#Cable termination insulator

Text

Comparative Analysis of Top Cable Termination Insulator Manufacturers

In the fast-paced world of electrical engineering, the demand for reliable and efficient cable termination insulators has never been higher. As industries evolve, so does the need for cutting-edge solutions that ensure safety, longevity, and optimal performance. In this blog post, we will take a closer look at Radiant Enterprises, one of the leading cable termination insulator manufacturers in India. We'll explore the nuances that set them apart and delve into the details of their offerings, with a focus on medium voltage cable fittings and customized epoxy termination plugs.

Understanding Cable Termination Insulators

Before we dive into the specifics of Radiant Enterprises, let's establish a foundational understanding of cable termination insulators. These crucial components play a pivotal role in electrical systems, providing insulation and sealing for cables at the point where they connect to various equipment. The right cable termination insulator ensures the prevention of current leakage, protects against environmental factors, and contributes significantly to the overall reliability of the system.

Radiant Enterprises: Setting the Standard

Radiant Enterprises has emerged as a key player in the cable termination insulator manufacturing sector, setting high standards for quality and innovation. Their commitment to excellence is reflected in their range of products designed to meet the diverse needs of medium voltage cable fittings.

Customized Epoxy Termination Plugs

One of the standout features of Radiant Enterprises is their expertise in providing customized epoxy termination plugs. These plugs are tailored to meet the unique requirements of different projects, showcasing a commitment to versatility and adaptability. The ability to customize termination plugs ensures that clients receive solutions that align precisely with their project specifications, a feature that sets Radiant Enterprises apart in a market that demands flexibility.

Medium Voltage Cable Fittings

Radiant Enterprises excels in the manufacturing of medium voltage cable fittings. These fittings are crucial for ensuring optimal performance in electrical systems operating at medium voltage levels. The precision and reliability of Radiant Enterprises' medium voltage cable fittings contribute to the overall efficiency and safety of the systems in which they are employed.

Comparative Analysis

1. Quality and Innovation

Radiant Enterprises leads the industry in terms of quality and innovation. Their continuous investment in research and development keeps them at the forefront of industry trends, offering cutting-edge solutions that consistently exceed customer expectations. The commitment to providing customized solutions, such as epoxy termination plugs, demonstrates Radiant Enterprises' dedication to innovation and client satisfaction.

2. Technological Advancements

Radiant Enterprises stands out for its focus on technological advancements. The incorporation of the latest technological features in their products ensures that clients benefit from state-of-the-art solutions. Radiant Enterprises consistently adopts advanced manufacturing processes and materials, positioning them as a manufacturer at the forefront of technological evolution in cable termination insulators.

3. Tailor-Made Solutions

The ability to provide tailor-made solutions is a key strength of Radiant Enterprises. The customization options available for epoxy termination plugs showcase their commitment to meeting the unique requirements of different projects. This bespoke approach not only sets them apart but also demonstrates a customer-centric focus that is crucial in the competitive landscape of cable termination insulator manufacturing.

Conclusion

In the realm of cable termination insulators, Radiant Enterprises stands as a beacon of quality, innovation, and customer satisfaction. Their expertise in providing customized epoxy termination plugs and their excellence in manufacturing medium voltage cable fittings make them a reliable choice for various projects.

As industries continue to advance, the cable termination insulator market is likely to witness further innovation and the adoption of cutting-edge technologies. Manufacturers that can adapt to these changes while maintaining a focus on quality and customer satisfaction, as exemplified by Radiant Enterprises, will undoubtedly lead the way in this dynamic industry.

#Customized epoxy termination plugs#Medium voltage cable fittings#Cable termination insulator manufacturers in India#Cable termination insulator

6 notes

·

View notes

Text

Heat shrink puzzles,would you find which are the thin wall heat shrink tubing, and which are the heat shrink connector. Is there cold shrink here?

#shrink tubing#upm heat shrink specialist#cable protection#heat shrink#shrink sleeve#heat shrink connector#shrink terminator#expandable braided sleeve#shrink end cap#cold shrink tube#high shrink ratio 6:1#bus bar insulation#fiber optic splice#solder sleeve#thin wall tube#electronic wire insulation

0 notes

Link

Multimet Overseas is the most trusted and leading manufacturer, supplier and exporter of Cable Lugs & Connectors. Cable lugs and connectors are key components for the highest safety requirements. In order to guarantee the safest connections, even with simple connection material, premium quality is a must. Benefit from our wide assortment of high-quality cable lugs and connectors.

#Trusted Supplier & Exporter of Cable Lugs & Connectors#Non-insulated cable lugs and connectors#LV Cable Lugs Manufacturer#LV Mechanical terminal & Connectors

0 notes

Text

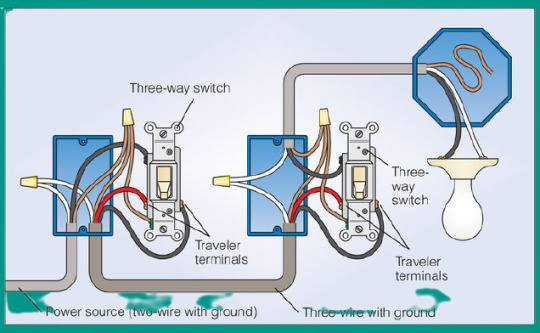

How to Wire a 3-Way switch

You may be new to electrical installation but wish to wire a 3-way switch.

3 way switch wiring is harder than a single pole. It is the interconnection of two or more switches.

3-way light control helps in hallways and large rooms to turn the lights from two locations.

But it’s harder to install than a single-pole switch

Read this article to learn how to wire a 3-way switch

Components of a three-way switch

The common

Two traveller terminals

Ground or Earth terminal.

How the 3-way switch works

A three-way switch allows you to control a light fixture like other switches, but they do this from two ends.

When the toggles from both switches are up or down, the circuit is complete and the light will be ON. When they are opposite, the circuit opens and there will be no light. This allows any of the switches to turn on or off the light.

Tools and materials required to wire a 3-way switch.

They include:

Four in one screwdriver

Wire stripper

Plier

Voltage tester

Electrical tape

Utility knife

Materials required

Two 3-way switches

14-3 or 12-3 Romex cable.

Electrical boxes.

Note: Before any electrical installation, ensure that you power off the circuit breaker and also wear your protective glove to prevent electric shock and other hazards.

Steps to Wire 3-Way switches

There are three methods, but all depend on whether the hot wire goes to the switch first or the light fixture.

Whichever way you prefer, installing a 3-way light is easy when you follow our switch wiring procedures.

Turn off your circuit breaker

Locate the circuit breaker that controls the branch circuit and turn off the circuit’s power.

This is to prevent electrocution and other hazards during the installation.

Mount the electrical box

Locate the two places you want to mount your switch and install the metal boxes.

This may be at the entrance and inside of your room, ends of the hallway, staircase, or any place of your choice.

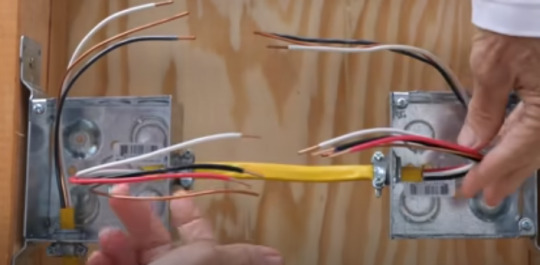

Feed in your cables.

Feed in a lengthy 14-3 NM Romex cable, or 12-3h if you are connecting to a 12-gauge wire. The 14-3 cable is a 14 gauge Romex cable with three insulated conductors, plus a ground wire.

The three insulated conductors are black, red, white, plus the earth wire.

Connect the wires and switches

The 3-way switch comes with 4 terminals, the black or common terminal, two brass colour or traveler terminals, and the green screw “earth terminal”.

Connect the black (hot) cable coming from the power source to the black terminal of the switch

Join the neutral or white wire from the power to the white wire from the NM cable, using a wire nut

Also join the two brown wires together

Fix the bare copper or green earth cable to the metal box and connect it to the green terminal

Connect the black and red traveler wires from the NM cable to the brass terminals on the switch.

Moving to the second switch box,

Join the two white wires

Join the two brown wires too

Connect the black wire that goes to the lamp holder to the black terminal of the switch

Fix the earth wire on the body of the switch box and connect it to the green terminal

Connect the black and red travelers from the first switch to the traveler screws or terminals of the second switch to complete the installation.

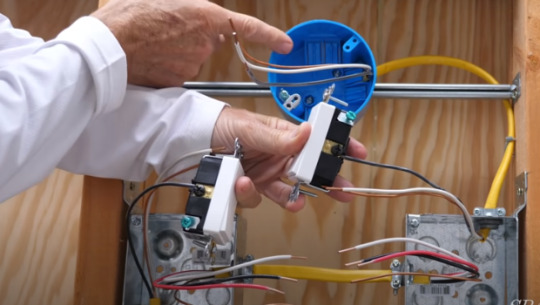

Install the lamp holder

Connect the black or hot wire from the second switch to one of the screw terminals, and the white or neutral wire to the second terminal, fix your bulb and test-run your project.

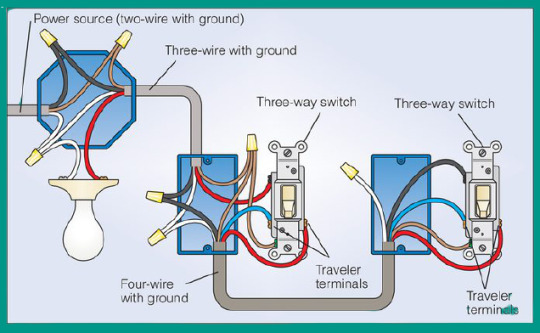

Three-Way Switch Wire Diagrams

In this section, you will see different ways you can wire a 3-way switch

3-way wiring diagram: Power to Light Fixture.

This shows how you can wire a three-way light when the power is coming from the light fixture.

From the diagram, you can see that the power source enters the fixture box

The hot or black wire connects to the common terminal of the second dimmer.

Blue and red wires link the traveler terminals for both switches

We also connected the red wire to the common terminal of the first switch, which moves back to the light.

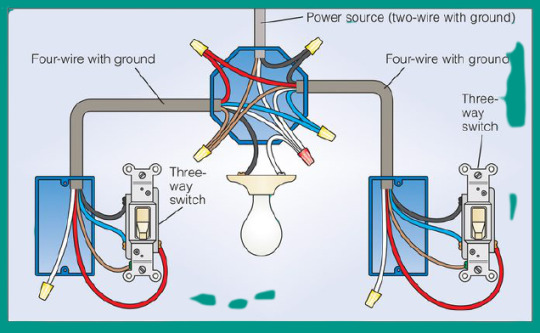

Three-way switch wire diagram: power to the switch

This shows a 3-way light control when the power enters from the switch.

From the diagram, you can see that we connected the incoming live wire to the common terminal of the first switch.

We then connected the traveling terminals of the two switches with black and red wires before connecting the second common terminal to the bulb.

Note: The neutral (white) wire from the supply moved to the bulb without branching to any switch.

3-way wiring diagram: Power to the junction box.

From the above wiring, the supply enters the junction box and connects to the common terminal of the right switch.

Two Romex cables with four wires and an earth cable joined at the junction box to connect the traveler terminal of the two switches and the bulb.

Difference between three-way switches and single poles

A single pole light switch has two terminals and a ground screw while a three-way switch has 3, plus a ground screw.

The toggle switch for a single-pole has ON and OFF while the 3-ways doesn’t have.

A single-pole switch controls a ceiling light from one location while the three-way control light from two different locations.

A single pole is good for small rooms with few light sources, while a multi-way switch is for large rooms and stairwells.

Frequently Asked Questions

Does it matter which wire goes where on a 3-way light switch?

Yes, the black “hot wire” from the power source must connect to each switch’s common screw terminal, to enable it to carry the current from the source to the switches and then to the light fixture.

How many wires are hot in a 3-way switch?

Two hot or black wires. The one from the source which connects to the first switch common terminal, and the second one that runs from the 2nd switch common terminal to the light fixture.

What happens if you wire a light switch the wrong way?

if you wire a light switch the wrong way, the switch will not work properly, and may even lead to electrical hazards.

2 notes

·

View notes

Text

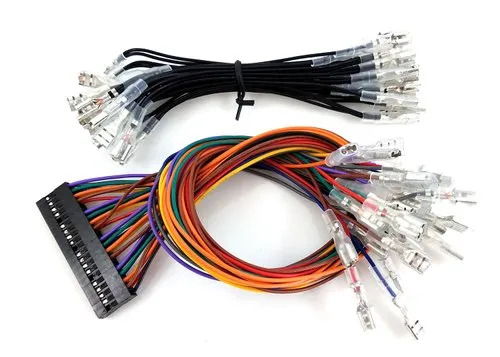

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

i don't know how long Valin and Drone have been together... they first met in the Dark Age, but only in transcience, since Drone mostly spent her time patrolling and otherwise protecting old Warmind facilities.

the first time they met, Drone tore his eye out for her own amusement because she had not seen an organic being in a very long time and they were more like fancy animals to her than something worth communing with. this one she had found lurking in her facility, and she'd been led to it by the same omniscient guiding hand that had compelled her to patrol this region to begin with.

the creature wasn't wearing a helmet, so she redirected her aim to its legs and shot out both kneecaps; Drone is an impulsive woman, she simply liked all the pretty colours the thing exuded and wanted to look at it much more closely.

Valin is polite, so he stayed nice and still as this errant machine-woman straddled his stomach and prodded at him with her cold silicone-plasteel fingers, gripping his jaw with such strength that he felt her thumb push into uncrowned wisdom teeth, turning his head to the side so she could follow the starlight trailing his skin.

Valin had never seen a creature like her, an apparent living machine. a breathing, biomechanical woman. her mind felt very human, though it was clear to him that this was not always her body, because he'd never met anything that felt trapped in tar like she did. a woman caged by processing strata, a million dense wires piercing her skin, long umbilicals that wrapped around her body and terminated at individual segments of her spine. the umbilicals carried a separate mind-thing, resting his palms on it gave him the acute awareness that he was being watched by something other than the woman.

being in (figuratively) two places at once is a nauseating sensation, and so Valin chose to linger in this mind-cage rather than focus on his physical form. the pain ceases registering... and he does not care that the woman has pressed a finger against the corner of his mouth to expose his molars and rip them out. she does not need any instrument to do so, and distracts herself with the shape of the roots, fingers caked in clotted blood and dried saliva.

there's a slight purple afterglow to Valin's normally yellow eyes, when he is focused on something through psionics. had the machine-woman noticed, she would've certainly stuck her fingers into his remaining eye, carefully pressing her metal thumbnail into the optic nerve and watching how the lights in his iris flicker. she'd done it to his other eye, of course.

when, finally, she moved to draw her blade, Valin ran his claws along the uppermost umbilical and dug his fingers through the shielding and insulation, reaching in and tearing out as many wires as he could find. something shouted at him as he did so, a loud, distorted tone. a man's voice, though it too was machinoform in nature. red sparks flew from the cables where the conductors separated between his fingers.

Drone felt the creature's hands on her mind—hot pins and needles at the base of her skull, and a strange purple gaze—before everything went black.

when Ghost revived her, Drone was a little hurt at the blue thing escaping her. she'd wanted to cut it open and examine its strange biology further, she'd wanted to stick her blade into the skeins of light that travelled along his body and see what happened. she was too busy sulking to pay attention to Ghost as he read out the data on the inexplicable neurological event that had preceded her immediate death.

"How did it escape?"

" – increased activity suggestive of... oh you weren't listening AT ALL, were you?"

"Its blood is here."

"You're unbelievable! Ugh. He turned onto his stomach and crawled out from under 300 pounds of rude, stubborn, audacious, dead metal. There, is that good enough?"

"No."

"... You had his lower legs trapped and he struggled to get free, better?"

"..."

"Um. Lots of snappy noises from the bones and tissue. Lots of it."

"Did it scream?"

"A little."

"Good."

#started writing in my Notes app. transferred it here.#naturally unstructured mess. unsorry.#nobody should be new here we all know i use the train-of-thought-into-contemplative-story format.#oc: drone#oc: valin#GEMU DRONE my beloved..

1 note

·

View note

Text

Replace a wiring harness if an electrical connector melts or burns

Introduction: The heat from the electrical connector can melt or burn the insulation in a wire. If this happens, you need to replace the wiring harness as soon as possible.

Replace a Wiring Harness if an Electrical Connector Melt or Burn.

Patching a blown electrical connector can be a challenging task, but it’s important to do your research before starting. To help avoid any trouble down the road, follow these steps:

1. Look for an electrical diagram of the product you’re repairing or replacing. This will help you understand how the connector works and where potential problems may exist.

2. Remove all accessories from the system and store them away in a safe place. This includes cords, power adapters, and any other devices that may be used in the replacement process.

3. Connect one end of the new wiring harness to an appropriate terminal on the old connector and connect the other end to a power outlet or another ground terminal.

4. Place the old connector in a safe place and wait until it has cooled slightly (about 20 minutes). Then replace it with the new wiring harness.

5. reattach any accessories that have been removed during restoration or replacement, if necessary.

Replace a Wire Harness if It Burns.

If your electrical connector starts to melt or burn, you will need to replace it. Here are some tips on how to do this:

1. First, check the connector for any damage. If there is damage, it will need to be replaced.

2. Next, find a wire harness that Match Your Model and Year of Use. This can be difficult because the Harness may not be marked anywhere specific. To find a wire harness that matches your year of use and model, you can use this online search tool:

3. Once you have found a wire harness that matches your year of use and model, cut the wires off the old harness and place them into the new one. Be sure to match up all of the wires so they are properly connected.

4. Finally, reattach the power cord to the electrical outlet and turn on the appliances you need to stay plugged in while you work on fixing the problem with your wiring harness (like turning on a light).

Replace a Wire Harness if It Burns.

If a wire harness melts or burns, follow these steps to replace it:

1. Cut the harness cable off of the electrical connector.

2. Tie each end of the new wire harness together with a knot (or other strong tie) and place it back on the electrical connector.

3. Replace the electrical connector if it has been melted or burned down.

4. Check for any damage to the electrical connector and replace if necessary.

Conclusion

Replacement wiring harness if an electrical connector melts or burns can be a difficult task. However, if done correctly, it can prevent any damage to your equipment. By checking the electrical connector for damage and replacing it if necessary, you can keep your equipment running smoothly.

2 notes

·

View notes

Text

Welcome to V&S Unique Kits

V&S Electric Company has been recognized for its technical potential and is reckoned to be one of the largest integrated companies in manufacturing Cable Jointing Kits and Power Cable Accessories.

What Products Do We Sell?

Heat Shrink Single Core Straight Through Joint [11Kv-33 Kv]

Heat Shrinkable Busbar Insulation Tape

Heat Shrinkable Busbar Insulation Tubing (Red & Brown)

Heat Shrinkable Indoor Terminations Kits XLPE [11Kv-33Kv]

Heat Shrinkable Outdoor Termination Kit [11Kv-33 Kv]

Polymeric Drop Out Fuse (Solid Core)

Polymeric Grab Switch

Polymeric Insulators [11Kv-33Kv]

Self Amalgamating Tape

Surge Arresters [11Kv-33 Kv]

Who We Are?

Welcome to our site!

An ISO 9001:2008 certified company, presenting a wide range of hi-tech Heat shrinkable cable jointing kits & Terminations Kits, Power cable Accessories

The company markets its product line under the Brand "Unique Kits". It is one of the ethically solid, professionally reliable, and financially independent companies, engaged in manufacturing and exporting high-quality and a complete range of Cable Jointing Kits that efficiently provide a strong joint that can withstand the water pressure as well as ensure mechanical protection. As an ISO 9001:2008 recognized manufacturer, exporter, trader, and supplier of Cable Jointing Kits, we have set a benchmark in answering the quality & price expectations of clients. We fabricate the products from qualitative constituents, using advanced technology, and subsequently, conduct a variety of tests in order to ensure the characteristics like the ease and fast to use owing to simple designs and effective technology. Our product range has a broad application in numerous domains such as Electrical & Electronics, Telecommunication, Pharmaceutical, Automobile, and Defense sectors.

Our vision is to introduce an ingenious array of products that can wholly fulfill the prospective requirement of the industries we serve to. So, we periodically enhance our infrastructural resources and adapt to leading-edge technology. In line with this objective, we bear up the intensive R&D activities, which help us in improving our product engineering competence as well as streamlining the process. Making wise use of these arrangements, we fabricate high-technology Cable Jointing Kits which are further put through quality analysis and testing in order to offer efficient and innovative products. Thanks to our experienced and competent workmen who are responsible for manufacturing in accordance with the quality framework and standard set by the company, we have been recognized for the excellence of our work in the market places.

For How Many Years We Are In This Industry?

12+ Years Of Trust

Make Sure You Visit Our Website uniquevns.com

Thank You For Choosing Us!

2 notes

·

View notes

Text

Bhagyadeep Cables: Empowering Automotive Innovation with Precision Auto Wiring Harness Solutions

In the dynamic landscape of automotive engineering, where innovation is the driving force, Bhagyadeep Cables emerges as a pivotal player, empowering automotive manufacturers with precision-engineered auto wiring harness solutions. With a steadfast commitment to excellence, innovation, and reliability, Bhagyadeep Cables stands as a beacon of quality in the realm of auto wiring harnesses, reshaping the future of mobility through seamless connectivity and advanced engineering prowess.

Pioneering Precision: The Essence of Auto Wiring Harnesses

Auto wiring harnesses, the intricate networks of wires, connectors, and terminals, serve as the nervous system of modern vehicles, orchestrating the seamless integration of various electrical components, from engine management systems to infotainment modules. These harnesses play a crucial role in ensuring reliable power distribution, signal transmission, and data communication within the vehicle's architecture, thereby facilitating smooth operation and enhanced safety features.

At the heart of every successful automotive wiring harness lies a delicate balance between precision engineering, quality materials, and stringent manufacturing processes. This is where Bhagyadeep Cables excels, setting new benchmarks in the industry through its unwavering dedication to craftsmanship and innovation.

Unraveling the Expertise: Bhagyadeep Cables' Auto Wiring Harness Solutions

1. Customized Solutions for Every Need:

Recognizing the diverse requirements of automotive manufacturers, Bhagyadeep Cables offers bespoke auto wiring harness solutions tailored to specific vehicle models and applications. Whether it's a compact city car or a high-performance luxury sedan, Bhagyadeep Cables possesses the expertise to design and manufacture custom wiring harnesses with precision and efficiency.

2. Advanced Materials and Technologies:

Leveraging cutting-edge materials and technologies, Bhagyadeep Cables ensures optimal performance and reliability in its auto wiring harnesses. From high-temperature-resistant insulation materials to corrosion-resistant connectors, every component is carefully selected to withstand the demanding environments of automotive applications, ensuring long-term durability and safety.

3. Stringent Quality Assurance:

Quality is paramount in automotive engineering, and Bhagyadeep Cables leaves no stone unturned in ensuring the highest standards of quality in its wiring harnesses. Rigorous testing procedures, conducted at every stage of the manufacturing process, guarantee compliance with industry standards and customer specifications, thereby instilling confidence in the reliability and performance of Bhagyadeep Cables' products.

4. Innovative Design and Engineering:

Embracing innovation as a driving force, Bhagyadeep Cables continuously explores new design concepts and engineering solutions to enhance the functionality and efficiency of its auto wiring harnesses. Whether it's reducing weight and complexity or improving assembly processes, Bhagyadeep Cables remains at the forefront of automotive technology, delivering solutions that exceed expectations.

Transforming Mobility: Applications Across the Automotive Spectrum

1. Electric and Hybrid Vehicles:

In the era of electric and hybrid vehicles, where efficiency and sustainability are paramount, Bhagyadeep Cables' wiring harnesses play a critical role in enabling the seamless integration of battery systems, powertrain components, and electronic controls, ensuring optimal performance and range.

2. Advanced Driver Assistance Systems (ADAS):

With the rapid advancement of ADAS technologies, Bhagyadeep Cables' wiring harnesses facilitate the integration of sensors, cameras, and control units, enabling features such as adaptive cruise control, lane-keeping assistance, and autonomous emergency braking, thereby enhancing vehicle safety and driver convenience.

3. Infotainment and Connectivity:

In the age of connected vehicles, Bhagyadeep Cables' wiring harnesses enable the integration of sophisticated infotainment systems, navigation devices, and wireless connectivity features, providing passengers with a seamless and immersive in-car experience.

4. Safety and Reliability:

Above all, Bhagyadeep Cables prioritizes safety and reliability in its auto wiring harness solutions. By adhering to stringent quality standards and employing advanced engineering principles, Bhagyadeep Cables ensures that its wiring harnesses withstand the rigors of automotive use, delivering consistent performance.

Driving Toward a Sustainable Future

As an industry leader, Bhagyadeep Cables is committed to sustainability and environmental responsibility. From eco-friendly manufacturing processes to recyclable materials, the company strives to minimize its carbon footprint while delivering exceptional products to its customers. By embracing sustainable practices and promoting eco-consciousness, Bhagyadeep Cables aims to contribute to a cleaner, greener future for generations to come.

Conclusion: Redefining Automotive Connectivity

In a rapidly evolving automotive landscape, where innovation is the currency of progress, Bhagyadeep Cables stands as a catalyst for transformation, redefining the standards of automotive connectivity with its precision-engineered auto wiring harness solutions. With a legacy of excellence, a relentless pursuit of innovation, and a steadfast commitment to quality, Bhagyadeep Cables is driving the future of mobility forward, one wire harness at a time. As the automotive industry continues to evolve, Bhagyadeep Cables remains at the forefront, empowering manufacturers with the tools they need to create safer, more efficient, and more connected vehicles for the road ahead.

0 notes

Text

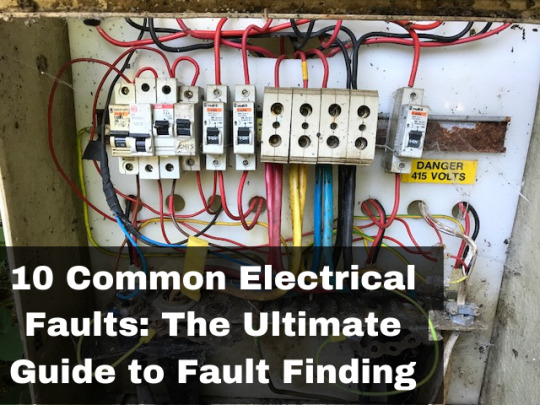

10 Common Electrical Faults: The Ultimate Guide to Fault Finding

Introduction

Navigating the intricacies of electrical systems can be daunting, especially when faced with unexpected issues. From flickering lights to tripped circuit breakers, electrical faults can disrupt daily life and pose safety hazards. In this comprehensive guide, we delve into the realm of fault finding electrical, exploring the ten most common electrical faults and equipping you with the knowledge and tools to address them effectively.

Short Circuits: Identifying the Culprit

Understanding Short Circuits

Short circuits occur when a hot wire comes into direct contact with a neutral wire or a ground wire, bypassing the intended electrical pathway. This can result in excessive current flow, overheating, and potential fire hazards.

Diagnostic Approach

When confronted with a short circuit, a systematic diagnostic approach is essential. Start by visually inspecting the affected area for signs of burnt insulation, melted wires, or damaged outlets. Utilize a multimeter to measure continuity and resistance, pinpointing the location of the short circuit.

Overloaded Circuits: Balancing Electrical Loads

Recognizing Overloaded Circuits

Overloaded circuits occur when the electrical demand exceeds the capacity of the circuit, leading to overheating and potential fire hazards. Common signs include tripped circuit breakers, flickering lights, and warm outlets.

Load Assessment

To prevent overloaded circuits, conduct a thorough assessment of electrical loads in your home or facility. Identify high-power appliances and redistribute them across multiple circuits to ensure balanced electrical loads.

Loose Connections: Bolstering Electrical Integrity

Detecting Loose Connections

Loose connections can lead to intermittent power loss, flickering lights, and potential arcing. Inspect electrical terminals, outlets, and junction boxes for signs of looseness or corrosion.

Tightening Procedures

When tightening electrical connections, exercise caution to avoid over-torquing, which can damage components. Utilize appropriate tools, such as screwdrivers or wrenches, and ensure connections are snug and secure.

Ground Faults: Minimizing Shock Hazards

Understanding Ground Faults

underground cable fault occur when a hot wire comes into contact with a grounded surface, such as a metal junction box or a plumbing fixture. This can result in a short circuit and pose significant shock hazards.

Differential Circuit Breakers

Install ground fault circuit interrupters (GFCIs) or residual current devices (RCDs) to detect ground faults and automatically disconnect power, minimizing the risk of electric shock.

Insulation Damage: Protecting Electrical Integrity

Identifying Insulation Damage

Insulation damage occurs when the protective covering of electrical wires becomes worn or compromised, exposing conductive material. This can lead to short circuits, arcing, and potential electrical shocks.

Regular Inspections

Perform regular inspections of electrical wiring and insulation to identify signs of wear, deterioration, or rodent damage. Replace damaged insulation promptly to prevent electrical faults and ensure safety.

Corroded Connections: Preserving Electrical Conductivity

Recognizing Corroded Connections

Corroded connections occur when metal components are exposed to moisture or chemicals, leading to rust and oxidation. This can increase electrical resistance and cause overheating.

Corrosion Prevention

Apply anti-corrosion compounds or coatings to metal terminals and connectors to protect against moisture and chemical exposure. Regularly inspect and clean electrical connections to maintain conductivity.

Overheated Outlets: Addressing Potential Hazards

Detecting Overheated Outlets

Overheated outlets can occur due to loose connections, overloaded circuits, or faulty wiring. Signs include discoloration, melting plastic, and get rid of fire smell in house.

Thermal Imaging

Utilize electrical fault finding tools such as thermal imaging cameras to detect temperature variations indicative of overheated outlets. Investigate and address the underlying cause to prevent fire hazards.

Tripped Circuit Breakers: Resetting Electrical Protection

Causes of Tripped Circuit Breakers

Tripped circuit breakers occur when the electrical load exceeds the capacity of the circuit, causing the breaker to trip and interrupt power flow. Short circuits, overloaded circuits, and malfunctioning appliances are common reasons.

Resetting Procedures

To reset a tripped circuit breaker, locate the tripped breaker in the electrical panel and firmly push it to the "off" position, then back to the "on" position. Investigate the cause of the trip and address it accordingly.

Flickering Lights: Troubleshooting Illumination Issues

Investigating Flickering Lights

Flickering lights can be indicative of loose connections, voltage fluctuations, or faulty wiring. Identifying the underlying cause is essential to prevent safety hazards and ensure proper functionality.

Voltage Testing

Use a multimeter to measure voltage at the affected light fixture, ensuring adequate voltage supply and identifying potential voltage fluctuations. Check connections and fixtures for signs of looseness or damage.

Arc Faults: Mitigating Fire Risks

Understanding Arc Faults

Arc faults occur when electrical current jumps between two conductors, creating a spark or arc. This can happen due to damaged wiring, loose connections, or insulation breakdown, posing a fire hazard.

Arc Fault Circuit Interrupters

Install arc fault circuit interrupters (AFCIs) to detect arc faults and automatically disconnect power, reducing the risk of fire. AFCIs provide an additional layer of protection against electrical hazards.

Conclusion

In conclusion, understanding and addressing electrical faults is essential for maintaining a safe and functional electrical system. By recognizing common issues and utilizing electrical fault finding tools and techniques, you can diagnose and rectify faults effectively, ensuring the safety and reliability of your electrical installations.

0 notes

Text

High Voltage (HV) Cable Market Growth Analysis

High Voltage (HV) Cable Market research report identifies, assesses, and analyses the up-and-coming trends along with major drivers, restraints, challenges and opportunities in the market for Energy industry. The High Voltage (HV) Cable Market report contains estimations of CAGR values, market drivers and market restraints about the Energy industry which are helpful for businesses in deciding upon numerous strategies. The market type, organization size, availability on-premises, end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa are kept into view while formulating this global High Voltage (HV) Cable Market analysis report.

Download Free Sample Report: https://www.delvens.com/get-free-sample/high-voltage-hv-cable-market

High Voltage (HV) Cable Market by Product Type (Cables (XLPE, EPR, HEPR, MI), Accessories (Joints, Termination, Fittings & Fixtures), Conductor Type (Aluminum, Copper), Installation, Voltage, End User and Region (North America, Europe, Asia-Pacific, Middle East and Africa and South America). The global High-Voltage (HV) Cable market size was estimated at USD 40.5 billion in 2023 and is projected to reach USD 59.3 billion in 2030 at a CAGR of 5.6% during the forecast period 2023-2030.

High Voltage (HV) Cable Market Competitive Landscape:

Prysmian Group

Sumitomo Electric Industries Ltd.

Nexans

LS Cable & System Ltd.

NKT A/S

Furukawa Electric

Taihan Cable & Solution Co., Ltd.

ZTT

Elsewedy Electric Company

Wuxi Jiangnan Cable

Riyadh Cables

PFISTERER Holding AG

DUCAB

TE Connectivity

Brugg Kabel AG

KEI Industries Ltd.

Tratos

Southwire Company,

Tele-Fonika Kable SA

Synergy Cables

High Voltage (HV) Cable Market Recent Developments:

In May 2023, The Prysmian Group has issued an announcement pertaining to the triumphant acquisition of a contract with an estimated worth exceeding USD 864.9 million. This contractual agreement is in reference to the initiation of a new power interconnection project between France and Spain, which is set to be implemented for the benefit of INELFE. It should be noted that INELFE is a joint venture that is co-owned by Red Electrica, the Spanish grid operator, and Réseau de Transport d’Électricité (RTE), the French grid operator.

In April 2023, Nexans finalized the purchase of Reka Kaapeli Oy, for a total of USD 57.29 million. The integration of Reka Cables into Nexans' Distribution & Usage business group was included in the acquisition. Being a part of Nexans presents Reka Cables with the chance to enhance its growth and development, while also enabling increased investments in renewable energy solutions.

For Purchase Inquiry at: https://www.delvens.com/Inquire-before-buying/high-voltage-hv-cable-market

High voltage cables are utilized for the transmission and distribution of power at elevated voltages. These cables possess structural components comprising of one or more conductors, protective jackets, and insulators. An important structural divergence that sets high voltage cables apart from other cable types is the existence of additional internal layers within the insulation jacket that facilitate the control of electric flow surrounding the conductor. This attribute assists in mitigating power losses during long-range transmissions, thereby rendering high voltage cables more efficient than their counterparts in power transmission. High voltage cables may be installed as overhead cables, buried cables in industrial settings, or even submarine cables for power transmission between different states and countries.

The market for high voltage power cables is ultimately dependent on electricity demand across the world. The increasing demand for electricity is further anticipated to bring lucrative growth opportunities for the market. The replacement of the aged grid infrastructure and transmission lines is another factor that drives the growth of the market. Also, the increasing penetration of renewables such as solar energy and wind energy requires setting up new utility grids with new transmission & distribution networks. Therefore, the growing penetration of renewables acts as the market driver for high voltage cables.

High Voltage (HV) Cable Market Key Findings:

On the basis of installations, the worldwide high voltage cables market is divided into three segments, namely overhead, submarine, and underground, based on the type of installation. The proliferation of overhead installation is primarily attributed to its convenient installation process and low transmission losses across extended distances. Furthermore, the economic benefits of these cables, which do not entail complex technologies, account for their widespread adoption.

On the basis of Analytics, the market is categorized into three segments, namely 100 kV – 250 kV, 251 kV – 400 kV, and above 400 kV. Currently, the 251 kV – 400 kV segment holds the largest market share due to the extensive application of high voltage cables within this voltage range. In developing countries, the power transmission industry is still flourishing, resulting in the increased use of low and medium voltage cables. Consequently, the above 400 kV segment in these countries possesses a relatively minor presence. However, during the forecast period, the 251 kV – 400 kV segment is expected to grow in various regions owing to the substantial installation of these voltage lines. In North America and Europe, the above 400 kV segment is anticipated to witness a rise in their market share, primarily due to technological advancements that support their installation.

On the basis of end-user, the global market for high voltage cables is bifurcated into two segments, namely utility and industrial, wherein the former serves as the primary source of power for most sectors across the nation, consequently constituting a significant proportion of the market. With the escalation of rural electrification plans, population growth, and urbanization, the end-user demand for electricity has substantially increased. This augmented demand for power has led to the integration of renewable energy sources for power generation, thereby facilitating the installation of new grids required to cater to power needs across distant locations. The industrial sector, particularly the exploration and railways industry, also leverages high voltage cables for their operations. Moreover, the market is expected to experience a positive growth trajectory owing to the proposed plans and presence of metros in diverse parts of the world.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. North America possesses a limited market share within the industry. However, due to the prevailing replacement of antiquated grids throughout the region, the high voltage cable market is anticipated to experience gradual growth within the area.

High Voltage (HV) Cable Market Regional Analysis:

North America to Dominate the Market

North America possesses a limited market share within the industry. However, due to the prevailing replacement of antiquated grids throughout the region, the high voltage cable market is anticipated to experience gradual growth within the area.

The exploration endeavors of the oil and gas industry have significantly contributed to the expansion of the industrial sector of the market.

Get Direct Order of this Report: https://www.delvens.com/checkout/high-voltage-hv-cable-market

Browse Related Reports:

Heat Shrink Tubing (HST) Market

Next Generation Biofuels Market

Power Grid Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-3290-6466

#High Voltage (HV) Cable Market#High Voltage (HV) Cable#HV Cable#HV Cable Market#Energy#consulting company#strategic advisory firm#best market reports#market analysis reports#trending reports#syndicated reports

0 notes

Text

Cable termination insulator manufacturers in India | radiantenterprises

Explore our premium range of cable termination insulators, meticulously crafted for superior performance. As leading cable termination insulator manufacturers in India, Radiant Enterprises ensures top-notch quality and precision in every product. Discover excellence in medium voltage cable fittings with our specialized solutions. Additionally, we offer customized epoxy termination plugs, tailored to meet your unique requirements.

Choose Radiant Enterprises for reliable, innovative, and customized solutions in the realm of cable termination insulators.

#Cable termination insulator#Cable termination insulator manufacturers in India#Medium voltage cable fittings#Customized epoxy termination plugs#Newzealand#Australia#Brazil#Europe#USA

6 notes

·

View notes

Text

7 Efficiency Hacks for Your Bike & Car Battery to Maximize Your Ride

Your bike & Car battery is the heartbeat of your two-wheeled companion, providing the necessary power to ignite the engine and keep essential electrical components running smoothly. Whether you're a seasoned rider or a weekend enthusiast, maximizing the efficiency and longevity of your bike battery is essential for uninterrupted rides and hassle-free adventures. In this guide, we'll uncover seven efficiency hacks to help you optimize your bike battery's performance and make the most of every ride. Plus, we'll explore how industry-leading companies like Uno Minda are revolutionizing battery technology to enhance your riding experience.

Optimize Charging Habits

Proper charging habits play a crucial role in maintaining the health and longevity of your bike battery. Avoid overcharging by using a smart charger with automatic shutoff functionality to prevent damage from excessive voltage. Additionally, aim to keep your battery charged between 50% and 80% capacity to avoid deep discharges, which can reduce battery life over time.

Keep Connections Clean and Tight

Corrosion and loose connections can impede electrical conductivity and drain your bike battery's power. Routinely inspect the battery terminals and cables for signs of corrosion or buildup, and clean them using a mixture of baking soda and water. Ensure that all connections are tight and secure to minimize resistance and maximize efficiency.

Limit Parasitic Drain

Parasitic drain occurs when electrical components continue to draw power from the battery even when the bike is not in use. To minimize parasitic drain, turn off all lights, accessories, and electronic devices when parking your bike for extended periods. Consider installing a battery disconnect switch to completely cut off power flow and preserve battery life during storage.

Invest in a High-Quality Battery

Not all bike batteries are created equal, and investing in a high-quality, reliable battery can make a significant difference in performance and longevity. Look for reputable manufacturers like Uno Minda that specialize in innovative battery technology and offer products designed to withstand the rigours of motorcycle riding. A premium battery will provide superior cranking power, enhanced durability, and longer service life, ensuring dependable performance on every ride.

You Need to also Visit:- Online Original Spare Parts for Bike | Bike Parts

Avoid Extreme Temperatures

Extreme temperatures, both hot and cold, can have a detrimental effect on your bike battery's performance and lifespan. Whenever possible, park your bike in a shaded area or garage to shield it from direct sunlight and prevent overheating. During the winter months, consider using a battery tender or insulation wrap to keep your battery warm and maintain optimal operating conditions.

Practice Regular Maintenance

Routine maintenance is essential for keeping your bike battery in top condition and preventing unexpected failures. Check the electrolyte levels in lead-acid batteries and top them up with distilled water as needed. For maintenance-free sealed batteries, inspect the casing for signs of damage or swelling and replace them if necessary. Additionally, periodically test your battery's voltage and charging capacity to ensure it meets manufacturer specifications.

Other Information:- Online Shopping for Car Spares Parts | Car Parts

Opt for LED Lighting

Traditional incandescent bulbs draw more power from your bike battery and can contribute to faster drain and reduced runtime. Consider upgrading to energy-efficient LED lighting, which consumes less power and produces brighter, more focused illumination. LED headlights, taillights, and turn signals not only enhance visibility and safety but also help conserve battery power for other essential functions.

UNO Minda: Leading the Charge in Battery Innovation

As a trusted leader in automotive components and battery solutions, Uno Minda is dedicated to pushing the boundaries of innovation and delivering superior performance to riders worldwide. With a focus on research, development, and cutting-edge technology, Minda's battery solutions are engineered to meet the demanding requirements of modern motorcycles and deliver unmatched reliability, durability, and efficiency. From advanced lead-acid batteries to next-generation lithium-ion solutions, Uno Minda offers a comprehensive range of products designed to elevate your riding experience and maximize your bike battery's performance.

More Insights on Uno Minda: Top #1 Car Alloy Wheels Manufacturer in India

Conclusion

With these seven efficiency hacks and the support of industry-leading companies like UNO Minda, you can supercharge your bike battery's performance and enjoy worry-free rides for miles to come. By optimizing charging habits, maintaining clean connections, minimizing parasitic drains, investing in quality batteries, avoiding extreme temperatures, practicing regular maintenance, and upgrading to LED lighting, you'll ensure that your bike battery remains in peak condition, ready to power your adventures whenever the open road calls.

0 notes

Text

Raychem Termination kits

What should we know about the Raychem Termination Kit?

Raychem offers a comprehensive splice kit for a variety of cables. The company's bonding kits are designed to withstand extreme climates and pollution, ideal for underground and overhead installation reliability. Transeletric provide quality-guaranteed products, timely delivery, and an affordable pricing policy.

About Raychem Termination Kit

Get the correct industry standard wire connector from Transeletric's wide selection of wholesale termination kits. Each terminal connection is made of 99.9% pure copper, efficiently preventing corrosion, electrical sparks and oxidation. After heating evenly, this adhesive-coated heat shrink connector releases hot melt adhesive and instantly shrinks and bonds to the wire insulation. In this way, a totally water-resistant and wear-proof environmental closure can be created. This unit can be used for terminal wiring of specialist equipment such as batteries, power distribution boxes and cables.

The feat rate of joining wires be contingent on the average of the terminal. There is no need to worry. Depending on your needs, choose wire or screw terminals from Transeletric's range of termination kits. This Termination Kit will save you time. It would support if you had a high temperature gun to blast the joints, and you're virtuous to go. In particular, spade connectors track the universal size, which makes them adaptable. Furthermore, an elegant, high-standard widening opening helps wire insertion and laid-back operation even in demanding applications. All these benefits are found in Transeletric's bulk Raychem termination kits.

Get the Raychem Termination Kit online.

The terminals are designed to fit into tight, confined spaces and can be bent after connection, eliminating the need for soldering or crimping in tight areas. Control the temperature with the heat gun. Each lug also has specification markings to help you quickly find the correct terminal and make the connection faster and easier. This electrical terminal kit can knob almost any wiring prerequisite, from simple wire acquaintances to rigorous shuddering applications. We also have a team of experienced and dedicated marketing experts, quality inspection experts and other support staff overseeing the production process. Additionally, our approach towards ethical business practices helps us stay ahead of our competitors in this industry. Furthermore, we are committed to building long-term relationships with our customers by providing quality Raychem Termination Kit per their specifications. Furthermore, during this period, our company has partnered with various domestic and international players to offer products that are authentic and value for money. To further our objectives and provide the best service in the industry, we have set up a wholly-owned branch office in Chennai. Building infrastructure closer to the customer's front door reduces response and delivery times. Browse Rechem Termination Kits at Transeletric and choose from various options today.

1 note

·

View note

Text

Heat Shrink

Heat shrink tubing is a versatile product used across various industries for electrical insulation, mechanical protection, and cable management.

0 notes

Text

Powering Networks: Medium Voltage Cable Accessories and GIS Cable Termination Insights

In the realm of power distribution, the efficiency and reliability of medium voltage (MV) cable networks are of paramount importance. Within this domain, two critical components stand out: medium voltage cable accessories and Gas Insulated Switchgear (GIS) cable termination techniques. In this article, we delve into the significance of these elements, exploring their roles, advancements, and insights for optimizing power networks.

Understanding Medium Voltage Cable Accessories

Medium voltage cable accessories are essential components that ensure the integrity and performance of MV cable networks. These accessories encompass a range of devices and technologies designed to facilitate cable installation, termination, and protection. From cable joints and terminations to insulation and earthing systems, each accessory plays a vital role in maintaining the reliability and safety of the network.

Advancements in Medium Voltage Cable Accessories

Recent years have witnessed significant advancements in medium voltage cable accessories, driven by the need for enhanced performance, durability, and sustainability. Innovations in materials, manufacturing processes, and design techniques have led to the development of accessories with improved electrical properties, mechanical strength, and environmental resistance.

Key Features and Benefits of Modern MV Cable Accessories

Modern medium voltage cable accessories boast a multitude of features and benefits that contribute to the efficiency and reliability of power networks. These include:

Enhanced insulation materials for improved electrical performance and longevity.

Innovative sealing systems to prevent moisture ingress and environmental degradation.

Integrated monitoring and diagnostics capabilities for proactive maintenance and fault detection.

Modular designs for easy installation, scalability, and flexibility.

Compatibility with renewable energy integration and smart grid technologies.

GIS Cable Termination Insights

Gas Insulated Switchgear (GIS) cable termination techniques are critical for ensuring reliable and efficient power transmission in high-voltage environments. GIS systems offer compact, space-saving solutions for substations and urban areas where space is limited. Cable terminations within GIS systems require specialized techniques and components to maintain electrical integrity and operational efficiency.

Challenges and Solutions in GIS Cable Termination

Despite their advantages, GIS cable terminations present unique challenges related to insulation coordination, thermal management, and installation complexity. Addressing these challenges requires innovative solutions such as:

Advanced insulation materials with high dielectric strength and thermal conductivity.

Precision-engineered termination components to ensure proper alignment and contact pressure.

Thermal management systems to dissipate heat and prevent overheating under high load conditions.

Robust sealing mechanisms to protect against environmental factors and maintain insulation integrity.

Conclusion: Optimizing Power Networks for the Future

In an era of increasing energy demand and environmental awareness, the optimization of power networks is essential for ensuring sustainability and reliability. Medium voltage cable accessories and GIS cable termination techniques play crucial roles in this optimization process, offering innovative solutions to enhance network performance, efficiency, and resilience. By leveraging the latest advancements in these technologies, power utilities and infrastructure developers can build robust, future-proof networks that meet the needs of today and tomorrow.

0 notes