#pmma

Text

Innovation in Clarity: Exploring the Applications of Poly Methyl Methacrylate (PMMA) (2023-2034)

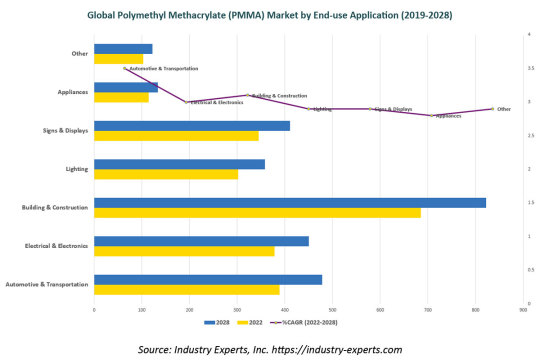

Ever heard of Polymethyl methacrylate (PMMA)? PMMA is a transparent and rigid thermoplastic, crafted from the monomer methyl methacrylate, holding impressive resistance to UV light and weathering. With its crystal-clear clarity, PMMA finds its way into a myriad of applications, from sleek car windows and durable smartphone screens. Read more about the versatility and manufacturing of PMMA in this blog! The global Poly Methyl Methacrylate (PMMA) market is likely to flourish at a CAGR of 4.05% by the year 2034.

Introduction

A scientific term, Poly (methyl methacrylate), refers to the clear and lightweight plastic commonly called acrylic or plexiglass. In its natural state, it's easily broken, but it can be colored, textured, and shaped in many ways. Crystal-clear plastic, known as Polymethyl methacrylate (PMMA) or acrylic, stands out for its toughness. Unlike glass, it won't shatter, making it a popular choice as a substitute. PMMA boasts several advantages over other clear plastics like polycarbonate (PC) and polystyrene (PS). These include superior resistance to sun damage and weather, exceptional light transmission, and the ability to be colored in any shade imaginable.

Scientific Properties: PMMA is scratch resistant and remains unaffected by aqueous solutions. However, exposure to certain chemicals like aromatic or chlorinated hydrocarbons, esters, or ketones can compromise its surface.

Sound and Break-Resistance: PMMA acts as a sound-resistant material, reducing the transmission of external sound waves. This quality makes it ideal for constructing spaces that require internal sound insulation, such as audio studios, libraries, quiet rooms, and vehicles.

Environmental Sustainability: PMMA exhibits excellent outdoor durability, resisting corrosion, ultraviolet light, and various environmental factors. Furthermore, it is both recyclable and BPA-free, making it one of the safer plastics in terms of environmental impact. These characteristics contribute to PMMA's sustainability profile, aligning with eco-conscious practices and initiatives.

Manufacturing Process

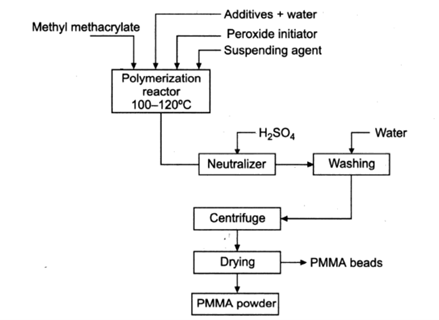

PMMA, derived from methacrylic acid (CH2=C[CH3]CO2H), is a significant member of the acrylic resin family. Its production primarily involves propylene, obtained from the lighter fractions of crude oil, and benzene, reacting to form cumene or isopropylbenzene. The resulting cumene undergoes oxidation to cumene hydroperoxide, then acid treatment to yield acetone. Subsequently, acetone undergoes a three-step process to produce methyl methacrylate (CH2=C[CH3]CO2CH3), a flammable liquid. Methyl methacrylate is polymerized, either in bulk liquid form or as fine droplets suspended in water, using free-radical initiators to form solid PMMA. This polymerization process links the molecules together, resulting in the formation of PMMA with a repeating unit structure.

The polymerization reactor receives a feed mixture consisting of a monomer, water acting as the reaction medium, suspending agents, and a monomer-soluble initiator. To adjust the density of the aqueous medium, decrease the monomer's water solubility, and increase interfacial tension, an inorganic salt is added. Polymerization occurs at around 100°C. After polymerization, the resulting slurry is neutralized with sulfuric acid before undergoing filtration or centrifugation. The material is then dried. This method ensures the controlled production of the desired polymer, achieved through the precise interaction of monomers, reaction medium, initiators, and additives within the polymerization reactor.

Applications of Poly Methyl Methacrylate (PMMA)

Construction

PMMA is very useful in building. It is commonly used for shatterproof skylights. It may also be found in many shower and bath systems, and many people prefer acrylic over ceramic tiles. As previously said, acrylic may be found in many sound-proof rooms, audio studios, and automobiles.

Automotive

PMMA sheets are utilized in automobile windows, motorbike windshields, interior and exterior panels, fenders, and other vehicle components. Colored acrylic sheets are also utilized in automotive indication light covers and interior light covers, among other applications. It is also utilized for ship windows (salt resistance) and aviation applications.

Electronics

Because of its superior optical clarity, high light transmission, and scratch resistance, PMMA is widely utilized in LCD/LED television screens, computers, smartphone displays, and electrical equipment. PMMA is also utilized as a cover material in solar panels due to its strong UV resistance and light transmission properties, which allow for high energy conversion efficiencies.

Furniture

PMMA provides exceptional features like transparency, hardness, and attractiveness to make chairs, tables, kitchen cabinets, bowls, and table mats in any shape, color, or finish.

Market Outlook:

The PMMA market is embracing sustainability. As environmental concerns grow, manufacturers are seeking eco-friendly solutions for PMMA, either through bio-based materials, improved recycling, or circular economy approaches. This aligns with the global push for sustainability and positions PMMA to meet evolving consumer and regulatory demands. Additionally, PMMA's clear optics, biocompatibility, and easy sterilization make it ideal for healthcare applications like lenses, instruments, and dental materials. As healthcare technology advances, PMMA's properties are well-suited for these demanding medical uses, creating exciting opportunities for market growth and diversification.

Poly Methyl Methacrylate (PMMA) Major Players

Significant companies in the Global Poly Methyl Methacrylate (PMMA) market are Mitsubishi Rayon Co., Ltd., Evonik, Chi Mei Corporation, Sumitomo Chemical, LX MMA, Wanhua Chemical, Suzhou Double Elephant Optical Materials, and Kuraray Co., Ltd., Lotte MCC, and Others.

Poly Methyl Methacrylate (PMMA) market restraints

The Poly Methyl Methacrylate (PMMA) market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Poly Methyl Methacrylate (PMMA) production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Poly Methyl Methacrylate (PMMA) manufacturers.

Difficulty in Recycling: While clear acrylic sheets can be recycled, the process is complex. Breaking down large pieces and using specialized methods like perspex recycling are just the first steps. This difficulty contributes to a global problem of acrylic waste harming ecosystems. In some areas, acrylic buildup disrupts the natural balance of CO2 and O2 exchange, hindering plant growth.

Conclusion:

The Polymethyl Methacrylate (PMMA) market has boomed in recent years, driven by its use in key industries like electronics, automotive, and construction. PMMA's unique properties, such as high durability and chemical resistance, suggest continued growth in the coming years. Rising urbanization, increasing demand for modern electronics, and projected growth in vehicle sales are all expected to fuel PMMA demand by 2034.

#PMMA#PMMAprices#PMMAmarket#PMMApricetrend#PMMApriceforecast#PMMAmarketprice#priceofPMMA#PMMAdemand#PMMASupply

1 note

·

View note

Text

Acrylic Sheet Direct Factory👈

-Size: 1220*2440(customize)

-Thickness: 1-8mm (customize)

-Color: Clear, White, Black, Red, Blue, etc.

#guangzhougoodsense#acrylicsheet#plexiglasssheet#acrylicpanel#plasticsheet#pmma#mirroracrylic#directfactory

1 note

·

View note

Text

As a transparent and lightweight alternative to glass, PMMA continues to shape industries and innovations worldwide.

Learn more about us at the website: www.szgtprototype.com

1 note

·

View note

Text

PMMA (polymethyl methacrylate) is a versatile polymeric material that is well-suited for many imaging and non-imaging microelectronic applications. PMMA resists are simply PMMA polymer dissolved in a solvent like anisole (safe solvent). Exposure causes scission of the polymer chains. PMMA is most commonly used as a high resolution positive resist for direct write e-beam offering extremely high-resolution, ease of handling and excellent film characteristics. PMMA is also used as a protective coating for wafer thinning, as a bonding adhesive and as a sacrificial layer.

#PMMA#Copolymer#PMMA Positive Resists#Copolymer Positive Resists#polymethyl methacrylate#PMMA polymer#AGAS

0 notes

Text

Comando-Geral da PMMA apura ação policial que resultou em suspeito baleado durante abordagem

A PMMA informou que instaurou um procedimento administrativo para apurar qualquer excesso que a guarnição possa ter cometido

O Comando-Geral da Polícia Militar do Maranhão (PMMA) está apurando uma ação policial que resultou em um suspeito baleado durante uma abordagem em Vitorino Freire, na tarde de segunda-feira (24).

De acordo com a nota divulgada pela PMMA, os policiais foram acionados para atender a uma ocorrência de roubo e, ao identificarem o suspeito, que portava uma arma branca, realizaram sua prisão. Durante…

View On WordPress

#Blog#Blog Jornalístico#Blogs#Brasil#Comanda-geral da PMMA#Governo do Maranhão#Grande Ilha#jornal#jornalismo#Maranhão#PMMA

0 notes

Link

0 notes

Text

I bought some matches today that marketed themselves as eco friendly, and they aren't exactly lying, but it is still a plastic based product, so it's not exactly green imo. I wasn't aware they were plastic when I bought them, based on the packaging it looked like it was some sort of compressed paper product. Either way, I'm a mix of dissapointment and surprise, with the ever growing conviction that humanity is going to hurt itself very badly in its confusion of sorting out the climate change mess. I'm really struggling to accept that anything involved with the plastic industry, which is heavily reliant on the oil industry, will ever be good for the planet. But I don't make the big descisions.

#the matches are called firestixs#by olympia inc#but its not on their website#the material is pmma (acrylic)#i found some documentation that seems to support the claim of thus being a 'clean' burning plastic#but its a whole chain to make the product#your telling me its greener to make a bunch of little plastic sticks insteads of do things with trees?#we can sustainably manage forests for our wood needs with electric equipement#and sure a wooden match may output for co2 and it all adds up#but also#is making a plastic stick the solution to wooden matches?#im quite unconvinced#enviromentalism#greenwashing#not an expert just a concerned citizen who did some googling#trees#matches#acrylic#pmma

1 note

·

View note

Text

PC PMMA GPPS Sheet & Plate Extrusion Line

We're professional plastic sheet & plate extrusion machine manufacturer with over 25 years experience and have ranked No.1 in the plastic extrusion industry for 11 consecutive years, accumulating rich manufacturing experience and advanced extrusion technology. JWELL exports over 3000 sets high-level extrusion production line to over 120 countries and areas every year. With high-quality equipment quality and sincere after-sales service, we have won the recognition and support of customers at home and abroad.

Our PC, PMMA, GPPS sheet and plate extrusion line is suitable to produce high quality PC plate, PC corrugated plate, PMMA plate and GPPS plate. The whole plate production line adopts intelligent PLC control system, high-performance single screw developed and made by our own factory, precise temperature control system device, which ensures good product quality and smooth production. Also, we provide 24-hour sustainable service during the whole project: workshop planning, marketing research, installation instructions online or on site, operation training online or on site, free spare parts and equipment upgrade.

PMMA/ACRYLIC is an important optical plastic with good comprehensive performance and optical performance. Its transparency can be comparable to that of optical glass, with light transmittance > 91%, good gloss, light and strong, good molding processability, good chemical resistance and weather resistance. It can be used as optical lens and industrial lens. It is a widely used plastic building material in the world and has incomparable advantages over other building decoration materials (such as glass, plexiglass, etc.).

PC has high toughness (with the same thickness, the impact strength of PC plate is 30-50 times that of PMMA plate), environmental protection, high heat resistance and cold resistance bending resistance, tensile strength equivalent to nylon, high elongation and elastic modulus, good dimensional stability, wear resistance equivalent to nylon, corrosion resistance and high transparency.

Advantages of PC PMMA GPPS Sheet & Plate Extrusion Line

04.

High-performance single screw extruder guarantees stable running and high capacity.

05.

Easy operation, energy saving, high speed production.

Specification of PC PMMA GPPS Sheet & Plate Extrusion Line

Model

JW130/38-2200

JW120/38-1400

Materia

PC, PMMA, GPPS

PC, PMMA, GPPS

Products Width

2200mm

1400mm

Products Thickness

1.5-10mm

1.5-10mm

Extruder Specification

Φ130/38; Φ45/30

Φ120/38

Capacity (Max.)

550kg/h

450kg/h

The Application of PC PMMA GPPS Sheet & Plate Extrusion Line

With its excellent weather resistance, impact resistance and high light transmittance, PC corrugated plate sheets are widely used on the roof of buildings, such as the sun room, swimming pool, ski resort and other infield passages, station rest booths, etc and has a broad market prospect.

PC endurance plates are applied to interior and exterior decoration materials of commercial buildings, curtain walls of urban buildings, transparent containers for aviation, windshield of motorcycles, aircraft, trains, ships, automobiles, steamboats, submarines and glass military and police shields; Layout of telephone booth, advertising signboard and light box advertising display exhibition; Noise barriers for highways and urban viaducts.

Ordinary PMMA plates are mainly used for advertising, decoration, decoration, process products, specimen signs, etc; Plating plate is used for vacuum plating plastic lenses; Lighting guide plate is used for advertising decoration such as ultra-thin light box, LED flat panel display lamp and poster frame; Liquid crystal light guide plate is used for computer, TV and other liquid crystal display components.

0 notes

Text

PMMA Market to Showcase Robust Growth in the Upcoming Year to 2032 | Asahi Kasei Corporation, Evonik Industries AG, Kolon Industries

PMMA Market to Showcase Robust Growth in the Upcoming Year to 2032 | Asahi Kasei Corporation, Evonik Industries AG, Kolon Industries

The Global PMMA Market 2023-2032 report is a collection of details related to industry performance. Every aspect is studied in detail in the research report. The market analysis report provides comprehensive analysis of all the financial topics associated with the PMMA industry. The growth pattern seen in the PMMA industry performance over the time is studied in the market report. The study helps…

View On WordPress

#PMMA#PMMA manufacturing companies#PMMA market#PMMA Market Size#PMMA market trends#Scope of PMMA industry

0 notes

Text

#HIPOLYMER#HIPOLYMER INTRODUCTION#WWW.HIPOLYMER.COM.CN#OPTICAL MATERIALS#LGP#DIFFUSER#REFLECTOR#PC#PMMA#PS#[email protected]

0 notes

Photo

@teraevents conception et fourniture, pour tout besoin en matière de conception et de fourniture de panneaux lumineux, contactez nous sur [email protected] /0797278813 /0772156872 /www.teraevents.com #teraevents #panneaux #design #constantine #panneauxpublicitaires #panneauxlumineux #pub #communication #pmma #forex https://www.instagram.com/p/Cf9vKGYrvIK/?igshid=NGJjMDIxMWI=

#teraevents#panneaux#design#constantine#panneauxpublicitaires#panneauxlumineux#pub#communication#pmma#forex

0 notes

Text

youtube

🌟Goodsense Group is ready to roll!💪

#guangzhougoodsense#goodsense#backtowork#SpringFestival2024#SpringFestival#aluminumcompositepanel#mosaicaluminumcompositepanel#ACP#acrylicsheet#mirroracrylic#plexiglass#pmma#Youtube

1 note

·

View note

Text

they should invent a nail polish that actually hardens in less than 24 hours. or ever

#sat with my nails directly in front of a fan for 45 minutes straight. felt them and they were totally dry. washed 3 dishes. nails smudged#fortunately it was just that the very tips got wrinkly so i was able to pat them somewhat smooth again#and i can trim off the messy parts once they fully harden for real#but still god. what the fuck does it take to get my nail polish to dry in a timely manner#don't talk to me about acrylics or gels btw my nails are wayyyy too brittle as is#plus i get so much exposure to pmma and uv light in dentistry already

11 notes

·

View notes

Text

Characteristics of transparent raw materials commonly used in plastics and injection molding process

Because plastic is light in weight, has good toughness and is easy to form. Due to its advantages such as low cost, plastic is increasingly used instead of glass in modern industries and daily products. It is especially used in optical instruments and packaging industries, is developing particularly rapidly. However, due to requirement of good transparency, high wear-resistant parts, and good…

View On WordPress

#characteristics and injection molding process of transparent plastics#Defects and solutions of transparent plastic parts#Defects of transparent products and methods to overcome#injection molding process#Injection molding process of transparent plastic#injection molding process of transparent plastics#injection molding processes#injection pressure#Mechanical Properties#mold design#Mold temperature#Performance issues of transparent plastics#PET process characteristics#plastic molding#Process characteristics of PC#Process characteristics of PMMA#Process characteristics of transparent plastics#product design#Transparent plastic injection molding process parameters

0 notes

Text

Cerca de 200 kg de drogas foram incinerada durante operação em Açailândia

A destruição das drogas foi acompanhada por representantes do Ministério Público e agentes da Vigilância Sanitária do município.

Na tarde da última quarta-feira(14), com a autorização da justiça, a Polícia Civil do Maranhão, incinerou aproximadamente 200 quilos de crack, pasta base de cocaína e cocaína que foram apreendidos através de operações realizadas pela Polícia Civil, Polícia Militar e Polícia Rodoviária Federal ao longo do ano de 2022 nas cidades de Açailândia, Cidelândia, Itinga do Maranhão, São Francisco do…

View On WordPress

#Açailândia#Brasil#Governo do Maranhão#Grande Ilha#Maranhão#PCMA#PMMA#Secretaria de Segurança Pública

0 notes