 Shortcomings of the Benefit-Cost Methodology 194 5. 5.5 Cost-Effectiveness Analysis 195 6. 5.6 Issues Related to Risk 198 1. 5.6.1 Accepting and Managing Risk 200 2. 5.6.2 Coping with Uncertainty 201 3. 5.6.3 Non-Probabilistic Evaluation Methods when Uncertainty Is Present 202 4. 5.6.4 Risk-Benefit Analysis 207 5. 5.6.5 Limits of Risk Analysis 210 7. 5.7 Decision Trees 210 1. 5.7.1 Decision Tree Steps 217 2. 5.7.2 Basic Principles of Diagramming 218 3. 5.7.3 Use of Statistics to Determine the Value of More Information 219 4. 5.7.4 Discussion and Assessment 222 8. 5.8 Real Options 223 1. 5.8.1 Drivers of Value 223 2. 5.8.2 Relationship to Portfolio Management 224 1. Team Project 225 2. Discussion Questions 228 3. Exercises 229 4. Bibliography 237 5. Appendix 5A: Bayes’ Theorem for Discrete Outcomes 239 6. 6 Multiple-Criteria Methods for Evaluation and Group Decision Making 241 1. 6.1 Introduction 241 2. 6.2 Framework for Evaluation and Selection 242 1. 6.2.1 Objectives and Attributes 242 2. 6.2.2 Aggregating Objectives Into a Value Model 244 3. 6.3 Multiattribute Utility Theory 244 1. 6.3.1 Violations of Multiattribute Utility Theory 249 4. 6.4 Analytic Hierarchy Process 254 1. 6.4.1 Determining Local Priorities 255 2. 6.4.2 Checking for Consistency 260 3. 6.4.3 Determining Global Priorities 261 5. 6.5 Group Decision Making 262 1. 6.5.1 Group Composition 263 2. 6.5.2 Running the Decision-Making Session 264 3. 6.5.3 Implementing the Results 265 4. 6.5.4 Group Decision Support Systems 265 1. Team Project 267 2. Discussion Questions 267 3. Exercises 268 4. Bibliography 271 5. Appendix 6A: Comparison of Multiattribute Utility Theory with the AHP: Case Study 275 6. 6A.1 Introduction and Background 275 7. 6A.2 The Cargo Handling Problem 276 1. 6A.2.1 System Objectives 276 2. 6A.2.2 Possibility of Commercial Procurement 277 3. 6A.2.3 Alternative Approaches 277 8. 6A.3 Analytic Hierarchy Process 279 1. 6A.3.1 Definition of Attributes 280 2. 6A.3.2 Analytic Hierarchy Process Computations 281 3. 6A.3.3 Data Collection and Results for AHP 283 4. 6A.3.4 Discussion of Analytic Hierarchy Process and Results 284 9. 6A.4 Multiattribute Utility Theory 286 1. 6A.4.1 Data Collection and Results for Multiattribute Utility Theory 286 2. 6A.4.2 Discussion of Multiattribute Utility Theory and Results 290 10. 6A.5 Additional Observations 290 11. 6A.6 Conclusions for the Case Study 291 12. References 291 7. 7 Scope and Organizational Structure of a Project 293 1. 7.1 Introduction 293 2. 7.2 Organizational Structures 294 1. 7.2.1 Functional Organization 295 2. 7.2.2 Project Organization 297 3. 7.2.3 Product Organization 298 4. 7.2.4 Customer Organization 298 5. 7.2.5 Territorial Organization 299 6. 7.2.6 The Matrix Organization 299 7. 7.2.7 Criteria for Selecting an Organizational Structure 302 3. 7.3 Organizational Breakdown Structure of Projects 303 1. 7.3.1 Factors in Selecting a Structure 304 2. 7.3.2 The Project Manager 305 3. 7.3.3 Project Office 309 4. 7.4 Project Scope 312 1. 7.4.1 Work Breakdown Structure 313 2. 7.4.2 Work Package Design 320 5. 7.5 Combining the Organizational and Work Breakdown Structures 322 1. 7.5.1 Linear Responsibility Chart 323 6. 7.6 Management of Human Resources 324 1. 7.6.1 Developing and Managing the Team 325 2. 7.6.2 Encouraging Creativity and Innovation 329 3. 7.6.3 Leadership, Authority, and Responsibility 331 4. 7.6.4 Ethical and Legal Aspects of Project Management 334 1. Team Project 335 2. Discussion Questions 336 3. Exercises 336 4. Bibliography 338 8. 8 Management of Product, Process, and Support Design 341 1. 8.1 Design of Products, Services, and Systems 341 1.

8.1.1 Principles of Good Design 342 2. 8.1.2 Management of Technology and Design in Projects 344 2. 8.2 Project Manager’s Role 345 3. 8.3 Importance of Time and the Use of Teams 346 1. 8.3.1 Concurrent Engineering and Time-Based Competition 347 2. 8.3.2 Time Management 349 3. 8.3.3 Guideposts for Success 352 4. 8.3.4 Industrial Experience 354 5. 8.3.5 Unresolved Issues 355 4. 8.4 Supporting Tools 355 1. 8.4.1 Quality Function Deployment 355 2. 8.4.2 Configuration Selection 358 3. 8.4.3 Configuration Management 361 4. 8.4.4 Risk Management 365 5. 8.5 Quality Management 370 1. 8.5.1 Philosophy and Methods 371 2. 8.5.2 Importance of Quality in Design 382 3. 8.5.3 Quality Planning 383 4. 8.5.4 Quality Assurance 383 5. 8.5.5 Quality Control 384 6. 8.5.6 Cost of Quality 385 1. Team Project 387 2. Discussion Questions 388 3. Exercises 389 4. Bibliography 389 9. 9 Project Scheduling 395 1. 9.1 Introduction 395 1. 9.1.1 Key Milestones 398 2. 9.1.2 Network Techniques 399 2. 9.2 Estimating the Duration of Project Activities 401 1. 9.2.1 Stochastic Approach 402 2. 9.2.2 Deterministic Approach 406 3. 9.2.3 Modular Technique 406 4. 9.2.4 Benchmark Job Technique 407 5. 9.2.5 Parametric Technique 407 3. 9.3 Effect of Learning 412 4. 9.4 Precedence Relations Among Activities 414 5. 9.5 Gantt Chart 416 6. 9.6 Activity-On-Arrow Network Approach for CPM Analysis 420 1. 9.6.1 Calculating Event Times and Critical Path 428 2. 9.6.2 Calculating Activity Start and Finish Times 431 3. 9.6.3 Calculating Slacks 432 7. 9.7 Activity-On-Node Network Approach for CPM Analysis 433 1. 9.7.1 Calculating Early Start and Early Finish Times of Activities 434 2. 9.7.2 Calculating Late Start and Late Finish Times of Activities 434 8. 9.8 Precedence Diagramming with Lead–Lag Relationships 436 9. 9.9 Linear Programming Approach for CPM Analysis 442 10. 9.10 Aggregating Activities in the Network 443 1. 9.10.1 Hammock Activities 443 2. 9.10.2 Milestones 444 11. 9.11 Dealing with Uncertainty 445 1. 9.11.1 Simulation Approach 445 2. 9.11.2 Pert and Extensions 447 12. 9.12 Critique of Pert and CPM Assumptions 454 13. 9.13 Critical Chain Process 455 14. 9.14 Scheduling Conflicts 457 1. Team Project 458 2. Discussion Questions 459 3. Exercises 460 4. Bibliography 467 5. Appendix 9A: Least-Squares Regression Analysis 471 6. Appendix 9B: Learning Curve Tables 473 7. Appendix 9C: Normal Distribution Function 476 10. 10 Resource Management 477 1. 10.1 Effect of Resources on Project Planning 477 2. 10.2 Classification of Resources Used in Projects 478 3. 10.3 Resource Leveling Subject to Project Due-Date Constraints 481 4. 10.4 Resource Allocation Subject to Resource Availability Constraints 487 5. 10.5 Priority Rules for Resource Allocation 491 6. 10.6 Critical Chain: Project Management by Constraints 496 7. 10.7 Mathematical Models for Resource Allocation 496 8. 10.8 Projects Performed in Parallel 499 1. Team Project 500 2. Discussion Questions 500 3. Exercises 501 4. Bibliography 506 11. 11 Project Budget 509 1. 11.1 Introduction 509 2. 11.2 Project Budget and Organizational Goals 511 3. 11.3 Preparing the Budget 513 1. 11.3.1 Top-Down Budgeting 514 2. 11.3.2 Bottom-Up Budgeting 514 3. 11.3.3 Iterative Budgeting 515 4. 11.4 Techniques for Managing the Project Budget 516 1. 11.4.1 Slack Management 516 2. 11.4.2 Crashing 520 5. 11.5 Presenting the Budget 527 6. 11.6 Project Execution: Consuming the Budget 529 7. 11.7 The Budgeting Process: Concluding Remarks 530 1. Team Project 531 2. Discussion Questions 531 3. Exercises 532 4. Bibliography 537 5. Appendix 11A: Time–Cost Tradeoff with Excel 539 12. 12 Project Control 545 1. 12.1 Introduction 545 2. 12.2 Common Forms of Project Control 548 3. 12.3 Integrating the OBS and WBS with Cost and Schedule Control 551 1. 12.3.1 Hierarchical Structures 552 2. 12.3.2 Earned Value Approach 556 4. 12.4 Reporting Progress 565 5. 12.5 Updating Cost and Schedule Estimates 566 6. 12.6 Technological Control: Quality and Configuration 569 7. 12.7 Line of Balance 569 8.

12.8 Overhead Control 574 1. Team Project 576 2. Discussion Questions 577 3. Exercises 577 4. Bibliography 580 13. Appendix 12A: Example of a Work Breakdown Structure 581 14. Appendix 12B: Criteria 583 15. 13 Department of Energy Cost/Schedule Control Systems Research and Development Projects 587 1. 13.1 Introduction 587 2. 13.2 New Product Development 589 1. 13.2.1 Evaluation and Assessment of Innovations 589 2. 13.2.2 Changing Expectations 593 3. 13.2.3 Technology Leapfrogging 593 4. 13.2.4 Standards 594 5. 13.2.5 Cost and Time Overruns 595 3. 13.3 Managing Technology 595 1. 13.3.1 Classification of Technologies 596 2. 13.3.2 Exploiting Mature Technologies 597 3. 13.3.3 Relationship Between Technology and Projects 598 4. 13.4 Strategic R&D Planning 600 1. 13.4.1 Role of R&D Manager 600 2. 13.4.2 Planning Team 601 5. 13.5 Parallel Funding: Dealing with Uncertainty 603 1. 13.5.1 Categorizing Strategies 604 2. 13.5.2 Analytic Framework 605 3. 13.5.3 Q-Gert 606 6. 13.6 Managing the R&D Portfolio 607 1. 13.6.1 Evaluating an Ongoing Project 609 2. 13.6.2 Analytic Methodology 612 1. Team Project 617 2. Discussion Questions 618 3. Exercises 619 4. Bibliography 619 5. Appendix 13A: Portfolio Management Case Study 622 16. 14 Computer Support for Project Management 627 1. 14.1 Introduction 627 2. 14.2 Use of Computers in Project Management 628 1. 14.2.1 Supporting the Project Management Process Approach 629 2. 14.2.2 Tools and Techniques for Project Management 629 3. 14.3 Criteria for Software Selection 643 4. 14.4 Software Selection Process 648 5. 14.5 Software Implementation 650 6. 14.6 Project Management Software Vendors 656 1. Team Project 657 2. Discussion Questions 657 3. Exercises 658 4. Bibliography 659 5. Appendix 14A: PMI Software Evaluation Checklist 660 6. 14A.1 Category 1: Suites 660 7. 14A.2 Category 2: Process Management 660 8. 14A.3 Category 3: Schedule Management 661 9. 14A.4 Category 4: Cost Management 661 10. 14A.5 Category 5: Resource Management 661 11. 14A.6 Category 6: Communications Management 661 12. 14A.7 Category 7: Risk Management 662 13. 14A.8 General (Common) Criteria 662 14. 14A.9 Category-Specific Criteria Category 1: Suites 663 15. 14A.10 Category 2: Process Management 663 16. 14A.11 Category 3: Schedule Management 664 17. 14A.12 Category 4: Cost Management 665 18. 14A.13 Category 5: Resource Management 666 19. 14A.14 Category 6: Communications Management 666 20. 14A.15 Category 7: Risk Management 668 17. 15 Project Termination 671 1. 15.1 Introduction 671 2. 15.2 When to Terminate a Project 672 3. 15.3 Planning for Project Termination 677 4. 15.4 Implementing Project Termination 681 5. 15.5 Final Report 682 1. Team Project 683 2. Discussion Questions 683 3. Exercises 684 4. Bibliography 685 18. 16 New Frontiers in Teaching Project Management in MBA and Engineering Programs 687 1. 16.1 Introduction 687 2. 16.2 Motivation for Simulation-Based Training 687 3. 16.3 Specific Example—The Project Team Builder (PTB) 691 4. 16.4 The Global Network for Advanced Management (GNAM) MBA New Product Development (NPD) Course 692 5. 16.5 Project Management for Engineers at Columbia University 693 6. 16.6 Experiments and Results 694 7. 16.7 The Use of Simulation-Based Training for Teaching Project Management in Europe 695 8. 16.8 Summary 696 1. Bibliography 697 1. Index 699 Nomenclature AC annual cost ACWP actual cost of work performed AHP analytic hierarchy process AOA activity on arrow AON activity on node AW annual worth BAC budget at completion B/C benefit/cost BCWP budgeted cost of work performed BCWS budgeted cost of work scheduled CBS cost breakdown structure CCB change control board CCBM critical chain buffer management CDR critical design review CE certainty equivalent, concurrent engineering C-E cost-effectiveness CER cost estimating relationship CI cost index; consistency index; criticality index CM configuration management COO chief operating officer CPIF cost plus incentive fee CPM critical path method CR capital

recovery, consistency ratio C/SCSC cost/schedule control systems criteria CV cost variance DOD Department of Defense DOE Department of Energy DOH direct overhead costs DSS decision support system EAC estimate at completion ECO engineering change order ECR engineering change request EMV expected monetary value EOM end of month EOY end of year ERP enterprise resource planning ETC estimate to complete ETMS early termination monitoring system EUAC equivalent uniform annual cost EV earned value EVPI expected value of perfect information EVSI expected value of sample information FFP firm fixed price FMS flexible manufacturing system FPIF fixed price incentive fee FW future worth GAO General Accounting Office GDSS group decision support system GERT graphical evaluation and review technique HR human resources IPT integraded product team IRR internal rate of return IRS Internal Revenue Service ISO International Standards Organization IT information technology LCC life-cycle cost LOB line of balance LOE level of effort LP linear program LRC linear responsibility chart MACRS modified accelerated cost recovery system MARR minimum acceptable (attractive) rate of return MAUT multiattribute utility theory MBO management by objectives MIS management information system MIT Massachusetts Institute of Technology MPS master production schedule MTBF mean time between failures MTTR mean time to repair NAC net annual cost NASA National Aeronautics and Space Administration NBC nuclear, biological, chemical NPV net present value OBS organizational breakdown structure O&M operations and maintenance PDMS product data management system PDR preliminary design review PERT program evaluation and review technique PMBOK project management body of knowledge PMI Project Management Institute PMP project management professional PO project office PT project team PV planned value PW present worth QA quality assurance QFD quality function deployment RAM reliability, availability, and maintainability; random access memory R&D research and development RDT&E research, development, testing, and evaluation RFP request for proposal ROR rate of return SI schedule index SOW statement of work SOYD sum-of-the-years digits SV schedule variance TQM total quality management WBS work breakdown structure WP work package WR work remaining Preface We all deal with projects in our daily lives. In most cases, organization and management simply amount to constructing a list of tasks and executing them in sequence, but when the information is limited or imprecise and when cause-and-effect relationships are uncertain, a more considered approach is called for. This is especially true when the stakes are high and time is pressing. Getting the job done right the first time is essential. This means doing the upfront work thoroughly, even at the cost of lengthening the initial phases of the project. Shaving expenses in the early stages with the intent of leaving time and money for revisions later might seem like a good idea but could have consequences of painful proportions. Seasoned managers will tell you that it is more cost-effective in the long run to add five extra engineers at the beginning of a project than to have to add 50 toward the end. The quality revolution in manufacturing has brought this point home. Companies in all areas of technology have come to learn that quality cannot be inspected into a product; it must be built in. Recalling the 1980s, the global competitive battles of that time were won by companies that could achieve cost and quality advantages in existing, well-defined markets. In the 1990s, these battles were won by companies that could build and dominate new markets. Today, the emphasis is partnering and better coordination of the supply chain. Planning is a critical component of this process and is the foundation of project management. Projects may involve dozens of firms and hundreds of people who need to be managed and coordinated. They need to know what has to

be done, who is to do it, when it should be done, how it will be done, and what resources will be used. Proper planning is the first step in communicating these intentions. The problem is made difficult by what can be characterized as an atmosphere of uncertainty, chaos, and conflicting goals. To ensure teamwork, all major participants and stakeholders should be involved at each stage of the process. How is this achieved efficiently, within budget, and on schedule? The primary objective in writing our first book was to answer this question from the perspective of the project manager. We did this by identifying the components of modern project management and showing how they relate to the basic phases of a project, starting with conceptual design and advanced development, and continuing through detailed design, production, and termination. Taking a practical approach, we drew on our collective experience in the electronics, information services, and aerospace industries. The purpose of the second edition was to update the developments in the field over the last 10 years and to expand on some of the concerns that are foremost in the minds of practitioners. In doing so, we have incorporated new material in many of the chapters specifically related to the Project Management Body of Knowledge (PMBOK) published by the Project Management Institute. This material reflects the tools, techniques, and processes that have gained widespread acceptance by the profession because of their proven value and usefulness. Over the years, numerous books have been written with similar objectives in mind. We acknowledge their contribution and have endeavored to build on their strengths. As such in the third edition of the book, we have focused on integrative concepts rather than isolated methodologies. We have relied on simple models to convey ideas and have intentionally avoided detailed mathematical formulations and solution algorithms––aspects of the field better left to other parts of the curriculum. Nevertheless, we do present some models of a more technical nature and provide references for readers who wish to gain a deeper understanding of their use. The availability of powerful, commercial codes brings model solutions within reach of the project team. To ensure that project participants work toward the same end and hold the same expectations, short- and long-term goals must be identified and communicated continually. The project plan is the vehicle by which this is accomplished and, once approved, becomes the basis for monitoring, controlling, and evaluating progress at each phase of the project’s life cycle. To help the project manager in this effort, various software packages have been developed; the most common run interactively on microcomputers and have full functional and report-generating capabilities. In our experience, even the most timid users are able to take advantage of their main features after only a few hours of hands-on instruction. A second objective in writing this book has been to fill a void between texts aimed at low- to mid-level managers and those aimed at technical personnel with strong analytic skills but little training in or exposure to organizational issues. Those who teach engineering or business students at both the late undergraduate and early graduate levels should find it suitable. In addition, the book is intended to serve as a reference for the practitioner who is new to the field or who would like to gain a surer footing in project management concepts and techniques. The core material, including most of the underlying theory, can be covered in a one-semester course. At the end of Chapter 1, we outline the book’s contents. Chapter 3 deals with economic issues, such as cash flow, time value of money, and depreciation, as they relate to projects. With this material and some supplementary notes, coupled with the evaluation methods and multiple criteria decision-making techniques discussed in Chapters 5 and 6,

respectively, it should be possible to teach a combined course in project management and engineering economy. This is the direction in which many undergraduate engineering programs are now headed after many years of industry prodding. Young engineers are often thrust into leadership roles without adequate preparation or training in project management skills. Among the enhancements in the Third Edition is a section on Lean project management, discussed in Chapter 8, and a new Chapter 16 on simulationbased training for project management. Lean project management is a Quality Management initiative that focuses on maximizing the value that a project generates for its stakeholders while minimizing waste. Lean project management is based on the Toyota production system philosophy originally developed for a repetitive environment and modified to a nonrepetitive environment to support project managers and project teams in launching, planning, executing, and terminating projects. Lean project management is all about people—selecting the right project team members, teaching them the art and science of project management, and developing a highly motivated team that works together to achieve project goals. Simulation-based training is a great tool for training project team members and for team development. Chapter 16 discusses the principles of simulation- based training and its application to project management. The chapter reports on the authors’ experience in using simulation-based training in leading business schools, such as members of the Global Network for Advanced Management (GNAM), and in leading engineering schools, such as the Columbia University School of Engineering and the Technion. The authors also incorporated feedback received from European universities such as Technische Universität München (TUM) School of Management and Katholieke Universiteit Leuven that used the Project Team Builder (PTB) simulation-based training environment. Adopters of this book are encouraged to try the PTB—it is available from http://www.sandboxmodel.com/—and to integrate it into their courses. Writing a textbook is a collaborative effort involving many people whose names do not always appear on the cover. In particular, we thank all faculty who adopted the first and second editions of the book and provided us with their constructive and informative comments over the years. With regard to production, much appreciation goes to Lillian Bluestein for her thorough job in proofreading and editing the manuscript. We would also like to thank Chen Gretz-Shmueli for her contribution to the discussion in the human resources section. Finally, we are forever grateful to the phalanx of students who have studied project management at our universities and who have made the painstaking efforts of gathering and writing new material all worthwhile. Avraham Shtub Moshe Rosenwein What’s New in this Edition The purpose of the new, third edition of this book is to update developments in the project management field over the last 10 years and to more broadly address some of the concerns that have increased in prominence in the minds of practitioners. We incorporated new material in many of the chapters specifically related to the Project Management Body of Knowledge (PMBOK) published by the Project Management Institute. This material reflects the tools, techniques, and processes that have gained widespread acceptance by the profession because of their proven value and usefulness. Noteworthy enhancements in the third edition include: An expanded section regarding Lean project management in Chapter 8; A new chapter, Chapter 16, discussing the use of simulation and the Project Team Builder software; A detailed discussion on activity splitting and its advantages and disadvantages in project management; Descriptions, with examples, of resource-scheduling heuristics such as the longest-duration first heuristic and the Activity Time (ACTIM) algorithm; Examples that demonstrate