#electronic wire insulation

Text

Heat shrink puzzles,would you find which are the thin wall heat shrink tubing, and which are the heat shrink connector. Is there cold shrink here?

#shrink tubing#upm heat shrink specialist#cable protection#heat shrink#shrink sleeve#heat shrink connector#shrink terminator#expandable braided sleeve#shrink end cap#cold shrink tube#high shrink ratio 6:1#bus bar insulation#fiber optic splice#solder sleeve#thin wall tube#electronic wire insulation

0 notes

Text

Just heard a YouTube science communicator (who should know better) say "higher voltage means you can get more current in the same cable" and felt my skin crawl for a second

#volt = difference in potential energy#current is the movement of the charge which is what the wire is actually facilitating#voltage is a difference a single point in a cable has no voltage thus the voltage is irrelevant for single points in a cable#w higher voltage u can get more *wattage* bc ur increasing voltage w the same current#watt=volt*amp#the voltage limitation for a single type of cable is also bc its a difference#its rating the max difference between a point in the wire & the environment/another point in the cable#current rating on a cable is meant to b independent of voltage so long as the voltage is within rating of the insulation#like obv it was probably a brain fart and he understood that but that should b one of those things where you immediately notice#(note - movement of charge is different than movement of electrons. electrons r fairly slow)#(and obv things like 'single points' are abstractions so theres nuance when you rly need to b precise#but for most nontechnical applications dw abt it)

20 notes

·

View notes

Text

How a Computer Works - Part 3 (Miniaturization and Standardization)

For anyone just joining in, I'm writing a series of posts explaining perhaps haphazardly all there is to know about how a computer works, from the most basic fundamental circuitry components to whatever level of higher functionality I eventually get to. As explained in the first post on this subject, I am doing this just in pure text, so that if you are inclined you can straight up print these posts out or narrate them onto some audio tape or whatever and have full access to them should every computer in the world suddenly collapse into a pile of dust or something. Part 1 mainly covered the basic mechanical principles of circuitry and how to physically construct a logic gate. Part 2 covered logic gates in detail and how to use them to create a basic working architecture for a general purpose computer. Today we're going to be talking more about what you're looking at when you crack a machine open so you can make sense of all the important fiddly bits and have maybe a starting point on how to troubleshoot things with a multimeter or something.

Before getting into it though, I do have to shake my little donation can again and remind you that I do not know how I am going to get through the winter without becoming homeless, so if this is valuable to you, I'd appreciate some help.

Boards of Bread and Printed Circuits

With the things I've explained so far, you could totally build a computer right now, but it'd be a bit messy. You can totally buy resistors, transistors, capacitors, and diodes by the bagful for basically nothing, and cheap rolls of insulated wire, but there's all these long exposed pins to cut short and soldering things in mid-air is a messy nightmare and you'd just have this big tangle of wires in a bag or something that would almost certainly short out on you. So let's look into ways to organize stuff a little.

If you start playing around with electronics on your own, one of the first things you want to hook yourself up with besides raw components and wires is a breadboard or 12. And if you're watching people explain these things with visual aids, you'll also see a lot of them, so it's good to know exactly what they are and how they work. Your standard breadboard is a brick of plastic with a bunch of little holes in it. Incidentally, the name comes from how the first ones were literally just named after the wooden cutting boards for slicing bread people recycled to make them. Inside these holes there's some pinching bits of conductive metal which connect to each other in a particular way (pretty sure you can just see the strips that connect one if you pry the bottom off), so you can just jam a thing wire or prong into a hole, have it held in place, and make a connection to every other hole its connected to on the other side.

There is a ton of standardization to all of this. The holes should always be 0.1 inches apart () and split into two big grids. Everyone I've ever seen has 63 rows, each with 5 holes labeled A-E, a shallow channel through the middle of the board, and then another 5, F-J, and we generally have numbers printed every 5 rows. Down underneath, for any given row, the set of 5 pins on each side of the channel are connected. So, holes 1A, 1B, 1C, 1D, and 1E are all connected to each other, and nothing else. Holes 1F, 1G, 1H, 1I, and 1J are also connected to each other. There's no connection though between 1E and 1F, or 1A and 2A.

Most breadboards will also have a couple of "power rails" along the sides. These are just going to be labeled with a long red line and +, and a long blue or black line and -, and have holes in 2x5 blocks staggered out. With these, all 25 or 50 or whatever holes near the red + line connect with each other, and all the ones near the black line connect with each other. The gaps every 5 holes don't serve any purpose beyond looking different enough from the big grid so you hopefully don't mix it up and forget that these ones all connect down the length, and not in in little clumps across the width like everything else. The idea, for the sake of convention, is you plug a wire connected directly to the positive side of your battery or DC adapter or whatever into any red line hole, the negative side to any blue/black hole, and then tada, you can make a circuit just by plugging a wire in from red to a normal grid line, whatever bits you want span from that grid line to another, and eventually you connect the far end back anywhere on the black/blue line.

With a nice circuit board, there's also little snap-together pegs along the sides, and the power rails are just snapped on with those. So you can just kinda cut through the backing with a knife or some scissors, snap those off, connect multiple boards together without redundant power rails in the middle, and then just have these nice spare long lines of linked sockets. In the computer I'm building on these, I'm just using spare power rails for the bus. Oh and the big grooved channel down the middle also has a purpose. Bigger electronic components, like our good good friend the integrated circuit, are generally designed to be exactly wide enough (or more, but by a multiple of 0.1 inches) to straddle that groove as you plug their legs into the wires on either side, so they nicely fit into a breadboard, and there's a handy gap to slide something under and pry them off later on.

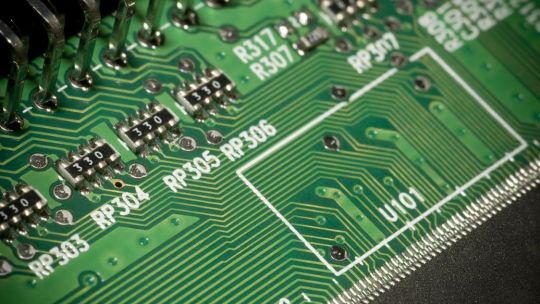

Typically though, you don't see breadboards inside a computer, or anything else. They're super handy for tinkering around and designing stuff, but for final builds, you want something more permanent. Usually, that's a printed circuit board, or PCB. This is pretty much what everyone's going to picture when they think about the guts of a computer. A big hard (usually) green board with a bunch of intricate lines, or "traces" running all over made of (usually) copper. And maybe with some metal ringed holes punched all the way through (they call those vias). These tend to look really complicated and maybe even a little magical, but they're honestly they're just pre-placed wires with a sense of style.

Most of the material of the board is insulated. The copper traces conduct real well, and manufacturers have done the math on just how close together they can be run without connecting to each other in places you don't want. The holes that go all the way through are for either plugging other bits in that tend to come with long legs you maybe want to keep intact, or just ways to run a trace through to the other side, where we often have traces on the back too to maximize our space. Most of what makes them look all cool and magical is how the traces run as close packed as possible to conserve space, and tend to only turn at 45 degree angles, which is just an artifact of how the machinery used to etch them out sued to be iffy about anything else.

So tada, you have all your wires pre-stuck to a nice sturdy board, and maybe even have labels printed right on there for where you solder all the various components to finish the thing. Oh and when you hear people talk about like, motherboards and daughterboards? The big main board you have for everything is a motherboard. Sometimes you need more than that, so you make smaller ones, and connect them up ether with some soldering or cartridge style with end-pins sliding snugly into sockets, and those we call daughterboards.

Integrated Circuits, or as they're also known, "chips"

The last thing you're likely to find if you crack open a computer, or just about any other electronic device that isn't super old or super super simple, are integrated circuits. Generally these are think black plastic bars that look like you'd maybe try to awkardly use them to spread cheese or peanutbutter on crackers in a prepacked snack or something, with rows of tiny little legs that running along either side. Kinda makes them look like little toy bugs or something. Sometimes they're square with pins along every edge, because sometimes you need a lot of pins. These are integrated circuits, or microchips, or just chips, and wow are they handy.

Sometime back in the 60s when people were really getting their heads around just how ridiculously small they could make electronic components and still have them work, we started to quite rapidly move towards a point where the big concern was no longer "can we shrink all this stuff down to a manageable size" and more "we are shrinking everything down to such an absurdly tiny size that we need to pack it all up in some kind of basically indestructible package, while still being able to interact with it."

So, yeah, we worked out a really solid standard there. I kinda wish I could find more on how it was set or what sort of plastic was used, but you take your absurdly shrunken down complex circuit for doing whatever. You run the teensiest tiniest wires you can out from it that thicken up at the ends into standard toothy prongs you can sink into a breadboard or a PCB with that standardized pin spacing, and you coat it all in this black plastic so firmly enveloping it that nothing can move around inside or get broken, hopefully.

And honestly, in my opinion, this is all TOO standardized. The only real visible difference between any two given integrated circuits is how many legs they have, and even those tend to come to some pretty standard numbers. They're always the same size shape and color, they all have the same convention of having a little indented notch on one side so you know which end is which, and they all seem to use just the worst ink in the world to print a block of numbers on the back with their manufacturer, date of assembly, a catalog number, and some other random stuff.

For real if there's any real comprehensive standard for what's printing on these, I can't for the life of me find it. All I know is, SOMEWHERE, you've got a 2 or 3 letter code for every manufacturer, a number for the chip, and a 4 digit date code with the last 2 digits of the year, and which week of that year it was. These three things can be in any order, other things can also be on there, probably with zero spacing, and usually printed in ink that wipes away like immediately or at least is only readable under really direct light, it sucks.

Once you know what a chip is though and look up the datasheet for it, you should have all sorts of handy info on what's inside, and just need to know what every leg is for. For that, you find which end has a notch in it, that's the left side, sometimes there's also a little dot in the lower left corner, and hopefully the label is printed in alignment with that. From there, the bottom left leg is pin 1, and then you count counterclockwise around the whole chip. You're basically always going to have positive and negative power pins, past that anything goes. You can cram a whole computer into a single chip, yo can have someone just put like 4 NAND gates on a chip for convenience, whatever.

OK, but how do they make them so small?

OK, so, mostly a circuit we're going to want to shrink down and put on a chip is just gonna be a big pile of logic gates, we can make our logic gates just using transistors, and we can make transistors just by chemically treating some silicon. So we just need SUPER flat sheets of treated silicon, along with some little strands of capacitive/resistive/insulating material here and there, and a few vertically oriented bits of conductive metal to pass signals up and down as we layer these together. Then we just need to etch them out, real real small and tight.

And we can do that etching at like, basically infinite resolution it turns out. It just so happens we have access to special acids that eat through the materials we need them to eat through, but that only work when they're being directly hit with fairly intense UV light. And a thing about light is when you have say, a big cut out pattern that you hold between a light and a surface, it casts a shadow on it... and the scaling of that shadow depends entirely on the distances between the light, the pattern, and the surface. So if you're super careful calibrating everything, you can etch a pattern into something at a scale where the main limiting factors become stuff like how many molecules thick things have to be to hold their shape. Seriously, they use electron microscopes to inspect builds because that's the level of tininess we have achieved.

So yeah, you etch your layers of various materials out with shadow masks and UV acid, you stack them up, you somehow align microscopic pins to hold them together and then you coat the whole mess in plastic forever. Tada. Anything you want in a little chip.

ROMs, maybe with various letters in front

So there's a bunch of standard generally useful things people put into ICs, but also with a computer you generally want some real bespoke stored values with a lookup table where you'll keep, say, a program to be run by feeding whatever's inside out to the bus line by line. For that we use a chip we call Read Only Memory, or ROM. Nothing super special there, just... hard wire in the values you need when you manufacture it. Manufacturing these chips though is kind of a lot, with the exacting calibrations and the acid and the clean rooms and all. Can't we have some sort of Programmable ROM? Well sure, just like build it so that all the values are 1, and build a special little thing that feeds more voltage through than it can handle and physically destroy the fuse for everything you don't want to be a 1.

OK that's still kind of a serious commitment. What if I want to reuse this later? Oh, so you want some sort of Erasable PROM? OK someone came up with a funky setting where you overload and blow out the fuses but then if you expose the guts of the chip to direct UV light through this little window, everything should reform back to 1. Just like, throw a sticker on there when you don't want to erase it. Well great, but can we maybe not have me desolder it and take it out to put under a lamp? Oh la de da! You need Electronically Erasable PROMs? EEPROMs? I guess we can make THAT work, somehow. They're still gonna be slow to write to though, can't have anything. I mean, not unless we invented like, flash memory. Which somehow does all this at speeds where you can use it for long term storage without it being a pain. So that's just kinda the thing we have now. Sorry I don't quite get the principles behind it enough to summarize. Something about floating components and needing less voltage or whatever. Apparently you sacrifice some read speed next to older options but hey, usable rewritable long term storage you just plug in, no jumping through extra hoops.

So OK. I think that's everything I can explain without biting the bullet and explaining ALUs and such. Well, there's keyboards (they're just buttons connecting input lines), monitors (these days, LEDs wired up in big grids), and mice (there's spokes in wheels that click X times or cameras checking the offset values of dust on your desk or whatnot).

Maybe throw me some money before we move on ?

CONTINUED IN PART 4

#computers#computer science#pcb#printed circuit board#integrated circuits#microchip#breadboards#education#electronics

54 notes

·

View notes

Text

New faces - pack bonds part 3

Toby was quiet but you could still see a glint of curiosity in their eye as your brother pulled out strange tools from his case. You were worried at first that they'd be scared but if anything, they were in awe.

They sat themselves up a little straighter on the couch and carefully reached for James, stopping when they'd gained his attention before they'd even touched him. "Um, what do these do?" Toby asked, voice quiet but not mumbling.

Your brother's eyes flickered to you before looking back at Toby. "These are some lock picking tools," he explained, picking up a set of lock picks, "these are for manual locks like the one on that door." He pointed to your front door. "For this though, they won't be much help." He looked over his shoulder, "mum said this would be a digital lock."

"Isn't it?" She asked.

"No, digital usually has a combination or something. There isn't anything like that here," James took Toby's hands, turning them over to see if there was anything he could use. "How does this work normally? Do they use a key? A fob?"

"They have a button," Toby said, "it activates the restraints or releases them. The button looks like it's tied to a network of switches that send wireless signals to the restraints."

"Alright," your brother took out a clamp meter and attached it to one of the bands.

"What is that?" Toby asked.

"It's a clamp meter, it can measure any electrical signals in the bands so I can see what I'm working with." James said, not looking up from the screen.

"Will it work with this?" Toby asked, "this tech won't be anything like yours."

"If it's still AC or DC it should be fine," James shrugged, "you may be alien but basic physics should still work, right?"

"I-I guess." Toby nodded.

James hummed and looked at the readings. Remarkably, he was getting them. It looked like it wasn't all too different after all. The problem was, there were no visible wires to cut, seemingly no power source to drain. These were simple, black, metal bands. They were too tight against Toby's wrists to just pull off too, not without hurting the kid.

"I have an idea."

"I'm not going to like it, am I?" You mumbled, knowing James wouldn't have stopped there if it was a good idea.

"It's kinda a 'see what happens' type of deal," James grinned, pulling out a small device. It was like a taser but you know, mostly because he's used it on you, that it was a lot weaker than a regular taser. It was mostly to stun electronics.

It was a homemade device with the odd couple wires sticking out and the grip made by wrapping duct tape around rubber insulation. There was a metal tip that delivered the shock.

Toby looked between you and James as you glared. "Don't you dare," you said.

"Look, we gotta figure out how this works, right? Besides, it's not a dangerous current. It's just a little sting," James said, "see?" He jutted it at you and you shrieked before he even pressed the button.

"James!" You shoved him when he laughed.

"See? It's fiiiine," James looked at Toby, "don't mind her, she's a drama queen." You hit him again on the shoulder.

"Drama queen?" Toby tilted their head then turned to you, "you didn't say you were royalty."

James paused then burst out laughing. You rolled your eyes, trying not to smile yourself, "it's just an expression. It means someone's a very dramatic person." James was laughing so much, he was leaning against you for support. You quickly moved and let him fall to the floor.

"Ok, I like this kid," James chuckled, finally starting to calm down, "can we keep him?" Your dad just chuckled in the background until you shot him a look.

"They've probably got parents looking for them," your mother said and the light mood wore off both you and Toby. "We might need to find a way to reunite them somehow."

"No," you said immediately as Toby's breathing picked up.

"May?" Your mother asked.

Toby crawled over to you and small panicked bleats escaped him. You lifted an arm to let them curl into you. "They don't get to call themselves parents." You said stubbornly.

"I can't go back," Toby whined, "I can't-"

"Wow, wow," James said, "calm down mama bear, we won't take him away from you." You gave your brother a look and he gave you a nod back, a serious look falling over his face. He went back to picking at the bands around Toby's arms. "Ok, this might sting a bit but it'll only be for a second, ok?" He looked up and Toby nodded at him.

James shocked the band and suddenly both lit up blue along with the metal collar around Toby's neck. The bands magnetised and pinned his wrists together and two more that were disguised in the fur on their legs pinned his legs together.

Toby shrieked and tripped over themselves, falling off the couch and onto the floor. They fought for their hands, bleating and whining in vain as the electromagnetic force was too strong.

"Wow, hang on." James said, getting down on the floor with Toby but the alien kicked out, propelling themselves along the floor and squirming away.

"Wait," you took your brother's shoulder, keeping him in place.

Toby backed themselves up against the wall and curled their limbs up close. They shivered and squeezed their eyes closed. You approached slowly, coming at them from the side. They didn't acknowledge you as they mumbled to themselves.

"Toby?" You asked, quietly.

Toby let out a quiet bleat and started mumbling to themselves. "S'not my name." You overheard them say in their mindless rambling.

"Tobs," you said, "do you know where you are right now?"

Toby didn't acknowledge you as you crept closer. You caught movement in the corner of your eye and you turned to see your brother fiddling with wires and a large nail. You decided to figure that out later.

"Open your eyes, Toby. Just take a look around. You're safe."

"I-I'm good," Toby said slightly louder than their previous ramblings, "I'm good, I swear. I'll be good." They let out another whine that twisted your heart painfully in your chest.

"You are good, Tobs." You carefully put your hand on the top of their head, in between their horns. Toby flinched initially but when your hand did nothing more but ruffle through their hair, they sunk into the touch. "Open your eyes, it's ok, you're safe with me. It's May. I promise, you're safe."

Toby didn't open their eyes yet, still too scared but they leaned towards you. You shifted your body to be beside them and you pulled them closer, keeping physical contact light but supporting.

Your mother stood up from her seat and sat against the wall perpendicular to you. You watched her move, unable to keep the kicked puppy expression off your face. You felt horrible that there was nothing you could do for the little alien. Your mother started humming.

The hum was soft but audible. It was a lullaby, one you were familiar with. Your mother was always a lovely singer and even after years of not hearing it, the song was just as beautiful as when she'd sung to you after a nightmare. You rubbed circles into Toby's back while she sang.

Your brother snuck close now. On seeing what he had in his hand, you recognised the electromagnet in his hand. It was simple and rather crude considering the tech he was using it against but you could hear a faint buzzing as he got closer with it. He held it up to Toby's collar and the lights dimmed a little before turning back to the usual flashing yellow. Toby's arms fell away from each other and their ankles were also able to separate.

Once they were freed, you pulled Toby onto your lap, picking them up and taking them to another room so they could better calm down.

< Previous

Next >

#creative writing#writing#humans and aliens#alien oc#human and alien bonding#protective human#trauma

60 notes

·

View notes

Photo

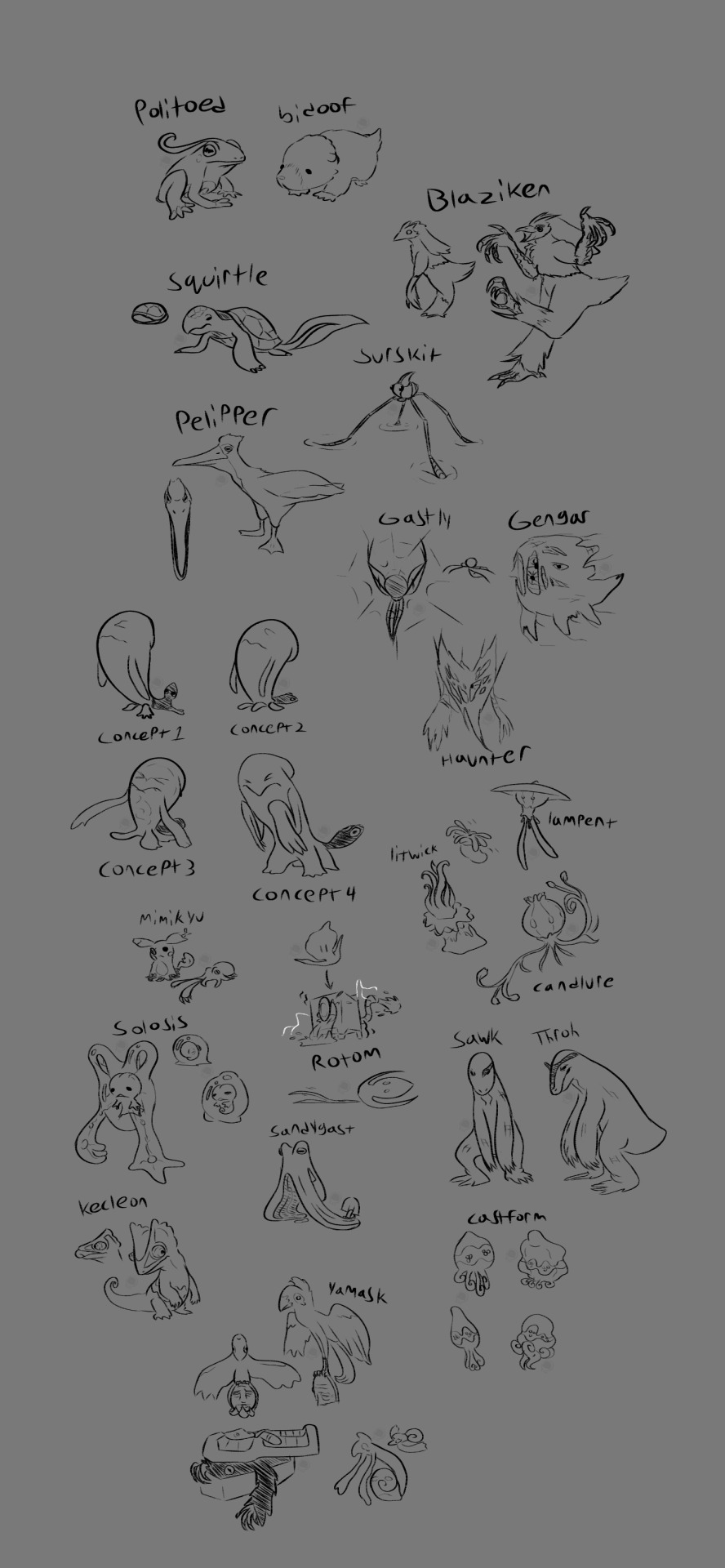

a BIG list of “Realistic” pokemon!

Politoed: like the lyrebird of frog pokemon, sets off every frog pokemon in their area because they mimic the calls of other frogs, confusing them.

Bidoof: its a baby beaver

Squirtle: squirtles live out in the sea or in deep lakes for a long time, before they develop a more stout, Snapping-turtle like body plan to facilitate them becoming more terrestrial to avoid competing too much with their young

Blaziken: this chicken remembered it was a dinosaur and stood up

Pelipper: a fell beast known as a Pelican. but with an even BIGGER throat pouch

Surskit: the nymph stage of maquerain. their undeveloped wings come together to form a protective spike for now

Gastly Line: misinterpreted as spirits of the dead, these spider-pokemon have a peculiar defense, by folding their limbs together with coloration that makes them resemble a big scary face with a dangling tongue. as they grow older they weave more webbing together to make a false Puppet-body to hide in and protect itself (known at this point as a ‘Haunter’). when they reach a certain age, many Haunter will move into the same web-body together and mate continuously with each other (Colloquially known as a “Gengar”). their webs are coated with a substance that dries easily and is toxic when inhaled, as a defense mechanism they shake their web furiously to scatter this substance as a toxic cloud of powdered dust.

Wobbuffet: wasnt sure what to do with wobbuffet, my beloved weirdo. had 4 ideas. 1: wobbuffet is a gecko with a huge tail. 2: Wobbuffet is a sea cucumber with an inflatable filament. 3: wobbuffet is some sort of hydrozoan. 4: wobbuffet is it’s own funky monstery thing. could be any of em

Chandelure line: getting it’s own post soon

Mimikyu: a land cuttlefish that once used hide and furs from dead pokemon to cover itself as a decoy and keep its body from drying out (putting it in direct competition with Banette) now moved onto the much more plentiful human-made cloth scraps and plushies. when surprised they flash and strobe in bright lights and colors, causing epileptic seizures in those who are sensitive.

Rotom: a form of flatworm, once considered a pest. they are attracted to old electronics due to the rubber gaskets, fittings and wire insulation. they feed on these before gradually breaking down the copper wiring. due to an instinct to aggressively defend their food source with electronic shocks, and being attracted to areas of high current (like the control panel or capacitors) this gives the impression that rotom ‘Possesses’ electronics

Solosis line: an amphibian pokemon that evolved to retain it’s gelatinous egg casing as a protective coating. the jelly is full of muscle fibers and neurons in a sort of mesh that is difficult to see.

Sandygast: an octopus pokemon that prowls the beach for krabby to eat. they cover themselves in sand to protect from the beating sun, even stealing unattended shovels from children on the beach to help. they prop themselves up as false shelter to the krabby to hide in away from wingull, before plopping down on them and devouring them.

Sawk & Throh: 2 morphs of the same species of short tailed/Tailless komodo dragon pokemon. living in small groups that fight constantly to establish pecking order. the sawk morph is very speedy and nimble in exchange for being very frail in comparison, while the Throh morph is much stronger and heavier but extremely slow. there is a misunderstanding that sawk and throh are ‘entirely male’ but this is untrue, rather they have a genital configuration similar to hyena’s, not to mention mating is rarely ever observed and thus poorly understood.

Kecleon: a lizard pokemon with a highly sophisticated form of camouflage, their scales even capable of taking on levels of bioluminescence and phosphorescence to increase the effectiveness of the disguise. the red band along their midsection is a clear selection of scales over a patch of light-sensitive cells that automatically adjust levels of light for their camouflage while the eyes focus on depth, shapes, details and colors.

Yamask line: black scavenger birds that build nests from glittering, sparkling objects. in the past they were known to appear in the homes of recently deceased in the unovan desert, attracted by the bronze ‘death mask’ laid over the face of the deceased, the fact that they were constantly found taking them created the myth that these birds are in fact the souls of the departed. when they mature they lose the ability to fly, but gain much greater strength and developed phalanges on their former-wings that helps them carry their nest easier. in the past they wove their nests as baskets with both lid and container to retain all the sparkling materials theyve gathered with a special, weblike secretion from their Mucus glands. but with the increasing popularity of coffins, caskets and sarcophagi in bright, glittering colors they became much more entranced by them and grew in strength to use them as semi-mobile shelter. they are Highly aggressive and possessive of anything theyve gathered.

Castform: a form of jellyfish pokemon. while technically speaking very resistant to changes in weather, they Do react strongly to it, which was a trait long bred into them by humans for weather prediction. as such, they are 'made' by humans, but not as directly as some 'synthetic' pokemon

#my art#realistic pokemon#speculative biology#pokemon#politoed#bidoof#Blaziken#pelipper#squirtle#sirskit#Gastly#haunter#gengar#wobbuffet#Litwick#lampent#chandelure#mimikyu#rotom#solosis#duosion#reuniclus#sandygast#sawk#throh#kecleon#yamask#cofagrigas#castform

147 notes

·

View notes

Text

[Sits up in a cold sweat]

The quiet was suffocating. Like a cold hand against his face as his joints and pistons loosened out of positions they'd held for as long as he could remember. It was unnatural—wrong. It made him uncomfortable, even past the soft, light brushes of warm kindness.

He was too late to disable the thruster disengage. He was too late to complete their mission.

What he was not too late for, however, was an... emergency protocol. Granted, one he just made up, but he hadn't ever expected to be in space, really. He certainly hadn't expected to be jettisoned along with his friends.

Well, Zane supposed it didn't really matter. He had been shot out into space, and now, drifting amongst the faint, stagnant lights of distant stars, he found himself curled up, knees pulled up to his chest. At the sides of his face, his vents whirred a soft melody, though they moved nothing. There was no air to move in space... how long could he survive without overheating? He was insulated against most elements, but that made it difficult to remove heat given he obviously couldn't vent it.

He needed to think about something else.

His thoughts drifted to the pondering of how long he could last in open space. Particle radiation was a cruel thing to electronics, and it was entirely possible for him to simply fall victim to—

Deep inside—under his exterior shell, further below the wires that kept him running, hidden away where Zane would consider his core—something shifted. It was a little thing, a shrug, almost in the pile of heat radiators that had his liquid coolant working overtime.

Not for the first time in his existence was he glad to not have a gag reflex or anything of the sort, as not a moment after the first, the rest began shifting. Limbs stretched, voices rose. Zane raised his head from his knees as if he could see them. Tension bled from his dorsal nervous column.

"Hey those are my ribs—"

"It's not my fault you landed on top of me!"

"You stink. Do you ever bathe—"

The stretching devolved quickly into pushing and shoving, as it did frequently when there was a lack of personal space. Had it not sent a relief washing from head to toe, Zane would have been annoyed. a smile tapped at the edges of his faceplate. "I see the bonds of brotherhood are strong, today."

The movement stopped immediately, though it was promptly followed by a nigh circuit-rattling "Zane!" from his team. The token "where are we" skipped for all of their familiarity, the first question that managed its way into intelligibility was something to the effect of "what happened," albeit filtered through no less than three voices before it even managed to register as a question.

"The rocket thrusters disengaged. The previous pieces collided, and the hull was breached. I... did what I thought I should." A pause as his gaze scraped their surroundings. "We will arrive late to the meteor, but we are in its path... for the most part." At these speeds, he may be flattened, but that mattered little in the long run.

"My... life support functions should keep everyone stable for the duration of this trip."

When Jay spoke, it was like he was testing the feel of the words on his tongue. "Life... support? Since when have you had life support in here?"

"Since yesterday," came the bland reply. "I thought it pertinent to have a... backup plan."

#submission#phyre-anon#not my writing#screaming and crying dude this is so amazing#your writing never ceases to amaze me holy crap#I am looking. Directly at it#Zane my goofy guy my beloved#they’re all so near and dear to me#look at him protecting his friends please someone give him a hug please#I can so vividly see them all stacked in a little pile inside please it’s so cute#soft vore#safe vore#g/t vore#fandom vore#n.injago vore#the blorbos ever

26 notes

·

View notes

Note

💕

following up my birds on a wire fun fact, certain high voltage wires are left completely bare (them wires Naked), there's a bunch of reasons for this, one the insulation needed to make a high voltage wire safe would make the wires Unbearably heavy, the strain on the cables and the towers would be incredible, two insulation makes heat harder to dissipate (the heat is generated by friction from electrons moving in the conductors) and when conductors are hot they Suck at transporting electricity, and finally its SPENSIVE, really really spensive

what do they do instead? cables use the air! Air is in fact an insulator and it keep the electricity in its cables quite well, just don't get within that air gap or you might just be the perfect point to take the electricity to ground x.x

send me an emoji and i'll send you a fun fact about my special interest

4 notes

·

View notes

Note

Requesting some C:tL Character Behavior for WIP Wednesday because that sounds delightful.

She was harmless and insubstantial, just curious, and the wards easily convinced, weak enough that they barely tingled more than the glass as she slid through them and into a cluttered living room. Once she was standing in the center of the apartment, the whole of it visible from her spot next to the kitchen counter. She nodded and hummed cheerfully at the refrigerator. Its indicator lights flickered back at her and she closed her eyes to spread her senses to the rest of the room, thinking through the well trod paths of playful sparks through their insulated wires, their outlets. The overhead light pulsed warmly as it tried to turn itself on when her attention passed over it and she soothed it while she looked for the odd pooling of power that indicated electronic locks.

3 notes

·

View notes

Text

7.10. Storage

A number of large crates fill the area. Inside (1D4):

1. Electrical components, meant for repairs in the power station.

2. Battery cells, compatible with a wide variety of machines and electronics.

3. Spools of cable, insulated copper wire.

4. 1D3 diving suits with air tanks, meant for maintenance of the turbine nearby.

11 notes

·

View notes

Text

DC Plug Supply Socket is used for supplying power to the development boards, power supply converter PCBs, in small electronic devices and equipment. This is a standard sized barrel jack connector that has been in use for a long time now and it is very reliable and proven to be used in industry. Its other side is a miniUSB connector that you can plug not your PC or powerbank or any other device to make the device you are powering portable and easy to handle. This cable can take upto 1.5A of current easily so you can connect the heavy electrical loads through this cable. The plastic insulation is very reliable so you don’t have to worry about getting electrical shocks from it.

2 notes

·

View notes

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Photo

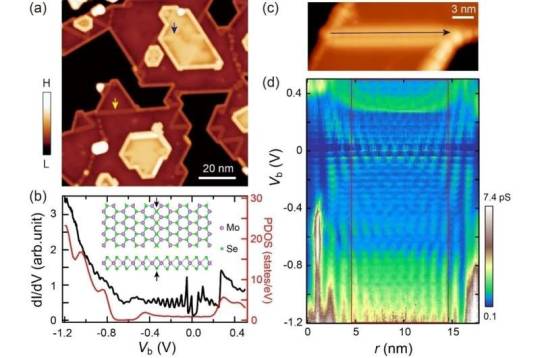

A Hubbard-type Coulomb blockade effect discovered in the mirror twin boundary of MoSe₂

In a study of one-dimensional electron correlation states at the MTB of monolayer and bilayer MoSe2, a research team found that two types of correlated insulating states driven by a dubbed Hubbard-type Coulomb blockade effect could be switched by tip pulses.

By means of molecular beam epitaxy, this team has grown single-layer and double-layer MoSe2 films with one-dimensional MTB on graphene substrates. It is found by scanning tunneling microscopy that the one-dimensional MTB has metallic states. Due to its limited length, the one-dimensional states are subject to quantum confinement effect, resulting in quantized discrete energy levels.

They found two types of MTBs with different ground states, defined as in-phase and out-of-phase states respectively, according to the spatially modulated phase of the two discrete levels spanning the Fermi surface. More interestingly, by applying tip pulses, it is possible to reversibly switch the two states.

They showed that the Coulomb energies, determined by the wire length, drive the MTB into two types of ground states with distinct respective charge orders. The quantum well states at the Fermi surface are affected by the Coulomb effect.

Read more.

15 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Note

you KNOW im gonna ask about grounding and bonding!!!!

i thought i fucking answered this but tumblr is a Webbed Site

so in my blorbos explain electrical safety fic there is this section:

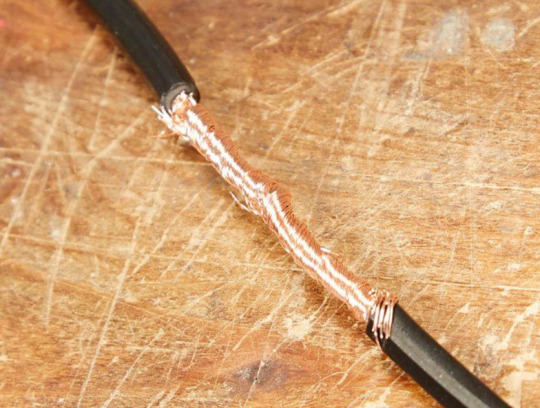

They point at a juncture between two multi stranded wires, they seemed to be connected with some sort of silver metal and tied with another metal strap of some kind.

“These splices here, first of all, that,” they point at the strap. “Is a hose clamp.”

For this little bit i went through electrician forums to find the worst wiring jobs i could and these are a sample:

gentle reader, i don't even know where to begin creating an alt text for these monstrosities, they are genuinely awful.

i would like to draw your attention to the first image. Under code we size wires to the amperage (the amount of electricity in the wire, you have to make room for all the electrons) so you can almost be guaranteed that the larger the wire the more electricity there is In said wire to kill you very very dead

just for reference this is a much better multi strand cable splice

the wire is basically interwove and wrapped around itself, it is then soldered in place and wrapped in either a heat shrink or crimped jacketing

this careful joinery method and insulated coating prevents many problems that we as engineers work very very hard to avoid, notably arcing and ground faults

if you've never seen an electrical arc in person 1) good keep it that way 2) go to a tesla coil show

the latter are very fun and its amazing that people make music out of them but also they are Terrifying outside of the more or less controlled environment a tesla coil provides

but back to the above monstrosities

you will notice a hose clamp is a terrible splicing jacket for a very simple reason, they're made of metal, and metal conducts, and therefore will do Jack All to stop an arc event

i have to assume that it was diy work because if that was contract work that contractor should be stripped of their license and tried at the hauge

so the horror morgan feels upon popping open a panel in a public place of business and seeing that? understandable, justified, would you like a gun my liege, if not please see the mass murderer to your right

electrical safety is not a joke kids, it will kill you and it will hurt the entire time you are dying

7 notes

·

View notes

Text

CIHS EIM STRANDS WORKSHOP TOUR-BASIC ELECTRICAL WIRING TUTORIAL

WIRING ELECTRICAL TOOLS

1.PHILIP SCREW DRIVER

DEFINITION : THE PHILIP SCREW DRIVER WILL BE USED TO TIGHTEN THE SCREW ON OUR WIRING BOARD TO ADJUST THE CONNECTION OF THE JUNCTION BOX, UTILITY BOX AS WELL AS THE PANEL BOARD AND OTHERS

2. FLAT SCREW DRIVER

DEFINITION : A SCREW DRIVER WITH WITH A FLAT WEDGE-SHAPED TIP THAT FITS INTO A SLOT IN THE HEAD OF A SCREW. TYPE OF: SCREWDRIVER. A HAND TOOL FOR DRIVING SCREW; HAS A TIP THAT FITS INTO THE HEAD OF A SCREW.

3.LINE MAN PLIERS

DEFINITION : USED IN THE ELECTRICAL TRADE TO CUT , STRAIGHTEN , AND BEND WIRE , AND ALSO TO TWIST WIRES TOGETHER WHEN MAKING SPLICES

4.LONG NOSE PLIERS

DEFINITION :PROPER USE OF LONG NOSE PLIERS : USE TO GRIP SMALL OBJECTS , REACH AWKWARD PLACES , HOLDING WIRES, BEND LOOPS , AND ATTACH WIRES . WORK INVOLVING SMALLER GAUGE WIRE.

5.SIDE CUTTER PLIERS

DEFINITION : SIDE CUTTERS ARE USED ON WIRE AND THE LEADS OF ELECTRONIC COMPONENTS , AS WELL AS TO STRIP INSULATION . STRIPPING REFERS TO SAFELY REMOVING THE OUTER LAYER WITHOUT DAMAGING THE CONDUCTORS UNDERNEATH . IF THEY DO GET NICKED , THE CONNECTION MAY BREAK OR IT COULD CAUSE AN ELECTRICAL SHORT CIRCUIT.

6.LEVEL BAR

DEFINITION : A LEVEL IS A TOOL USED TO DETERMINE WHETHER A SURFACE IS HORIZONTAL (LEVEL ) OR VERTICAL (PLUMB ). WITHOUT THIS , YOU CAN'T BUILD A HOUSE THAT WORKS WELL OR LOOKS GOOD —NOT TO MENTION HANG KITCHEN CABINETS OR TRIM OUT A DOOR.

7.WIRE STRIPPER

DEFINITION : WIRE STRIPPERS ARE AN ESSENTIAL TOOL FOR ANY ELECTRICIAN OR MECHANICAL ENGINEER . WIRE STRIPPERS CREATE A NEAT AND TIDY CUT TO REVEAL YOUR WIRES , READY TO BE SOLDERED OR HAVE A CONNECTOR ATTACHED

8.PULL PUSH RULE

DEFINITION :A PUSH -PULL RULER IS A TAPE MEASURE THAT CAN BE WRAPPED TOGETHER IN A COMPACT CASE . IT IS USED TO MEASURE LONG , SHORT AND STRAIGHT LENGTHS . THE BODY OF THE TAPE MEASURE IS THE CASE.

9.MULTIMETER

DEFINITION: A MULTIMETER OR A MULTITESTER, ALSO KNOWN AS A VOLT/OHM METER OR VOM, IS AN ELECTRONICS MEASURING INSTRUMENT THAT COMBINESSEVERAL MEASUREMENT FUNCTIONS IN ONE UNIT. A TYPICAL MULTIMETER MAY INCLUDE FEATURESSUCH AS THE ABILITY TO MEASURE VOLTAGE, CURRENT AND RESISTANCE

A VIDEO IS ABOUT CIHS EIM STRANDS WORKSHOP TOUR-BASIC ELECTRICAL WIRING TUTORIAL

youtube

#activityemtechcihs

#youtube

2 notes

·

View notes

Text

Chip, semiconductor, integrated circuit, do you know the relationship and difference between them

1、 What is a chip

Chip, also known as microcircuit, microchip, integrated circuit (IC), refers to the silicon chip containing integrated circuit, which is very small and often a part of computer or other electronic equipment.

Chip is the general term of semiconductor component products. It is the carrier of integrated circuit (IC), which is divided by wafer.

A silicon chip is a small piece of silicon containing an integrated circuit, which is part of a computer or other electronic equipment.

2、 What is semiconductor

Semiconductors refer to materials with conductivity between conductors and insulators at room temperature. For example, diodes are devices made of semiconductors. Semiconductor is a material whose conductivity can be controlled from insulator to conductor.

Whether from the perspective of science and technology or economic development, the importance of semiconductors is very great. Today, the core units of most electronic products, such as computers, mobile phones or digital recorders, are closely related to semiconductors. Common semiconductor materials include silicon, germanium, gallium arsenide, etc., and silicon is one of the most influential semiconductor materials in commercial applications.

There are many forms of matter, such as solid, liquid, gas, plasma, etc. We usually call materials with poor conductivity, such as coal, artificial crystals, amber, ceramics, etc., insulators. Metals with good conductivity, such as gold, silver, copper, iron, tin, aluminum, are called conductors. The material between conductor and insulator can be simply called semiconductor

3、 What is integrated circuit

Integrated circuit is a kind of micro electronic device or component. Using a certain process, the transistors, resistors, capacitors, inductors and other components and wiring required in a circuit are interconnected, fabricated on a small or several small semiconductor chips or dielectric substrates, and then packaged in a shell to become a micro structure with the required circuit functions; All the components have formed a whole in structure, making the electronic components a big step towards miniaturization, low power consumption, intelligence and high reliability. It is represented by the letter "IC" in the circuit.

The inventors of integrated circuits are Jack Kilby (integrated circuit based on germanium (GE)) and Robert neuth (integrated circuit based on silicon (SI)). Nowadays, silicon-based integrated circuits are widely used in semiconductor industry.

Integrated circuit is a new type of semiconductor device developed from the late 1950s to 1960s. It is an electronic device that integrates the semiconductors, resistors, capacitors and other components required to form a circuit with certain functions and the connecting wires between them on a small piece of silicon after oxidation, lithography, diffusion, epitaxy, aluminum evaporation and other semiconductor manufacturing processes, and then welds and packages them in a shell. Its packaging shell has many forms, such as round shell type, flat type or dual in-line type.

Integrated circuit technology includes chip manufacturing technology and design technology, which is mainly reflected in the ability of processing equipment, processing technology, packaging and testing, mass production and design innovation.

4、 What is the difference between a chip and an integrated circuit?

The emphasis to be expressed is different.

A chip is a chip. Generally, it refers to a piece with many small feet that you can see with the naked eye or that you can't see with your feet, but it is obviously square. However, chips also include all kinds of chips, such as baseband, voltage conversion and so on.

The processor emphasizes function more, which refers to the unit that executes processing, which can be said to be MCU, CPU, etc.

The scope of integrated circuit is much wider. Integrating some resistance capacitance diodes together is an integrated circuit, which may be an analog signal conversion chip or a logic control chip, but in general, this concept is more inclined to the underlying things.

Integrated circuit refers to the electronic circuit in which the active components, passive components and their interconnections are made on the semiconductor substrate or insulating substrate together to form a structurally closely related and internally related example. It can be divided into three main branches: semiconductor integrated circuit, film integrated circuit and hybrid integrated circuit.

Chip is the general term of semiconductor component products. It is the carrier of integrated circuit (IC), which is divided by wafer.

5、 What is the relationship and difference between semiconductor integrated circuits and semiconductor chips?

Chip is an abbreviation of integrated circuit. In fact, the real meaning of the word chip refers to a little bit of large semiconductor chip inside the integrated circuit package, that is, die. Strictly speaking, chips and integrated circuits cannot be interchanged. Integrated circuits are made through semiconductor technology, thin film technology and thick film technology. All circuits with certain functions that are miniaturized and made in a certain package can be called integrated circuits. A semiconductor is a substance between a good conductor and a bad conductor (or insulator).

Semiconductor integrated circuits include semiconductor chips and peripheral related circuits.

Semiconductor integrated circuit is to interconnect active components such as transistors, diodes and passive components such as resistors and capacitors on a single semiconductor chip according to a certain circuit, so as to complete specific circuit or system functions.

A semiconductor device that can realize a certain function is made by etching and wiring on a semiconductor sheet. Not only silicon chips, but also common semiconductor materials such as gallium arsenide (gallium arsenide is toxic, so don't be curious about decomposing some inferior circuit boards), germanium, etc.

Semiconductors are also trendy like cars. In the 1970s, American enterprises such as Intel gained the upper hand in the dynamic random access memory (D-Ram) market. However, due to the emergence of large computers, Japanese enterprises were among the best in the 1980s when high-performance D-Ram was needed.

According to the introduction of the chip failure analysis laboratory, it can implement the testing work according to international, domestic and industrial standards, carry out the comprehensive testing work from the underlying chip to the actual product, from physics to logic, and provide chip pretreatment, side channel attack, optical attack, intrusive attack, environment, voltage burr attack, electromagnetic injection, radiation injection, physical security, logical security, function Compatibility, multi-point laser injection and other safety testing services. At the same time, it can carry out failure analysis and testing services to simulate and reproduce the failure of intelligent products and find out the failure causes, mainly including probe station, reactive ion etching (RIE), micro leakage detection system (Emmi), X-ray detection, defect cutting observation system (FIB system) and other testing tests. Realize the evaluation and analysis of the quality of intelligent products, and provide quality assurance for chips, embedded software and applications of intelligent equipment products.

Prepare your supply chain

Buyers of electronic components must now be prepared for future prices, extended delivery time, and continuous challenge of the supply chain. Looking forward to the future, if the price and delivery time continues to increase, the procurement of JIT may become increasingly inevitable. On the contrary, buyers may need to adopt the "just in case" business model, holding excess inventory and finished products to prevent the long -term preparation period and the supply chain interruption.

As the shortage and the interruption of the supply chain continue, communication with customers and suppliers will be essential. Regular communication with suppliers will help buyers prepare for extension of delivery time, and always understand the changing market conditions at any time. Regular communication with customers will help customers manage the expectations of potential delays, rising prices and increased delivery time. This is essential to ease the impact of this news or at least ensure that customers will not be taken attention to the sudden changes in this chaotic market.

Most importantly, buyers of electronic components must take measures to expand and improve their supplier network. In this era, managing your supply chain requires every link to work as a cohesive unit. The distributor of the agent rather than a partner cannot withstand the storm of this market. Communication and transparency are essential for management and planning. In E-energy Holding Limited, we use the following ways to hedge these market conditions for customers:

Our supplier network has been reviewed and improved for more than ten years.

Our strategic location around the world enables us to access and review the company's headquarters before making a purchase decision.

E-energy Holding Limited cooperates with a well -represented testing agency to conduct in -depth inspections and tests before delivering parts to our customers.

Our procurement is concentrated in franchise and manufacturer direct sales.

Our customer manager is committed to providing the highest level of services, communication and transparency. In addition to simply receiving orders, your customer manager will also help you develop solutions, planned inventory and delivery plans, maintain the inventory level of regular procurement, and ensure the authenticity of your parts.

Add E-energy Holding Limited to the list of suppliers approved by you, and let our team help you make strategic and wise procurement decisions.

2 notes

·

View notes