#extrusion

Text

taro mochi donuts with hokkaido milk tea glaze, by painacafelv on ig

x | x | x

x | x | x

x | x | x

#talos gifs#stim gifs#stim#food stim#food#irl food#sweets#donuts#cooking#mechanical#extrusion#deep frying#squishy#irl hands#gloved hands#metallic#silver#brown#purple

263 notes

·

View notes

Text

2 notes

·

View notes

Photo

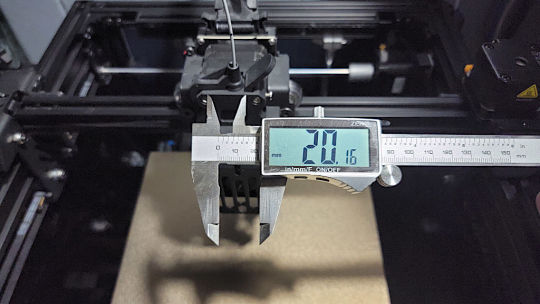

3D Printer Extruder Calibration Guide

Under- and over-extrusion FDM print quality issues are well-known in 3D printing. Calibration of the extruder, which involves calculating E-steps and tuning the extrusion multiplier, is essential. In this guide, we will walk through the full process for Marlin and Klipper firmware-based extrusion calibration. Also, we will dig into the filament flow rate, or extrusion multiplier, setting.

https://3dwithus.com/3d-printer-extruder-calibration-guide

4 notes

·

View notes

Photo

Virat Special Steels Pvt Ltd., is one of #India’s top Tool Steel, Die Steel suppliers, and Mould Steel Stuckists.

This company provides special steel of every kind in sizes and shapes (#flat, #round, or #bars) per customer requirements. Based in Gurgaon (Haryana) India

.

#SpecialSteels #ViratSpecialSteels #MakeinIndia #India #Gurgaon

Virat Special Steels offer “Make In INDIA” products at competitive prices, better quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their domestic customers.

As importers, Virat Special Steels fulfill any and all niche steel alloy that customers may require.

As one of India’s leading special steel suppliers, Virat Special Steels can supply the following grades of steel practically off-the-shelf.

- For Forging

- For Pressure Die Casting

- For Extrusion

- For Automotive

- For Plastic Moulding

- For Components

The above are cut to up to 2500mm - 1100mm as per customer requirement.

Learn more:

http://viratsteels.com

Any further queries feel free to contact us :

Email: [email protected] or Call: +91 98140 21775

#forging#pressurediecasting#extrusion#automotive#plasticmoulding#components#toolsteel#toolsteelsupplier#tool steel market#viratsteels#viratsteelsindia#2714steel#h13steel#din2714#din2738#db6steel#din2344#diesteel#mouldsteel#mouldsteelstockist#nipponsteel#metalworking

2 notes

·

View notes

Text

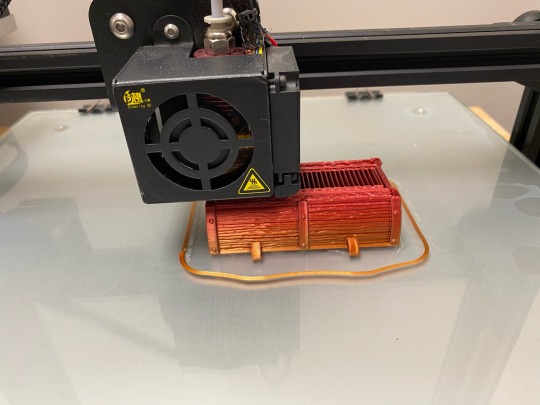

Broke out the printer for the first time in a long time and found this cool locking chest model. I was actually super impressed by the quality, even without any real tweaking on the slicer. It locks when fully closed, and unlocks with a cute little key.

Y'all have any suggestions for cool stuff to print? Tomorrow I'm gonna try to print some of those chopstick finger things that lets you snack while keeping your hands clean and free.

5 notes

·

View notes

Text

Source

1 note

·

View note

Text

Discover the versatility of 8020 Aluminum! From DIY projects to industrial applications, this T-slotted aluminum extrusion offers endless possibilities.

0 notes

Text

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Empowering Makers with Versatile Extrusions, Plates, Brackets, Fasteners, and more, Maker Store is thrilled to announce the launch of the much-anticipated 40-Series T-Slot Hardware.

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions. This versatile hardware collection includes; Extrusions, Plates, Brackets,…

View On WordPress

#3D Printers#40-Series#40-Series-Hardware#Aluminium Extrusion#Bracket#Brackets#Extrusion#Hardware#Plates

0 notes

Text

We want to Buy Your Equipment!

Have machinery sitting around that you aren't using anymore?

Arlington buys all types of plastic processing equipment in varying condition.

Need to upgrade a machine or looking for a totally different machine?

We also offer trade-ins or trade-in credit!

CLICK HERE! Tell us what you have and we will get back to you quickly with an offer!

Arlington is always looking for all kinds of plastic processing machinery including extrusion equipment, granulators, shredders, screen changers, injection molding machines and plastic support equipment.

#arlingtonmachinery#injectionmolding#extruder#extrusion#shredders#plasticsupport#lookingtobuy#tradeins#granulators#screenchangers

0 notes

Text

0 notes

Text

Unlocking the Potential of Aluminium Extrusions: A Comprehensive Guide

Introduction

Aluminium extrusions have become an integral part of various industries due to their versatility, durability, and cost-effectiveness. These extrusions, also known as aluminium extrusion profiles, are used in a wide range of applications, from architecture to automotive and beyond. In this blog, we will delve into the world of aluminium extrusions, exploring what they are, their benefits, and their applications. We will also touch upon the aluminium extrusions industry in the UK.

What are Aluminium Extrusions?

Aluminium extrusion refer to the process of shaping aluminium into a desired profile or shape by forcing it through a die. The result is a product with a consistent cross-sectional shape, which can be as simple as a solid rod or as complex as intricate architectural components. This process allows manufacturers to create custom profiles with precision, making aluminium extrusions suitable for a myriad of applications.

Benefits of Aluminium Extrusions

Lightweight: Aluminium is known for its lightweight properties, making it an excellent choice for applications where weight is a concern, such as in the aerospace and automotive industries.

Strength and Durability: Despite its lightness, aluminium is remarkably strong and corrosion-resistant, ensuring longevity and minimal maintenance.

Versatility: Aluminium extrusions uk can be customized to meet specific design requirements, enabling engineers and designers to create innovative solutions.

Cost-Effective: The extrusion process is efficient and minimizes material waste, leading to cost savings. Moreover, aluminium is a highly recyclable material, further reducing production costs.

Excellent Thermal and Electrical Conductivity: Aluminium has outstanding thermal and electrical conductivity properties, making it suitable for applications in the electronics and construction industries.

Applications of Aluminium Extrusions

Architectural: Aluminium extrusion profiles are commonly used in the construction industry for building facades, curtain walls, window frames, and structural components. Their lightweight and corrosion-resistant properties make them ideal for these applications.

Transportation: The automotive and aerospace industries benefit from aluminium extrusions due to their lightweight nature, helping to improve fuel efficiency and reduce emissions.

Electronics: Heat sinks, housing for electrical components, and mounting systems often utilize extruded aluminium profiles to dissipate heat and provide structural support.

Industrial: In the industrial sector, extruded aluminium profiles are used for conveyor systems, machine frames, and various other components due to their strength and ease of customization.

Consumer Goods: Products like aluminium extruded profiles are used in the manufacturing of furniture, kitchen appliances, and sporting goods, thanks to their aesthetic appeal and durability.

Aluminium Extrusions in the UK

The United Kingdom boasts a robust aluminium extrusions industry, with several companies specializing in the production and distribution of extruded aluminium profiles. These companies play a vital role in supporting various sectors, from construction to manufacturing, by providing high-quality, customized aluminium extrusions. The availability of these products in the UK ensures that local businesses have access to the materials they need for their projects.

Conclusion

Aluminium extrusions have revolutionized numerous industries by offering a versatile, lightweight, and durable material for a wide range of applications. Whether you're designing a modern architectural masterpiece or developing cutting-edge technology, aluminium extrusion profiles can be tailored to your specific needs. With the thriving aluminium extrusions industry in the UK, businesses can readily access these materials, contributing to the nation's innovation and development efforts.

0 notes

Text

Engineering Plastic Extrusion Profiles

Engineering plastic extrusion profiles are made from several technical polymers, each of which has special qualities including high elasticity, high wear and tear resistance, and great chemical resistance. Together with these qualities, the material manufactured by plastic extrusion manufacturers also has great machinability, dimensional stability, and resilience to high temperatures. These extrusion profiles provide solutions for sealing, electrical and thermal insulation, structural components, fluid management, and other high-performance applications. They are utilized in a variety of sectors, including automotive, aerospace, medical, and industrial. Extrusion profiles made of engineering plastics provide a number of benefits over materials like metal, rubber, and wood in terms of versatility, cost, and other factors.

Types of Engineering Custom Plastic Extrusion Profiles

Custom Nylon Profile

nylon is a tough and durable plastic material, known for its high resistance to wear and tear. Nylon extrusion profiles are commonly used in industries such as automotive, industrial, and construction.

Custom Elastomer Profile

elastomer materials offer high elasticity and flexibility, making them ideal for sealing or vibration damping applications.

Custom PC Extrusions Profile

polycarbonate provides high transparency, good impact resistance, and is commonly used in optical-grade applications such as lenses and windows.

Custom Enhancement GF Extrusion Profile

glass fiber is a material that can be added to plastic to provide reinforcement and increase strength, stiffness, and temperature resistance.

Other Custom Plastic Extrusion Profiles

there are several other engineering plastic materials available for extrusion profiles, including acetal, PEEK, PTFE, and PET, among others.

Advantages of Using Engineering Plastic Extrusion Profiles in Packaging and Storage

Plastic extrusion profiles offer several advantages for packaging and storage applications, including durability, chemical resistance, flexibility, and customization. These custom extruded profiles can be designed to fit specific product requirements, and their lightweight nature also makes them ideal for transport and storage. Additionally, extrusion profiles can be produced in high volumes, reducing costs and inventory management issues by plastic profile extrusion companies. Their ability to be recycled also makes them an environmentally-friendly choice. Overall, plastic extrusion profiles provide cost-effective and versatile solutions for various packaging and storage requirements.

0 notes

Text

Get Ready for a Wild Ride: The Surprising Surge of the Global Purging Compound Market in 2032: AMR

0 notes

Text

PVC fiber braiding pipe extrusion production line

0 notes

Text

0 notes