#Ed Moulthrop

Photo

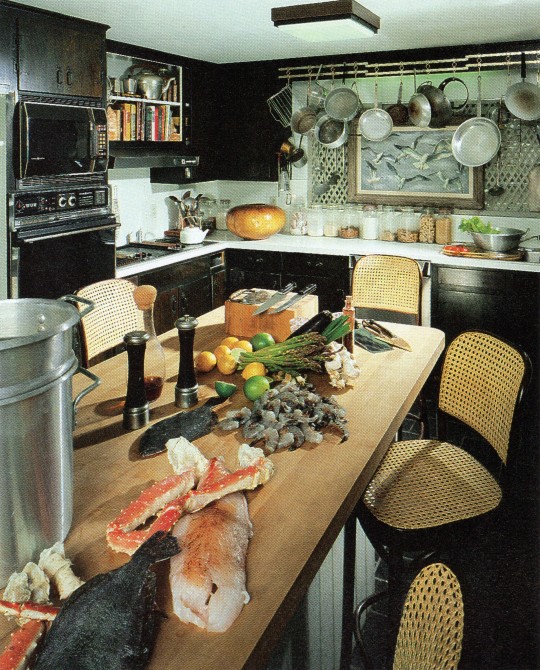

Seafood specialties are ready for cooking in the kitchen of the main house. A wooden bowl turned by Ed Moulthrop rests on the countertop. The painting of seagulls is by Ben Shute.

Southern Interiors, 1988

#vintage#vintage interior#1980s#interior design#home decor#eat in kitchen#kitchen#dining room#dining table#cane chair#seafood#dinner#cookware#lattice#southern#style#home#architecture#Ed Moulthrop

433 notes

·

View notes

Photo

Vessel, Philip Moulthrop, 2004, Minneapolis Institute of Art: Decorative Arts, Textiles and Sculpture

flying saucer-shaped, with flat foot, flaring outward to low, wide shoulder; flat top flaring inward to wide mouth opening; tans, light brown, mottled red-orange areas and two irregular black areas; star-like pattern at interior bottom; high gloss finish Philip Moulthrop's father Ed discovered nature's hidden beauty through his work with ashleaf maple, a wood local to Georgia, which when turned reveals surprisingly vibrant swaths of reddish pink. Philip and Matt Moulthrop continue to work with this colorful wood, as seen in this flying-saucer shaped bowl.

Size: 5 5/16 x 19 x 19 in. (13.49 x 48.26 x 48.26 cm)

Medium: Ashleaf maple

https://collections.artsmia.org/art/106773/

2 notes

·

View notes

Photo

Southern Magnolia Bowl, Ed Moulthrop, 1988, Art Institute of Chicago: American Art

Gift of Arthur and Jane Mason

Size: 88.9 × 25.4 cm (35 × 10 in.)

Medium: Magnolia wood

https://www.artic.edu/artworks/148049/

1 note

·

View note

Text

Wood Switching - Getting Going With the Fundamentals

Timber transforming is becoming a popular enhancement to the woodworker's arsenal of abilities. Nevertheless, it can be a challenge for the newbie as to what is needed to begin with the timber turret and what might already be around the store. There are simply a few fundamentals needed to start with this remarkable hobby. Carving Blanks

Obviously, the first thing one needs is a wood turret. Unless the budget is unrestricted, most turners begin with a beginning device. Thankfully wood turrets are less complicated and also consequently less costly than are metal turrets. Nevertheless, there are a few points even the beginner can look for with ease to make the financial investment go further Turning Blanks.

The lathe needs to be as heavy as you can afford. This can later on be amended by including sandbags to the stand, a really usual practise amongst woodturners, yet a hefty, cast iron turret is an excellent point to have. Timber turrets are sized by the optimum dimension of the item of wood they can deal with, however few turners will certainly wish to make use of the optimum capability of most newbie lathes.

Among the factors is the minimum rate of the lathe will certainly be also quickly in many cases for huge pieces of wood. Generally the minimum speed of a novice turret will certainly be in the 6 hundred change per minute or rpm array. This is all right for a 10 inch dish empty 3 inches thick, yet not for a 10 inch diameter log of maple thirty seven inches long as well as out of balance. Many novice lathes will hold that large a piece of timber however are most likely not safe to transform it. Try to find the most affordable minimum speed you can find Turning Blanks.

The turret will certainly frequently included a headstock and tailstock center which are utilized to hold spindles in position for turning. Most often there is additionally a faceplate made use of for holding bowls as well as such. Nonetheless, there will certainly not likely be a set of tools for to in fact reduce the wood. Distributors will market devices separately and also in collections. For many novices, a beginner set will certainly do great. Look for it to have a roughing cut, a number of spindle gouges, a couple of scrapes, a parting tool and a couple of skews. Make certain it is constructed from broadband steel which may be abbreviated as HSS.

Those devices will require to be sharpened but most stores will have a mill in them already. Get an aluminum oxide wheel of eighty to one hundred grit and also change among the wheels with this new one. A cabinet is a requirement. A developing jig is ruled out a need but I would highly suggest purchasing of making one for the newbie. It will conserve a lot of worry.

All that is left is the timber. For the beginning and also for that issue the innovative turner I recommend the wood pile as a wonderful place to look, particularly because many woodworking shops already have a bandsaw or various other means to prepare the timber for the lathe Turning Blanks.

Timber Dish Blanks - Wet and Dry

Wooden bowls are the pillar of several woodturners as well as an assumption of any individual taking a look at the work of a woodturner. In order to make a bowl, one requires an item of timber called a bowl space. These are either in wet or completely dry timber and require various strategies to end up the item.

Dry dish spaces are normally made use of for smaller bowls just because they are extremely tough to completely dry without splitting and also consequently seldom offered by suppliers. Small bowls, on the other hand might be made from spaces cut from two by six stock boards. Considering that this supply is truly just one and also five eighths by five and also 5 8s in hardwood as well as somewhat much less in softwood, it will certainly make a dish regarding five inches in size as well as one and also a fifty percent inches deep Turning Blanks.

To begin, reduce a circle out of the board simply over five inches in diameter. Mount it to the lathe with a faceplate or screw chuck and transform the outside of the dish, squashing the bottom and marking a circle as the turret turns. This need to be a little smaller sized than the bottom of the bowl.

Fasten a waste block to the faceplate and transform it rounded and also level. Currently turn it to fit the circle made use of the bottom of the dish space. Use warm glue to secure the waste to the space. It may be quickly placed to the turret. Real up the outside of the bowl and turn out the within. Currently sand and finish. To get rid of the blank either take it off the lathe as well as sharply hit a carve at the glue line or, much better, part know the waste block to concerning a fifty percent inch tenon and lever off the piece. The rubbing of the parting cut softens the adhesive as well as makes it very easy Turning Blanks.

Larger bowls are typically made from environment-friendly timber as well as are dual transformed. Initially rough the bowl out both inside as well as outside in between centers or using a chuck. It should be entrusted a density concerning 10 percent of its size. Cover the outdoors with wax solution to reduce drying out and also avoid cracking. The harsh transformed dish is currently let dry for 3 months or longer to permit it to readjust gradually to the loved one moisture of the shop. It will certainly warp as it dries but hopefully not crack. Flatten all-time low of the harsh dish with an airplane or sander and proceed as prior to making use of warm adhesive and also a waste block.

From Woodturning Blanks To Unique Handrafted Wood Products: A Background And Overview

The art of woodturning stemmed centuries earlier, in European nations where pin and dish turrets were driven manually, with pedals like a bike. They were much bigger as well as extra elaborate than the compact devices these days, and also were made use of to transform vessels of all sizes. However, these ancient devices generally run at really low speeds (visualize woodturning at a rate of one transformation per 2nd!) as well as required a lot of time as well as perseverance to finish any type of job of significance. The power tools these days's generation, by contrast, permit you to totally complete little projects such as pen kipping down the area of simply a couple of hours! As well as, to several in this period of "pleasure principle", even that might appear like a very long time to some. Yet, the delights of woodworking are often discovered in this process, time-consuming though it might be; if art can be quickly and also without thought produced, it sheds its charm and definition Turning Blanks.

When dealing with a lathe, you ought to be prepared with a range of devices that you'll use to shape the wood as it transforms. Newbies' woodturning sets are readily available with a typical variety of reducing tools, which will cover a range of sizes from little to big, depending on their objective. These include gouges, chisels, scrapers, and also alters. Make sure to shapen these tools before utilizing them in your woodturning, for ideal results!

Turning blanks been available in all ranges, from all-natural materials like wood and leather to acrylic and other synthetic materials. Creations from all-natural woodturning blanks carry themselves with class as well as dignity, and also show off a timeless look that will certainly never ever show up obsoleted, contrasted to patterned acrylics that mirror contemporary stylings. Wood turning blanks are offered in a significant variety of forms, sizes, tree species, textures and also colors. Most highly desirable are "figured" timber blocks that show undulating grain patterns, having even more all-natural contrast, interest, as well as visual charm. Spalted maple offers a specifically dynamic appearance, and also can be made use of to create really captivating objects!

Wood Turning Turret - Is Larger Better?

Wood turning lathes appear to be equipments on steroids some days. They are growing and also much more massive all the time. This is most likely in reaction to 2 trends in the timber transforming globe. First is the response from manufacturers to a propensity amongst turners to make bigger as well as bigger items. Second is the dominating concept that larger is always much better in almost every component of life. Often it is just not so Turning Blanks.

Ed Moulthrop was most likely not the first to transform big items but he became famous for them in the twentieth century. His backyard would certainly be filled with big areas of tree trunk more than 3 feet in diameter, awaiting their turn on his residence made turret. Most of them would certainly be prepared on an incline above the shop to make them easier to handle when trying to obtain them inside your home. He needed to utilize a block as well as take on to obtain them to as well as on the turret and the lathe was house made to obtain something big enough and also slow enough to transform them securely.

Right here we get an idea of what the turner of huge items of wood needs to contend with each time a piece takes place the lathe. Wood is heavy as well as the wood that a lot of turners work with is much heavier still. When you take into consideration that a lot of us start with eco-friendly timber, the weight is even greater. The amount of people will actually intend to duke it out a portion of wood more than 150 pounds in weight each time they desire to transform? That is a section of log big sufficient to turn a 24 inch dish. A 24 inch hollow kind will conveniently begin at 300 pounds for the space. Taking into consideration that some turners turn upwards of 4 foot size bowls, the weight is substantial. In maple the space, assuming you might locate a tree 4 feet in size, would certainly have to do with 1200 pounds.

For the average turner, if such an individual exists, a huge bowl often tends to be 12 inches in size and also for the beginner, 10 inches is a good dimension. It will hold a lot of salad, is big sufficient to manage, and also can appear more challenging than it needs to be. Numerous newbie level lathes will certainly deal with a 10 to 11 inch dish as well as will normally serve for a number of years ahead Turning Blanks.

What is necessary for the beginner is to obtain a lathe. Make certain it is tough sufficient to use with security and enjoyment. Wood transforming is growing swiftly and also timber transforming turrets for newbies are coming to be prominent with the makers. This is a good time to begin your enjoyment with a timber transforming lathe.

Wood Switching Projects - Discovering while Producing

Among the very first points a timber turner planned does is put a piece of wood on the new lathe as well as turn it rounded. After a couple of tries there is a simplicity to getting a round piece of timber that is only amounted to by the simplicity of obtaining stacks of satisfying shavings around one's feet. Then the question develops, "what next?" A lot of timber turners start turning on their own without instruction besides a book or a video and also probably a website for motivation. Quickly they discover timber turning jobs Turning Blanks.

Bowls are an essential of the turner's craft as well as a pillar of life. Small bowls can be easily made from "two by" supply such a 2x6. This enables the novice to discover a piece of dry wood conveniently as the majority of wood providers will certainly have kiln dried wood supply such as oak and maple readily available. A dish blank requirements to be reduced from the stock. This is just a circle of wood and in this case it could be regarding 5 1/2" in size.

This is installed to a tiny faceplate with screws as well as the beyond the bowl is transformed, seeking a pleasing curve. After that it is attached to a glue block, the inside is resorted to a constant wall surface density and the whole piece is fined sand. Ultimately, the bowl is turned around onto a jam chuck and all-time low is completed. To complete the dish a wood surface is used and allow dry. From this a beginner has discovered to develop a pleasing contour, to transform the inside as well as beyond a dish to consistent density, making use of glue blocks as well as jam chucks, sanding, as well as ending up. Additionally, there is a pleasing little dish to take pleasure in at the end of the procedure.

Spindles are a standard building block for lots of turning ventures. Tool handles are a great novice's timber turning project as many timber transforming devices are offered handleless. While this does conserve a couple of dollars it is in fact done due to the fact that several turners like to make their own manages custom fit to their hand. A block of timber sufficient for the device handle is secured between facilities and also transformed round. It is then shaped to best fit the hand of the wood turner. Most simply check out the deal with of their favorite tool as well as copy it, making the small changes that will certainly customize it and fit their own hand. Commonly an item of copper pipe is fitted throughout of the tool for a ferule as well as the end should be properly turned for a press fit. Off the lathe the deal with is pierced to fit the device shaft and also it is fitted on. With this simple project a wood turner learns to transform an item of timber to round, form it to a pleasing contour and fit, and also accurately look to a given measurement so that the ferule fits without sliding.

Most novice wood turning jobs should be conveniently as well as inexpensively repeatable. Exotic and also costly timbers can left for later on when experience is gained. Regional woods have an appeal of their very own and are simpler to get as the projects are done time and again. In this fashion the required abilities are obtained with interesting work and the turner discovers to develop interest in style with minor changes such as a modified curve or grains as well as coves that transform the appearance of the piece. Each project ought to show new skills and develop old ones to ensure that every piece turned is far better than the one in the past.

0 notes

Photo

Ed Moulthrop. Leigh Yawkey Woodson Art Museum, Wausau Wisc.

10 notes

·

View notes

Photo

Bowls by David Ellsworth:

These forms represent the earliest of my efforts in turning hollow forms using the bent tools I developed beginning in 1975. Almost all of these early pieces were made from planks of exotic woods, as was the fashion of the times. As my tools became more sophisticated in design, so, too, did the forms, especially the temptation to make smaller and smaller holes thereby increasing the mystery of their interiors.

My use of the term “bowls” may seem a bit misleading to those who interpret the term synonymous with “function.” I used the term in my early work because my friend Ed Moulthrop used it to describe his hollow forms. All artists steal their best ideas, and I figured it was important to steal from the best. In truth, I don’t think either of us knew what to call our work, so we just called them bowls.

The term ‘bowls’ fairly describes my work up until about 1979, at which point I was introduced to fresh-cut green wood and my whole design philosophy changed. It was because of this change that I began calling my pieces “vessels.”

4 notes

·

View notes

Photo

Issue #41, July 1983 On the cover, Ed Moulthrop turns a bowl big enough to to store @kenney.matt 's monthly ration of Swedish Fish.

0 notes

Photo

“I endeavor to inject into each one a balance of color and form, shape and substance that fully displays the beauty and richness of the tree. Each tree has a story to tell. Wormholes convey past life, rings communicate growth, and certain colors tell the story of death by lightening or blight. My job is to tell the story in picture book fashion, showing rather than talking, lengthening the life of the tree rather than ending it.”

— Matt Moulthrop

Generations: Turned Bowls by Ed, Philip, and Matt Moulthrop, an exquisite exhibition of eighteen large and small scale Moulthrop turned wooden bowls, opens March 25 at the Morris Museum of Art + remains on display through June 22. All of the pieces in this exhibition are on loan to the Morris from private collectors in Augusta, Georgia.

#Morris Museum of Art#Morris Museum#Matt Moulthrop#Ed Moulthrop#Philip Moulthrop#turned wooden bowls#art exhibition#AugustaGA

2 notes

·

View notes

Photo

Symbols of the ash tree are tenacity and adaptability. It's always been an ally of man in the production of artefacts. It grows rapidly and abounds in our woods. Oak is very elastic. This wood has the privilege of reminding of the sea, of wine and of precious and durable things.

1 note

·

View note

Photo

Vessel, Philip Moulthrop, 2004, Minneapolis Institute of Art: Decorative Arts, Textiles and Sculpture

flying saucer-shaped, with flat foot, flaring outward to low, wide shoulder; flat top flaring inward to wide mouth opening; tans, light brown, mottled red-orange areas and two irregular black areas; star-like pattern at interior bottom; high gloss finish Philip Moulthrop's father Ed discovered nature's hidden beauty through his work with ashleaf maple, a wood local to Georgia, which when turned reveals surprisingly vibrant swaths of reddish pink. Philip and Matt Moulthrop continue to work with this colorful wood, as seen in this flying-saucer shaped bowl.

Size: 5 5/16 x 19 x 19 in. (13.49 x 48.26 x 48.26 cm)

Medium: Ashleaf maple

https://collections.artsmia.org/art/106773/

5 notes

·

View notes

Text

Timber Turning - Beginning With the Fundamentals

Wood turning is coming to be a popular addition to the woodworker's collection of abilities. Nevertheless, it can be a problem for the beginner as to what is needed to start with the wood turret and what might currently be around the shop. There are just a few essentials required to start with this fantastic hobby.

Clearly, the initial thing one requires is a timber lathe. Unless the budget is unrestricted, most turners begin with a beginning tool. Fortunately wood lathes are much less complex and also therefore less costly than are metal turrets. Nevertheless, there are a couple of points even the newbie can look for with ease to make the financial investment go further Turning Blanks. Turning Blanks

The lathe should be as hefty as you can pay for. This can later be modified by including sandbags to the stand, a very typical practise among woodturners, yet a heavy, cast iron turret is a fantastic thing to have. Wood turrets are sized by the maximum dimension of the piece of timber they can handle, however few turners will certainly wish to make use of the maximum capability of a lot of beginner turrets.

Among the reasons is the minimal rate of the turret will be as well quick in many cases for big pieces of timber. Generally the minimal speed of a beginner turret will certainly remain in the 6 hundred change per minute or rpm variety. This is all right for a ten inch bowl empty 3 inches thick, but not for a 10 inch diameter log of maple thirty seven inches long as well as out of balance. Several newbie turrets will hold that large an item of wood however are most likely not safe to transform it. Try to find the lowest minimum speed you can discover Turning Blanks.

The turret will usually come with a headstock and tailstock facility which are made use of to hold pins in position for transforming. Frequently there is additionally a faceplate made use of for holding bowls and also such. Nonetheless, there will certainly not likely be a set of devices for to actually reduce the wood. Vendors will sell devices separately and in sets. For many newbies, a beginner collection will do great. Search for it to have a roughing cut, a couple of pin cuts, a number of scrapers, a parting device as well as a couple of alters. Make certain it is made from high speed steel which might be abbreviated as HSS.

Those devices will certainly need to be honed however most shops will have a grinder in them currently. Grab an aluminum oxide wheel of eighty to one hundred grit and replace among the wheels with this brand-new one. A dresser is a necessity. A developing jig is not considered a requirement however I would highly recommend purchasing of making one for the novice. It will certainly save a lot of irritation.

All that is left is the timber. For the start as well as for that issue the advanced turner I recommend the wood pile as a terrific location to look, especially because many woodworking stores currently have a bandsaw or various other means to prepare the wood for the turret Turning Blanks.

Timber Dish Blanks - Wet and Dry

Wooden bowls are the essential of lots of woodturners and an expectation of any individual taking a look at the work of a woodturner. In order to make a dish, one requires a piece of timber called a dish blank. These are either in wet or dry wood and also need various strategies to end up the item.

Dry bowl blanks are usually made use of for smaller sized bowls just because they are really tough to dry without cracking as well as therefore seldom readily available by suppliers. Small bowls, on the various other hand might be made from blanks reduced from 2 by 6 supply boards. Because this stock is truly only one and also 5 eighths by five and 5 8s in hardwood as well as slightly much less in softwood, it will certainly make a bowl regarding five inches in diameter and also one and a fifty percent inches deep Turning Blanks.

To begin, reduce a circle out of the board just over 5 inches in diameter. Mount it to the turret with a faceplate or screw chuck and turn the beyond the bowl, flattening all-time low and noting a circle as the lathe transforms. This should be a little smaller than the bottom of the bowl.

Secure a waste block to the faceplate and turn it rounded and also flat. Currently transform it to fit the circle made use of all-time low of the dish blank. Usage hot glue to fasten the waste to the space. It might be promptly placed to the turret. True up the outside of the bowl and also turn out the within. Now sand as well as coating. To eliminate the blank either take it off the lathe and greatly hit a sculpt at the adhesive line or, better, component know the waste block to regarding a fifty percent inch tenon as well as lever off the item. The friction of the parting reduced softens the glue and makes it easy Turning Blanks.

Bigger bowls are normally made from environment-friendly wood and are dual transformed. First rough the bowl out both inside and also outside between facilities or utilizing a chuck. It should be entrusted a density about 10 percent of its size. Cover the outside with wax emulsion to slow down drying and also avoid breaking. The rough transformed bowl is currently allow completely dry for 3 months or longer to allow it to change slowly to the loved one humidity of the store. It will warp as it dries out however ideally not crack. Flatten all-time low of the rough dish with a plane or sander as well as continue as prior to utilizing hot glue as well as a waste block.

From Woodturning Blanks To Distinct Handrafted Timber Products: A Background And Guide

The art of woodturning stemmed centuries back, in European countries where spindle and also dish lathes were driven manually, with pedals like a bike. They were a lot larger and also a lot more intricate than the small devices these days, and also were utilized to turn vessels of all sizes. Nevertheless, these ancient devices typically operated at really low speeds (imagine woodturning at a rate of one transformation per second!) as well as required a great deal of time as well as patience to finish any project of importance. The power devices these days's generation, by comparison, permit you to completely complete tiny projects such as pen kipping down the room of simply a couple of hrs! And also, to numerous in this period of "instant gratification", even that may feel like a very long time to some. Yet, the joys of woodworking are frequently found in this process, lengthy though it may be; if art can be quickly as well as thoughtlessly produced, it loses its allure and also significance Turning Blanks.

When dealing with a turret, you ought to be prepared with a selection of tools that you'll make use of to shape the timber as it transforms. Novices' woodturning collections are available with a typical selection of cutting tools, which will certainly cover a variety of dimensions from little to big, depending on their function. These include cuts, blades, scrapes, and also alters. Make sure to shapen these tools prior to utilizing them in your woodturning, for best results!

Turning blanks come in all ranges, from all-natural materials like timber and natural leather to acrylic as well as various other fabricated materials. Creations from all-natural woodturning blanks carry themselves with course as well as dignity, and flaunt a classic look that will certainly never show up dated, compared to patterned polymers that reflect contemporary stylings. Timber turning blanks are available in a substantial variety of forms, dimensions, tree species, structures as well as colors. Most highly desirable are "figured" timber blocks that program undulating grain patterns, having even more natural contrast, rate of interest, as well as visual charm. Spalted maple provides a specifically vibrant look, and also can be used to produce very appealing objects!

Wood Switching Lathe - Is Bigger Much better?

Wood turning lathes seem to be devices on steroids some days. They are growing and also a lot more enormous all the time. This is most likely in action to two fads in the wood turning globe. First is the response from producers to a tendency amongst turners to make larger and also bigger items. Secondly is the prevailing idea that bigger is constantly better in nearly every component of life. Often it is simply not so Turning Blanks.

Ed Moulthrop was most likely not the first to turn huge items yet he arrived for them in the twentieth century. His backyard would be full of significant sections of tree trunk greater than three feet in diameter, awaiting their turn on his house made turret. A lot of them would certainly be organized on a slope above the shop to make them less complicated to manage when attempting to get them inside. He had to make use of a block and take on to obtain them to as well as on the turret and the turret was home made to obtain something large sufficient as well as reduce sufficient to turn them safely.

Here we obtain an idea of what the turner of large pieces of timber has to emulate each time a piece takes place the turret. Wood is heavy and the hardwood that the majority of turners collaborate with is larger still. When you take into consideration that a lot of us start with eco-friendly timber, the weight is even greater. The number of people will really want to wrestle with a chunk of timber more than 150 pounds in weight each time they want to turn? That is a section of log large enough to transform a 24 inch bowl. A 24 inch hollow type will quickly start at 300 extra pounds for the blank. Thinking about that some turners transform upwards of 4 foot diameter bowls, the weight is substantial. In maple the blank, thinking you can locate a tree 4 feet in diameter, would have to do with 1200 extra pounds.

For the average turner, if such a person exists, a big bowl often tends to be 12 inches in size and also for the beginner, 10 inches is a great size. It will certainly hold a great deal of salad, is huge enough to deal with, and can appear more daunting than it requires to be. Several novice degree lathes will certainly deal with a 10 to 11 inch bowl as well as will generally offer for a number of years to come Turning Blanks.

What is important for the newbie is to acquire a lathe. Be sure it is sturdy enough to use with security and satisfaction. Timber transforming is expanding promptly as well as wood transforming turrets for newbies are becoming preferred with the suppliers. This is a great time to start your pleasure with a timber transforming lathe.

Wood Switching Projects - Knowing while Making

Among the initial points a wood turner in the making does is put an item of timber on the new turret and also turn it rounded. After a couple of attempts there is a simplicity to getting a round piece of wood that is only equaled by the simplicity of obtaining piles of satisfying shavings around one's feet. After that the question emerges, "what next?" The majority of timber turners start activating their own without guideline except for a book or a video and also perhaps an internet site for motivation. Soon they find out about wood turning jobs Turning Blanks.

Bowls are a pillar of the turner's craft as well as an essential of life. Small bowls can be quickly made from "two by" stock such a 2x6. This makes it possible for the newbie to find a piece of completely dry timber quickly as a lot of timber suppliers will certainly have kiln dried out hardwood stock such as oak and maple conveniently offered. A dish empty needs to be cut from the stock. This is just a circle of timber and in this case maybe about 5 1/2" in size.

This is installed to a small faceplate with screws as well as the beyond the bowl is transformed, seeking a pleasing curve. After that it is attached to an adhesive block, the inside is looked to a constant wall thickness as well as the entire piece is fined sand. Ultimately, the bowl is reversed onto a jam chuck and the bottom is completed. To finish the dish a wood surface is used and let completely dry. From this a newbie has discovered to create a pleasing curve, to turn the within and outside of a dish to consistent density, using adhesive blocks as well as jam chucks, sanding, as well as completing. Furthermore, there is a pleasing little bowl to enjoy at the end of the process.

Spindles are a basic building block for lots of transforming endeavors. Device takes care of are an excellent newbie's timber transforming job as many timber transforming devices are sold handleless. While this does conserve a couple of bucks it is in fact done because many turners like to make their very own handles customized fit to their hand. A block of wood adequate for the tool take care of is anchored in between centers and also transformed round. It is then formed to ideal fit the hand of the wood turner. Many just look at the deal with of their preferred device as well as copy it, making the mild adjustments that will certainly personalize it and also fit their own hand. Often a piece of copper pipe is fitted throughout of the tool for a ferule and completion should be precisely transformed for a press fit. Off the lathe the handle is drilled to fit the device shaft and it is fitted on. With this straightforward task a wood turner discovers to turn an item of timber to round, form it to a pleasing curve and fit, as well as accurately look to a provided dimension so that the ferule fits without slipping.

Most beginner timber turning tasks must be quickly and also inexpensively repeatable. Unique and also costly woods can left for later when experience is gained. Local hardwoods have an appeal of their very own and are simpler to obtain as the tasks are done time after time. In this way the necessary skills are obtained with fascinating work and also the turner discovers to construct rate of interest in layout with minor changes such as an altered contour or beads and also coves that change the look of the piece. Each task must teach brand-new abilities and develop old ones to ensure that every item turned is far better than the one before.

0 notes

Photo

Vessel, Ed Moulthrop, 1984, Minneapolis Institute of Art: Decorative Arts, Textiles and Sculpture

flat base with raised tall foot; rounded bottom; roughly cylindrical sides; thin rim; dark to light brown shadings with area of short lines (worm holes?); glossy surface Ed Moulthrop, the patriarch of the Moulthrop wood-turning family, was father to Philip Moulthrop and grandfather to Matt Moulthrop, whose work is also shown in this case. Ed developed an affinity for woods local to his Atlanta studio, including tulipwood, which he turned on a small and large scale; an example of the latter can be seen in the photograph on the text panel in this exhibition.

Size: 13 3/8 x 7 9/16 x 7 13/16 in. (33.97 x 19.21 x 19.84 cm)

Medium: Figured tulipwood

https://collections.artsmia.org/art/106767/

1 note

·

View note

Photo

Vessel, Matt Moulthrop, 2005, Minneapolis Institute of Art: Decorative Arts, Textiles and Sculpture

small flat base; outward-flaring to wide shoulder and inward flaring to wide mouth opening; medium to dark brown with dark brown mottled lines in irregular shapes; high gloss finish Matt is the youngest of the three generations of Moulthrop wood turners (he is Philip's son and Ed's grandson). Matt apprenticed in his grandfather's workshop in Atlanta, where he learned to use local woods to create elegant vessel forms. Though each Moulthrop uses subtle details to distinguish his pieces, the three men's collective works are cohesive and easily identifiable because of their generous vessel forms and their attention to the wood's grain and surface treatment. Ed, Philip, and Matt also share a similar creative process: the wood is turned while green, then treated with polyethylene glycol (to prevent warping and to emphasize the grain) and allowed to dry for six months before it is turned again, sanded, and coated with a high gloss epoxy finish.

Size: 9 3/8 x 20 1/4 x 20 1/4 in. (23.81 x 51.44 x 51.44 cm)

Medium: Red maple

https://collections.artsmia.org/art/106768/

1 note

·

View note

Photo

Southern Magnolia Bowl, Ed Moulthrop, 1988, Art Institute of Chicago: American Art

Gift of Arthur and Jane Mason

Size: 88.9 × 25.4 cm (35 × 10 in.)

Medium: Magnolia wood

https://www.artic.edu/artworks/148049/

0 notes

Photo

Vessel, Ed Moulthrop, 1986, Minneapolis Institute of Art: Decorative Arts, Textiles and Sculpture

very large bowl, flaring outward from raised foot In this massive turned wood vessel, artist Ed Moulthrop revealed both flame-like and linear patterns of the cedar by using his own specially-designed long-handled tools, as well as his own strength. In order to find specimens this size, Moulthrop sourced near his Atlanta, Georgia, home. Besides the availability, he admired the beauty of local southern woods, including ashleaf maple and white pine, knowing that no two trees—and therefore no two turnings—would be alike.

Size: 21 7/8 x 29 7/16 x 29 7/16 in. (55.56 x 74.77 x 74.77 cm)

Medium: Deodara cedar

https://collections.artsmia.org/art/66476/

0 notes

Photo

Join us: Thurs. March 27, 6 pm, Exhibition Opening: Generations: Turned Bowls by Ed, Philip, and Matt #Moulthrop. Philip and Matt Moulthrop discuss the process of turning ordinary wood into extraordinary artworks. Roy Simkins, an ardent Moulthrop collector, will provide their introduction. Reception follows. Members, free; nonmembers, $5.

#ed moulthrop#MattMoulthrop#philip moulthrop#Moulthrop bowls#turned wooden bowls#art exhibition#Morris Museum of Art#MorrisMuseum#AugustaGA#Roy Simkins#artwork#opening reception

0 notes