#portland concrete

Photo

Toronto Concrete Pavers Front Yard

Inspiration for a medium-sized, contemporary front yard with concrete pavers and partial sun.

0 notes

Text

Types of wall cracks that should never be ignored

A crack in the wall is just another pain in your eyes. A crack in your wall might be a warning signal that the home needs serious repair. However, the damage doesn't need to be serious. Some cracks are harmless and can easily be repaired, while some are hazardous and needs immediate inspection by a professional. In this article, you will get an idea about different types of cracks that you should never ignore.

Vertical cracks

Vertical cracks are the most common type of cracks and are often considered less serious. Vertical cracks often happen due to shrinkage during the curing process. If a vertical crack appears, it is essential to monitor the size of the crack. If you notice that the size of the cracks is getting wider, it means you need to contact a professional to inspect your wall or probably the whole area to get an idea of what to repair and what not to do. On the other hand, if the size of the cracks is not increasing, then there is nothing to worry about. It will only require a small patch repair.

2. Diagonal cracks

Diagonal cracks are the type of cracks that should never be ignored. Diagonal cracks develop in the beam or on the corner of a wall. In most cases, these cracks occur due to the shifting of the foundation. You can fix the diagonal cracks by filling the gap using a quality patching compound or proper Portland concrete. Then, apply flexible sealant along the edges of the crack. Lastly, paint and texture the area to match the rest of the wall. Please make sure to use high-quality products while fixing these cracks and make sure they don't reappear in the future. If it reappears, it would be better to contact a professional inspector immediately. It's essential to closely monitor and repair these kinds of cracks promptly.

3. Stair Step Cracks

Another type of crack that appears on the corner of the wall is quite dangerous and should never be ignored. These cracks are 10 to 15 cm long, which is a clear indication of the shifting of the foundation. Many foundations have the problem of water seepage. The water weakens the wall over time and finally forms cracks. If the walls do not dry out quickly, stair-step cracks can form. You need to contact a structural engineer or a professional to fix this problem. Note that it is not recommended to fix this issue all by yourself as it can lead to further damage if not done correctly. It is best to hire a professional to avoid further damage.

4. Radial Cracks

Radial crack is one of the worst types of cracks. These cracks appear on the corner of the walls in a circular pattern and indicate the wider spread of moisture problem. These cracks often get unnoticed until serious damage occurs. These cracks are caused by poor construction techniques. So it is essential to maintain a proper construction technique, such as a proper water-cement ratio. To fix the radial cracks, you may need to install a proper drainage system, repoint brickwork, or replace the brick. However, it is best to have a professional inspect the walls to determine the exact cause and recommended course of action.

5. Bulging Walls

Bulging walls typically state that the wall is bulging outward from its foundation. A bulging wall is a sign of a more serious soil or structural issue and mostly happens due to inadequate drain systems, soil infiltration heavy rainfall, or organized tree roots. Failure to address the bulging wall leads to structural damage, further water infiltration, and even total collapse of the walls.

It is important to note that wall cracks are often an indication that something is wrong with the foundation. If wall cracks are found and are not addressed promptly and completely, it could lead to more severe problems. So if you ever spot a crack in the wall, be sure to schedule an inspection with a contractor to determine the cause and extent of the damage.

Other problems such as water infiltration, faulty construction or settling soil can also cause wall cracks. Therefore, it is important to inspect walls regularly to determine the cause and consider any necessary repairs. If the cracks become extensive and costly, it is important to communicate with your contractor or engineer and reach an agreement on the best solutions to remedy the situation.

It can be tempting to ignore wall cracks, but this could lead to bigger problems in the future. Therefore, it is important to address any signs of structural damage on your walls and immediately take necessary action.

#water-cement ratio#portland concrete#types of wall cracks#wall cracks that should never be ignored#wall cracks which are dangerous#do not ignore wall cracks#vertical cracks#diagonal cracks#stair step cracks#radial cracks#bulging walls

0 notes

Text

November 2003 PDX Portland Oregon U.S.A.

© KOJI ARAKI Art Works

Daily life and every small thing is the gate to the universe :)

#2003#November#November 2003#PDX#Portland#Oregon#neighborhood#evening#evening photo#PGE PARK#clock#electric signboard#sidewalk#rain#reflection#A clock and an electronic sign reflect on the concrete sidewalk as it rains#photographers on tumblr#b&w photography#black and white photography#monochrome photography#original photography#photography#koji araki art works#SONY Cyber-shot DSC-F77#Cyber-shot#SONY

58 notes

·

View notes

Text

09.10.2023. SE Industrial Portland

#industrial#photography#photos#building#city#urban#exploring#portland#adventure#explore#architecture#concrete#modern#oregon

2 notes

·

View notes

Text

Someone says "waiting for the cement to dry" and I am so so strong in that moment

#actually its concrete and it doesnt 'dry' it cures because the portland cement in the mixture reacts and combines to form a complex#(breathes) crystal lattice tgat binds with the gravel and sand in the mixture#hence why it is inportant to keep comcrete wet for a few days aftee pourinf#^what i want to say but dont

2 notes

·

View notes

Text

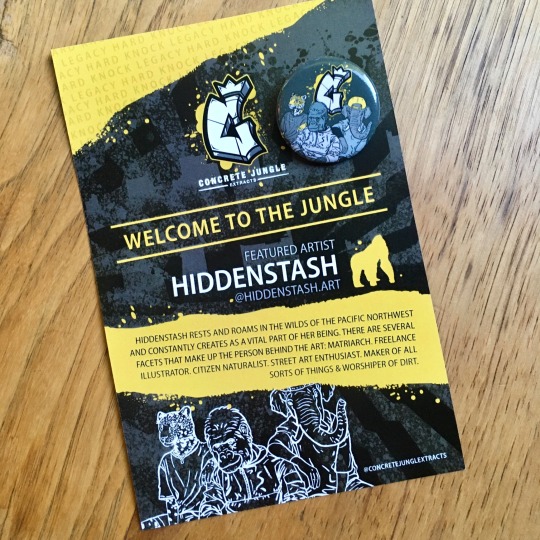

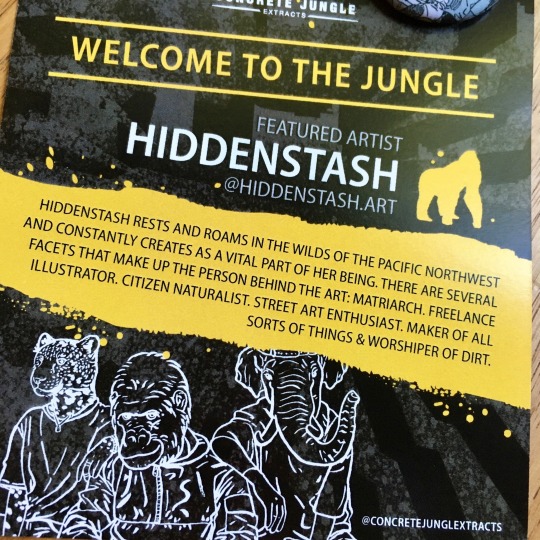

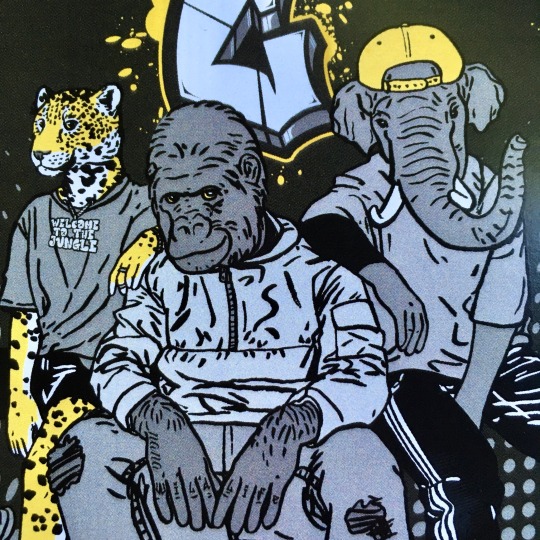

#concrete jungle#Portland#Portland Oregon#concrete jungle extracts#anthro art#furry art#HiddenStash#HiddenStashArt#420#stoners on tumblr#artists on tumblr

4 notes

·

View notes

Text

https://www.kamdhenucement.com/top-rated-psc-cement-the-best-choice-for-your-construction-needs

#best cement#no 1 cement in india#which is the no 1 cement in india#cement price#rmc concrete#ppc cement#Psc Cement#cement mandate#ready mix concrete plant#rmc plants#cement#cement products#best cement for roof#cement supplier#cement dump#portland cement

0 notes

Text

Ensuring Quality in Cement Construction: Inspection and Testing

In the construction industry, cement serves as the backbone of structural integrity, providing the foundation upon which buildings and infrastructure stand. However, the efficacy and durability of these structures heavily depend on the quality of the cement used. With numerous options available in the market, it's imperative to understand the importance of inspection and testing to ensure that only the best cement is employed for construction projects.

When it comes to selecting the best cement in India, the discerning builder or contractor seeks not only reliability but also consistency in quality. Among the myriad choices available, one brand consistently stands out for its excellence – JSW Cement. Renowned for its superior quality and performance, JSW Cement has established itself as the no. 1 cement in India, trusted by professionals across the construction industry.

Quality Assurance Through Inspection and Testing

Before delving into the specifics of JSW Cement, it's essential to underscore the significance of inspection and testing in cement procurement. The process of ensuring quality begins right from the procurement stage, where cement undergoes rigorous inspection to assess its conformity to relevant standards and specifications.

Key aspects evaluated during inspection include chemical composition, particle size distribution, fineness, compressive strength, and setting time. Additionally, visual inspection of the cement's colour and consistency aids in identifying any anomalies that may affect its performance.

Following inspection, thorough testing is conducted to validate the cement's quality and suitability for the intended application. Testing procedures encompass both physical and chemical analyses, with tests such as compressive strength testing, consistency testing, and soundness testing being integral to the assessment process.

Selecting the Best Cement: Why JSW Cement Stands Out

In the quest for the best cement in India, JSW Cement emerges as a frontrunner, distinguished by its unwavering commitment to quality and innovation. With a comprehensive range of cement products catering to diverse construction needs, JSW Cement epitomizes excellence in the industry.

Buy white cement from JSW Cement, and you'll experience firsthand the unparalleled quality that sets it apart from the competition. Renowned for its purity and brightness, white cement from JSW Cement is coveted for architectural and decorative applications, delivering pristine aesthetics coupled with exceptional performance.

As the leading producer of ordinary Portland cement, JSW Cement ensures uncompromising quality across its product portfolio. Engineered to deliver superior strength, durability, and consistency, ordinary Portland cement from JSW Cement is the preferred choice for a wide array of construction projects, ranging from residential buildings to infrastructural developments.

JSW Cement: A Testament to Quality and Excellence

JSW Cement exemplifies the epitome of quality and excellence in the cement industry. With a steadfast commitment to innovation and customer satisfaction, JSW Cement continues to set benchmarks for quality assurance and performance, earning the trust and accolades of industry professionals nationwide.

In your pursuit of the best cement in India, look no further than JSW Cement for unparalleled quality, reliability, and performance. Whether you're embarking on a residential construction project or undertaking large-scale infrastructure development, JSW Cement stands ready to surpass your expectations and elevate the standards of cement construction.

Incorporating JSW Cement into your construction endeavors isn't just a choice; it's a testament to your commitment to quality and enduring excellence. Trust JSW Cement for all your cement needs, and experience the difference that superior quality makes in cement construction.

Ensure quality in your construction projects with JSW Cement – the benchmark of excellence in the cement industry.

JSW Cement reigns supreme as a beacon of quality and excellence. With its unwavering dedication to innovation, reliability, and customer satisfaction, JSW Cement has rightfully earned its status as the preferred choice for discerning professionals across the construction industry. Whether it's ordinary Portland cement or white cement, JSW Cement stands as a symbol of unparalleled quality, ensuring durability and performance that exceed expectations. Trust JSW Cement for your construction needs, and witness firsthand the transformative power of superior quality cement in shaping a robust and enduring built environment.

0 notes

Text

#concrete contractor near me#hardscaping near me#concrete patio contractors near me#hardscaping companies near me#hardscaping contractor near me#concrete patio near me#concrete driveway near me#concrete driveway repair near me#stamped concrete patio near me#concrete patio installers near me#patio designs near me#concrete contractor portland#hardscaping services near me#concrete patio repair near me#portland concrete contractor#hardscaping portland#hardscaping portland oregon#concrete contractor portland or#concrete contractor portland oregon#portland concrete patio#concrete patio portland#concrete patio portland oregon#concrete patio portland or#concrete driveway portland or#concrete driveway portland#portland or concrete contractor#portland hardscaping#hardscaping portland or#concrete driveway portland oregon#concrete driveway repair portland

0 notes

Text

More on Roman Concrete

I started this year off with a post on Roman concrete, and since this will be my last post for 2023, why not end with the same subject? You might think there cannot be much more to say about that, but that would be wrong. You may think that once you have concrete, it will be there forever; it is effectively a rock, but that is not true.

First, there are a range of cements. The very first one was…

View On WordPress

#aluminosilicate#calcium silicate#cement range#construction maintenance#Portland cement#pozzolan#self-healing concrete#slaked lime

0 notes

Text

Well played Rodney!

Stupid is as stupid does.

0 notes

Text

Contemporary Deck Portland

Outdoor kitchen deck - mid-sized contemporary backyard outdoor kitchen deck idea with no cover

#black concrete counter#outdoor dining#wood deck#wood deck railing#concrete countertops#portland outdoor

0 notes

Text

What are the repair and restoration options for concrete spalling

Concrete Spalling is the process of chipping or flaking of the surface of the concrete, which usually occurs due to natural or chemical reactions. Concrete Spalling results in the development of small or large pieces that break away from the surface, leaving the concrete rough and uneven. Spalling typically occurs when the concrete is exposed to moisture or extreme temperature changes, including freeze-thaw cycles, corrosion, and excessive wear and tear, causing the concrete to expand and contract. Due to repetitive cycles of expansion and contraction, the concrete gets weakened and breaks apart, leading to spalling. Therefore, it is crucial to repair and restore spalled concrete at the earliest. In this article, we will discuss some of the repair and restoration options available for concrete spalling.

Surface Patching

One of the best methods of repairing concrete spalling is by applying surface patching material. For surface patching, you just mix up some sand, a little hydrated lime, and Portland cement and trowel this onto the concrete. It is the most affordable and quick way to repair small areas. To patch the concrete, the damaged area is first cleaned and cleared with safe water and masonry cleaner. Then the surface patching is applied to the affected area, and the surface is levelled off to match the surrounding concrete surface. Though Surface Patching is very effective for the smaller areas of spalling, it is not suitable for more significant or deeper spalling damage.

2. Resurfacing

If the damage is much deeper, then resurfacing becomes the best option so that the concrete can be evenly applied. It involves applying a thin layer of concrete, effectively giving it a new surface layer. The surface is first cleaned and prepared, and a bonding agent is applied to ensure that the new layer of concrete will adhere to the old surface. After that, a fresh coating of concrete is poured and polished over the top. The look of concrete surfaces that have been harmed by spalling can be effectively restored through resurfacing, but this is not a long-term fix.

3. Overlaying

Overlaying is another option that is much similar to resurfacing. The only difference is it involves a thin layer of portland concrete which should be at least 1.5 inches to ensure proper bonding and durability. If there are no major cracks, a thin overlay of 1.5 to 2 inches (38 to 51 mm) may be sufficient to enhance its appearance or improve its performance.

4. Chemical Treatment

To tackle the corrosion issue, it is important to use epoxy-based chemicals. Epoxy is generally used for small cracks ranging from 0.02 mm to 6 mm in width. Steel bars are coated with epoxy-based chemicals to increase their corrosion resistance capacity. It can also be applied to the surface of concrete, forming a protective layer that resists abrasion and chemical damage.

5. Replacement of concrete

In extreme instances of spalling, where the damage is too serious to be fixed with surface patching, resurfacing, or overlays, replacing the concrete may be the only choice. The injured concrete surface is removed, and a fresh coating of portland concrete is then poured in its place in the process of replacing concrete. In situations where spalling has jeopardized the structural stability of the concrete, concrete replacement is a more involved and expensive option, but it is frequently required.

The best option for repairing spalling depends on the severity of the damage, the location of the spalling, the desired outcome, and the type of cement used for repairing. Various cement companies such as Wonder Cement, Ambuja Cement, Ultratech Cement, ACC cement, Bangur Cement, etc. provide the best quality cement to repair and restore spalled concrete. Surface patching, resurfacing, overlays, epoxy coatings, and concrete replacement are all effective solutions for repairing spalled concrete. It is essential to address spalling damage as soon as it is noticed to prevent further damage and ensure the longevity of the concrete surface.

#portland cement#portland concrete#concrete spalling#cement industry#cement manufacturing company#cement supplier#cement company#acc cement#ultratech cement#ambuja cement#bangur cement#wonder cement

0 notes

Text

November 2003 PDX Portland Oregon U.S.A.

© KOJI ARAKI Art Works

Daily life and every small thing is the gate to the universe :)

#2003#November#November 2003#PDX#Portland#Oregon#neighborhood#evening#evening photo#PGE PARK#clock#electric signboard#sidewalk#rain#reflection#A clock and an electronic sign reflect on the concrete sidewalk as it rains#photographers on tumblr#b&w photography#black and white photography#monochrome photography#original photography#photography#koji araki art works#SONY Cyber-shot DSC-F77#Cyber-shot#SONY

37 notes

·

View notes

Text

The American Plaza Towers. Portland, OR.

#concrete#modern#architecture#portland#photography#explore#adventure#brutalist#tower#high rise#buuldings

0 notes

Text

Poolhouse Portland

Ideas for a sizable transitional backyard remodel with a rectangular natural pool

0 notes