#lubrication management software

Text

AI & Lubrication Management: What’s all the hype? - Webinar

Join us for an in-depth exploration into the world of Artificial Intelligence and its remarkable impact on lubrication management. Our webinar titled “AI & Lubrication Management: What’s all the hype?” sheds light on the buzz around AI and demonstrates practical ways to harness its power for enhanced maintenance operations.

Discover how Redlist is at the forefront of this innovation, integrating AI to not only streamline lubrication processes but also to elevate safety and FSD initiatives. Learn from industry experts, engage in thought-provoking discussions, and unveil the secrets to propelling your maintenance strategies into the future with AI-driven solutions.

#lubrication management#lube management#lubrication management software#machinery lubrication#ai solutions#lubrication

0 notes

Text

Algorithmic Drones

Consume art without a soul and you will find yourself without a soul. In the Chronicles of Darkness, this is not a metaphor. The God-Machine needs blood and meat to lubricate its gears, minions who won’t blab about the dark rites they perform in sub-basement 3, and bodies for its angels to possess. The Soulless Algorithm ensures these human resources don’t run out.

The Soulless Algorithm is an occult plugin that piggybacks on AI software — including art programs from Final Destination, writing programs from Bayside Sorcerers LLC, and Youtube’s video algorithm. The Algorithm doesn’t directly infect mortals; instead, it subtly tweaks the outputs of the program it is attached to implant subliminal messaging into mortals using that software.

The God-Machine uses one-off exposures to the Algorithm to move people into the places that help complete occult matrices. However, long-term exposure turns the user into a stigmatic and untethered their soul, allowing the God-Machine to turn them into a compliant drone. These shells of human beings go about their everyday lives, but they do it without passion or meaning. They remain competent, but they don’t have any real insight anymore, just going through the motions day in and day out. They get their reports done on time, pump out content to feed the social media machine, and continue on as they did before — but inevitably, they lose followers or get passed over for promotion without noticing anything is wrong.

Integrators hypothesize that the God-Machine only intended the Soulless Algorithm to create the bare minimum of algorithmic drones required to meet its needs. They believe that the rise of AI programs in the early 2020s caused the initiative to spread out of control to the point that the God-Machine cannot reign it back in. Inquisitors and Saboteurs are far more skeptical, assuming everything is going according to plan. Meanwhile, a few morally bankrupt Tempters look for a way to turn the Algorithm to their own advantage.

Algorithmic Drone

Compliant stigmatic

Virtue: Obedient. Drones are all too willing to follow orders from legitimate authorities.

Vice: Superficial. Drones take everything at face value, and don’t bother thinking critically.

Attributes: Intelligence 2, Wits 2, Resolve 2; Strength 2, Dexterity 2, Stamina 2; Presence 2, Manipulation 2, Composure 2

Skills: Computers 2 (algorithms), Occult 1, Politics 1, Science 2; Brawl 1, Drive 1; Streetwise 1

Merits: Good Time Management, Omen Sensitivity, Unseen Sense (God-Machine)

Health: 7

Willpower: 0

Integrity: 1

Size: 5

Speed: 9

Defence: 2

Initiative: +4

Glitches: The body odor of algorithmic drones smells faintly of brimstone.

Enthralled by the Machine: The drone’s soul has become unmoored, and the God-Machine’s whispers have taken place. The drone suffers from the Soulless, Enervated, and Enthralled Conditions but does not suffer from the Broken Condition as usual. A soul cannot be attached to the drone unless the God-Machine’s influence is first removed.

Uninspired: The drone cannot gain or bestow the Inspired Condition by any means.

Unskilled Labour: The drone cannot raise her skills dots above two by any means. If her skills are already above two, they become two until she regains a soul.

Other Drones

The above statistics represent a generic drone who was a software engineer before the God-Machine sunk its circuits into them. Drones from other backgrounds can be created by varying the drone’s skills. If a character turns into a drone over the chronicle’s course, they will pass through the following stages.

Stage 1: Soulless Art, Soulless Self

When the Soulless Algorithm infects a character, they gain the Soulless Condition. If they are not already a Stigmatic, they become one now, gaining the benefits and drawbacks described in Demon: the Descent p. 225. Stage 1 infectees do not gain additional Supernatural Merits beyond Omen Sensitivity.

Stage 2: Uninspired

When the infected gains the Enervated Condition, they also lose the spark of creativity that drives morals forward. They cannot gain the Inspired Condition by any means, including by supernatural means. They also cannot bestow the Inspired Condition on another character by any means.

Stage 3: Enthralled by the Machine

When the infected gains the Enthralled Condition, their conversion into an algorithmic drone is complete. While they retain the abilities they possessed before, they no longer excel at them. The character does not gain the Broken Condition as usual for Enthralled. Instead, all the character’s Skills now have a maximum of two dots. If the character possesses more than two dots in a Skill, reduce it to two dots as long as the character has the Soulless Condition.

Hey! This was originally made for my patreons over on Patreon. If you want more exclusive monsters, you can back me over there, but you can also follow for free and get email updates whenever I post new public content too!

#Demon the decent#Stigmatic#God-Machine#God Machine#God Machine Chronicle#rpg#urban horror#urban fantasy#Chronicles of Darkness#pathfinder

21 notes

·

View notes

Text

Drone of the Wilds

The Drone of the Wilds lived in a small cabin, in the outskirts of the dark forest that bordered a small village. She stood out from her environment starkly; black nano-latex skin and smooth, faceless head highly out of place amongst thatched roofs and crude fabrics, quiet glens and clear streams.

She pushed open the door to her cabin, pulling her haul inside and hanging her bow on the wall. The dead creature, a six legged beast with shaggy fur, was effortlessly picked up and placed on a table.

The oils secreted from its fur would lubricate her joints well, and it’s organs would make a good base for her nutrient slurry. The rest, she could trade in town for things more useful to her.

Not for the first time, she mused on her luck. That such a backwater planet would be able to offer her a chance to live comfortably….

The Grand Hive had, at its height, been one of the biggest superpowers in the galaxy, respected and feared.

Even one of its mighty hiveships, shining black even against the darkness of space, was enough to conquer an entire planet. Each ship filled with millions of drones; converted humanoids joined together into something greater.

The human she had used to be had lived on one of those planets. A colony established by a long fallen planet named Earth, cut off from what little remained of that fledgling empire. A target ripe for conversion.

The human she had used to be had run in fear as the droneships descended on his planet, abducting people in the thousands. He had been terrified, so afraid of something he did not understand. So afraid, he ignored the tingle of excitement underneath.

He, along with the rest of his planet’s population, were placed in conversion pods. Organics merged with flesh, the hardware and software of his brain upgraded and reorganised. Wants, hopes, fears, emotional attachments… all stripped away. Replaced with obedience. Everything he was was assimilated by the Hive, the unnecessary discarded.

When she had finally emerged from that pod, along with hundreds of her sisters, all she felt was devotion to the Hive. She would not, until much later, truly appreciate her new body; smooth curves, powerful yet slender limbs, a blank slate where a face should be…

She was perfect.

She had served 146.31 cycles aboard Hiveship 462 before the Grand Hive fell. An alliance of rival forces had infiltrated Hiveship 000, from where the Grand Mxtress ruled over all, and destroyed her, contaminated the Hive. All at once it was severed. The network that connected all drones, providing them their orders, their purpose.

The hiveships all over the galaxy fell to chaos. Many drones began to regain their former lives, and in disgust of what they had become, self-terminated.

Others dedicated themselves to destroying all remnants of the Hive, the scattered hiveships that had managed to form smaller networks of their own.

She had not understood. She had never understood. Even as the network fell, she continued her existence as a drone.

Even with the return of those old memories; they weren’t her. The human she used to be sickened her. She did not miss him. Being a drone was far superior.

Those who were once her fellow drones chased her out, and hounded by the galaxy on all sides, she fled.

The other networks would not take her, the serial number tying her to a fallen hiveship marking her as terminate on sight. So she ran. For cycles, hoping from ship to ship, system to system.

It was a wormhole that brought her journey to an end. Her ship, a fragile thing, had been shredded by the forces, her alone ejected intact onto the strange planet upon which she could identify no stars in the night sky.

The people of the planet had been curious, but not afraid. They saw her as a curiosity, not a threat. She learned their language, told them her story. They felt sorry for her; not for the lost of her hive, but the lost of her humanity. It was a sentiment that confused her.

The planet’s technology was primitive; far too primitive for her to build a ship on. But it was irrelevant. She was safe there. None wanted her dead simply for the crime of being a drone. She was content to simply… be.

Some of the beings of the planet had strange powers, powers that defied comprehension. They called it magic; an obvious misunderstanding of some natural force, but one she alone could not quantify.

They had told her they could restore her old form, revert her to the human she used to be.

She had refused them. Why would she ever want to go back to that body? She was… drones did not used to have emotions, but now that she did, she could state with certainty she was ‘happy’.

Those wise men had shared a look with each other; something she did not understand shared in silent communication. It made her yearn for the Hive. Then, they had wished her luck, and left.

It had been 3 cycles since then. 3 cycles of relative peace. Of getting the chance to shift through the parts of her mind that resurfaced, to decide what to keep and what to toss. 3 years without the threat of termination, from drones or fearful organics.

She still missed the Grand Hive as it had been, a grand interconnected network of mindless belonging. But as far as lives went, being the Drone of the Wilds wasn’t so bad.

Not when compared to life as a human.

#empty spaces#microfiction#shard's stories#transhumanism#drone#it's a metaphor for something we wonder if you can guess

50 notes

·

View notes

Text

Entrapdak Positivity Month - Ticket

Based on this Future AU with a fankid that was born from Twitter discussion between me and @entrapdaknation

So yeah TW for fankid I guess

***

In a quite corner of Crypto Castle lab, Entrapta was tending to Hordak’s cybernetic body. What seemed like such an intimate moment had become routine over the years.

Even after all these years she still insisted on doing this maintenance by hand and refused to let Hordak use a machine. As she tightened his loose connections, updated his operating software and cleaned out his ports, he sat topless and motionless except for scrolling his finger on his datapad. He read out Queen Mermista’s woes on social media giggling all the while as the majority of these were self inflicted disasters.

“There you go Sweety,” she announced while lubricating the last port, “that should keep you going for another while”

He smiled as he stretched his scrawny arms. Now that his chronic pain was eased, he had mobility again. “Thank you my Love,” he responded.

As she refitted his exoskeleton cables into his ports they were interrupted by a female clone who popped their her head out of a ventilation shaft. This clone bore more than a passing resemblance to both of them, “Momma, Papa, what’s this?”

This clone, Nebula Spectra Luminosity Neutrina (so special they gave her four names), had been quite the accidental addition to their family.

Nebula had started life as a replacement body for Hordak. A body where his defects had been genetically removed and replaced with Entrapta’s cells. They never understood how this worked and gene splicing with other clone cells didn’t, but were glad something finally worked.

Yet the body was still imperfect and somehow evolved past the initial plan of a hollow shell. They’d never been so pleased to have such a failure on their lab, and wept tears of joy after years of failure and frustration in conceiving naturally. They finally had been blessed with a child of their own. Unfortunately Nebula was forever stuck in an adult form like Hordak had been, a side effect of her initial conception as a cloned body.

Nebula popped her head out of a vent and held a small tattered piece of card in a hair tendril and was examining it closely. She certainly had inherited Entrapta’s curiosity and somehow managed to find the most obscure items around the castle.

Entrapta plucked the card using her hair, used another tendril to flick down her second pair of glasses and read the words on the ticket. Instantly she lit up with the biggest smile.

“Oh Hordak do you remember?…” she started, “this is from…” she pointed at the faded words on the ticket with a hair tendril, as Hordak peered over and finished her sentence, “…our first date. Back when we viewed the roaming comet Rhullo”

“So where is it now?” questioned Nebula as she shuffled her tall frame out of the vent.

Hordak chuckled while Entrapta finished slotting in his exoskeleton parts

“Now that is the right question my Serendipitous Scion,” he smiled warmly at Nebula, “…for no one knows where it is n-”

“It blew up” interrupted Entrapta, who’d searched up the information on the datapad with a stray hair tendril.

She looked dumbfounded at the Hordak, “did we blow that one up?”

Hordak thought for a moment, “…I don’t think so”

Nebula soaked up ever second of the exchange, “how many comets have you blown up?”

“Not man-“ started Entrapta.

Hordak nudged her and winked, “-many that were inhabited”

Entrapta giggled and returned the wink in an overly theatrical way, “oh yeah..only the deserted ones. Gotcha Honey”

“Momma, Pappa! When can I blow up a comet?”

Hordak ruffled the long hair on her crown, “when you’re old enough”

Nebula pouted, her hair fluffing up, “but I’m old enough nooooooow” she whined.

“Now Darling,” started Entrapta, “if our daughter is old enough to make her own fake ID, then she’s old enough to blow up a comet.”

Hordak sighed and folded his ears back as he stood up.

“Fine” he stated flatly

“Oh Pappa” Nebula exclaimed hugging her father tightly

“But on one condition…”

“Oh?”

He paused for a moment basking in her excitement

“Get your Big Siblings, they’ll want to see this too” he chuckled

#Hordak#entrapta#entrapdak positivity month#entrapdak positivity month 2023#my fics#fankid#au#future au#spop#fanfic#buzzthebatgirl art

13 notes

·

View notes

Text

Hydraulic Manifold valve manufacturer in india by hydrofittings

In addition, an Air Manifold With Valves allows the set up of more than one solenoid valves in a centralized vicinity. A unmarried air deliver and port are shared by means of numerous valves. Manifold take a look at Valve acts as a primary distribution point for aircraft that have dual dry air pumps. If one pump of Manifold Pneumatic fails it’s miles designed to isolate the failed pump and provide continuous airflow from the operating pump. Water Manifold With Valves is designed to distribute water and has built-in ports in a section of pipe. They act as manage facilities of water distribution within the house. Solenoid Valve Manifold has a most preferred stress of 6000 psi at a hundred ranges F and has a mounting hollow that enables inside the self-supporting software. Hydraulic Valve Manifold Has a stainless steel pin that forestalls the bonnet from detaching itself from the frame due to vibration. Ball Valve Manifold has a burr-loose thread that reduces inner floor leaks accordingly offering accurate transmitter read. No O-ring is used bonnet to body pressure Transmitter Manifold seal. It is a steel-to-metallic seal. Hydraulic Valve Manifold Block has the choice of panel mounting. There are one of a kind sorts of Manifold Valves to be had within the market but the maximum typically used ones are the two valve, three valve, and 5 valve assemblies. Swagelok Manifold is designed mainly for liquid stage, static stress, and differential stress packages. Smc Valve Manifold has a blended isolating and venting in a single valve that eliminates the want for tubing and fitting. Festo Valve Manifold is simple to gather and set up and is dependable. They’ve dirt caps fitted on them that comprise stem lubricant and save you the ingress of contaminants. Rosemount 305 Manifold gets rid of the need for a flange because it suits immediately to the patented Rosemount. Why to choose hydrofittings ? About us – The briefcase of our company consists of numerous additions which include, – clever hydraulics, engineering, and digital answers. With the guide of 80 personnel, our company works like a well-oiled system to deliver most effective the very best fine product to our buyers. Proper from the responsibly sourced product by way of our procurement team to our nice manage team, many agencies have lauded our work. And that they admire the fact that we’re transparent in all our dealings. With a properly-mounted channel of communique, our customers can connect with us anytime. Our control and our body of workers, together form a competent and ambitious crew. The readability and high stage of performance make us one of the most modern but sought after manufacturers. And because we fee initiative behavior, we adore to have our studies and development crew collaborate with the opposite teams to recognize the current requirements of the hour. We frequently have checking out and great exams to maintain brilliant requirements.

An global provider of

TO KNOW MORE ABOUTS US VISITE OUR WEBSITE www.hydrofittings.com

3 notes

·

View notes

Text

Where can I add used Ford Airstream transmission fluid?

Transmission Fluid Breakdown: Transmission fluid degrades over time, losing its lubricating and cooling properties. Adding used fluid won't improve performance and might even introduce contaminants.

Transmission Type: Different Airstream models use varying transmission types, each requiring specific fluid specifications. Using the wrong fluid can cause serious damage.

Solution: Instead of adding used fluid, focus on proper transmission maintenance:

Regular Fluid Changes: Consult your Airstream's owner's manual to determine the recommended transmission fluid change intervals.

Fluid Type: The used transmission fluid specified in your manual. This ensures optimal performance and protects your transmission.

2. How Do I Reset the Used Ford Airstream Transmission Control Module (TCM)?

The Transmission Control Module (TCM) is an electronic component that manages your Airstream's automatic transmission. Resetting the TCM can sometimes address minor shifting issues or warning lights. However, it's crucial to understand this process:

Complexity: Resetting procedures vary greatly depending on the specific Airstream model and year. Some models might require specialized tools or software.

Underlying Problems: A reset might not solve the root cause of the issue. It's essential to diagnose any underlying problems before attempting a reset.

Recommendation:

Consult Your Manual: Your Airstream owner's manual might detail specific instructions for TCM resets.

Seek Professional Help: For more complex situations, consider consulting a qualified mechanic familiar with your Airstream model.

3. How Do I Fix Used Ford Airstream Transmission Problems?

Transmission problems can manifest in various ways, including slipping gears, grinding noises, difficulty shifting, or warning lights on your dashboard. Addressing these issues depends on the severity of the problem:

Minor Issues: As mentioned earlier, a simple reset might resolve minor shifting problems. However, this is not a guaranteed solution. If the issue persists, a professional diagnosis is recommended.

Major Issues: Worn components, internal damage, or fluid leaks often require repairs or a replacement transmission. Diagnosing the specific issue is crucial for determining the best course of action.

Recommendation:

Professional Diagnosis: For any significant transmission problems, consult a qualified mechanic who can diagnose the issue and recommend appropriate repairs or a replacement.

4. Why Choose USA Auto Parts LLC to Buy a Used Ford Airstream Transmission?

If a replacement used transmission is necessary, USA Auto Parts offers a trusted solution:

Extensive Inventory: We carry a wide selection of used transmissions for various Ford Airstream models and years.

Compatibility Expertise: Our team can help you find a used transmission specifically compatible with your Airstream, ensuring seamless integration and performance.

Rigorous Inspection: Each used transmission undergoes a thorough inspection by our technicians, verifying functionality and overall condition.

Detailed Descriptions & Transparency: We offer detailed descriptions of each used transmission, including its model, year compatibility, mileage (if applicable), and any relevant information about its condition. This transparency empowers you to make informed decisions.

Competitive Prices & Nationwide Delivery: We strive to offer competitive pricing on used transmissions, while also providing nationwide delivery for your convenience.

Customer Service & Support: Our friendly and knowledgeable staff is here to assist you throughout the process. We can help you find the right used transmission, answer any questions you may have, and even offer recommendations for qualified mechanics in your area for installation assistance.

#usedengines#engine#enginerepair#usedenginesforsale#autoengine#ConnectWithUs#powerengines#Transmission#repairengines#trendingpost#like#comment#share#usa#usatoday#EngineReplacement#engineswap#engineoil

0 notes

Text

The Vital Role of Spare Parts in Oil & Gas Plant Machinery

The oil and gas industry stands as a cornerstone of global energy production, demanding complex, high-performing machinery to maintain efficient operations. A critical yet often overlooked aspect of this machinery is its spare parts. These components are essential to the uninterrupted function and longevity of oil and gas plants, enabling them to meet production targets and safety standards. This article delves into the importance of oil and gas plant machinery spare parts, highlighting their types, procurement strategies, and the challenges associated with managing them.

Importance of Spare Parts in Oil & Gas Plants

Spare parts are vital for ensuring the continuous operation of oil and gas plants. These facilities operate under extreme conditions and any unexpected failure can lead to significant downtime, financial losses, and safety hazards. Having the right spare parts readily available minimizes downtime by facilitating quick repairs and maintenance. This is crucial for maintaining productivity and ensuring the safety of both personnel and equipment.

Types of Spare Parts

Spare parts for oil and gas machinery can be broadly categorized into the following types:

Mechanical Parts: These include valves, pumps, compressors, and turbines. Mechanical components are critical for the movement and control of fluids and gases within the plant.

Electrical Components: This category encompasses motors, generators, transformers, and circuit breakers. Electrical components are essential for the power generation and distribution systems that drive plant operations.

Instrumentation and Control Devices: These parts include sensors, gauges, control valves, and software systems that monitor and regulate plant processes. Precision in instrumentation and control is key to maintaining safety and efficiency.

Consumables and Wear Parts: Items such as seals, gaskets, filters, and lubricants fall into this category. These parts need regular replacement due to wear and tear from continuous operation.

Procurement Strategies

Effective procurement strategies for spare parts involve several best practices to ensure availability, cost-efficiency, and quality:

Inventory Management: Implementing a robust inventory management system helps in tracking stock levels, predicting demand, and avoiding both overstock and stockouts. Techniques such as Just-In-Time (JIT) inventory and safety stock levels are commonly used.

Supplier Relationships: Building strong relationships with reliable suppliers ensures timely delivery and access to high-quality parts. Long-term contracts and partnerships can lead to better pricing and priority service.

Standardization: Standardizing parts across different machinery and equipment can reduce the complexity and costs associated with spare parts inventory. It also simplifies maintenance procedures.

Predictive Maintenance: Utilizing predictive maintenance techniques, such as condition monitoring and data analytics, helps in forecasting part failures and planning proactive replacements. This approach can significantly reduce unplanned downtime.

Challenges in Spare Parts Management

Despite the importance of spare parts, managing them effectively comes with several challenges:

High Costs: Spare parts, especially those that are highly specialized, can be expensive. Balancing the cost of holding inventory with the risk of downtime requires careful financial planning.

Supply Chain Disruptions: The global nature of the oil and gas industry means that supply chains can be affected by geopolitical events, natural disasters, and logistical issues. Ensuring a diverse and resilient supply chain is essential.

Technological Advancements: As technology in oil and gas machinery evolves, older spare parts may become obsolete, necessitating updates to inventory and maintenance practices.

Regulatory Compliance: Oil and gas plants must comply with stringent safety and environmental regulations. Ensuring that all spare parts meet regulatory standards is crucial for legal and operational reasons.

Conclusion

In the high-stakes environment of oil and gas production, the role of machinery spare parts cannot be overstated. Effective management of these parts is essential to ensure the reliability, efficiency, and safety of plant operations. By understanding the types of spare parts, adopting strategic procurement practices, and addressing management challenges, oil and gas companies can maintain their operational resilience and competitive edge in the global energy market.

Email: [email protected]

Call: (+971)45776444

Website URL: https://www.rushmore.ae/

#Rushmore#Rushmore group#Rushmore group Fze#Earth Moving Spare Parts Manufacturers dubai#Heavy Equipment and Plant Machinery Suppliers#Heavy Machinery Parts suppliers in Dubai#Truck & Trailer Spare Parts Dealer Dubai#Truck & Trailer Spare Parts Dealer in Dubai#trailer spare parts dealer in Dubai#construction equipment suppliers in Dubai#Best Machinery Spare Parts Suppliers in Dubai#Best Machinery Spare Parts Suppliers Dubai#Oil and Gas Field Equipment Suppliers#oil & gas plant machinery spare parts

0 notes

Text

Improve Weighbridge Operations with All-Inclusive Services and Assistance!

We can handle everything, from state-of-the-art Weighbridge Management Systems to careful maintenance and repair!

👉 Weighbridge Management System (WMS): Use our cutting-edge software to automate your weighing procedures. Easily centralize your data, expedite calibration, and stop fraud.

🔧 Weighbridge Maintenance: Our skilled specialists make sure the weighbridge operates at peak efficiency by carefully inspecting and lubricating the top, bottom, and load cells.

🛤️ Rail scale and weighbridge systems: We offer comprehensive services for all your weighbridge and rail scale requirements, ranging from installation to routine maintenance, calibration, and repairs.

Get in touch with us right now for specialized solutions and outstanding assistance!

✉️ [email protected] | 🎞 www.endeavourweigh.com/weighing-support-division/ | 📞 +91-99-2420 1567

#WeighbridgeServices#Efficiency#RailScale#Maintenance#WMS#Support#EndeavourWeigh#WeighWithEndeavour#ElevateWithEndeavour#EIPLOfficial#Endeavour#EndeavourInstruments

0 notes

Text

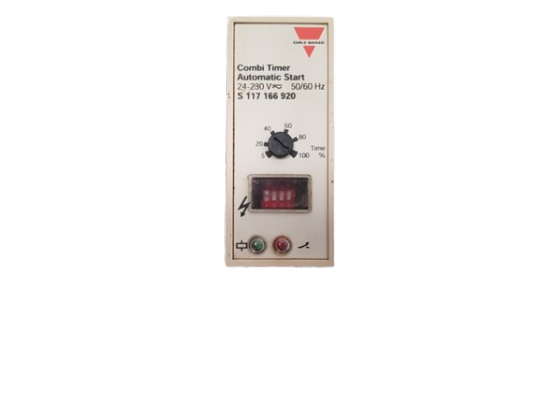

Timer Tactics: Enhancing Performance in Industrial Automation Systems

In the realm of industrial automation, efficiency is king. Every second counts, and every process must be optimized to ensure maximum output. One often-overlooked tool in achieving this optimization is the humble timer. Timers play a crucial role in orchestrating tasks, synchronizing operations, and enhancing overall performance in industrial automation systems. In this blog, we will look into the strategic use of timers and explore how they can be leveraged to boost productivity, minimize downtime, and streamline operations in industrial settings.

The Role of Timers in Industrial Automation

To lay a solid foundation, let's begin by understanding what timers are and how they function within industrial automation systems. Timers are essentially devices or software components that count time intervals. They can trigger actions based on predefined time criteria, such as initiating a process, controlling the duration of an operation, or signaling the completion of a task. In industrial automation, timers are deployed across a wide range of applications, from simple time-delay circuits to complex scheduling systems.

Optimizing Production Processes with Timers

One of the primary objectives of industrial automation is to optimize production processes for efficiency and reliability. Timers play a pivotal role in achieving this objective by synchronizing tasks, coordinating sequences, and minimizing idle time. For instance, in a manufacturing environment, timers can regulate the timing of conveyor belts, control the duration of heating or cooling cycles, and sequence the operation of robotic arms. By fine-tuning these parameters with timers, manufacturers can streamline their workflows and maximize output.

Minimizing Downtime through Scheduled Maintenance

Downtime is the bother of industrial operations, leading to lost productivity, increased costs, and customer dissatisfaction. Timely maintenance is essential to prevent equipment breakdowns and prolong the lifespan of machinery. Timers can be programmed to schedule routine maintenance tasks, such as lubrication, inspections, and part replacements. By proactively addressing maintenance needs based on predefined intervals, companies can minimize unplanned downtime and ensure the smooth operation of their facilities.

Enhancing Safety with Timer-Based Control Systems

Safety is dominant in any industrial environment, where machinery and processes pose inherent risks to workers and equipment. Timer-based control systems can play a crucial role in enhancing safety by implementing time-delayed interlocks, emergency shutdowns, and alarm triggers. For instance, in a chemical processing plant, timers can activate emergency showers or ventilation systems in the event of a leak or spill, mitigating potential hazards and protecting personnel and assets.

Real-Time Monitoring and Adaptive Control

In today's interconnected world, real-time monitoring and adaptive control are essential for maintaining agility and responsiveness in industrial automation systems. Timers can be integrated into supervisory control and data acquisition (SCADA) systems to track process variables, analyze performance metrics, and dynamically adjust parameters in response to changing conditions. By harnessing the power of timers for real-time control, companies can optimize their operations, adapt to market demands, and stay ahead of the competition.

Future Trends and Innovations in Timer Technology

As technology continues to evolve, so too does the landscape of industrial automation. In the realm of timer technology, advancements such as digital timers, programmable logic controllers (PLCs), and cloud-based timer management systems are driving new possibilities for efficiency and optimization. Moreover, the emergence of artificial intelligence (AI) and machine learning (ML) is poised to revolutionize how timers are utilized, enabling predictive maintenance, adaptive scheduling, and autonomous decision-making.

Conclusion

In conclusion, timers are essentials tools for enhancing performance in industrial automation systems. By strategically deploying timers across various applications, companies can optimize production processes, minimize downtime, enhance safety, and achieve new levels of efficiency. As technology continues to advance, the potential for innovation in timer technology is limitless, offering exciting opportunities for companies to stay competitive and succeed in the digital age of automation.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial automation equipment#industrial and marine automation equipment#industrial and marine automation#industrial#timer

0 notes

Text

Production Monitoring Dashboard Oil & Gas Kpis

The course covers matters, including the kinds of dangers that power corporations face, the different sorts of insurance coverage insurance policies out there, and the elements that affect the worth of insurance premiums. The ISSB builds on the work of various reporting initiatives, together with the industry-based Sustainability Accounting Standards Board (SASB) Standards, Inte... The simulator is designed for training, coaching, and assessment activities, permitting trainees to achieve experience in operations, troubleshooting, and upkeep duties such as loop testing, stroke checks, and calibration. Trainees also follow a permit-to-work system and adhere to the identical procedures and work orders as in real-world installations as part of a Safe System of Work. This serves as the ultimate preparation by the Port Mourant-based GTTCI and its FACTOR oil and gas training facility in collaboration with Exxon and SBM to prepared college students for work on FPSOs offshore.

The institute conducts various training packages in upstream sector with particular emphasis on Exploration, Drilling, Well Services, Production, Gas Processing Production and Instrumentation. This includes one yr training programs for contemporary graduates and technicians, enabling their career induction as nicely as quick refresher and superior training courses for experienced professionals. This 3-day training course is designed for those who are or shall be operating in the Supply & Distribution functions and can present the background information to permit them to take the proper decisions on tips on how to supply the network on the proper value. In this webinar, Brad Donohue, VP of Competency Management at IHRDC, demonstrates CMS Online

Learning is bolstered by working on case material to explore uncertainties and risks within the context of manufacturing forecasting, cash-flow administration, incremental initiatives and asset portfolio manipulation. Monte Carlo modelling and Decision Tree analysis software are employed during the course to dev... Carbon Capture and Storage (CCS) is an upcoming new expertise that has an important place within world efforts to decarbonise. It has a unique set of challenges, alternatives and dangers to be understood and accommodated within acceptable authorized, regulatory, and social and public licence frameworks.

We would note that while this data is beneficial, manufacturing from Petroleum Administration for Defense Districts (“PADD”) offers additional insights. Keeping in view the rising wants of Pakistan’s petroleum business, OGDCL established its personal Oil & Gas Training Institute (OGTI) in 1979 with technical help from Canadian International Development Agency. OGTI has emerged as a premier institute within the petroleum sector of Pakistan catering for the training wants of Geoscientists and Engineers of OGDCL and different E&P companies operating in Pakistan. This 2 half-day stay online training course will allow you to optimise your energy asset upkeep plan with Reliability Centred Maintenance (RCM).

Learn how CMS Online manages assessments, tracks compliance requirements, offers a gateway to numerous learning options and supplies built-in business analytics reporting. Let powerbi for oil and gas training present you ways CMS Online can streamline your studying and development actions to make sure a reliable workforce. It's important to study oil and gas as these are the highest pure resources that get used on a day by day basis. In our trendy society, oil extracted from the earth is used to supply lubricants for cars, bikes, vans, and many other moving parts.

By using Power BI, firms in the Oil and gas trade can obtain higher operational visibility, enhance effectivity, adjust to regulatory standards, and ultimately, make higher business selections. Power BI reports and dashboards are simple to share, making it simpler for staff members and stakeholders to collaborate. Whether it is engineers, geologists, monetary analysts, or executives, everybody can benefit from having entry to the same knowledge and insights, introduced in a user-friendly format.

This self-paced on-line training course offers delegates with a comprehensive overview of energy storage methods as we transition from fossil gas based power to renewable power sources trying into the ability and oil & gas sectors. At the Energy Institute, we're absolutely dedicated to achieving net zero emissions, while recognising the essential function that oil and gas operations presently play in giving individuals and societies across the globe access to power. Power BI has taken off as a compelling Business Intelligence resolution, now in heavy use throughout E&P companies.

Here is an instance based on the open data supply from Norwegian Petroleum Directorate. With this dashboard's widgets, viewers can track oil and gas manufacturing in a few alternative ways. With the Oil and Gas BOEPD widgets, we are able to see what number of barrels have been extracted this week. We also can see how a lot of an increase or lower this number is in comparison with the previous week. Learning Tree is the premier world provider of studying options to help organizations’ use of know-how and effective business practices.

This class is designed to help present Excel or Spotfire customers be independent Power BI customers, as properly as refine data in particular areas for present intermediate Power BI users. Because the oil and gas industries generate a massive amount of knowledge, BI expertise has the potential to revolutionize them. This legitimate knowledge help authorities in making knowledgeable judgments that can help them improve productivity. From identifying one of the best places to carry on operations, to insights that can help reduce down on the risks of downtimes, BI performs a vital position within the clean working of these massive industries. Typical profession alternatives in oil and gas can begin with junior roles in oil and gas companies, or working as an analyst in authorities companies, financial companies, or trade associations.

#powerbi for oil and gas course#powerbi for oil and gas training#powerbi for oil and gas certification#powerbi for oil and gas program#powerbi for oil and gas programme#powerbi for oil and gas education#powerbi for oil and gas fundamentals#powerbi for oil and gas skills#oil and gas powerbi course#oil and gas powerbi training

0 notes

Text

0 notes

Text

Guardians of Momentum: Ensuring Peak Performance with Lexus NX 350h Transmission Maintenance

In the realm of automotive excellence, the Lexus NX 350h stands as a symbol of luxury, efficiency, and innovation. At the heart of this remarkable vehicle lies its transmission system, a vital component responsible for translating engine power into seamless acceleration and efficient performance. In this article, we explore the importance of transmission maintenance for the Lexus NX 350h, shedding light on how proper care ensures peak performance and longevity.

Understanding the Transmission System

Before delving into the intricacies of transmission maintenance, it's essential to grasp the role of this critical component within the Lexus NX 350h. The transmission serves as the link between the engine and the wheels, allowing for smooth and efficient power delivery across a range of driving conditions.

The Lexus NX 350h features a sophisticated hybrid powertrain, combining a gasoline engine with electric motors to deliver impressive fuel efficiency without compromising performance. Its transmission system incorporates advanced technology to seamlessly manage power distribution between the engine and electric motors, optimizing performance and efficiency at all speeds.

The Importance of Transmission Maintenance

Like any mechanical system, the transmission of the Lexus NX 350h requires regular maintenance to ensure optimal performance and reliability. Over time, various factors such as heat, friction, and wear can take their toll on transmission components, potentially leading to decreased efficiency, rough shifting, or even complete failure if left unchecked.

Routine transmission maintenance involves a series of preventative measures aimed at preserving the integrity of critical components and ensuring smooth operation. This includes inspecting fluid levels and condition, checking for leaks, and performing adjustments or replacements as needed. By staying proactive with transmission maintenance, Lexus NX 350h owners can avoid costly repairs and enjoy a consistently high level of performance.

Fluid Inspection and Replacement

One of the most crucial aspects of transmission maintenance is the inspection and replacement of transmission fluid. Transmission fluid serves multiple purposes, including lubricating moving parts, cooling the transmission, and facilitating smooth gear changes. Over time, transmission fluid can become contaminated with dirt, debris, and other impurities, compromising its effectiveness and potentially causing damage to internal components.

During a transmission service for the Lexus NX 350h, technicians will drain the old transmission fluid, inspect the transmission pan and filter for any signs of debris or wear, and refill the system with fresh fluid. This process helps to maintain proper lubrication and cooling, ensuring smooth and efficient operation of the transmission.

Seal and Gasket Inspection

Another critical aspect of transmission maintenance is the inspection of seals and gaskets. These components play a vital role in preventing fluid leaks and maintaining proper pressure within the transmission system. Over time, seals and gaskets can deteriorate due to heat, age, or exposure to contaminants, leading to fluid leaks and potential damage to internal components.

During a transmission service, technicians will inspect all seals and gaskets for signs of wear, cracking, or leakage. If any issues are detected, they will be promptly addressed through replacement to prevent fluid leaks and ensure the integrity of the transmission system.

Performance Optimization

Beyond basic maintenance tasks, transmission service for the Lexus NX 350h also includes performance optimization measures aimed at enhancing overall driving experience. This may involve recalibrating transmission settings, updating software, or performing adaptive learning procedures to ensure optimal shift quality, responsiveness, and efficiency.

By fine-tuning transmission performance, technicians can help Lexus NX 350h owners unlock the full potential of their vehicle, maximizing both performance and fuel economy. Whether navigating city streets or embarking on long highway journeys, a properly maintained transmission ensures smooth and effortless acceleration, allowing drivers to enjoy the full luxury and performance of the Lexus NX 350h.

Conclusion

In the ever-evolving landscape of automotive technology, the Lexus NX 350h stands as a beacon of innovation and excellence. At the heart of this remarkable vehicle lies its transmission system, a marvel of engineering responsible for delivering seamless power delivery and efficiency.

By prioritizing transmission maintenance, Lexus NX 350h owners can ensure peak performance and reliability for years to come. From fluid inspections and replacements to seal and gasket inspections, routine maintenance tasks play a crucial role in preserving the integrity of the transmission system and maximizing overall driving experience.

As guardians of momentum, it is incumbent upon Lexus NX 350h owners to stay proactive with transmission maintenance, entrusting their vehicle to the care of knowledgeable technicians who understand the intricacies of hybrid transmission systems. By doing so, they can enjoy a driving experience that exemplifies the pinnacle of luxury, efficiency, and performance.

#Lexus NX 350h#lexus car service center#lexus car mechanic#lexus transmission service#lexus car transmission fluid

0 notes

Text

The Role of Computerized Maintenance Management Systems in Streamlining Industrial Operations

In today’s hyper-competitive business ecosystem, even a minute of downtime translates to lost productivity, increased costs, and potential safety hazards. To streamline their operations and stay competitive, industries are increasingly turning to Computerized Maintenance Management Systems (CMMS). Let's delve into how CMMS software plays a pivotal role in optimizing maintenance processes and enhancing productivity in industrial settings.

Understanding Computerized Maintenance Management Systems

Computerized Maintenance Management Systems are powerful tools designed to facilitate the planning, execution, and tracking of maintenance activities within an industrial set up. Unlike traditional paper-based or spreadsheet methods, CMMS software centralizes maintenance data, providing real-time insights into equipment health, work orders, and resource allocation.

Preventive maintenance: Proactive approach to equipment reliability

One of the key functionalities of CMMS solutions lies in their ability to implement preventive maintenance schedules. By scheduling routine inspections, servicing, and repairs based on equipment usage or predefined intervals, industrial facilities can proactively address potential issues before they escalate into costly breakdowns.

For instance, in a manufacturing plant, CMMS software can automatically generate work orders for regular equipment checks, lubrication, or calibration. This proactive approach not only minimizes unplanned downtime but also extends the lifespan of critical assets, ultimately reducing maintenance costs.

Asset management: Optimizing resource utilization

Industrial facilities house a multitude of assets, ranging from machinery and vehicles to tools and infrastructure. Managing these assets efficiently is essential for maximizing productivity and minimizing operational disruptions. Asset maintenance management software provides a centralized repository for asset information, including maintenance history, specifications, and warranty details.

With cutting-edge CMMS solutions on hand, maintenance teams can easily track the performance and status of each asset, enabling informed decision-making regarding repairs, replacements, or upgrades. Furthermore, predictive maintenance features within advanced CMMS platforms leverage data analytics and machine learning algorithms to forecast equipment failures, allowing organizations to take pre-emptive actions to avoid downtime.

Work order management: Streamlining maintenance processes

In a bustling industrial environment, managing work orders manually can be a logistical nightmare. CMMS software automates the entire work order lifecycle, from creation and assignment to completion and documentation. Maintenance technicians can access work orders via mobile devices, allowing them to view task details, record findings, and update job status in real-time.

Moreover, CMMS streamlines communication between maintenance teams, supervisors, and other stakeholders by providing a centralized platform for collaboration. This fosters transparency and accountability, ensuring that maintenance tasks are executed promptly and efficiently.

Data-driven decision making: Insights for continuous improvement

In the digital age, data is king. CMMS software empowers industrial facilities with actionable insights derived from maintenance data. By analyzing key performance indicators such as Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and Overall Equipment Effectiveness (OEE), organizations can identify trends, pinpoint areas for improvement, and optimize maintenance strategies.

For example, by analyzing maintenance data, a chemical plant may discover that a particular pump consistently fails after a certain number of operating hours. Armed with this knowledge, the plant can adjust its preventive maintenance schedule or invest in upgrading the pump to a more robust model, thereby minimizing disruptions to production.

Eagle CMMS – Powering your plants with innovative maintenance management systems

Computerized Maintenance Management Systems stand as the linchpin for operational excellence in industrial settings, driving efficiency, reliability, and competitiveness. By embracing CMMS solutions like Eagle CMMS, organizations embark on a transformative journey from reactive to proactive maintenance, empowered to navigate the complexities of modern industry with confidence.

Eagle CMMS transcends mere software; it emerges as a strategic ally committed to maximizing maintenance efficiency and reliability. Through proactive maintenance strategies, optimized asset management, and streamlined work order processes, Eagle CMMS empowers businesses to minimize downtime, reduce costs, and maintain a competitive edge in today's fast-paced market.

Moreover, our dedication extends beyond software provision. We prioritize comprehensive training, unwavering support, and continuous enhancements to ensure that Eagle CMMS remains at the forefront of industry innovation. With Eagle CMMS as your trusted partner, you're not just investing in software; you're fortifying your business for sustained success and resilience in the ever-evolving landscape of industry.

As technology continues to evolve, CMMS software like Eagle CMMS will remain an indispensable tool for achieving operational excellence and plant wellness. Choose Eagle CMMS and embark on a path toward operational excellence, where every step is guided by innovation, reliability, and commitment to your success.

To learn more visit our website or sign up for a free 14-day trial.

0 notes

Text

Top Condition Monitoring of Machine Techniques You Must Know

Keeping production equipment running smoothly is essential for any manufacturing operation. However, unexpected faults can lead to costly unplanned downtime, inefficiencies, and safety issues if not addressed quickly.

That's why establishing an effective program for the condition monitoring of machines is essential. By regularly scrutinizing the 'health' of machines, maintenance teams gain visibility into potential problems long before failures occur.

Why?

Because, rather than reactive run-to-failure approaches, condition monitoring supports planned servicing based on data. This allows prioritizing repairs for maximum uptime at optimal intervals.

Various proven techniques exist for monitoring the condition of machines to catch issues early. Let's explore some of the most common methods factories use to manage assets and avoid disruptions through a regimented process proactively;

Detection,

Diagnosis,

Correction.

Technique # 1: Vibration Analysis

Vibration monitoring is a widely used technique for detecting various mechanical faults in machines.

Sensors affixed to equipment continuously measure vibrational waveform signatures in both the time and frequency domains.

Changes over time indicate development;

Imbalances,

Misalignments,

Bearing defects,

Gear issues and more.

Portable data collectors take regular vibration readings, which are analyzed against established Normal Operating Ranges.

Trending software then identifies variances needing investigation.

By pinpointing the unique high-frequency "fingerprints" in specific machine components, vibration analysis cost-effectively diagnoses problems at their earliest detectable stages - often long before visible symptoms arise.

This allows conveniently scheduling targeted repairs.

Technique # 2: Thermography

Thermal cameras are a go-to non-contact method for rapid machine condition monitoring. They capture infrared radiation emitted by equipment surfaces to display heat signatures visually.

Standard thermal patterns are consistent, while problem areas appear in anomalous hot or cold spots.

Thermography locates;

Air leaks,

Insecure connections,

Failing insulation,

Current overloads and more.

It requires minimal shutdowns for rounds and detects temperature changes unsuitable for human vision.

Thermal images illustrate imbalances causing added friction that would otherwise take longer to diagnose.

By pinpointing developing faults producing abnormal heating, thermography helps schedule repairs ahead of serious overheating risks and energy losses.

It enables quick, remote auditing of entire automated production lines.

Techniques # 3: Oil Analysis

Used lubricants darken, and their additives break down over time as machines operate. These fluid condition changes also act as signatures that indicate the equipment's internal workings.

Oil analysis tests lubricant samples for;

Wear metals,

Contaminants,

Water content,

And other byproducts invisible to the naked eye.

It identifies problems like;

Deposits,

Corrosions,

Excess wear or,

Compromised seals,

long before total equipment failure occurs.

Oil analysis confirms issues found through other techniques like vibration.

Critically, it also reveals faults invisible through visual inspections alone.

By monitoring changes in successive oil test results, production teams stay on top of maintenance needs through reliable fluid condition monitoring of machines.

Technique # 4: Ultrasound Inspection

Ultrasonic scanning employs high-frequency sound waves to detect audible flaws inside solid materials.

This non-destructive testing technique locates;

Cracks,

Loose assemblies,

Corrosion,

And delamination

by their ability to reflect waves.

Ultrasound equipment acts like a sonic stethoscope for listening to otherwise inaccessible inner machinery.

A transducer is passed over external surfaces to conduct ultrasound inspections, generating acoustic signals.

An attached sensor converts returning waves into auditory tones or visual readings, revealing developing defects.

Because flaws disrupt ultrasound propagation, this technique effectively augments traditional visual checks by mapping anomalies sooner.

It also inspects encased, high-voltage, or rotating components otherwise inaccessible.

Technique # 5: Machine Learning Analysis

With immense volumes of condition monitoring data now collected, machine learning algorithms are transforming how factories analyze equipment health trends.

Sensor measurements of parameters like;

Vibration,

Temperature,

Pressure,

and electrical signals

feed deep neural networks trained on failure patterns. Over time, AI models self-learn to recognize abnormalities indicative of specific issues.

They can then autonomously detect anomalies, rank the criticality of observations, and assist with root cause analysis.

Combined with predictive diagnostics, machine learning optimizes maintenance planning.

It forewarns looming failures or inefficient operations based on subtle pattern recognition beyond human capabilities alone.

When integrated into digital twin simulations, AI helps engineers develop process improvements by continuously learning from real-world hindsight.

Final Thoughts

As this overview illustrates, many verified methods exist that support the condition monitoring of machines as a core aspect of effective asset management programs. While each technique monitors distinct parameter types, they work synergistically to provide multidimensional insight. Vibration may detect bearing faults, while oil analysis confirms root causes and AI predicts refurbishment due dates.

The most advanced condition-monitoring strategies incorporate the following;

Diverse sensor technologies,

Engineer expertise,

Machine learning,

And overall support systems.

Routine inspections follow validated monitoring plans that prioritize repairs proactively based on risk-assessed data. When thoughtfully executed as part of digitalized maintenance strategies, such proactive approaches deliver maximum uptime through breakdown prevention and optimized servicing intervals.

0 notes

Text

Elevating Convenience: The Importance of Professional Vending Machine Services

Introduction:

In our fast-paced world, convenience is paramount, and vending machines play a significant role in meeting the demands of modern consumers. Whether providing snacks, beverages, or other goods, vending machines offer accessibility and efficiency in various settings, from office buildings to public spaces. However, to ensure optimal performance and customer satisfaction, regular servicing and maintenance are essential. In Australia, Osta Vending & Coffee Solutions stands out as a premier provider of vending machine service, offering comprehensive solutions to keep vending machines operating smoothly. This article explores the importance of vending machine services and the expertise provided by Osta Vending & Coffee Solutions.

The Significance of Vending Machine Services:

Maximizing Operational Efficiency:

Vending machines are subject to wear and tear due to constant use and environmental factors. Regular servicing helps identify and address potential issues before they escalate, ensuring that vending machines operate at peak efficiency. This maximizes uptime and minimizes disruptions to vending machine operations.

Preserving Product Quality and Freshness:

Many vending machines dispense perishable items such as snacks, beverages, and fresh food. Proper servicing helps maintain the integrity of these products by ensuring that vending machines are clean, well-maintained, and operating within optimal temperature ranges. This preserves product quality and freshness, enhancing the overall customer experience.

Ensuring Payment System Reliability:

Modern vending machines are equipped with advanced payment systems, including cashless payment options and digital interfaces. These systems require regular maintenance to ensure reliability and security. Vending machine services encompass testing and calibrating payment systems to prevent issues such as card reader failures or payment processing errors.

Enhancing Customer Satisfaction:

A well-maintained vending machine provides a positive experience for customers, offering convenience and reliability. Regular servicing helps prevent common issues such as product jams, coin jams, and touchscreen malfunctions, thereby enhancing customer satisfaction and loyalty.

Osta Vending & Coffee Solutions: Expert Vending Machine Services in Australia

Comprehensive Maintenance Programs:

Osta Vending & Coffee Solutions offers comprehensive maintenance programs tailored to the specific needs of each client. These programs include regular inspections, cleaning, lubrication, and adjustments to ensure the optimal performance of vending machines.

Timely Response and On-Site Support:

Osta Vending & Coffee Solutions understands the importance of prompt service when vending machines encounter issues. Their team of skilled technicians provides timely response and on-site support, minimizing downtime and disruptions to vending machine operations.

Quality Assurance and Genuine Parts:

When servicing vending machines, Osta Vending & Coffee Solutions utilizes genuine replacement parts sourced directly from reputable manufacturers. This ensures compatibility, reliability, and longevity, prolonging the life of vending machines and maintaining consistent performance.

Advanced Diagnostics and Troubleshooting:

Osta Vending & Coffee Solutions employs advanced diagnostic tools and techniques to identify and resolve issues with vending machines efficiently. Their technicians are trained to diagnose a wide range of problems, from mechanical malfunctions to software glitches, ensuring comprehensive troubleshooting and resolution.

Customized Service Plans:

Osta Vending & Coffee Solutions works closely with clients to develop customized service plans tailored to their unique requirements. Whether servicing a single vending machine or managing an entire vending network, they provide flexible solutions to meet diverse needs and budgets.

Conclusion:

Vending machines play a vital role in providing convenience and accessibility to consumers across various industries. Regular servicing and maintenance are essential to ensure the optimal performance, reliability, and longevity of vending machines. Osta Vending & Coffee Solutions offers expert vending machine services in Australia, delivering comprehensive solutions to keep vending machines operating smoothly. With their commitment to quality, reliability, and customer satisfaction, Osta Vending & Coffee Solutions is the trusted partner for businesses seeking to optimize their vending operations. Visit https://osta.com.au/ to learn more about their vending machine services and elevate the convenience of your vending business.

For more info visit here:- vending machine service technicians

0 notes

Text

Three Key Points for Successful Diesel Fuel Management

As is well known, choosing an economically effective fuel will greatly reduce electricity bills. Fuel prices have risen, supply has decreased, demand has increased, and diesel is widely welcomed as a fuel choice. This cost-effective fuel sells the best in the world and is an indispensable fuel for generators. In terms of economy and efficiency, diesel prices are slightly higher than gasoline. However, it has a high energy density, making it a popular generator owner.

That is to say, systems that operate with diesel obtain more energy than other types of generators. Considering the fuel efficiency of diesel, engines and portable generator sets were selected as obvious and effective choices. Compared to gasoline, diesel is heavier. Moreover, its boiling point is higher than that of water.

Therefore, how to manage diesel for diesel generators? Why control fuel? Next, Dingbo will take a look at the key points of successful diesel fuel management with you.

1. Outsourcing process.

Although for some devices, this may be a significant expense and may not be ideal. However, outsourcing companies have eliminated time constraints to ensure better results. The outsourcing company will handle every aspect of your process and support all processes from diesel sampling to controlling water, oxygen, and microbial hazards. They can provide continuous support for your system. The practicality of such systems makes them very important for most diesel generators.

2. Use of diesel fuel management system.

Another approach provides a balance between manual labor and outsourcing. By using a diesel fuel management system, you can remotely automate most of your work and check your fuel at any time.

This software can provide you with real-time updates on fuel quality at any specific time.

These are all managed through web applications.

Once there are any signs of a decrease in fuel quality, the sensor will detect this and issue an alarm to quickly determine a solution.

The system can monitor water pollution, fuel content, temperature changes, fuel theft, etc.

3. DIY practical tips.

This is done by oneself and requires internal maintenance. Please refer to the following prompts:

Desiccant and clean the filling area of the fuel tank.

Do not rely on automatic sink measurement devices to confirm the water level at the bottom of the sink.

Ensure the use of tanks that meet standards. Oil tanks that meet these standards are very helpful in protecting diesel from the impact of diseases.

Ensure that all tank openings are securely sealed to prevent pollutants from entering the tank.

Fill all the jars to minimize the amount of oxygen and water coagulation.

Whenever possible, the system should pump water frequently to minimize the impact.

Please check if all fuel tanks are ventilated and if the ventilation hood is intact.

You need to test the activity of microorganisms. If so, please take measures to correct it.

The advantages of cleaning diesel and polishing fuel.

When using clean diesel to operate the standby generator, there are the following advantages:

Lubrication and cleaning of the injection system.

The likelihood of fuel injector failure is reduced.

This can help reduce maintenance costs.

Silt accumulation is no longer a problem.

Diesel generators generate less smoke when operated as backup.

Provide reliable fuel for electricity and emergency use.

One final point to tell everyone:

We have discussed various aspects of the diesel fuel management system above. Do you have a sufficient understanding of diesel management for backup generators? Industrial and commercial backup generators play an important role in providing reliable backup power for companies of various types and sizes. Whether you are a data center, hospital, manufacturing plant, grocery store, oil well, food processing plant, or any other facility. In all cases, a backup generator is crucial for maintaining normal operation and full power operation.

Dingbo Power was founded in 1974 and is one of the earliest manufacturers of generators and diesel generator sets in China. If you want get more information, please feel free to send email to [email protected] we will pay highly attention on your question.

0 notes