#integrated electronics

Text

How a Computer Works - Part 3 (Miniaturization and Standardization)

For anyone just joining in, I'm writing a series of posts explaining perhaps haphazardly all there is to know about how a computer works, from the most basic fundamental circuitry components to whatever level of higher functionality I eventually get to. As explained in the first post on this subject, I am doing this just in pure text, so that if you are inclined you can straight up print these posts out or narrate them onto some audio tape or whatever and have full access to them should every computer in the world suddenly collapse into a pile of dust or something. Part 1 mainly covered the basic mechanical principles of circuitry and how to physically construct a logic gate. Part 2 covered logic gates in detail and how to use them to create a basic working architecture for a general purpose computer. Today we're going to be talking more about what you're looking at when you crack a machine open so you can make sense of all the important fiddly bits and have maybe a starting point on how to troubleshoot things with a multimeter or something.

Before getting into it though, I do have to shake my little donation can again and remind you that I do not know how I am going to get through the winter without becoming homeless, so if this is valuable to you, I'd appreciate some help.

Boards of Bread and Printed Circuits

With the things I've explained so far, you could totally build a computer right now, but it'd be a bit messy. You can totally buy resistors, transistors, capacitors, and diodes by the bagful for basically nothing, and cheap rolls of insulated wire, but there's all these long exposed pins to cut short and soldering things in mid-air is a messy nightmare and you'd just have this big tangle of wires in a bag or something that would almost certainly short out on you. So let's look into ways to organize stuff a little.

If you start playing around with electronics on your own, one of the first things you want to hook yourself up with besides raw components and wires is a breadboard or 12. And if you're watching people explain these things with visual aids, you'll also see a lot of them, so it's good to know exactly what they are and how they work. Your standard breadboard is a brick of plastic with a bunch of little holes in it. Incidentally, the name comes from how the first ones were literally just named after the wooden cutting boards for slicing bread people recycled to make them. Inside these holes there's some pinching bits of conductive metal which connect to each other in a particular way (pretty sure you can just see the strips that connect one if you pry the bottom off), so you can just jam a thing wire or prong into a hole, have it held in place, and make a connection to every other hole its connected to on the other side.

There is a ton of standardization to all of this. The holes should always be 0.1 inches apart () and split into two big grids. Everyone I've ever seen has 63 rows, each with 5 holes labeled A-E, a shallow channel through the middle of the board, and then another 5, F-J, and we generally have numbers printed every 5 rows. Down underneath, for any given row, the set of 5 pins on each side of the channel are connected. So, holes 1A, 1B, 1C, 1D, and 1E are all connected to each other, and nothing else. Holes 1F, 1G, 1H, 1I, and 1J are also connected to each other. There's no connection though between 1E and 1F, or 1A and 2A.

Most breadboards will also have a couple of "power rails" along the sides. These are just going to be labeled with a long red line and +, and a long blue or black line and -, and have holes in 2x5 blocks staggered out. With these, all 25 or 50 or whatever holes near the red + line connect with each other, and all the ones near the black line connect with each other. The gaps every 5 holes don't serve any purpose beyond looking different enough from the big grid so you hopefully don't mix it up and forget that these ones all connect down the length, and not in in little clumps across the width like everything else. The idea, for the sake of convention, is you plug a wire connected directly to the positive side of your battery or DC adapter or whatever into any red line hole, the negative side to any blue/black hole, and then tada, you can make a circuit just by plugging a wire in from red to a normal grid line, whatever bits you want span from that grid line to another, and eventually you connect the far end back anywhere on the black/blue line.

With a nice circuit board, there's also little snap-together pegs along the sides, and the power rails are just snapped on with those. So you can just kinda cut through the backing with a knife or some scissors, snap those off, connect multiple boards together without redundant power rails in the middle, and then just have these nice spare long lines of linked sockets. In the computer I'm building on these, I'm just using spare power rails for the bus. Oh and the big grooved channel down the middle also has a purpose. Bigger electronic components, like our good good friend the integrated circuit, are generally designed to be exactly wide enough (or more, but by a multiple of 0.1 inches) to straddle that groove as you plug their legs into the wires on either side, so they nicely fit into a breadboard, and there's a handy gap to slide something under and pry them off later on.

Typically though, you don't see breadboards inside a computer, or anything else. They're super handy for tinkering around and designing stuff, but for final builds, you want something more permanent. Usually, that's a printed circuit board, or PCB. This is pretty much what everyone's going to picture when they think about the guts of a computer. A big hard (usually) green board with a bunch of intricate lines, or "traces" running all over made of (usually) copper. And maybe with some metal ringed holes punched all the way through (they call those vias). These tend to look really complicated and maybe even a little magical, but they're honestly they're just pre-placed wires with a sense of style.

Most of the material of the board is insulated. The copper traces conduct real well, and manufacturers have done the math on just how close together they can be run without connecting to each other in places you don't want. The holes that go all the way through are for either plugging other bits in that tend to come with long legs you maybe want to keep intact, or just ways to run a trace through to the other side, where we often have traces on the back too to maximize our space. Most of what makes them look all cool and magical is how the traces run as close packed as possible to conserve space, and tend to only turn at 45 degree angles, which is just an artifact of how the machinery used to etch them out sued to be iffy about anything else.

So tada, you have all your wires pre-stuck to a nice sturdy board, and maybe even have labels printed right on there for where you solder all the various components to finish the thing. Oh and when you hear people talk about like, motherboards and daughterboards? The big main board you have for everything is a motherboard. Sometimes you need more than that, so you make smaller ones, and connect them up ether with some soldering or cartridge style with end-pins sliding snugly into sockets, and those we call daughterboards.

Integrated Circuits, or as they're also known, "chips"

The last thing you're likely to find if you crack open a computer, or just about any other electronic device that isn't super old or super super simple, are integrated circuits. Generally these are think black plastic bars that look like you'd maybe try to awkardly use them to spread cheese or peanutbutter on crackers in a prepacked snack or something, with rows of tiny little legs that running along either side. Kinda makes them look like little toy bugs or something. Sometimes they're square with pins along every edge, because sometimes you need a lot of pins. These are integrated circuits, or microchips, or just chips, and wow are they handy.

Sometime back in the 60s when people were really getting their heads around just how ridiculously small they could make electronic components and still have them work, we started to quite rapidly move towards a point where the big concern was no longer "can we shrink all this stuff down to a manageable size" and more "we are shrinking everything down to such an absurdly tiny size that we need to pack it all up in some kind of basically indestructible package, while still being able to interact with it."

So, yeah, we worked out a really solid standard there. I kinda wish I could find more on how it was set or what sort of plastic was used, but you take your absurdly shrunken down complex circuit for doing whatever. You run the teensiest tiniest wires you can out from it that thicken up at the ends into standard toothy prongs you can sink into a breadboard or a PCB with that standardized pin spacing, and you coat it all in this black plastic so firmly enveloping it that nothing can move around inside or get broken, hopefully.

And honestly, in my opinion, this is all TOO standardized. The only real visible difference between any two given integrated circuits is how many legs they have, and even those tend to come to some pretty standard numbers. They're always the same size shape and color, they all have the same convention of having a little indented notch on one side so you know which end is which, and they all seem to use just the worst ink in the world to print a block of numbers on the back with their manufacturer, date of assembly, a catalog number, and some other random stuff.

For real if there's any real comprehensive standard for what's printing on these, I can't for the life of me find it. All I know is, SOMEWHERE, you've got a 2 or 3 letter code for every manufacturer, a number for the chip, and a 4 digit date code with the last 2 digits of the year, and which week of that year it was. These three things can be in any order, other things can also be on there, probably with zero spacing, and usually printed in ink that wipes away like immediately or at least is only readable under really direct light, it sucks.

Once you know what a chip is though and look up the datasheet for it, you should have all sorts of handy info on what's inside, and just need to know what every leg is for. For that, you find which end has a notch in it, that's the left side, sometimes there's also a little dot in the lower left corner, and hopefully the label is printed in alignment with that. From there, the bottom left leg is pin 1, and then you count counterclockwise around the whole chip. You're basically always going to have positive and negative power pins, past that anything goes. You can cram a whole computer into a single chip, yo can have someone just put like 4 NAND gates on a chip for convenience, whatever.

OK, but how do they make them so small?

OK, so, mostly a circuit we're going to want to shrink down and put on a chip is just gonna be a big pile of logic gates, we can make our logic gates just using transistors, and we can make transistors just by chemically treating some silicon. So we just need SUPER flat sheets of treated silicon, along with some little strands of capacitive/resistive/insulating material here and there, and a few vertically oriented bits of conductive metal to pass signals up and down as we layer these together. Then we just need to etch them out, real real small and tight.

And we can do that etching at like, basically infinite resolution it turns out. It just so happens we have access to special acids that eat through the materials we need them to eat through, but that only work when they're being directly hit with fairly intense UV light. And a thing about light is when you have say, a big cut out pattern that you hold between a light and a surface, it casts a shadow on it... and the scaling of that shadow depends entirely on the distances between the light, the pattern, and the surface. So if you're super careful calibrating everything, you can etch a pattern into something at a scale where the main limiting factors become stuff like how many molecules thick things have to be to hold their shape. Seriously, they use electron microscopes to inspect builds because that's the level of tininess we have achieved.

So yeah, you etch your layers of various materials out with shadow masks and UV acid, you stack them up, you somehow align microscopic pins to hold them together and then you coat the whole mess in plastic forever. Tada. Anything you want in a little chip.

ROMs, maybe with various letters in front

So there's a bunch of standard generally useful things people put into ICs, but also with a computer you generally want some real bespoke stored values with a lookup table where you'll keep, say, a program to be run by feeding whatever's inside out to the bus line by line. For that we use a chip we call Read Only Memory, or ROM. Nothing super special there, just... hard wire in the values you need when you manufacture it. Manufacturing these chips though is kind of a lot, with the exacting calibrations and the acid and the clean rooms and all. Can't we have some sort of Programmable ROM? Well sure, just like build it so that all the values are 1, and build a special little thing that feeds more voltage through than it can handle and physically destroy the fuse for everything you don't want to be a 1.

OK that's still kind of a serious commitment. What if I want to reuse this later? Oh, so you want some sort of Erasable PROM? OK someone came up with a funky setting where you overload and blow out the fuses but then if you expose the guts of the chip to direct UV light through this little window, everything should reform back to 1. Just like, throw a sticker on there when you don't want to erase it. Well great, but can we maybe not have me desolder it and take it out to put under a lamp? Oh la de da! You need Electronically Erasable PROMs? EEPROMs? I guess we can make THAT work, somehow. They're still gonna be slow to write to though, can't have anything. I mean, not unless we invented like, flash memory. Which somehow does all this at speeds where you can use it for long term storage without it being a pain. So that's just kinda the thing we have now. Sorry I don't quite get the principles behind it enough to summarize. Something about floating components and needing less voltage or whatever. Apparently you sacrifice some read speed next to older options but hey, usable rewritable long term storage you just plug in, no jumping through extra hoops.

So OK. I think that's everything I can explain without biting the bullet and explaining ALUs and such. Well, there's keyboards (they're just buttons connecting input lines), monitors (these days, LEDs wired up in big grids), and mice (there's spokes in wheels that click X times or cameras checking the offset values of dust on your desk or whatnot).

Maybe throw me some money before we move on ?

CONTINUED IN PART 4

#computers#computer science#pcb#printed circuit board#integrated circuits#microchip#breadboards#education#electronics

54 notes

·

View notes

Text

Latest in his Line!

#my art#new oc#he's just a totally normal guy!#definitely not a government created living integrated electronic network!#body horror

15 notes

·

View notes

Text

I need to educate myself further on the depths of early tech advancements and video art, but eventually I'd love to make a video essay about how it connects to electric dreams because I truly believe that in a way it's a love letter to the rising genre of video art and electronic sound art present in the movie's time period. I know it I just need more context to make proper connections.

#i mean#28 years before you had the first movie with an entirely electronically composed score that wasnt even allowed to be credited as music#it was instead credited as 'electronic tonalities' as it wasn't seen as 'real' music#a lot of early tech art and integration was highly criticized at the time#for ED to turn around and make the presence of tech and art relating to it an integral component of the movie in both production + thematic#idk. theres much to observe with the movies presence in its time period#which is also why a remake I feel may not carry the same message as the context surrounding the movie's themes are much different now#or maybe i just have a bias to early tech art lol

11 notes

·

View notes

Text

#Eric's Electrons#Richard Dawkins#science#orthodoxy#censorship#approved messaging#woke#wokeism#cult of woke#wokeness as religion#academic corruption#academic integrity#what science is#ideological corruption#ideological capture#religion is a mental illness

7 notes

·

View notes

Text

System Integration

Railway Signaling Systems

Power inverters

Controllers for industrial equipment

Medical devices and equipment

Fuel dispensing systems

Telematics modules

Camera and Vision Systems

Sensing and detection systems

#Complete Box Build#Life Cycle Management#Configuration Management#Cabinets#Enclosures#& Rack-Mount Systems#Functional Testing#Electromechanical Assemblies#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#System Integration

2 notes

·

View notes

Text

Ableton Live 11.3.10 Suite Download

Ableton Live 11.3.10 Suite represents the pinnacle of digital music production software, offering an unparalleled creative environment for musicians, producers, and DJs. This latest version builds upon Ableton's legacy of innovation and versatility, delivering a comprehensive toolkit that empowers users to craft music with precision and spontaneity.

Live 11.3.10 Suite offers a wide array of virtual instruments, effects, and sound libraries, allowing artists to explore new sonic horizons and experiment with diverse musical genres. Its intuitive interface streamlines the production process, making it accessible for both beginners and professionals. Live's Session View facilitates live performances and jamming sessions, while the Arrangement View offers meticulous control over your compositions.

This download includes a vast library of sounds, including synths, samplers, and acoustic instruments, along with cutting-edge audio effects. Additionally, the Suite version includes Max for Live, enabling users to create their own custom devices and expand their sonic palette even further.

With its continual updates and enhancements, Ableton Live 11.3.10 Suite is the ultimate choice for those seeking a dynamic, creative, and professional music production solution.

#Ableton Live 11.3.10 Suite#Music Production#Digital Audio Workstation#Live Performance#MIDI Sequencing#Audio Editing#VST Plugins#Audio Effects#Creative Sound Design#Music Arrangement#Beatmaking#Recording Software#Electronic Music#Ableton Push Integration#Audio Mixing#Live DJing#Music Composition#Ableton Instruments#Max for Live#Audio Production Tools#Audio Processing#Clip Launching#Live Looping#Ableton Live Packs#Session View#Arrangement View#MIDI Instruments#Audio Recording#Music Software#Ableton Live 11 Suite.

3 notes

·

View notes

Audio

MAGICKALLY THE GREAT INTEGRAL AWAKENING by GLAUFX GARLAND AND ELENI VON MONDLICHT

#bandcamp#witch house#witch house music#cyberpunk#cyberpunk music#techno#melodic techno#IDM#techno music#electronic music#awakening#independent#independent music#Greek music#alternative music#alternative#integral#great awakening#magickally

9 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

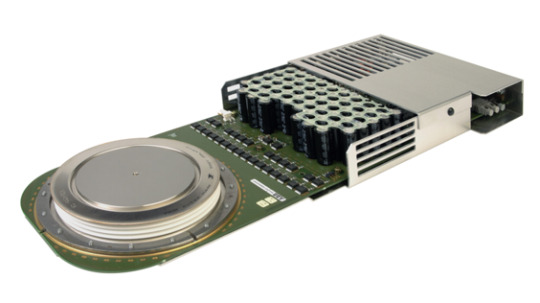

IGCT: Powering the Future of Electronics

IGCT (Integrated Gate Commutated Thyristors) is a powerful and versatile power semiconductor device widely utilized in the electronic components industry. With its exceptional performance, fast switching speed, and high current-carrying capability, IGCT has found extensive applications in power transmission, industrial drives, and power electronics.

Knowing more: smbom.com

2 notes

·

View notes

Text

Future Electronics boasts an industry-leading selection of connectors

The company boasts an industry-leading selection of connectors, including pin & socket, D-sub, backplane and more key components that are important to many new designs.

#Future Electronics#globally integrated#IT infrastructure#Capacitors#Film Capacitors#Analog#development tools#electromechanical#interconnect#lighting solutions#Switches#Amplifiers#Microcontrollers#Memory

2 notes

·

View notes

Text

Future Electronics’ stock reliability has long been a staple of the company

The company boasts an industry-leading selection of discrete semiconductor components, including diodes, transistors and circuit protection products.

#Future Electronics#globally integrated#IT infrastructure#Robert G. Miller#Capacitors#Film Capacitors#Analog#development tools#electromechanical#interconnect#lighting solutions#Switches#Amplifiers#Microcontrollers#Memory

2 notes

·

View notes

Text

As your trusted merchant services provider, Your Merchant Services Rep is committed to delivering reliable and flexible payment solutions that meet the unique needs of your business. With NMI Payment Gateway, you can streamline your payment processing, enhance your customer experience, and grow your business with confidence. Visit Us;

#nmi payment gateway#merchant account fees#electronic merchant solutions#online payment gateway integration#merchant account for car dealership

4 notes

·

View notes

Text

this may be a controversial take but I kinda like the doom 2016 ost more than doom eternal’s

#I feel like#2016 rly hits with the vibes#the atmosphere#eternal is just like. balls to the walls insanity ig#like ig it has more invidiual banger tracks#but the vibes are just like. killing demons and shit#doom 2016 hits it with the atmosphere and vibes#and have you ever listened to skullhacker bc GODDAMN#such a beautiful and violent track#I also still think rust dust and guts is underappreicated#it’s so groovy#I wish skullhacker played in more levels#I heard it the first time and was like OHHHHH MY GODDD the whole time#my gameplay leveled up#instant mass violence#okay one more point#I like that 2016 feels like it really integrated the electronic stuff with the metal stuff too#eternal does not feel like it does that#but the games have different vibes so it’s like. they both fit each game#I just like the cyber-y stuff too#the dissonance the dissonance#if only we got a true mick gordon doom eternal soundtrack :(#I still don’t understand how you have MICK GORDON composing your game’s soundtrack and you fuck it up that bad#the poor man#edit to add because I’m still awake for some reason#2016 also has rip and tear bfg division so. it wins#relentlesss bangers#where would we be without those two tracks. in despair that’s where we’d be

2 notes

·

View notes

Text

Geyer Electronic is an international provider of Frequency Control Products (Crystals and Oscillators), and demanding speciality batteries. The company has its headquarters in Gräfelfing near Munich, Germany, as well as offices in the US, Singapore, India, the UK and Hungary.

#President#Robert Miller#Future Electronics#globally integrated#IT infrastructure#Robert G. Miller#Capacitors#Film Capacitors#Analog#development tools#electromechanical#interconnect#lighting solutions#Switches#Amplifiers#Microcontrollers#Memory

2 notes

·

View notes

Text

By: Carine Hajjar

Published: Jan 3, 2024

If Harvard University wants to avoid more scandals like the ones that felled president Claudine Gay — and improve the educational experience on campus at the same time — the solution is straightforward: It needs to rebuild a culture on campus in which many points of view can be aired freely, whether the subject is affirmative action, transgender issues, Israel and Palestinians, or Harvard’s own decisions.

Conservatives, moderates, and even many liberals have been warning for years that Harvard has been drifting into dangerous ideological conformity, with progressive nostrums about race and gender identity promulgated as gospel, chilling what ought to be open debate over what are actually highly contested ideas. And now the university’s failure to do so has come home to roost.

Like a strong immune system, a healthy environment of open debate might have helped Harvard respond more effectively to its challenges over the past year — or maybe even to have avoided them in the first place.

Rebuilding that culture of open debate also means, inevitably, reforming the one that has increasingly taken its place. The university has created a diversity, equity, and inclusion bureaucracy that, despite its anodyne name, has had a pernicious effect on campus speech. Gay was part of that effort, dating to her tenure as dean of the faculty of arts and sciences.

What DEI offices like Harvard’s do can be hard to pinpoint and often sounds relatively innocuous. And some are, like diversifying “the portraiture of white men” on campus, which Gay’s Task Force on Visual Culture and Signage sought to do. But DEI also promotes a specific ideology that treats contentious ideas and terms — “white fragility,” for instance — as settled questions, and as part of the university administration, its diktats then carry a sense of authority.

From the outrage over Harvard’s admissions practices that essentially discriminated against Asian American students, to Harvard being ranked worst in free speech, to the bungling of the response to the Oct. 7 attack on Israel by Hamas, to Gay’s resignation, the events of Harvard’s tumultuous year are rooted in the school’s inability to accommodate heterodox viewpoints. Who was going to raise questions about Gay’s academic record — which might have prompted the university to scrutinize it more carefully before hiring her as president — when that would mean risking being labeled a racist or fragile under the university’s own DEI framework?

Sometimes faculty are hounded for stating science. Carole Hooven, a professor in Human Evolutionary Biology, was lambasted on campus for saying in 2021 that “there are in fact two sexes … and those sexes are designated by the kinds of gametes we produce.” The Harvard Crimson student newspaper reported that backlash included “some arguing Hooven’s remarks set back Harvard and the department’s diversity and inclusion efforts.” Hooven retired from Harvard and joined the American Enterprise Institute.

Gay, a progressive academic who appointed the first dean of Harvard’s Office of Diversity, Inclusion, and Belonging, was initially shielded from criticism by the Harvard Corporation, the university’s governing board, which should have investigated allegations of plagiarism as soon as they received them in October.

But Gay isn’t the sole offender. Harvard professor Steven Pinker told me she has been “caught up in a mess not of her own making.” That the board didn’t correct course sooner reflects a stubborn adherence to the school’s prevailing progressive agenda and the hubris of an institution that sees itself above criticism. Seemingly keeping Gay, a champion of the school’s progressive orthodoxy, was more important than enforcing rules of academic excellence.

To be clear, Harvard’s commitment to ideals like diversity and inclusion is good — when done correctly. Fostering a racially diverse, gender-balanced community helps to create nuanced conversations that enhance education and critical thinking. But as DEI has become the main priority of institutions of higher education, it has eclipsed the end that it is meant to serve: a well-rounded education that challenges students to think critically not only about their own ideas but the scrutiny of others.

What should institutional reforms look like? Pinker offered five good starting points in these pages, including adopting a “clear and conspicuous policy on academic freedom” and stopping students from disrupting events by exercising “a heckler’s veto, which blocks the speech of others.” Crucially, he encourages Harvard to “incentivize departments to diversify their ideologies” and to “disempower DEI.” I’d add reconfiguring job applications at Harvard to change or remove “DEI statements.” As the Bok Center for Teaching and Learning at Harvard describes them, such statements ask applicants to lay out “one’s accomplishments, goals, and process to advance excellence in diversity, inclusion, equity, and belonging as a teacher and a researcher in higher education” — a clear directive to mouth progressive policies.

All hope isn’t lost for Harvard. Pinker described this year as Harvard’s annus horribilis, evoking the term Queen Elizabeth II once used to describe an especially rough year for the British royal family. Even in the aftermath of her annus horribilis, though, Queen Elizabeth described the scathing critiques she received as “an effective engine for change.” Such change, she said, must “be incorporated into the stability and continuity of a great institution.” The first step is to create a place where such conversations can take place openly.

==

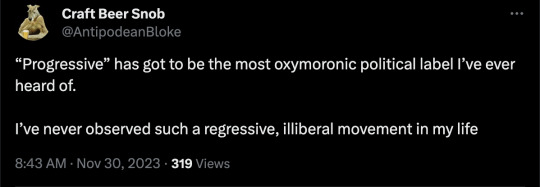

I despise the use of the term "progressive" here.

#Carine Hajjar#Nicholas Christakis#Eric's Electrons#Harvard#Harvard University#academic corruption#academic integrity#free speech#freedom of speech#higher education#diversity equity and inclusion#DEI bureaucracy#DEI must die#diversity#equity#inclusion#viewpoint diversity#academic freedom#heckler's veto#DEI statements#orthodoxy#conformity#Steven Pinker#affirmative action#racial discrimination#religion is a mental illness

3 notes

·

View notes

Text

Fighting for my life trying to find a phone or tablet with a headphone jack. Fighting for my life trying to find a laptop with a cd rom. Fighting for my life trying to get more than one usb port or, god forbid, an hdmi. Fighting for my life trying to find any electronics that haven't been streamlined into flimsy chastity belts with the structural integrity of a sopping sheet of paper which require me to buy 3 extra devices (each with their own separate charging requirements) all because some silicon valley jackass somewhere decided holes were a bad thing.

32K notes

·

View notes