#Bioink

Text

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Photo

Bio-Ink

Tattoos with tech-twist: dynamic, glowing designs that change with your mood.

0 notes

Text

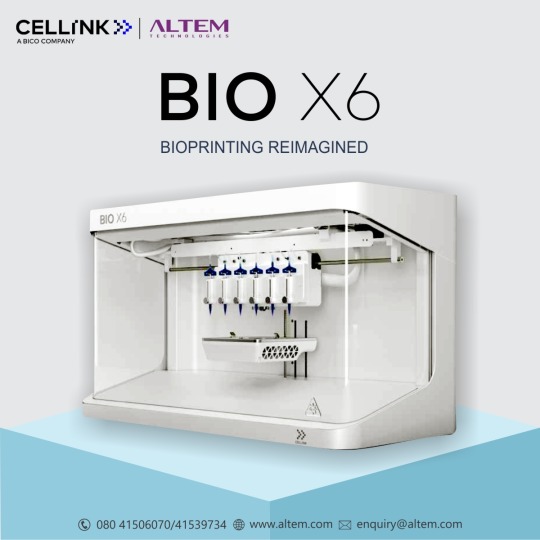

Print wide range of biocompatible biomaterials with BIOX6

The BIO X6 is designed as an open source system, ensuring compatibility with a diverse array of biomaterials.

The revolutionary BIO X6 elevates bioprinting to new heights. It is designed to enable an increased level of complexity without any added difficulty to researchers.

Know More: https://altem.com/bio-x6/

For more information, mail us at [email protected]

0 notes

Link

0 notes

Photo

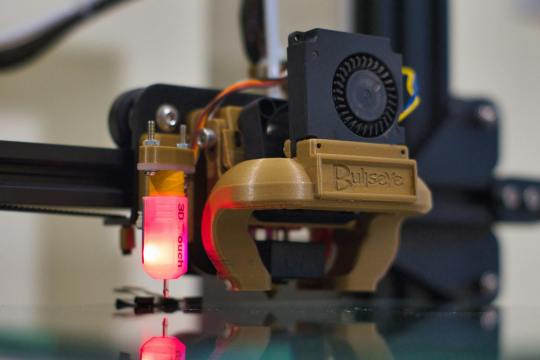

Where standard 3D printing uses a digital blueprint to manufacture an object out of materials like plastic or resin, 3D bioprinting manufactures biological parts and tissues out of living cells, or bioinks.

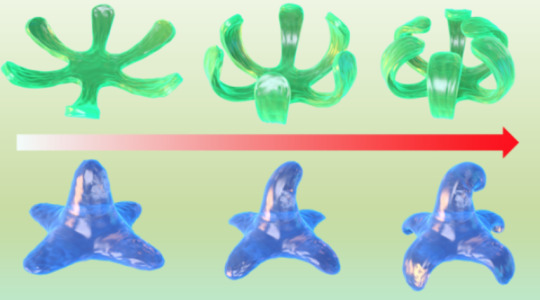

A fourth dimension — shape transformation over time — can be achieved by incorporating materials that enable printed constructs to morph multiple times in a preprogrammed or on-demand manner in response to external signals.

Bioprinting 4D constructs provide opportunities for scientists to better mimic the shape changes that occur during the development, healing, and normal function of real tissues and fabricate complex structures.

UIC Professor Eben Alsberg has developed a new cell-laden bioink, composed of tightly packed, flake-shaped microgels and living cells, for bioprinting 4D constructs. This new system enables the production of cell-rich bioconstructs that can change shape under physiological conditions. Read more.

0 notes

Photo

September 2022 | BioInk, 3D printing human tissue, and all the sci-fi bioscience you can dream of. Great visit to Axolotl Bioscience at @universityofvictoria for @bloombergbusiness. #Victoria #VancouverIsland #BritishColumbia #Canada #UniversityofVictoria #UVic #onassignment #bioscience #bioink #Axolotl #AxolotlBioscience #Bloombergphotos #scofiscience (at University of Victoria) https://www.instagram.com/p/CiZA7ubrYzJ/?igshid=NGJjMDIxMWI=

#victoria#vancouverisland#britishcolumbia#canada#universityofvictoria#uvic#onassignment#bioscience#bioink#axolotl#axolotlbioscience#bloombergphotos#scofiscience

0 notes

Text

How 3D Bioprinting Technology is Revolutionizing the Healthcare Industry?

3D printing also known as Additive manufacturing is the method of constructing a 3D object from a digital file. This technique is being used for several years and had a strong impact on manufacturing for industries such as – the art & jewelry industry, aerospace, construction, home development, soft sensors, firearms, computers (robot manufacturing), and several other industries. With the impactful use of 3D printing in several industries, in recent years exciting development in 3D bio-printing is being observed in the healthcare industry as well.

3D bioprinting has its application in various other fields like- imitation of medical devices, fabrication of anatomical models, and drug research.

Some of the Key Applications of 3D printing in the healthcare industry are as-

Bio-printing on Chip:

Bio-printing is a new technology in the field of the healthcare industry, which is used for constructing frames for tissue growth. Microfluidic organs-on-a-chip is a helpful platform that has several uses =, mostly seen in drug screening and pathological research. The majority of organs-on-a-chip technologies are designed for mechanistic investigations and proof-of-concept drug testing. These platforms frequently require advanced micro-fabrication methods. And, bio-printing technology provides the ability to automate this procedure and alleviate the throughput and the manufacturing challenges that are faced by traditional organ-on-a-chip systems encounter.

Bio-printing and Bone Grafts:

When the body faces considerable volumes of bone fractures, surgery and bone grafting are considered impactful procedures in the healing of the bones. Grafts do not frame the original form of the bone but have a detrimental impact on the success of facial reconstructive surgery. Recently, CAD technology combined with the improvements in additive manufacturing and 3D bio-printing technologies has provided impactful results in the production of frames for tissue regeneration, which have been implanted in the patients for the repair of blood vessels, and urethra, urinary bladder, and trachea.

Challenges and Limitations in 3D Bio-printing:

The endmost goal of 3D bioprinting is to provide a successful technology that is capable of producing 3D functioning for complex organs as a source for tissue grafts, full-organ transplants, and drug testing. The development in the technologies is still in its early stages but is progressing fast.

Biomaterials are important in 3D bio-printing because they support the structural and functional aspects of the 3D printing tissue while preserving structural integrity and bio-compatibility throughout tissue printing.

Companies working in Bio-printing:

In today’s world 3D bio-printing is not limited to specific industries. In days before the use of 3D bio-printing was used in the specific industries such as academic institutions and research centers, but over the past years the industry is progressing actively with impactful usage in many other idsustries incuding the prominent use in the Healthcare industry over the years. The fast progression in the industry over the past years, will provide a better solution for tissue construction in fatal cases of bone or facial complication.

The Key companies working in the field of 3D Bio-printing market are-

Organovo

3D systems

Regemat

Aspects Bio-systems

CYfuse

Nano4Imaging

Inventia Life Sciences

Vivax Bio

Regenovo

Get the in-depth knowledge about the 3D Bio-printing Technologies: https://www.delveinsight.com/blog/3d-bioprinting-in-the-healthcare-industry

Latest Reports and Blogs By DelveInsight-

Basal Cell Carcinoma Market

Birch Allergy Market

Bile Duct Neoplasm Market

Gingivitis Market

Lupus Nephritis Market

Severe Hypertriglyceridemia (SHTG) Market

Arthralgia Market

Severe Hypertriglyceridemia (SHTG) Market

Arthralgia Market Market

Congestive Heart Failure Market

Gingivitis Market Market

Lupus Nephritis Market

Erythromelalgia Market

AL Amyloidosis Market

Follicular Lymphoma Market

Chronic Pulmonary Hypertension Market

Adrenal Crisis Market

Retinoblastoma Market

Most Promising Therapies in the Food Allergy Treatment Market

What’s the Commercial Roadmap for the Launch: What can Biopharmaceuticals do to Increase the Odds of success?

How Contract Organizations are Impacting Pharma Development and Manufacturing

#3d bioprinting#Bioprinting#bio printing#Challenges and limitations of Bioprinting#Bioprinting on chip#Bioprinting and bone grafts#Bioprinting and Regenerative and Skin Tissue#Companies in the Bioprinting#Bioink#3d printing tissue#3d bioprinting companies#inkjet bioprinting

0 notes

Link

Every day in the United States, 17 people die waiting for an organ transplant, and every nine minutes, another person is added to the transplant waiting list, according to the Health Resources and Services Administration. One potential solution to alleviate the shortage is to develop biomaterials that can be three-dimensionally (3D) printed as complex organ shapes, capable of hosting cells and forming tissues. Attempts so far, though, have fallen short, with the so-called bulk hydrogel bioinks failing to integrate into the body properly and support cells in thick tissue constructs.

Now, Penn State researchers have developed a novel nanoengineered granular hydrogel bioink that makes use of self-assembling nanoparticles and hydrogel microparticles, or microgels, to achieve previously unattained levels of porosity, shape fidelity and cell integration.

The team published their approach in the journal Small.

"We have developed a novel granular hydrogel bioink for the 3D-extrusion bioprinting of tissue engineering microporous scaffolds," said corresponding author Amir Sheikhi, Penn State assistant professor of chemical engineering who has a courtesy appointment in biomedical engineering. "We have overcome the previous limitations of 3D bioprinting granular hydrogels by reversibly binding the microgels using nanoparticles that self-assemble. This enables the fabrication of granular hydrogel bioink with well-preserved microporosity, enhanced printability and shape fidelity."

Read more.

20 notes

·

View notes

Text

Bioinks and Bioprinters: Building Blocks of 3D Bioprinting in Medicine

Few innovations in medicine are as remarkable as 3D bioprinting. Scientists and researchers are venturing into the uncharted waters of this groundbreaking technology. 3D bioprinting, at its core, is the process of creating three-dimensional, living tissues and organs using layers of cells and biomaterials. It’s akin to traditional 3D printing, but instead of plastics or metals, the ‘ink’ used…

View On WordPress

0 notes

Text

Innovations in Biotechnology: Unraveling the Potential of 3D Bioprinting

3D bioprinting stands at the forefront of biomedical engineering, offering revolutionary solutions to some of the most complex challenges in medicine. Unlike traditional 3D printing, which constructs objects layer by layer using plastics or metals, 3D bioprinting utilizes living cells, biomaterials, and bioinks to fabricate tissues and organs. This cutting-edge technology has the potential to transform healthcare by providing personalized, regenerative therapies, and advancing our understanding of human biology.

At its core, 3D bioprinting involves the precise deposition of bioinks—bioactive materials containing living cells—onto a substrate according to a computer-generated model. By meticulously layering these bioinks, bioprinters can recreate the intricate structures found in natural tissues and organs. This ability to mimic the complexity of biological systems opens doors to a myriad of applications, ranging from tissue engineering and drug testing to regenerative medicine and organ transplantation.

One of the most promising aspects of 3D bioprinting is its potential to address the critical shortage of donor organs for transplantation. Every year, thousands of patients languish on waiting lists, hoping for a suitable organ match. With bioprinting, however, researchers envision a future where organs can be custom-made to match the specific needs of individual patients. By using a patient's own cells as the building blocks, the risk of rejection is minimized, and the need for immunosuppressive drugs is reduced, significantly improving post-transplant outcomes.

Moreover, 3D bioprinting offers new avenues for drug discovery and personalized medicine. Researchers can create realistic models of human tissues and organs, allowing for more accurate testing of potential therapies and reducing reliance on animal testing. These bioengineered models also enable clinicians to tailor treatments to individual patients, predicting how a particular drug or treatment will affect their unique physiology.

However, despite its tremendous potential, 3D bioprinting still faces several challenges. Scaling up production, ensuring the long-term viability of printed tissues, and navigating regulatory hurdles are just a few of the obstacles that researchers must overcome. Additionally, ethical considerations surrounding the creation and use of bioengineered tissues and organs raise complex questions about the intersection of science, technology, and morality.

In conclusion, 3D bioprinting represents a paradigm shift in healthcare, offering hope for patients in need of organ transplants, new therapies, and personalized treatments. While there are still hurdles to overcome, the ongoing advancements in bioprinting technology continue to push the boundaries of what is possible, promising a future where regenerative medicine is not just a dream but a reality.

#3D Bioprinting Market Demand#3D Bioprinting Market Share#3D Bioprinting Market Trend#3D Bioprinting Market Size

0 notes

Text

0 notes

Text

0 notes

Text

From Lab to Market: Harnessing the Power of Regenerative Therapies

The regenerative medicine market is experiencing a significant surge in interest and investment, driven by the revolutionary potential of this cutting-edge field. Regenerative medicine, with its focus on harnessing the body's natural healing processes to repair or replace damaged tissues and organs, represents a paradigm shift in healthcare. Stem cell therapies, tissue engineering, and gene editing technologies are at the forefront of this transformative movement, offering hope for patients with previously untreatable conditions.

Get a free Sample: https://www.marketdigits.com/request/sample/3073

In 2024, the Regenerative Medicine Market is valued at USD 25.04 billion and is anticipated to reach USD 164.9 billion by 2032, exhibiting a remarkable compound annual growth rate (CAGR) of 23.30% throughout the forecast period from 2024 to 2032.

Stem cell therapies, in particular, have captured widespread attention for their ability to regenerate damaged tissues and organs. Stem cells, with their unique capacity to differentiate into various cell types, hold immense promise for treating a wide range of diseases and injuries, including spinal cord injuries, heart disease, and neurodegenerative disorders like Parkinson's and Alzheimer's disease. Recent advancements in stem cell research, such as induced pluripotent stem cells (iPSCs) and mesenchymal stem cells (MSCs), have expanded the therapeutic potential of stem cell-based therapies, paving the way for personalized treatments tailored to individual patients.

Tissue engineering is another key focus area within the regenerative medicine market, offering innovative solutions for organ transplantation and tissue regeneration. 3D bioprinting technologies, which enable the fabrication of complex tissue structures using bioink formulations containing living cells, are revolutionizing the field of organ transplantation by addressing the critical shortage of donor organs. Moreover, tissue engineering approaches are being explored for applications ranging from skin grafts and bone implants to bioengineered organs like kidneys and hearts, offering new hope for patients awaiting life-saving transplants.

Major vendors in the global regenerative medicine market AstraZeneca plc, F. Hoffmann-La Roche Ltd., Integra Lifesciences Corp., Astellas Pharma, Inc., Cook Biotech, Inc., Bayer AG, Pfizer, Inc., Merck KGaA, Abbott, Vericel Corp., Novartis AG, GlaxoSmithKline (GSK) are and Others.

Gene editing technologies, such as CRISPR-Cas9, have emerged as powerful tools for precision medicine, allowing for targeted modifications of the genome to correct genetic defects underlying inherited disorders. In the realm of regenerative medicine, gene editing holds promise for treating genetic diseases like sickle cell anemia, cystic fibrosis, and muscular dystrophy by correcting or modifying faulty genes. Moreover, gene editing techniques are being employed to enhance the therapeutic properties of stem cells and to engineer tissues with improved regenerative capabilities, opening up new possibilities for personalized regenerative therapies.

Despite the immense promise of regenerative medicine, the field faces several challenges, including regulatory hurdles, ethical considerations, and the need for rigorous clinical validation. Ensuring the safety and efficacy of emerging therapies remains paramount, requiring robust preclinical studies and well-designed clinical trials. Moreover, addressing concerns related to patient access, affordability, and long-term follow-up will be essential for realizing the full potential of regenerative medicine in clinical practice.

In conclusion, the regenerative medicine market is poised for unprecedented growth and innovation, driven by advancements in stem cell therapies, tissue engineering, and gene editing technologies. With the potential to transform the treatment landscape for a wide range of diseases and injuries, regenerative medicine holds the promise of improving patient outcomes and quality of life. By harnessing the power of science and technology, we can unlock new frontiers in healthcare and usher in a new era of regenerative medicine.

0 notes

Text

3D Printed Wearable Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The 3D Printed Wearable Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global 3D Printed Wearable Market showcased a significant presence, boasting a valuation of US$ 3.88 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/3d-printed-wearable-market/

Projected Growth: Projections suggest that the 3D Printed Wearable Market will continue its upward trajectory, with a projected value of US$ 6.74 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 8.2%, reflecting a steady and robust growth rate for the 3D Printed Wearable Market over the coming years.

Technology Adoption:

Technology adoption in the 3D Printed Wearable market focuses on the utilization of additive manufacturing processes and advanced materials to produce customizable and functional wearable devices. 3D printing technologies such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) enable the fabrication of intricate wearable designs with high precision and accuracy. Additionally, advancements in biocompatible and flexible materials, including thermoplastics, elastomers, and bioinks, allow for the creation of comfortable and skin-friendly wearable products. Moreover, integration with digital design software and 3D scanning technologies facilitates personalized customization and mass customization of wearable devices.

Application Diversity:

The 3D Printed Wearable market serves diverse applications across various sectors, including healthcare, fashion, sports, and consumer electronics. In healthcare, 3D printed wearables such as prosthetics, orthotics, and medical braces offer personalized solutions for patients with mobility impairments or musculoskeletal disorders. Additionally, in the fashion industry, 3D printed wearables encompass a wide range of products, including jewelry, accessories, eyewear, and clothing, featuring intricate designs and custom fits. Moreover, in sports and fitness, 3D printed wearables such as customized footwear, performance trackers, and protective gear enhance comfort, performance, and injury prevention for athletes and enthusiasts.

Consumer Preferences:

Consumer preferences in the 3D Printed Wearable market are driven by factors such as comfort, aesthetics, functionality, and personalization. End-users prioritize wearable devices that offer ergonomic designs, lightweight construction, and breathable materials for enhanced comfort during prolonged wear. Additionally, consumers value stylish and customizable designs that reflect their personal preferences, lifestyle, and fashion tastes. Moreover, functionality and performance features such as durability, moisture-wicking properties, and sensor integration are important considerations for consumers, especially in sports and healthcare applications.

Technological Advancements:

Technological advancements in the 3D Printed Wearable market focus on improving printing speed, resolution, and material properties to meet the demands of diverse applications and user preferences. Research efforts aim to develop faster printing processes, such as continuous liquid interface production (CLIP) and high-speed sintering (HSS), for rapid prototyping and mass production of wearable devices. Additionally, advancements in multi-material printing, hybrid printing, and post-processing techniques enable the fabrication of complex wearables with customizable functionalities and surface finishes. Moreover, integration with smart materials, embedded sensors, and electronic components enhances the functionality and interactive capabilities of 3D printed wearables.

Market Competition:

The 3D Printed Wearable market is characterized by intense competition among 3D printing companies, wearable manufacturers, fashion brands, and healthcare providers, driven by factors such as design innovation, product performance, pricing, and brand recognition. Major players leverage their expertise in additive manufacturing, design capabilities, and industry partnerships to develop cutting-edge wearable solutions and capture market share. Meanwhile, smaller startups and design studios differentiate themselves through niche applications, unique design aesthetics, and collaborations with fashion designers or healthcare professionals. Additionally, strategic alliances, licensing agreements, and acquisitions are common strategies for companies to expand market reach and enhance product offerings in the competitive 3D Printed Wearable market.

Environmental Considerations:

Environmental considerations are increasingly important in the 3D Printed Wearable market, with stakeholders focusing on sustainable materials, production processes, and end-of-life disposal practices. Manufacturers strive to develop biodegradable and recyclable materials for 3D printing, such as PLA (polylactic acid) and TPU (thermoplastic polyurethane), to reduce environmental impact and promote circular economy principles. Additionally, efforts are made to optimize printing parameters, minimize material waste, and implement closed-loop recycling systems to conserve resources and reduce carbon emissions. Moreover, initiatives such as eco-friendly packaging, product life cycle assessment (LCA), and eco-labeling schemes promote transparency and accountability in sustainability practices throughout the 3D Printed Wearable supply chain.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Adidas

Nike

Under Armour

Apple

Google (Fitbit)

Hexoskin

Carbon, Inc

Formlabs

Protolabs

Xometry

The research report provides a comprehensive analysis of the 3D Printed Wearable Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/3d-printed-wearable-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Link

0 notes

Text

Marriage of synthetic biology and 3D printing produces programmable living materials

Scientists are harnessing cells to make new types of materials that can grow, repair themselves and even respond to their environment. These solid “engineered living materials” are made by embedding cells in an inanimate matrix that’s formed in a desired shape. Now, researchers report in ACS Central Science that they have 3D printed a bioink containing plant cells that were then genetically…

View On WordPress

0 notes