#Buy Injection Molded Plastic Parts

Text

Buy Injection Molded Plastic Parts

Are you looking to Buy Injection Molded Plastic Parts? then visit Nagual Precision Limited. We are your one-stop destination for top-tier injection molded components tailored to your needs. Our commitment to quality, innovation, and customer satisfaction has earned a reputation for excellence in the industry. Visit our website now.

0 notes

Text

Upgrade Your Plastic Manufacturing With High-quality Used Husky Plastic Injection Molding Machines

Husky is one of the best injection molding machines in the world. especially true in the realm of injection molding, where every detail matters in shaping the final product. Among the leading players in this industry is Husky Injection Molding Systems Ltd., renowned for its cutting-edge technology and innovative solutions. A new Husky machine may cost a lot, and this may prevent manufacturers from buying it.

Are you a manufacturer looking to get the best Husky molding machine? Get Used Husky Plastic Injection Molding Machines from Hunter Plastics. We provide various used machines that can help you with your production. Let's delve into the advanced features that make Husky Injection Molding Machines stand out from the crowd.

1. Precision Control Systems

Husky Injection Molding Machines are equipped with state-of-the-art precision control systems that ensure accurate and consistent molding processes. These systems utilize advanced algorithms and sensors to monitor and adjust key parameters such as temperature, pressure, and injection speed in real time.

2. Intelligent Hot Runner Technology

Husky's intelligent hot runner technology incorporates features such as valve gate sequencing, temperature profiling, and flow control to optimize material flow and distribution. This results in superior part quality, reduced material consumption, and faster cycle times, making it an ideal choice for high-volume production applications.

3. Energy Efficiency

Husky Injection Molding Machines are designed with energy-saving features that help reduce power consumption without compromising performance. These include servo-driven hydraulic systems, regenerative drives, and optimized heating and cooling processes. By minimizing energy waste, Husky machines not only lower operating costs but also contribute to a greener and more sustainable manufacturing industry.

4. User-Friendly Interface

Ease of use is another hallmark of Husky Injection Molding Machines. The intuitive HMI (Human-Machine Interface) provides operators with easy access to machine controls, diagnostics, and troubleshooting tools.

Conclusion:

These rich features make the Husky molding machine one of the best in the industry. We have various machines including Husky Injection Molding Machines for sale! Contact us today to get your ideal machine.

0 notes

Text

youtube

Watch the 2024 American Climate Leadership Awards for High School Students now: https://youtu.be/5C-bb9PoRLc

The recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by student climate leaders! Join Aishah-Nyeta Brown & Jerome Foster II and be inspired by student climate leaders as we recognize the High School Student finalists. Watch now to find out which student received the $25,000 grand prize and top recognition!

#ACLA24#ACLA24HighSchoolStudents#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental education#environmental justice#environmental protection#environmental health#high school students#high school#youth#youth of america#school

15K notes

·

View notes

Text

Source Diverse Plastic Raw Materials for Your Manufacturing Needs

Discover a comprehensive selection of high-quality plastic raw materials on Viztaar, your one-stop shop for polymer sourcing! Explore a wide range of polymers, including:

HDPE Pipe Grades: Meticulously formulated for superior performance in pipe manufacturing.

HDPE Film Grades: Ideal for creating sheets and films used in geomembranes, liners, and industrial packaging.

HD Blow Grades: Suitable for blow molding processes to produce hollow plastic products like bottles, containers, and industrial parts.

HD Moulding Grades: Formulated for injection molding techniques used in manufacturing complex plastic components.

HD Raffia Grades: Perfect for creating woven sacks, tarpaulins, and high-strength tapes used in agriculture and construction.

Benefits of Sourcing Polymers on Viztaar:

Competitive Pricing: Showcase your products to the vast network of suppliers for competitive pricing on plastic raw materials.

Streamlined Sourcing: Simplify your procurement process with a user-friendly platform for searching, comparing, and ordering materials.

Guaranteed Quality: Enjoy peace of mind knowing Viztaar prioritizes supplier vetting and quality assurance.

End-to-End Logistics Support: Benefit from efficient delivery schedules and streamlined logistics management.

Elevate your manufacturing processes and source the perfect plastic raw materials for your needs. Visit Viztaar today!

#bulkbuying#bulkmaterials#industrialsupplies#b2binnovation#industrialmaterials#qualityassured#reliablesourcing#sellerbenefits#viztaar#optimizedpurchases#ViztaarMarketplace

0 notes

Text

#temperature control system#Temperature- control units#Temperature Control Units (TCU)#TEMPERATURE CONTROL UNITS (WATER)#automatic water temperature control systems#temperature control units for injection molding#temperature control module#Temperature Controllers#Products - Temperature control units#injection molding process#plastic regrind machine

0 notes

Text

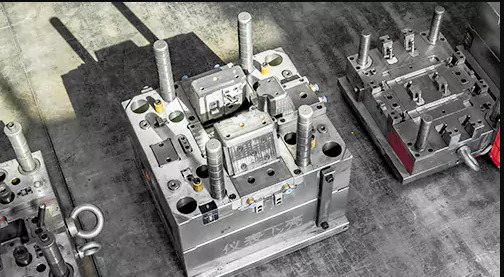

A Complete Overview Of Mold Making Process & Design Process

The processes of production and product design have changed as well as we've advanced from revolutionary innovations like the light bulb to the telecommunications age of the radio, phone, and television. Modern mold-making by plastic moulding manufacturers has advanced thanks to computers, the internet, renewable energy, and all that comes after.

What Is Mold Making?

Making injection molds for precise plastic components is a technique known as mold making. The molds must be created with extreme precision since they represent one of the biggest manufacturing investments. To guarantee that components can be mass manufactured with repeatable accuracy, modern plastic injection frisbee demands extremely high precision.

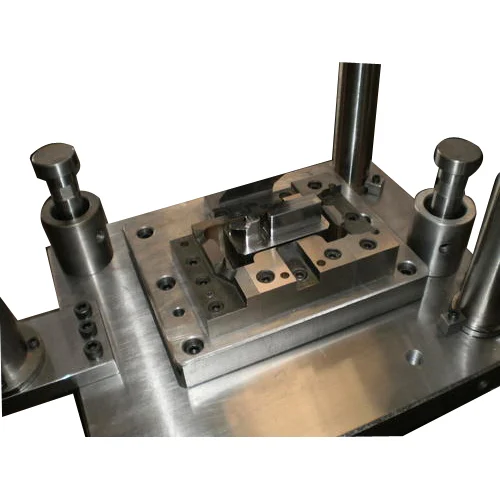

Stainless steel plastic injection mold's interior

The creation of the tools used to make, handle, or test things throughout manufacturing must also be flawless. Precision molds of the highest caliber are durable investments for any business. The following factors can affect how much the plastic injection mold costs:

Key Metal

The material selected for a mold is greatly influenced by the anticipated length of a production process. For instance, some plastic moulding manufacturers employ hardened steel (or another equally resistant metal) molds for large production runs and long-term projects and aluminum molds for short production runs and short-term projects. Consider if it is more cost-effective to buy an expensive but long-lasting mold or to use a less costly but less durable mold and replace it as it becomes worn when choosing a material for injection mold making.

Tip: To know more about plastic molds for chocolate making, visit Moulding Injection.

Cavities present

Family molds enable the simultaneous manufacture of several components. The majority of molders advise using one mold per part instead because they frequently result in parts with lower quality and performance characteristics.

Concerning mold production, the number of cavities impacts the time, labor, and costs required to manufacture a mold. In general, a mold design with fewer cavities requires less resource investment than one with more cavities, which requires more resource investment. Expert plastic injection mould manufacturer has to be able to maximize the number of cavities for maximum production effectiveness and the lowest cost.

Mold Base

The steel mold foundation serves as structural support for the mold cavities, inserts, and other parts. Depending on the size, the size, and the type of steel utilized

Cavity/Core Machining

Every mold is unique to the application's component and manufacturing requirements. Mold components including cavities, cores, cooling lines, and ejectors may all be customized. The degree of personalization affects the overall price, particularly if the mold is made of hardened steel or other metals.

Contact the chocolate packaging manufacturer at Moulding Injection. Get high-quality, customised molds as per your requirements.

Partially Complex

The cost of the necessary mold increases with the desired part's complexity. This beneficial link exists because the mold design must take into account all of the part design specifications, including those on tolerance and surface roughness.

What Has Modified?

In the 18th and 19th centuries, plastic injection molding initially became popular. When the Industrial Revolution was at its height, most tasks for toolmakers had to be completed by hand. It took a lot of time to form tools, heat treats them, sharpen them, machine the metal, then drill out the pattern by hand. Any item manufactured by human hands is unique, hence there were frequent conformity issues and no two molds were the same.

Two mold-making innovations that made a substantial difference in the transition from manual to computer-assisted machining are: Moulding Injection offers cutting-edge manufacturing solutions, such as mold design, mold construction, and high-volume part production. We are well known across the world for producing injection molded components of the finest quality and accuracy at incredibly low costs. We offer all of the resources required to swiftly and precisely accomplish any project, from conception to completion.

#plastic chocolate molds#plastic injection mold design#injection frisbee#plastic injection molding manufacturer#plastic injection mould manufacturer#injection molding solutions#best injection molding company

0 notes

Text

All That You Want to Learn About Custom Molding

Are you looking for Lane Divider Wellington in NZ? As a manufacturing cycle, custom molding offers some benefits over other production processes. It includes other varieties of molding. There's a reason that the global plastics market will soar $654.38 billion in value.

A major part of it lies in the extent to which molding serves a wide variety of applications. It finds application across the industry verticals.

What are the goods of using custom moldings?

Indeed, there is no one-size-fits-all term when it comes to manufacturing means. But, we have got reasons why injection molding should be on your list.

Custom molding has broad design flexibility.

Custom molding can design complex pieces as per the needs of the customer. There are some approaches of Custom Mouldings Extrusions that ensure efficient production.

The possibilities within the custom extrusion mean are limitless. It adheres to conventions like rounded corners. Toolmakers and injection molding users can meet even the most intricate requirements.

Custom molding is customizable.

The fact is injection molding resins are good enough to get colorants mixed with them. It produces surface coloring a bit different from the natural. Most stores can recreate Pantone colors for an injection molding means. It makes the process suitable for processes where aesthetics play a vital role.

Custom molding gives you control over quantities.

A custom molding supplier allows you to produce work in any quantity needed for your firm. You can work on medium, low and high prototype runs. Custom Mouldings Extrusions provide you with an affordable solution.

But, it loses value if you get forced into machine types or least orders.

The fact is that 3D printed models exist to make short-run injection molding better. It is an accessible and viable option.

Custom molding offers a combination of parts and materials.

Advanced techniques like co-molding make injection molding an easy means. It allows you to add customization to your products.

Using a process like custom molding means that the injection molded part doesn't limit you. You don't need to rely on materials just suitable for injection molding. For instance, you can set resin around a piece for added strength. It gives the metal part a more attractive appearance. It likewise renders a complex functionality to it.

If you want to buy Moulding Plastic Products New Zealand, you can contact us today.

Custom molding is inexpensive.

Price is one of the benefits of using custom molded parts. You've got another way to produce parts. When compared to bespoke molding, it offers more time, labor, and energy.

Manufacturing firms can work better and faster with custom molding. Hence, it passes down the savings to customers in form of low prices. You can save more money by choosing custom-molded parts. It likewise meets your business requirements.

Corrosion isn't a concern for custom-molded parts. The best thing is that it doesn't contain any material that's prone to corrosion. Hence, custom-molded parts can stand the test of time. For more info on Custom Mouldings Extrusions, stay tuned.

0 notes

Text

youtube

Watch the American Climate Leadership Awards 2024 now: https://youtu.be/bWiW4Rp8vF0?feature=shared

The American Climate Leadership Awards 2024 broadcast recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by active climate leaders. Watch to find out which finalist received the $50,000 grand prize! Hosted by Vanessa Hauc and featuring Bill McKibben and Katharine Hayhoe!

#ACLA24#ACLA24Leaders#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental justice#environment protection#environmental health#Youtube

15K notes

·

View notes

Text

A Brief History Of Diecast Toy Cars

A diecast (or die-cast) toy is a toy or a collectible model produced by using the diecasting method of putting molten lead, zinc alloy or plastic in a mold to produce a particular shape. Such toys are typically made of metal, with plastic, rubber, glass, or other machined metal parts. Wholly plastic toys are made by a similar process of injection molding, but the two methods are distinct because of the properties of the materials.

Process

The metal used in diecasting is either a lead alloy (used early on), or more commonly, Zamak (called Mazak in the UK), an alloy of zinc with small quantities of alluminium and copper. Lead or iron are impurities that must be carefully avoided in Zamac, as they give rise to a deterioration of the metal most commonly called zinc pest. The terms white metal or pot metal are also used when applied to alloys based more on lead or iron. The most common diecast vehicles are scale models of automobiles, aircraft, military vehicles, construction equipment, and trains, although almost anything can be produced by this method, like Monopoly game pieces, furniture handles, or metal garden sprinklers.

Industry leaders

While most often associated with Hot Wheels, diecast toys were first produced early in the 20th century by manufacturers such as Meccano (Dinky Toys) in the United Kingdom, Dowst Brothers (TootsieToys) in the United States and Fonderie de précision de Nanterre (Solido) in France. The first models on the market were basic, consisting of a small vehicle body with no interior. In the early days, as mentioned, it was common for impurities in the alloy to result in zinc pest, and the casting would distort, crack, or crumble. As a result, diecast toys made before World War II are difficult to find in good condition. The later high-purity Zamak alloy avoided this problem.

Lesney began making diecast toys in 1947. Their popular Matchbox 1-75 series was so named because there were always 75 different vehicles in the line, each packaged in a small box designed to look like those used for matches. These toys became so popular that the "Matchbox" became widely used as a generic term for any die-cast toy car, regardless of manufacturer.

The popularity of diecast toys developed through the 1950s as their detail and quality increased. More companies entered the field, including successful brands like Corgi brand, produced by Mettoy, Italian Mercury, Danish Tekno, or German Schuco and Gama Toys. Corgi Toys appeared in 1956 and pioneered the use of interiors and windows in their models.

In 1968, Hot Wheels were introduced in the United States by Mattel to address the complaint that they had no line of toys for boys to balance their line of Barbie dolls for girls. Because they looked fast and were fast (they were equipped with a low-friction wheels/axles), Hot Wheels quickly became the most popular diecast cars in the toy market, becoming one of the world's top sellers, challenging the popularity of Matchbox.

Although advertising had been used by Meccano (Dinky Toys) since 1934, during the 1960s new companies began to use diecast vehicles exclusively as promotional items. The idea that children play a large role in a family's purchasing decisions was key. There is also the fact that children grown up to buy products that they were exposed to when young. Matchbox vehicles mildly advertised a variety of mainly British products like Singer sewing machines, Tetley tea, Pickford's movers, or Coca-Cola. As time passed, companies such as McDonald's, Sears Roebuck, Kodak and Texaco commissioned toymakers to produce promotional models featuring their names and logos or licensed their use. One early example was an American Airlines London bus produced by Matchbox, an idea some other airlines quickly copied.

Beginning in the mid 1970s, trucks and other commercial vehicles grew greatly in popularity. Matchbox started the trend when they re-launched their "Models of Yesteryear" lineup. They made several different versions of their Y-12 Ford Model T van, along with other trucks in colorful liveries such as Coca-Cola, Colman's Mustard, and Cerebos Salt. They also made promotional versions for Smith's Crisps (potato chips) and Harrods department store. Some models were made exclusively for certain markets and immediately became quite expensive elsewhere: Arnott's Biscuits (Australia) and Sunlight Seife (soap, Germany) are examples.

Challenges and Changes (1980s-1990s)

The 1980s and 1990s brought challenges to the diecast car market. Environmental concerns led to changes in materials used in production, with lead being replaced by safer alloys. Additionally, economic fluctuations impacted consumer spending. Both Matchbox and Hot Wheels faced ownership changes and adaptations to evolving markets.

Revival and Modernization (2000s-Present)

In the 2000s, both Matchbox and Hot Wheels experienced revivals. Matchbox, acquired by Mattel in 1997, underwent a rebranding effort to modernize its image. Hot Wheels expanded its product range, including collectibles and multimedia tie-ins.

The internet has played a significant role in connecting collectors and enthusiasts. Online forums, auction platforms, and social media have allowed fans to share their passion, trade cars, and access valuable information about their collections.

Innovation and Sustainability (Present and Future)

In recent years, both Matchbox and Hot Wheels have focused on sustainability. They are producing diecast cars with more eco-friendly materials and promoting recycling initiatives.

Augmented reality (AR) and digital integration have also become part of the diecast car experience. Collectors can use smartphone apps to scan their cars and access digital content, adding a new layer of interactivity to the hobby.

Conclusion

The diecast car market, with Matchbox and Hot Wheels at its forefront, has come a long way from its humble beginnings. These miniature replicas of real vehicles have evolved into cherished collectibles, cherished by enthusiasts of all ages. As technology advances and environmental concerns persist, the future of diecast cars will continue to evolve, but their enduring appeal to both collectors and children remains a testament to their timeless charm.

0 notes

Text

The main points of organic fertilizer equipment parts selection

The complete set of equipment of organic fertilizer production line generally includes organic fertilizer granulator, flip machine, dryer, dust removal system and other equipment. The quality of the machine is closely related to its maintenance. No matter how good the machine is, if it is not refueled and maintained, it will not take long. Equipment maintenance is the guarantee of the normal production of the whole system. It is also very important to replace wearing parts during maintenance. The right choice is one of the criteria that users need to master. Let's take a look at the main points of accessories shared by manufacturers of organic fertilizer equipment: relatively high precision mechanical accessories. It generally refers to small mechanical parts that can be worn when the injection molding machine is assembled. The main materials are silica gel, copper, aluminum, cast iron, steel, iron, plastic and so on. Taking mechanical accessories as an example, they usually include: mechanical fixtures, mechanical fixtures/fixtures, suction cups, mechanical hardware (also known as suction cups), cylinders, buffers, various quick connections, fixture parts, fixture aluminum belts, etc.

First, pay attention to the "original matching", if conditions permit, the manufacturer can be equipped with a set of wearing parts. Because the original parts have a better match with different equipment in material, size or quality. And most of the original parts have a perfect after-sales service system. Therefore, it is recommended that consumers buy from the host manufacturer. Compare prices. Many consumers are easily misled by different manufacturers into thinking that the accessories of a device are similar. In fact, this is not the case. Since the manufacturing process of counterfeit and shoddy products is simpler and cheaper to produce, they often attract consumers with lower prices and greatly reduced quality. Therefore, consumers should be aware of the market price of some machine parts and be alert if the price differs too much from what you remember. There must be a reason parts are sold to you at a low price, and most of them are substandard parts.

0 notes

Text

As a professional metal stamping factory in China, Dongguan Orienson Hardware Electrical Co., Ltd. has complete supporting resources, which can provide customers with one-stop hardware products as well as the full set of processing services, we can independently develop and manufacture molds, and provide precision CNC machining services, plastic injection molding service, metal plating services, heat treatment, passivation, grinding, radium carvings and other surface treatment processing technology, besides, assembly services such as metal laser welding, resistance welding, automatic tapping, and automatic riveting is included, Orienson is equipped with a complete inspection and testing instruments to ensure quality from raw material production to delivery, thus reduce the loss and cost of the customer and also offer high-quality and cost-effective prototype metal stamping.

Types of Custom Service Stampings

Assembling ServiceAssembling Service

CNC MachiningCNC Machining

Plastic Injection MoldingPlastic Injection Molding

ElectroplatingElectroplating

Other Surface TreatmentOther Surface Treatment

Automatic TappingAutomatic Tapping

Automatic RivetingAutomatic Riveting

Advantages Of Metal Stamping Supporting ServicesAdvantages Of Metal Stamping Supporting Services

Assembly

Assembly refers to the process of assembing parts according to specifed technical requirements and making them qualifed products.

Products

As an excellent sheet metal stamping manufacturer, we provide highly consistent assembly services at every stage of your production process, from prototyping, proof of concept to mass production.

Professional Team

In addition, our professional automation engineering design team can provide comprehensive assembly.

How Do You Choose Metal Stamping Supporting Services

01

Rich Experience

Service from RED stage to mass production, Our technical team can design, manufacture and maintain.

02

Professional Technology

As an excellent sheet metal stamping manufacturer, we also have the support equipment for tapping machines, riveting machines, automatic assembly lines.

03

Automatic Assembly Line

Our production capability is more than 50 million pieces per month, mold developing and manufacturing capability.

04

R&D Capability

The in-house tool room has LS-WEDM, HS-WEDM, spark machines, grinding machines, milling machines, etc., which can meet all the demands.

05

Highest Cost Effectiveness

Including heat treating, plating, injection molding, CNC machining, etc., we work closely with our customers to ensure the most cost-effective material.

Why Choose Orienson Metal Stamping Supporting Services

Rapid open mold speed, high quality, mature bending process made Orienson widely welcomed by customers. Metal bending parts we produced has been widely used in automobiles, sensor electrical and electronic switches.

Mold speed, high quality, mature bending process

Automobiles, sensors, electrical and electronic switches

Under the guarantee of dimensional accuracy

Committed to providing smooth surface edge rolling parts

Custom Metal Stamping Supporting Services

Impact On Production To Meet Customers' need

Professional One-stop Whole Process CNC Service

Mold Opening, Material Selection

0 notes

Text

Unlocking Efficiency and Quality: The Ultimate Guide to Injection Molding Machine Sale

Injection molding is a process used in manufacturing to produce plastic parts. It involves melting plastic pellets and injecting them into a mold, where they cool and solidify into the desired shape. Injection molding machines are crucial in this process, as they are responsible for melting the plastic, injecting it into the mold, and controlling the cooling and solidification process. If you're looking to purchase an injection molding machine sale, this ultimate guide will help you unlock efficiency and quality in your manufacturing process.

Consider the Type of Injection Molding Machine You Need

There are several types of injection molding machines available in the market. The type you choose will depend on the size and complexity of the parts you want to produce. Here are some of the types of injection molding machines you can consider:

Hydraulic Injection Molding Machine: This is the most popular type of injection molding machine. It uses hydraulic power to create pressure, which is then used to inject plastic into the mold. Hydraulic injection molding machines are known for their high production speed and precision.

Electric Injection Molding Machine: These machines use electric motors to generate pressure and are more energy-efficient than hydraulic injection molding machines. They are also quieter and produce less waste.

Hybrid Injection Molding Machine: These machines combine the best features of hydraulic and electric injection molding machines. They are more energy-efficient than hydraulic machines and offer higher production speeds than electric machines.

Consider the Clamping Force You Need

The clamping force of an injection molding machine is the amount of pressure it can generate to hold the mold closed during the injection and cooling process. The clamping force you need will depend on the size and complexity of the parts you want to produce. As a general rule, you should choose an injection molding machine with a clamping force that is at least three times the weight of the part you want to produce.

Look for Energy-Efficient Features

Energy-efficient injection molding machines can help you save money on energy costs and reduce your carbon footprint. Some of the energy-efficient features you should look for include:

Variable Frequency Drives (VFDs): VFDs adjust the speed of the motor based on the load, which reduces energy consumption.

Servo Motors: Servo motors are more energy-efficient than traditional hydraulic or electric motors.

Regenerative Braking: Regenerative braking captures energy from the motor when it slows down and uses it to power other parts of the machine.

Look for Machines with High-Quality Control Systems

The control system of an injection molding machine is responsible for controlling the various processes involved in injection molding, such as temperature, pressure, and speed. A high-quality control system can help you achieve better part quality, reduce scrap rates, and increase productivity. Some of the features you should look for in a control system include:

Closed-Loop Control: Closed-loop control systems monitor the process variables in real-time and make adjustments as necessary to maintain consistent part quality.

Touchscreen Interfaces: Touchscreen interfaces make it easy to adjust machine settings and monitor the production process.

Data Collection and Analysis: Data collection and analysis tools allow you to track key performance metrics and identify areas for improvement in your production process.

Choose a Reputable Manufacturer

Finally, when purchasing an buy injection molding machine, it's important to choose a reputable manufacturer. A good manufacturer will offer high-quality machines, excellent customer service, and support after the sale. Some of the factors you should consider when choosing a manufacturer include:

Reputation: Look for a manufacturer with a good reputation in the industry. Check reviews and testimonials from other customers to get an idea of the manufacturer's track record.

Support: Make sure the manufacturer offers technical support and training for their machines.

Warranty: Look for a manufacturer that offers a comprehensive warranty on their machines.

Conclusion

Investing in the right injection molding machine can help you unlock efficiency and quality in your manufacturing process. When purchasing an injection molding machine, consider the type of machine you need, the clamping force, energy-efficient features, control systems, and the reputation of the manufacturer. With these factors in mind, you can make an informed decision and choose a machine that meets your needs and helps you achieve your production goals. By investing in the right injection molding machine, you can increase productivity, reduce waste, and produce high-quality parts consistently.

0 notes

Text

Buy Injection Molded Plastic Parts

Get the best deals on Plastics Injection Molding Machines when you shop the largest online selection at Nagual Precision (shenzhen) Limited. Our injection molded parts include plastic covers, plastic trays, plastics shrouds, plastic panels and plastic housing for the medical, business, for more info visit us.

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

The Advantages of Choosing Used Injection Molding Machines

Injection molding machines are crucial machinery that is responsible for creating the most plastic materials we see in our day-to-day lives. These are important for the plastic manufacturing industry, with the help of molds, the machine produces the plastic products efficiently. Getting a new Injection molding machine can cost a lot, but when you go for a used injection molding machine you can reduce the cost and it can be immediately set in production.

Looking to buy high-quality Used Injection Molding Machines for your industry? Contact Hunter Plastics today! We sell high-quality used injection molding machines for sale. We have thirty years of selling plastic machineries and equipments in North America.

Here’s Why You Should Choose Used Injection Molding Machines Proven Performance: Many used machines have a track record of performance in previous applications. This history can provide insight into the machine's reliability and performance over time. Additionally, reviews and recommendations from previous owners can help in assessing the quality of a specific used machine.

Quick Implementation: Since used machines are often sold as-is, there is usually less lead time between the decision to purchase and the machine being operational. This can be important for businesses that need to quickly ramp up production.Lower Depreciation: The initial depreciation of a new machine occurs rapidly in the first few years. By purchasing a used machine, you can avoid the steeper part of this depreciation curve, potentially saving money in the long run.

Upgrade Opportunities: Investing in a used machine may free up capital for other essential areas of your business, such as technology upgrades, process improvements, or employee training.

Reduced Environmental Impact: Opting for a used injection molding machine can be more environmentally friendly as it extends the lifespan of existing equipment and reduces the demand for new manufacturing resources.

Looking for high-quality used injection molding machines? Look no further than Hunter Plastics! With over thirty years of experience in the industry, we have built a reputation for selling the Best Used Injection Molding Machines in North America. Whether you need equipment for plastic manufacturing or other related industries, we have got you covered. We have various injection molding machines for sale! Contact us today!

0 notes

Text

Global Hydraulic Filter Market Outlook in Comparison to 2022-2032 Growth Forecast

The global hydraulic filter market is estimated at USD 2,124.3 Million in 2022 and is forecast to surpass USD 3,251.8 Million by 2032, growing at a CAGR of 4.3% from 2022 to 2032.

The hydraulic filters guard the hydraulic system from injury because of the particles or oil contamination. Approximately 1 million particles enter the compression system every moment and can affect hydraulic system parts. In order to increase the hydraulic component lifetime, the need to maintain good water filtration system is necessary as the adulteration of compression oil is easy. The effectiveness of the system is measured by its ability to remove impurities, removing particles and purifying the oil.

For More Insights into the Market, Request a Sample of This Report:

https://www.factmr.com/connectus/sample?flag=S&rep_id=3477?SP

The readability score of the Hydraulic filter Market Demand report is good as it offers chapter-wise layout with each section divided into a smaller sections.

The report encompasses graphs and tables to show the entire assembling. Pictorial demonstration of the definite and estimated values of key segments is visually appealing to readers.

This Hydraulic filter market outlook report explicates on vital dynamics such as the drivers, restraints and opportunities for key players and competitive analysis of Hydraulic filter along with key stakeholders as well as emerging players associated with the manufacturing of product.

Competitive Landscape: Top Companies in Hydraulic Filter Market

The global hydraulic filter market is highly fragmented and competitive owing to the existence of many domestic and regional players. Various marketing strategies are adopted by key players such as mergers and acquisitions, expansions, collaborations and partnerships.

Also, new product development as a strategic approach is adopted by the leading companies to upscale their market presence among consumers. These strategies have resulted in the growth of hydraulic filter market.

Fact.MR has provided detailed information about price points of key manufacturers in hydraulic filter market positioned across regions, sales growth, production capacity, and speculative technological expansion in the recently published report.

For instance:

In January 2019, Eaton Corporation plc – a multinational power management company – announced that the Aftermarket division of its Vehicle Group’s has entered an agreement with Bezares SA – a leading manufacturer of pumps, motors, and hydraulic systems – to improve its presence in North America. The company also declared that the partnership with Bezares will enable the company to offer a comprehensive mobile power hydraulic portfolio, including hydraulic filters, to cater to the North American customers’ dynamic needs.

In March 2019, UFI Filters – an Italian manufacturer in the hydraulic filter market – announced that it has expanded its aftermarket base in the UK with the launch of a new warehouse and a dedicated office. The new distribution center features over 3,000 SKUs in its aftermarket catalogue. The company aims to benefit from its newly-appointed supply chain partner DB Schenker – a German logistics company – to gain momentum in highly fragmented Irish and UK Aftermarkets, in the coming years.

For In-Depth Competitive Analysis, Buy Now:

Global Hydraulic Filter Market by Category:

· By Product Type, Global Hydraulic Filter Market is segmented as:

Suction Filter

Pressure Filter

Return Line Filter

Off-line Filter

Breather Filter

Other Product Type

· By Technology Type, Global Hydraulic Filter Market is segmented as:

With Sensor

Without Sensor

· By End-Use Industry, Global Hydraulic Filter Market is segmented as:

Industrial

Steel

Machine Tools

Presses

Pulp and Paper

Power Generation

Plastic Injection Molding

Marine

Mobile

Construction

Agriculture

Mining

Forestry

Material Handling/Lifting

· By Distribution Channel, Global Hydraulic Filter Market is segmented as:

Original Equipment Manufacturer (OEM)

Aftermarket

· By Region, Global Hydraulic Filter Market is segmented as:

North America

Latin America

Europe

East Asia

South Asia & Oceania

MEA

How will be insights and market estimations provided in the report on the Demand of Hydraulic filter make a difference?

The study takes a closer look at the major economic turmoil, with a focus on the recent COVID-19 pandemic disruptions

The assessment of key growth dynamics highlights the attractiveness of new automation technologies and offers readers insight on the prospect of these during the forecast period

The study tries to offer a balance perspective of the opportunities in mature and the most lackluster markets

Provides scrutiny of the industry trends that have shaped recent government policies

Provides an account of major breakthroughs in all segments that might change the course of the market considerably

Provides an incisive analysis of socio-political milieu in which the key markets operate, and how will that influence the lucrativeness of the overall Hydraulic filter Market

Analyzes how collaborations and partnerships among players from different industries shape the key growth dynamics in the near future

Evaluates the role of various stages of funding on new growth avenues in key regional markets

Contact:

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E-Mail: [email protected]

0 notes

Text

Quick Turn Injection Molding | Prototool.com

We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the Plastic Prototyping Service finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited.

There is no doubt that our services are unique. We make sure to provide you with unparalleled quality in terms of rapid protyping at the cost that you prefer under the standard quality management system of IATF 16949:2016 and ISO 9001:2015. Typically, it is quite difficult to find the right injection molding and CNC machining services you desire. If you require reliable Plastic Rapid Prototype products, you often have to sacrifice affordability. In Prototool you can have quality and cost-effective at the same time.We provide you with durable materials and machining services at the prices that you prefer and that is what makes us unique.

In fact, you can go through different materials and services that we offer on our website and just choose the ones you prefer. We will be sure to deliver the best services you need.As the leading manufacturing service provider, we offer various end-to-end holistic services that ensure maximum client satisfaction for our customers. Our mission is to provide rapid prototyping, low-volume manufacturing, and mass production without compromising on the Quick Turn Injection Molding standardization, quality, and affordability of the products.As a company, we believe in accelerating technological innovation by revolutionizing industrial manufacturing and production techniques. We empower businesses to bring new concepts to the industry by presenting them with the industry’s fastest and most inclusive production and manufacturing services.

0 notes

Text

Screen Printing Of Shirts

The Cube by 3D systems can build 5.5" x 5.5" x 5.5" models away from a associated with colored ABS plastics with less than 30 micron detail about $1,200! https://www.luxes3dprinting.com/red-wax-3d-printing-service/ has had the Thing-o-matic model out for a fairly while, but competition is removing its "say" in the market. Stratasys has launched the Mojo printer which creates slightly smaller, but slightly higher detailed prints in comparison to Cube, inside of a higher the price tag. Product developers have even been launching home DIY kits for Stereolithography (SLA) printers on-line for lower $2,400. We now in the "test stage" for home printers. Small businesses and homes can manage to take higher than normal detail FDM printers to homes and offices; i mean how well this will proceed!

If you have several photos and you'd prefer to print them in one go, the idea depends using the smartphone get if as a result possible. Some phones allow simultaneous printing of some photos. Positively luxes as Android smartphones, you can print a single photo at a time.

The researchers admire the quickness of making the hearing. The total process take less than 48 hours: half any day to scan and design the mold, one day to print, 30 minutes to inject the gel, and the 15 minute wait previously mentioned. This can be great for those that do n't want to wait weeks or months attain someone replace their ears.

You don't have spot the posters only your help of grommets or poles. Adhesive backs and static clings give the freedom to brighten the window glass or shop fronts with beautiful posters. Are generally flexible materials that can enlarge visuals to only 52X100 inches.

3D printing is an enthralling connected with manufacturing technology that allows for the layer by layer creation quite a few products from any wide associated with materials. This technology can use to create prototypes of products, some fancy desk art, functional parts, or intricate photos. In this article I to be able to highlight the force 3d printing of unique visuals. abs 3d printing can readily be some cool desk art or pieces, but they have very much potential.

Secondly, buy photo-editing laptop or computer. Look for simple software under $100 which more automatic features like color correction, brightness control; auto focus etc. next thing is to obtain good quality paper.

OIt is one among the cost-effective printing option for paper, card and paper label based printing product. Offset printing produces articles in color quality, producing high-definition and color accurate prints.

1 note

·

View note