#cncmilling

Text

What is a difficult-to-process material?

When difficult-to-process materials are mentioned, different images of materials come to mind. Among them are materials with low thermal conductivity such as titanium alloys. So far, we have been working on hard-to-cut materials such as titanium alloys processing dozens of products every year, and have accumulated daily processing experience.

And based on these records, we provide the best processing conditions for each product. In addition, special tools from our tool suppliers have solved the challenges of machining accuracy and productivity for us. Now, TPV Precision Machining can achieve high precision machining with tolerance width ± 0.003mm, low thermal expansion material area of 1000mm x 1000mm, and flatness of 0.02mm or less.

In the field of machined parts, we are engaged in a wide range of fields such as aircraft, automobiles, semiconductor manufacturing equipment, liquid crystal exposure equipment, and medical equipment, and have contributed greatly to supporting cutting-edge technology. And we have received high praise from our customers.

#machining#sales#communication#cncmachining#cncmanufacturing#cncmilling#cncmachine#cncmachinist#cncmachiningparts#cncgrinding#precisionmachining#precisionengineering#precision#precisionmanufacturing#3axis#4axis#5axis#5axismachining#5axiscnc#rapidprototyping#rapidtooling#rapid#automaticmachine#automative#medical#energi#car#millingmachine#turning#elections

2 notes

·

View notes

Text

𝐍𝐞𝐰 𝐑𝐎𝐁𝐎𝐃𝐑𝐈𝐋𝐋 - α-𝐃 𝐢𝐁 𝐏𝐥𝐮𝐬 𝐬𝐞𝐫𝐢𝐞𝐬

𝐇𝐢𝐠𝐡 𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 𝐕𝐞𝐫𝐭𝐢𝐜𝐚𝐥 𝐌𝐚𝐜𝐡𝐢𝐧𝐢𝐧𝐠 𝐂𝐞𝐧𝐭𝐞𝐫:

🔹Spindle Torque up to 100 nm max and Spindle speed of 24.000 1/min max.

🔹Excellent user interface for easy programming and setup.

🔹Latest CNC series 31 iB5 Plus

🔹Fast cycle time technology

🔹Fine surface technology.

🔹Integrated 5-Axis technology

#5axiscnc#robodrill#fanuc#studentstraining#technology#vmc#newtechnology#compactmachines#cncmilling#cncmanufacturing#vmcmachine#newtechnologies#solidcamtraining#designing#engineerdesign#metaldrilling#drillingmachine#drillmachine#fanucmachines#programming#surfacetechnology#verticalmachining#solidworks#machine parts designing

0 notes

Text

"Glowing Secrets of CNC Machining: Revealing the Special Tools for Metal Part Brightening"

Dive into the enchanting realm of CNC machining as we unveil the magical tools and processes that bring sheer radiance to metal components. Follow our blog to discover how these exceptional cutting tools transform ordinary parts into gleaming treasures. #CNCmachining #MetalBrightening #MagicalTools

#CNCmachining#MetalBrightening#MagicalTools#cncmilling#productdevelopment#instamachinist#autodesk#cncparts#innovation

0 notes

Text

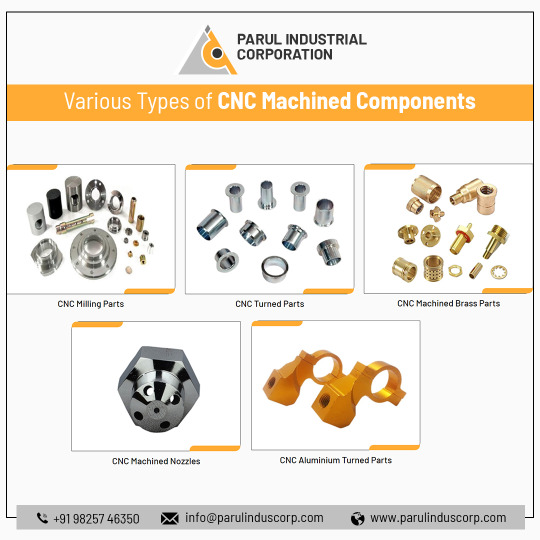

Parul Industrial Corporation presents a world of precision with a diverse range of CNC machined components. From CNC Milling and Turned Parts to CNC Machined Brass Parts and Nozzles, as well as CNC Aluminium Turned Parts – our collection covers it all.

For more details, visit- https://www.parulinduscorp.com/products/cnc-machined-components

#parulindustrialcorporation#cncmachinedparts#cncmachinedbrassparts#cncaluminiumturnedparts#cncmilling#cncmillingparts#cncturnedparts

0 notes

Text

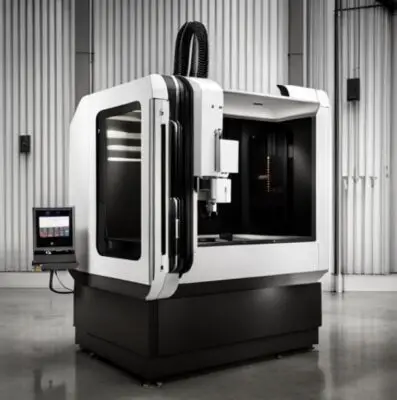

What You Should Know Before Buying a CNC Mill

Are you considering the purchase of a CNC (Computer Numerical Control) mill? With increasing options in precision machining and manufacturing, these specialized tools can provide powerful capabilities for detail-oriented work. Before taking the plunge into investing in a CNC mill, there are important points to consider such as cost and performance; understanding what is available on the market will help you make an informed decision. In this blog post, we'll explore some of the key features to look out for when buying a CNC mill so that you can find one that meets your needs while staying within budget.

What is a CNC Mill and how does it work?

A CNC mill is a machine used in manufacturing that employs computer-controlled engineering to produce highly precise parts and products. CNC mills utilize instructions in the form of numerical software to control the cutting process of a workpiece. The machine typically consists of a bed, spindle, motor, cutting tools, and worktable. The cutting tools, which range in shape and size, rotate at high speeds, shaving away material from the workpiece to create the desired shape.

The CNC mill allows for incredibly accurate and reliable production, making it ideal for creating complex and intricate parts for various industrial applications. The machine can be programmed to cut and shape a variety of materials, including metals, plastics, and composites, to create three-dimensional objects of nearly any shape.

The CNC mill works by utilizing a combination of computer software and hardware to control the process. A CAD (computer-aided design) program creates a digital model of the part or product, which is then translated into a series of instructions in G-code. The G-code provides the instructions for the CNC mill to precisely move the cutting tools and worktable, ultimately creating the desired shape.

Once the G-code is loaded into the CNC mill's computer, the machine begins cutting, precisely following the programmed instructions. The operator monitors the process, making adjustments as necessary to ensure the workpiece is produced to specifications.

The CNC mill provides a highly automated and precise way of manufacturing complex parts and products. By using a combination of computer software and hardware, the machine produces accurate and reliable results, meeting the demands of modern manufacturing processes.

What are the Different Types of CNC Mills and Their Uses?

Computer Numerical Control (CNC) mills are essential tools in modern-day manufacturing. CNC mills operate with the use of software and computer programs, which allow them to execute precise cutting and shaping of materials. Different types of CNC mills are available, and they come with varying capabilities to perform diverse functions.

Here are the different types of CNC mills and their uses:

1. Vertical Milling Machine:

Vertical milling machines are designed to work with flat or rectangular metal surfaces. The spindle is positioned vertically, enabling a wide range of cutting possibilities such as drilling, tapping, and milling. This type of mill is perfect for manufacturing large quantities of flat or rectangular parts.

2. Horizontal Milling Machine:

This mill is suitable for cutting and shaping materials from different angles. The spindle is positioned parallel to the worktable, allowing for precision cutting, drilling, and boring. Horizontal milling machines are excellent for producing parts in bulk quantities.

3. Bed Milling Machine:

Bed milling machines have a vertically adjustable spindle that moves along the Z-axis. The bed can move along the X and Y-axis, allowing the machine to cut along different paths. Bed milling machines are ideal for creating parts with various shapes and sizes.

4. Turret Mill:

A turret mill has a rotating spindle with a cutting tool at the end. This machine has a table that can be moved vertically and horizontally, giving it the capacity to cut and shape intricate forms. Turret mills are perfect for delicate jobs that need fewer cuts and a more precise finish.

5. CNC Router:

CNC routers are designed to remove material from a workpiece, allowing it to be formed into a particular shape or pattern. It uses a rotating cylindrical tool that moves along multiple axes, providing precision cutting for objects like wooden decorative pieces, furniture parts, signboards, and architectural moldings.

Different CNC mills are available for specific purposes, and the choice of the type depends on the materials, shapes, and productivity needs. While operating CNC mills may require skillful expertise, success hinges on selecting the right type of CNC machine for the particular task at hand.

Benefits of Using a CNC Mill for Manufacturing

Standard benefits:

- Increased accuracy and precision of parts compared to manual methods.

- Reduced production time with automated processes.

- Ability to produce complex shapes with ease.

Emotional benefits:

- Feel confident in the quality of your products due to increased accuracy and precision.

- Enjoy the satisfaction of creating high-quality parts quickly and efficiently using CNC Mill for Manufacturing technology.

Advantages and Disadvantages of CNC Milling

Computer Numerical Control (CNC) milling is a type of precision engineering process that utilizes computer-controlled cutting tools to remove material from the workpiece. CNC milling has become a popular manufacturing method due to its accuracy, efficiency, and versatility. However, just like any other manufacturing process, CNC milling has its own advantages and disadvantages that must be considered.

Advantages:

1. Precision and Accuracy: CNC milling machines are capable of producing complex and intricate shapes with high precision and accuracy. This is because the cutting tools are guided by the computer, which ensures that the dimensions are consistent throughout the production process.

2. Flexibility: CNC milling machines are extremely versatile and can produce a wide range of products. It is possible to create different shapes, sizes, and forms without the need for different setups.

3. Consistency: CNC milling machines can produce identical parts with high consistency. This means that once the program for a particular part has been created, it can be easily replicated with the same level of accuracy every time.

4. Efficiency: CNC milling machines are highly efficient and can produce a high volume of parts within a short time. This helps to reduce production time and costs.

5. Automation: The use of CNC milling machines reduces the need for manual labor, which can lead to a reduction in costs and an increase in productivity.

Disadvantages:

1. High Cost: CNC milling machines are expensive to purchase, install, and maintain. This makes it difficult for small businesses and startups to invest in this technology.

2. Complex Programming: CNC milling machines require complex programming to operate. This means that operators need to have specialized skills and knowledge to use them effectively.

3. Dependence on Electricity: CNC milling machines rely on electricity to operate. This means that power outages or fluctuations can result in downtime and production delays.

4. Limited Material Handling: CNC milling machines are limited in their ability to handle certain types of materials. This means that operators will need to use different machines for different materials, leading to increased costs and longer production times.

5. Lack of Flexibility: While CNC milling machines are highly flexible, they can be limited in their ability to produce certain types of shapes and materials. This means that some parts may need to be produced through other methods, leading to longer production times and increased costs.

CNC milling has revolutionized the manufacturing industry by providing accurate and efficient production of various parts and products. However, it is important to consider the advantages and disadvantages of this technology before investing in it. By weighing these factors carefully, businesses can make informed decisions about whether CNC milling is the right choice for their production needs.

Factors to Consider When Purchasing a CNC Mill

If you're looking to purchase a CNC mill, there are several factors that you should consider before making your final decision. A CNC mill is a computer-controlled machine that uses rotating tools to remove material from a workpiece. It offers many benefits, such as increased accuracy, repeatability, and automation, which improves efficiency and saves time. Here are the factors that you should take into account when purchasing a CNC mill.

1. Machine Size:

The size of the CNC mill that you choose will depend on the size of the workpieces that you're planning to mill. If you're working with large pieces of material, you'll need a larger machine that can handle the size and weight of the workpiece. Conversely, if you're working with small pieces, you'll need a smaller machine to ensure accurate and precise cuts.

2. Machine Capability:

Different CNC mills have varying capabilities. You should choose a machine that has the capabilities that you need for your specific application. Factors to consider include the number of axes, spindle speed, and cutting capacity. If you're working with complex parts that require multiple cutting operations, you'll need a machine that has a high number of axes to achieve the required cuts accurately.

3. Machine Accuracy:

Precision and accuracy are critical in CNC milling. When purchasing a CNC mill, ensure that it has the required tolerances and accuracy level for your application. The accuracy of a CNC mill is usually measured in microns, so choose a machine with an accuracy level that meets your needs.

4. Machine Price:

The price of a CNC mill can vary significantly depending on its capabilities, size, and accuracy. Ensure that you have a budget in mind before purchasing a machine, and choose a machine that offers the best value for your needs. Avoid choosing a machine based on price alone, as lower-priced machines may not have the required capabilities or accuracy levels.

5. Machine Support:

When purchasing a CNC mill, ensure that the manufacturer offers excellent after-sales support, including installation, training, and maintenance. Ensure that the manufacturer has a good reputation in the market and is known for providing high-quality and reliable machines.

Purchasing a CNC mill is a significant investment, and it's essential to consider several factors before making your final decision. Ensure that you choose a machine that has the required capabilities, accuracy, and support to meet your specific needs.

How to Operate a CNC Mill Safely

CNC mills are powerful machines that operate on computer-aided designs (CAD) to produce precise cuts and shapes in a variety of materials, including wood, metal, and plastics. However, the safety of the operator and those around the machine should always be a top priority. Here are some guidelines for operating a CNC mill safely:

1. Familiarize yourself with the machine: Before operating the mill, it is important to read and understand the owner's manual. Make sure you know the location of all the emergency buttons, switches, and other safety features. Additionally, make sure you are knowledgeable about the materials and tools that will be used during the milling process.

2. Wear appropriate safety gear: Before operating the CNC mill, it is essential to wear appropriate safety gear. This includes safety glasses, earplugs, gloves, and a dust mask to protect yourself from flying debris, loud noise, and harmful dust particles.

3. Secure the workpiece: Ensure that the workpiece is securely fastened to the mill bed before starting the milling process. Use clamps or other securing devices to prevent the workpiece from moving during the operation.

4. Program the CNC mill: A program must be written and loaded into the CNC machine before it can operate. Always double-check the program for errors before running the machine. Pay careful attention that the program does not exceed the limits of the machine’s settings.

5. Stand clear of the machine: Once the milling process begins, stand clear of the machine and never hold the material by hand. Never lean or get too close to the machine while it is operating, and always remove any loose clothing or jewelry.

6. Monitor the milling process closely: Always be vigilant while the machine is operating to ensure everything is running smoothly. Watch for unusual noises or vibrations, which may indicate something is wrong with the machine or tooling.

7. Clean the work area: Once the milling process is complete, ensure that the work area is clean, and the machine is properly turned off. Remove any remaining debris and relabel the program for future use.

Taking the necessary safety precautions before and during milling is vital to reduce the risk of accidents and injury. By following these guidelines, you can ensure the safe and efficient operation of your CNC mill.

Conclusion:

When shopping for a CNC mill, aspiring machinists and hobbyists should put careful consideration into the budget, performance, brand, and model quality that best suits their specific needs. While this process may seem daunting at first, it ultimately ensures that buyers receive a machine that meets their desires in terms of speed, accuracy, available features and more.

Furthermore, some manufacturers offer free trials on certain models to give interested customers an opportunity to test before they buy. Before making any actual purchase decisions or commitments with the seller, prospective buyers should always read reviews or contact other satisfied users for guidance.

Ultimately, all those seeking a CNC mill should be dedicated to researching their options thoroughly in order to find the perfect model for their project needs!

Read the full article

0 notes

Photo

Introducing our new Alard model violin peg set made from sustainable Richlite!

Richlite is a composite material made from recycled paper, making it a more eco-friendly option for an ebony replacement. Not only does it reduce waste, save endangered trees and ecosystems, but also offers the same characteristics, durability, and performance as traditional ebony wood.

#violin#sustainable#richlite#alard#ecofriendly#violinist#violinista#ebonywood#ebony#composite#violinplayer#compositematerials#cello#viola#cellist#violist#violinstagram#cncmachining#cncmilling#classicalmusic#luthier#luthieria#luthiery#viool#geige#violín#violino#violinstudent#stradivarius#twosetviolin

1 note

·

View note

Photo

4*8 popular linear automatic tool changer cnc at best price Your business development need one powerful and high precision model Jinan Queen CNC Machinery Co.,Ltd https://wa.me/8618254165298 #cncrouter #atccncrouter #cncwoodworking #cncmilling #woodmachines #woodmilling #cnccutting (在 Jinan Queen CNC Machinery Co.,Ltd) https://www.instagram.com/p/CmjRkXUr9on/?igshid=NGJjMDIxMWI=

0 notes

Video

NTTF TCSiON Certificate in CNC Milling - Get practical training by learning to work on CNC machines

Get practical training by learning to work on CNC machines and be at par with the demands of global industries as they move towards skilled manpower in CNC Milling. This phygital course by NTTF, enabled by TCS iON is the right amalgamation of live lectures and practical training. Our learning and practice Centres will help you operate CNC Vertical Machining Centre, interpret production drawings, and acquire skill proficiency. The eligibility for this is 10th pass.

Applications end on 30th September 2022. Join now!

https://www.nttftrg.com/

#SkillDevelopment#EngineeringDiploma#AdmissionsOpen2022#CNCMachines#CNCMilling#MoveUpInLife#TCSiON#NTTF

0 notes

Text

Types of Milling Machine - Pathak Machine Tools

We provide supreme-quality Milling Machines, that are specially fabricated and designed under the supervision of our skilled team compliance by using high-grade raw material purchased from the most renowned vendors on the market. We are one of the prominent Milling Machine Manufacturers in India.

Features:

-> Effective bearable capacity

-> Better work performance

-> Longer service life

-> Affordable price ranges

-> Highly productive results

#milling#millingmachine#cncmilling#millingcutters#millingmachineManufacturers#millingmachineSuppliers#millingmachineExporters#industry#tools#engineering#manufacturing#suppliers#exporters#pathak#Kolkata#products#manufacturers#pathakmachinetools#India

0 notes