#automotive bumpers market

Text

brang new bumpers available

#300#707#dodge#challenger#dodgechallenger#dodgechallengersxt#dodgechallengersxtplus#blacktoppackage#black#car#dodgeram1500#dodgetrucks#automotive bumpers market#car bumpers#car spare parts#bumpers#dodgeram#dodge cars

0 notes

Text

#Automotive Elastomer Bumper Market#Automotive Elastomer Bumper Market Size#Automotive Elastomer Bumper Market Share#Automotive Elastomer Bumper Market Trends#Automotive Elastomer Bumper Market Forecast#Automotive Elastomer Bumper Market Statistics

0 notes

Text

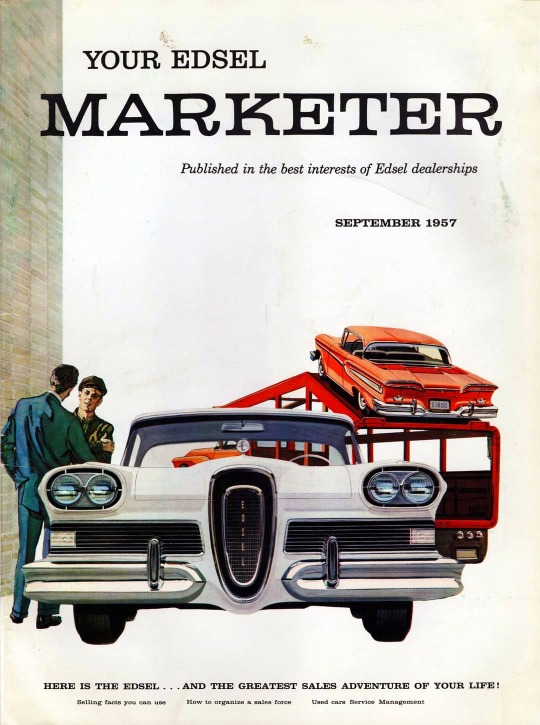

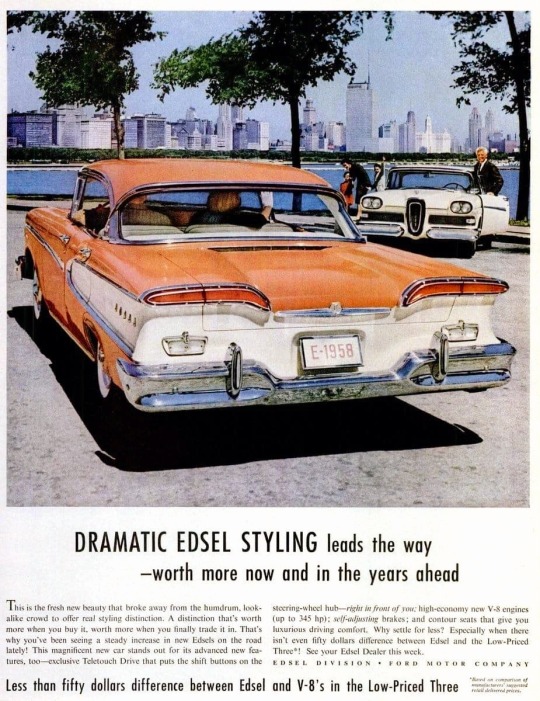

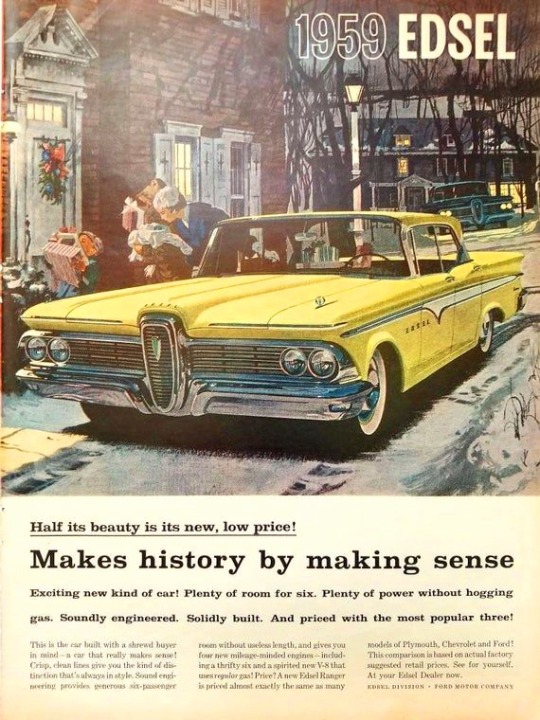

🇺🇲 Explore the intriguing history of the Ford Edsel—a car that captivated the automotive world with its bold design and innovative features! Introduced in 1956, the Edsel was envisioned as a revolutionary addition to the American automobile market.

🎩 Edsel was a division and brand of automobiles that was produced by the Ford Motor Company. Named after Edsel Ford, the son of company founder Henry Ford, the Edsel was intended to fill the gap between Ford and Mercury, offering consumers a new level of luxury and sophistication. With its distinctive styling and advanced engineering, the Edsel was poised to make a splash in the competitive automotive landscape.

🚘 Despite high expectations and extensive marketing campaigns, the Ford Edsel faced numerous challenges upon its release. Its unconventional design, characterized by a unique grille and distinctive "horse collar" front bumper, divided opinion among consumers and critics alike.

⚙️ Under the hood, the Edsel boasted a range of powerful engines and innovative technologies, including the "Teletouch" automatic transmission and "E-475" V8 engine. However, production delays and quality control issues tarnished its reputation in the eyes of consumers, leading to disappointing sales figures.

💔 The launch of the Ford Edsel on "E-Day" in September 1957 remains one of the most highly anticipated events in automotive history. Despite the initial hype, the Edsel failed to resonate with buyers, leading to its discontinuation in 1960 after just three model years.

🌟 Although the Ford Edsel may not have achieved commercial success, it remains a fascinating chapter in the annals of automotive history, showcasing the risks and challenges inherent in innovation and design.

#brits and yanks on wheels#retro cars#transatlantic torque#vehicle#cars#old cars#brands#companies#automobile#american cars#ford#edsel ford#edsel#ford motor company#michigan#made in usa#usa#made in america#american auto#old car#cool cars#classic cars#muscle car#car#v8#disivion#automotive#1950s cars#1950s#history

42 notes

·

View notes

Text

Sir Vival, the two-piece safety Hudson

Sir Vival, Walter Jerome's Hudson-based concept for the ultimate safety car, last moved under its own power sometime around when he showed the car at the New York World's Fair in 1964 or 1965. Since then, it's been split apart, reassembled, shuffled all over eastern Massachusetts, and remained hidden more or less in plain sight, but nobody's made an attempt to get it running again. That'll change now that longtime owner Ed Moore of Bellingham Auto Sales has sold Sir Vival to Jeff Lane of the Lane Motor Museum.

"It'll be the perfect fit," Lane said. "I've been pestering him about it for a while."

Moore, as we reported in November, has decided to close the doors at Bellingham, which he considers the last active Hudson dealership in the world, and has been either selling off his inventory of cars and parts or transferring portions of his lifelong collection to his house nearby.

In 1958, Worcester-based Walter Jerome decided it was about time somebody built a car designed primarily for safety and not for looks or speed. Rapidly increasing numbers of highway deaths - especially in the postwar period - led many to call for greater automotive safety as early as 1947, but the response from Detroit was tepid at best throughout the Fifties. Ford made a few gestures at improving automotive safety, including funding a study on safety cars at Cornell, but it largely fell to independents and individuals to build cars with safety features designed into the vehicle.

Jerome decided to start with a step-down Hudson - which he bought from Bellingham - and split it into two sections "to anticipate the possibility of collision from any angle." Similar to Bela Barenyi's idea for the crumple zone, Jerome intended the front section, mounted via a hinge to the rear section, to absorb a collision rather than deflect one, noting that the rigidity of typical cars was what led to injuries and deaths in collisions. To each of the two sections, Jerome added steel bumpers that acted, in his words, like a second frame, and rubber bumpers around the steel designed to redirect all but direct collisions. Yes, he built a full-size bumper car.

He didn't stop there. The driver controlled the car from a turret-mounted central driver's seat surrounded by a "full circle" windshield for greater visibility. (According to Jerome's literature, the windshield itself rotated past stationary windshield wipers as part of Jerome's quest for maximum driver visibility.) The exterior is fitted with high-visibility marker and signal lamps; the parallelogram doors are designed not to pop open in a crash; and the interior features seat belts, padding, and even a rollbar.

"It is all too obvious that Detroit has no plans to come up with anything really new," Jerome wrote. "Their 1964 cars are already on the drawing boards and spring from the same rigid frames. I hold that human life is important, far more important than Detroit's worry about the cost of retooling to produce an automobile which will save human lives. Adoption of the flexible Sir Vival design would make rigid vehicles obsolete and create a new market, almost immediately, for 65 million vehicles."

Moore and his family assisted Jerome over the years with Sir Vival, including one episode Moore recalls in which he went to Worcester to retrieve the vehicle from the fourth floor of a warehouse, where Jerome had stored it in two pieces, so it could be reassembled and transported to Jerome's house on Cape Cod. After Jerome's death in the early 1970s, the Moores took possession of Sir Vival and brought it back to Bellingham. While Moore had hoped Sir Vival would have gone to Eldon Hostetler's Hudson museum, it turned out fortuitous that he didn't donate it to Hostetler, given that the museum was closed and liquidated in 2018. Sir Vival has thus primarily sat in its pride of place in Bellingham Auto Sales's garage ever since.

"It needs gone right through," Moore said. "It's not really something I want to take home and just let it sit there. Jeff, he's the guy who'd really appreciate it. He'll build it and do it right."

Lane said he's only seen Sir Vival once in person, when he spent an entire day up at Bellingham Auto Parts four or five years ago. "I recall it as not terrible, but also not in great condition," he said. "It's not like it's been outside for 40 years, rusting away." While he won't have a more definitive plan about what to do with Sir Vival until he picks it up later this month, he said he wants to go through it mechanically without restoring the entire car, if possible.

"I'd say the closest it comes to any other vehicle in the (Lane Motor Museum's) collection is the Dymaxion," Lane said. "It's a really interesting story but it's really been pretty much hidden away from the general public."

Moore, for his part, said he'll continue selling Hudsons from his home garage even after the Bellingham Auto Sales property becomes a warehouse. "I still have my new and used car licenses," he said. "I know I can't keep them all, but I've tried."

UPDATE (6.January 2023): The Lane has started restoration on Sir Vival, according to a Facebook post from the museum. "Sir Vival has been separated into two pieces, and the automotive archaeology begins!"

22 notes

·

View notes

Photo

First Look: The Ferrari Purosangue

After years of anticipation by the international automotive fraternity, Ferrari has unveiled the Purosangue, the first ever four-door, four-seater car in the Prancing Horse’s 75-year history.

Since the marque’s earliest years, 2+2 cars (i.e. with two front and two smaller back seats) have played a significant role in its strategy. Many Ferraris have made combining benchmark performance with first class comfort one of the pillars of their success. Now, in the culmination of 75 years of leading-edge research, Ferrari has created a car that is unique on the world stage: not only do performance, driving pleasure and comfort coexist in perfect harmony, but it is also a peerless encapsulation of the Prancing Horse’s iconic DNA. This is the reason why the name Purosangue, Italian for ‘thoroughbred’, was chosen.

To enable the company to achieve the ambitious goals set for this project and create a car worthy of a place in its range, a completely different layout and innovative proportions compared to modern GT archetypes (so-called crossovers and SUVs) were adopted. The average modern GT’s engine is mounted forwards in the car, almost straddling the front axle with the gearbox coupled directly to it; this results in less than optimal weight distribution that delivers driving dynamics and driving pleasure well short of the standards of excellence to which Prancing Horse clients and enthusiasts have become accustomed.

The Purosangue, on the other hand, has a mid-front-mounted engine with the gearbox at the rear to create a sporty transaxle layout. The Power Transfer Unit (PTU) is coupled in front of the engine to provide a unique 4×4 transmission. This delivers exactly the 49:51% weight distribution that Maranello’s engineers deem optimal for a mid-front-engined sports car.

The Purosangue stands head and shoulders above the rest of the market thanks to its performance and comfort. It is the only car with these proportions to sport a mid-front-mounted, naturally-aspirated V12. Maranello’s most iconic engine debuts in this brand new configuration to ensure the car unleashes more power than any other in the segment (725 cv) whilst guaranteeing the most enthralling Ferrari engine soundtrack. Furthermore, it can deliver 80% torque even at low revs for unique driving pleasure at all times.

The Purosangue’s aero development focused on making the bodywork, underbody and rear diffuser as efficient as possible. New solutions include synergy between the front bumper and wheel arch trim which generates an air curtain that aerodynamically seals the front wheels, preventing turbulent transverse air flows being generated.

Ferrari has also given the Purosangue the very latest iterations of the vehicle dynamic control systems introduced on its most powerful and exclusive sports cars, including independent four-wheel steering and ABS ‘evo’ with the 6-way Chassis Dynamic Sensor (6w-CDS). Making its world debut is the new Ferrari active suspension system. This very effectively controls body roll in corners as well as the tyre contact patch over high-frequency bumps to deliver the same performance and handling response as in one of the marque’s sports cars.

The all-new chassis has a carbon-fibre roof as standard to keep weight down and lower the centre of gravity. Redesigning the bodyshell from scratch also meant the designers could incorporate rear-hinged back doors (welcome doors) to make ingress and egress easier while keeping the car as compact as possible. The cabin has four generous heated electric seats that will comfortably accommodate four adults. The boot is the largest ever seen on a Ferrari and the rear seats fold to increase the luggage space. Naturally enough, the Purosangue has a more commanding driving position than other Ferraris, but the configuration is the same as on every other Ferrari. As a result, the driving position is still intimate and close to the floor to provide greater connection to the car’s dynamic capabilities.

The Purosangue offers class-leading performance figures (from 0 to 100 km/h in 3.3 s and from 0 to 200 in 10.6 s); the driving position and the heady, naturally-aspirated V12 soundtrack deliver an entirely new yet also entirely Ferrari driving experience. The fact that a vast array of comfort-focused content is provided as standard, such as the Burmester© audio system, and that the many optional extras including the brand-new Alcantara® upholstery, derived from certified recycled polyester, make the Purosangue the most complete four-door, four-seater in the segment.

192 notes

·

View notes

Text

Upgrade Safely: Find Quality Used Car Bumpers for a Stylish Ride

Introduction:

In the world of automotive customization, upgrading your ride is not just about enhancing performance; it's also about making a statement. One often overlooked yet crucial aspect of this process is upgrading your car's bumpers. A stylish, well-maintained bumper not only adds to the aesthetics of your vehicle but also plays a vital role in ensuring safety on the road. In this blog, we'll explore the benefits of upgrading your car bumpers and why finding quality used ones is a smart and sustainable choice.

The Importance of Bumpers:

Car bumpers serve as the first line of defense in case of a collision, absorbing impact and protecting both the vehicle and its occupants. However, they are more than just safety features; they contribute significantly to the overall design and appeal of your car. Upgrading your bumpers can transform the entire look of your vehicle, giving it a unique and personalized touch.

Stylish Upgrades on a Budget:

While many car enthusiasts dream of customizing their vehicles, budget constraints can be a significant hurdle. Fortunately, there's a cost-effective solution – opting for quality used car bumpers. Contrary to common misconceptions, used bumpers don't mean compromising on quality. With a little research and the right approach, you can find bumpers that not only enhance your car's appearance but also meet safety standards.

Benefits of Choosing Used Bumpers:

Cost-Effective Solution: New car bumpers can be expensive, especially if you're looking for high-quality materials and unique designs. Choosing used bumpers allows you to achieve the desired look without breaking the bank.

Sustainability: Opting for used bumpers is an eco-friendly choice. By reusing existing parts, you contribute to reducing the demand for new manufacturing, ultimately decreasing the environmental impact associated with automotive production.

Compatibility: Finding the right fit for your make and model is often easier with used bumpers. Original equipment manufacturer (OEM) bumpers from the same model year can seamlessly replace your existing ones, ensuring a perfect fit and finish.

Wide Variety: The used car parts market offers a vast array of options, allowing you to explore various styles and designs that might not be available in the new aftermarket. This diversity enables you to create a truly unique look for your vehicle.

Reliability: Many used bumpers come from vehicles that have been involved in minor accidents, resulting in minimal damage to the bumper itself. These parts are often in excellent condition and can offer the same level of protection as a new bumper.

Conclusion:

Upgrading your car bumpers for a stylish ride doesn't have to be a costly or environmentally unfriendly endeavor. By choosing quality used bumpers, you not only save money but also contribute to the sustainable use of resources. So, the next time you're considering a makeover for your vehicle, explore the world of used car bumpers – a smart and stylish choice for both your budget and the planet.

2 notes

·

View notes

Text

Electric Vehicle Plastics Market: An In-Depth Exploration and its Contribution to a Circular Automotive Industry

The global electric vehicle plastics market size was estimated at USD 13.33 billion in 2030 and is anticipated to grow at a compound annual growth rate (CAGR) of 28.0% from 2024 to 2030. The industry is projected to witness significant growth in terms of consumption, on account of high application scope and increasing demand from the growing population. The Polypropylene (PP) resin demand in the Asia Pacific region is estimated to grow at the fastest CAGR over the forecast period. Strong government support & initiatives regarding emissions and increasing investment by manufacturers are propelling the growth of the region.

Electric Vehicle Plastics Market Report Highlights

The Asia Pacific region is estimated to grow at the fastest CAGR from 2022 to 2030. Increasing demand from the growing population coupled with environmental concerns among others are anticipated to drive market growth in the region

The battery segment is anticipated to register the fastest CAGR from 2022 to 2030. Batteries are one of the significant components of an EV and, in comparison to combustion engines, battery vehicles do not produce any emissions and are eco-friendly. The growing demand for EVs has promising growth for EV batteries

The exterior application segment accounted for the largest revenue share in 2021 and is estimated to continue its dominance over the forecast period due to the high demand in aesthetics

The BEV vehicle type segment led the industry in 2021 and it is anticipated to continue growing over the forecast period as PHEVs have higher maintenance costs than BEVs

For More Details or Sample Copy please visit link @: Electric Vehicle Plastics Market Report

Furthermore, EVs are efficient and require less maintenance as compared with traditional vehicles. These factors are expected to boost the demand for EVs, which is expected to drive the demand for plastics over the forecast period. Increasing utilization of plastics in EVs is anticipated to boost industry growth positively over the forecast period. Plastics have proven to perform well under harsh conditions through their resistance to shock, moisture, oxidation, and further maintaining their chemical and mechanical properties. Plastics will be crucial material for manufacturing lightweight and energy-efficient EVs. Based on resin type, PP is expected to witness major demand during the projected years.

Polypropylene is used in many components of the vehicle including bumpers, carpet fibers, cable insulation, and others. Properties, such as good heat, chemical & fatigue resistance, and others, are anticipated to drive the demand for PP in the industry. Major manufacturers are adopting expansion strategies, such as new product development, production facility expansions, mergers & acquisitions, and joint ventures. For instance, in October 2021, DuPont launched a new extension of its existing Zytel HTN range, named as Zytel 500 series. These products are developed to provide enhanced retention properties in e-mobility oils, electrically friendly characteristics, and a high Comparative Tracking Index (CTI).

EVPlastics #ElectricVehicles #SustainableDriving #EcoFriendlyCars #ElectricVehicleTech #CleanTransportation #GreenMobility #EVInnovation #PlasticsInEVs #FutureOfTransport #SustainableMaterials #EcoAutoDesign #EVManufacturing #PolymerInnovation #ZeroEmissionVehicles #GreenTechAuto #CleantechPlastics #EVDesign #EcoFriendlyPlastics #CircularAutoEconomy

#EV Plastics#Electric Vehicles#Sustainable Driving#Eco-Friendly Cars#Electric Vehicle Tech#Clean Transportation#Green Mobility#EV Innovation#Plastics In EVs#Future Of Transport#Sustainable Materials#Eco Auto Design#EV Manufacturing#Polymer Innovation#Zero Emission Vehicles#Green Tech Auto#Cleantech Plastics#EV Design#Eco-Friendly Plastics#Circular Auto Economy

2 notes

·

View notes

Text

The Most Complete Summary of Thermoforming

Thermoforming process is a kind of processing method to adsorb the plastic sheet or plastic film on the surface of the mold through suction after heating and softening, and then form the required products after cooling. Thermoforming process has the advantages of low cost, high production efficiency, short production cycle, and so on, so in the modern industrial production has been widely used.

Through continuous development and changes, the vacuum forming process has now become highly automated and mechanized. Through continuous improvement of the vacuum forming equipment, we have improved the temperature control of the vacuum forming machine and the technical difficulties of the transmission method, and solved the process technology of the high tensile and high-precision vacuum forming products, including solving the problem of the processing technology of different plastic materials as well as the thick sheet materials.

Principles of Thermoforming

Thermoforming is the use of thermoplastic materials, the plastic manufacturing process shell products method, is the plastic sheet cut to a certain size after heating and softening, with the help of the sheet on both sides of the air pressure difference and mechanical pressure, so that the deformation of the deformation of the mold profile in a specific affixed to the surface, after the cooling of the mold, and cut edge trimming to complete the desired shape products process.

There are several thermoforming methods used in actual production, and the most basic ones are six: differential pressure forming, overmolding, plunger-assisted molding, suction molding, countermolding, and twin sheet forming.

In the process, heated sheet, and then the air between it and the mold is quickly extracted, resulting in a vacuum state, forming a pressure difference, so that the plastic sheet is adhered to the mold's molding surface, and then the plastic material is cooled and shaped, and then cut and trimmed to become the required individual products.

Thermoforming Equipment

Classification According to Sheet Thickness

Thick Gauge Thermoforming

Thick gauge thermoforming common products are: household appliance liner shell, luggage, display rack accessories, decoration, automotive interior, bumpers, fenders, beauty equipment, light box shell, toy car shell, industrial panels, advertising light boxes, thermoforming LOGO, sanitary products, refrigerator liner and so on.

Thin Gauge Thermoforming

The common products on the market are: daily necessities thermoforming packaging, small hardware thermoforming packaging, automotive thermoforming packaging, electronic products thermoforming packaging, food thermoforming packaging, cosmetic thermoforming packaging, computer peripherals thermoforming packaging, toys thermoforming packaging, sporting goods thermoforming packaging, stationery thermoforming packaging and so on.

The main structure of the machine is composed of feeding, pulling, upper and lower electric heating furnace, lower gate, multifunctional adjustable size, lower mold plate, upper mold, upper gate, knife gate, slicing, releasing and with a vacuum device, etc., pneumatic device as the main source of power, and pulling the piece, sending the piece of electric power, speed reducer, time relays, intermediate relays, travel switches and other electrical appliances to form a full-automatic control system.

Different Pressurization Methods

According to the different pressurization methods of thermoforming, the mainstream thermoforming equipment is mainly divided into the following three categories.

1. Vacuum negative pressure thermoforming machine, mainly through the negative pressure vacuum way, makes the plastic material affixed to the mold.

2. Positive pressure thermoforming, through the air compressor on the front of the plastic sheet with atmospheric pressure, so that the softened plastic sheet affixed to the mold.

3. Positive and negative pressure thermoforming machine, is through the way of pressure and vacuum, in the plastic sheet on both sides of the formation of a strong pressure difference, so that the softening of the plastic material molding method.

These three kinds of equipment, each has its own advantages and disadvantages, according to the characteristics of the product on the machine to choose.

Different Forming Steps

According to the forming steps, thermoforming equipment can be divided into two categories

1. One-step forming machine, is the plastic material heating, plastic absorption forming, die-cutting process into one, high production efficiency, suitable for quality requirements are not high thermoforming products.

2. Two-step forming machine, is the plastic sheet heating, thermoforming process and die-cutting processing separately, suitable for higher quality requirements of thermoformed products.

Thermoforming Technology

To produce a good quality plastic products, need to pay special attention to two points: one is the thermoforming mold, the second is the processing requirements.

Mold

Thermoforming molds play a very important role for the advantages and disadvantages of thermoforming products, thermoforming molds can be divided into three kinds of molds: positive mold, negative mold and positive and negative mold.

Both negative and positive mold are a type of plastic processing that uses thermoplastic material to form products through the thermoforming process. The negative mold is characterized by a concave bottom of the mold, and the workpiece is softened by heating above the mold and is adsorbed at the bottom of the mold to form the product. On the other hand, the positive mold is convex at the bottom of the mold, and the workpiece is adsorbed at the top of the mold after being heated and softened underneath the mold to form the product.

For positive mold, the inner size of the product is very accurate, because it is the side that connects with the vacuum mold tool. On the contrary, for negative mold, the outer dimensions of the part are precise because it is in contact with the vacuum forming tool on the outside.

The negative mold production of the product does not fit with the cavity wall side of the better quality, the thinnest part of the cavity side and the bottom of the junction, and with the increase in the depth of the cavity products at the bottom of the corner of the wall becomes even thinner, so in the processing of deeper products, there should be a correspondingly large opening area.

The maximum part of the wall thickness of the products produced by the male mold is at the top of the male mold, and the thinnest part is at the junction of the side and bottom of the male mold, which is also the last part of the molding process, the side of the products often appear stretching and cooling stripes, resulting in stripes is due to the various parts of the sheet to fit the mold surface, the first part of the first contact with the surface of the die first cooled by the mold and produce stripes, and in the process of the subsequent related to the cavity, is drawn to the sides of the mold cavity. This streaking is usually highest at the sides near the top of the mold face and affects the appearance of the thermoforming product.

Advantages of Positive Mold

1. Product surface is smooth and good quality

2. Low mold investment cost, long mold life

Disadvantages of Positive Mold

1. Only suitable for manufacturing simple geometries;

2. Unable to manufacture larger size workpieces.

3. Since the pattern is pre-made, the pattern effect will be lost during the skin stretching process. Where the stretching is high, the pattern becomes shallow or even disappears.

4. There is a limitation on the R angle of the parts.

Advantages of Negative Mold

1. Enables the manufacture of more detailed and complex workpieces.

2. Larger size workpieces can be manufactured.

3. Low cost of mold making and use.

4. Better surface pattern effect.

Disadvantages of Negative Mold

1. Lower material utilization rate.

2. Product surface quality may be problematic.

3. Higher mold investment costs and equipment requirements.

Attention to the Production of Positive Molds

1. When processing with high right angle molds, especially when the height of the mold is high, it is easy to produce draw line wrinkles.

2. Tend to produce cooling streaks at the corners.

3. Uneven wall thickness at the male edge.

4. Difficulty in demolding due to insufficient sidewall slope.

Attention to the Production of Negative Molds

1. Uniformity of edge thickness.

2. Thinner corner parts should be carefully watched not to perforate.

How to Choose Between Negative or Positive Mold

The choice of negative or positive mold depends on the production needs matched mold forming. If complex workpieces or larger sizes need to be produced, negative mold thermoforming is more suitable. If you need to produce simple geometries or products with high surface quality, or if you require high production efficiency, then positive mold is more suitable.

Overall, both negative and positive mold have their own advantages and disadvantages, different situations to choose different processing methods to better meet the production needs.

Process Requirements

De-molding Slope

In order to be able to release the mold smoothly, the sides of the mold must have a certain degree of inclination. In the direction of demolding, the inclination of the side of the mold is called demolding inclination. Demolding inclination should be made as large as possible, the larger the demolding inclination, the faster the demolding, the shorter the molding cycle, and in the process of demolding the product deformation possibility is small, demolding inclination is generally greater than 1 degree.

Aspect Ratio

The ratio of the width of the mold to its depth is usually called the aspect ratio. Generally speaking, because the male mold can have drag and pre-stretching effect on the sheet, the height of molding with the male mold can be slightly smaller, but not less than 1. The width-to-height ratio of molding with the female mold is usually not less than 1.4.

Forming Area and Product Area

Forming area refers to the range of length and width area inside the clamping frame, product area refers to the area where traction stretching occurs during the molding process, which mainly depends on the specification size of the thermoforming product. In the heating process, the stretching part needs to be heated, and its stretching range is larger, and for the non-product area with less heating, the amount of stretching is also smaller. It should be noted that uneven heating will also cause the problem of uneven shrinkage and deformation of the thermoforming product after molding and cooling.

Exhaust Surfaces, Exhaust Holes, Exhaust Slots

In the vacuum forming process, in order to remove the gas stored between the plastic material and the mold, the mold must be able to exhaust or have enough exhaust holes or exhaust grooves; this allows the air to be removed quickly through the extraction device (or transfer).

Therefore, in the thermoforming process, it is necessary to ensure that the vacuum system of the vacuum forming equipment can maintain a sufficient amount of vacuum to ensure that the plastic sheet is heated and softened, there can be enough vacuum suction is the plastic material can be completely adhered to the surface of the mold.

On the other hand, it is necessary to exhaust holes, exhaust grooves and other channel systems to maintain a smooth state, to avoid clogging due to foreign objects leading to a reduction in the degree of vacuum, resulting in the pressure forming is not in place.

Shrinkage Deformation of Thermoforming

In the process of thermoforming production, there will be frequent cases of product shrinkage and deformation, which need special treatment for different situations. After heating the molding, cooling stage through the mold shaping and maintain the amount of vacuum, can make the size of the thermoforming products will not change too much, but after demolding due to temperature changes, the size of the contraction deformation will occur to a certain extent, and will be with the increase in time contraction deformation will be greater. After 24 hours of molding, the shrinkage situation is basically stable, and the size measured at this time is more accurate.

Application

Thermoforming Automotive Industry

Automobile interior parts, motorcycle decorative plate, electric scooter shell, car hood, logistics turnover tray, tool car shell.

Food, Medical, Home Appliance industry Thermoforming

Thermoforming food trays (egg trays, fast food containers, cup lids, food preservation trays, etc.), cosmetics and other thermoforming packaging, refrigerator liner thermoforming, bathtubs, electronic trays, door panels, medical appliances, lamps, etc.

With the development of plastic thermoforming industry, the thermoforming of the application field is also more and more extensive, from the beginning of the thin sheet of thermoforming to the current alternative to the injection molding machine products of the thick sheet of thermoforming, from simple thermoforming of food trays, electronic trays to the current logistics thermoforming turnover trays, hardware, plastic, and so on. From the simple thermoforming food tray, electronic tray to the current logistics thermoforming turnover tray, hardware tools car, cooling water tower piece, bathtubs, and to the inward ride of the car's thermoforming parts and so on, from the original thermoforming packaging products to become a part of the product thermoforming, it can be said that now plastic thermoforming products are everywhere in our lives.

Conclusion

Pressure forming process as a very mature thermoforming technology has reached a wide range of applications, in the use of its advantages are low mold processing costs, production time is short, high production efficiency, high output per unit of time; no exhaust, wastewater, waste emissions, in line with environmental protection requirements; can be made into a variety of shaped packages and transparent packaging, to solve the shortcomings of the paper packaging; suitable for mechanization, automation of the packaging, saving manpower.

With the development of plastic thermoforming industry, the thermoforming application field is also more and more extensive, from the beginning of the thin sheet thermoforming to the present can replace the injection molding machine products of thick plate thermoforming, from the simple thermoforming food trays, electronic trays to the present logistics thermoforming turnover trays, hardware tool carts, cooling water towers, bathtubs and inwardly ride the automobile's thermoforming parts, and so on, from the original thermoforming packaging products to become a part of the products of the thermoforming, it can be said that now the plastic thermoforming products are ubiquitous in our lives.

0 notes

Text

mg auto body parts dealer supplier in sharjah

Elevating Your Vehicle's Appeal: MG Auto Body Parts Dealer Supplier in Sharjah

In the vibrant automotive market of Sharjah, where discerning drivers seek to enhance their vehicles' performance and aesthetics, the demand for high-quality auto parts reigns supreme. Among the myriad of brands available, MG stands out for its blend of style, performance, and reliability. Whether you're a dedicated car enthusiast or a daily commuter, upgrading your vehicle with MG auto body parts can significantly elevate its appeal and functionality. And in this pursuit of automotive excellence, finding a trusted MG auto body parts dealer supplier in Sharjah becomes paramount. Enter Al Ajil Auto Parts UAE, your premier destination for authentic MG auto body parts in Sharjah.

Understanding the Essence of MG Auto Body Parts

MG, with its illustrious heritage dating back to the early 1920s, has carved a niche for itself as an iconic automotive brand synonymous with British craftsmanship and engineering excellence. From timeless classics to contemporary releases, MG vehicles exude elegance and sophistication, captivating drivers worldwide. However, like any automobile, MG cars may require maintenance and occasional upgrades to ensure optimal performance and appearance.

Auto body parts play a pivotal role in preserving a vehicle's design integrity while enhancing its functionality. Whether it's replacing damaged components, upgrading for performance gains, or customizing for personal preferences, selecting the right auto body parts is crucial for every MG owner. From bumpers and grilles to headlights and fenders, each part contributes to the overall aesthetic appeal and performance of the vehicle.

Al Ajil Auto Parts UAE: Your Trusted MG Auto Body Parts Dealer Supplier in Sharjah

In the dynamic automotive landscape of Sharjah, locating a reliable dealer supplier for MG auto body parts can be a daunting task. This is where Al Ajil Auto Parts UAE shines as a beacon of trust and quality. As a leading supplier of auto parts in the region, Al Ajil Auto Parts UAE has garnered a stellar reputation for its unwavering commitment to excellence, extensive product range, and unparalleled customer service.

At Al Ajil Auto Parts UAE, we recognize the unique needs of MG enthusiasts, which is why we stock a diverse selection of authentic MG auto body parts designed to meet the highest standards of quality and performance. Whether you're restoring a vintage MG or customizing a modern model, our comprehensive inventory caters to various MG models, ensuring compatibility and reliability with every purchase.

Why Choose Al Ajil Auto Parts UAE as Your MG Auto Body Parts Dealer Supplier in Sharjah?

Genuine Quality Assurance: We procure our MG auto body parts directly from reputable manufacturers, ensuring authenticity and superior quality with every product.

Extensive Product Range: From OEM replacements to aftermarket upgrades, our extensive inventory encompasses a wide range of auto body parts to suit your specific requirements.

Expert Guidance: Our team of automotive experts is dedicated to assisting you in finding the perfect MG auto body parts for your vehicle, offering professional advice and recommendations tailored to your needs.

Competitive Pricing: We believe in providing exceptional value to our customers. Our competitive pricing ensures that you get the best deals on genuine MG auto body parts without compromising on quality.

Convenient Ordering: With our user-friendly online platform, ordering MG auto body parts is effortless. Simply browse through our catalog, place your order, and enjoy doorstep delivery anywhere in Sharjah.

Experience Excellence with Al Ajil Auto Parts UAE

As a proud MG owner, you deserve nothing but the best for your beloved vehicle. Whether you're looking to restore its original splendor, enhance its performance, or customize its appearance, Al Ajil Auto Parts UAE is your trusted partner for all your MG auto body parts needs in Sharjah.

Discover the difference that genuine quality and exceptional service can make. Visit our website today to explore our extensive catalog of MG auto body parts and embark on a journey to elevate your driving experience with Al Ajil Auto Parts UAE, your preferred MG auto body parts dealer supplier in Sharjah.

0 notes

Text

0 notes

Text

Brand new and fairly used dodge bumpers

We sell à large variety of car numbers of all types and you are welcome to get to us if need be.

#dodgetrucks#ford#dodgechallenger#moparperformance#hellcat#camaro#srt8#mopar#dodgeram1500#dodgeram#bumpers#car bumpers#car spare parts#dodge cars#automotive bumpers market#LP

1 note

·

View note

Text

Chevy C10: A Cult Phenomenon

Did you know that the Chevy C10 has achieved cult status among truck enthusiasts?

With its timeless appeal and iconic design, the Chevy C10 has garnered a devoted following unlike any other.

What started as a reliable workhorse has transformed into a cultural phenomenon, capturing the hearts of both old-school classic aficionados and a new generation of truck enthusiasts.

In this article, we'll delve into the rich history of the Chevy C10, explore its enduring appeal, and uncover why it has become more than just a truck.

From its distinctive design to its exhilarating performance, we'll showcase why the Chevy C10 holds a special place in the hearts of enthusiasts across the country.

Key Takeaways:

- The Chevy C10 has achieved cult status among truck enthusiasts.

- Its iconic design and timeless appeal have made it a sought-after classic.

- The Chevy C10 offers exhilarating performance and power.

- Enthusiasts have a myriad of customization options to make their Chevy C10 unique.

- The enduring allure of the Chevy C10 has solidified its status as a cherished classic.

A Brief History of the Chevy C10

The Chevy C10 holds a special place in automotive history, being the predecessor to the iconic Silverado.

Its production spanned from 1960 to 1998, encompassing several generations and leaving a lasting impact on truck enthusiasts worldwide.

The story of the Chevy C10 begins in 1960 when Chevrolet introduced it as part of the C/K series, which aimed to provide a diverse range of trucks for different purposes.

The first generation of the C10 featured a smooth and timeless design, capturing the hearts of buyers with its combination of functionality and style.

Over the years, the Chevy C10 saw various updates and improvements, reflecting the changing needs and trends of the truck market.

The second generation, introduced in 1967, featured a more muscular and aggressive appearance, with a wider track and improved handling.

In 1973, the third generation of the Chevy C10 was unveiled, marking a major redesign that focused on safety and comfort.

With the introduction of energy-absorbing bumpers and a more spacious interior, the C10 became more user-friendly and appealing to a wider audience.

"The Chevy C10 is a testament to Chevrolet's commitment to innovation and progress. It has evolved over the years, incorporating advancements in technology and design to stay relevant in the ever-evolving automotive landscape."

In subsequent years, the Chevy C10 continued to receive updates and refinements, solidifying its status as one of the most popular trucks in America.

It became known for its reliability, durability, and versatility, attracting both commercial users and personal truck enthusiasts.

The Chevy C10 became an automotive icon, teaching the world that trucks could be more than just workhorses.

It symbolized freedom, adventure, and the American spirit of exploration.

Its timeless appeal and classic design make it a sought-after collectible among car enthusiasts and truck lovers alike.

Generation

Years

Notable Features

First Generation

1960-1966

Classic design, reliable performance

Second Generation

1967-1972

Muscular appearance, improved handling

Third Generation

1973-1987

Safety enhancements, spacious interior

Fourth Generation

1988-1998

Modernized design, increased comfort

Iconic Design and Timeless Appeal

Iconic Design and Timeless Appeal by autoambiente.com

When it comes to automotive design, few vehicles can match the enduring legacy of the Chevy C10.

Its iconic design and timeless appeal have captivated enthusiasts for decades, making it a sought-after classic in the truck world.

The Chevy C10 boasts a distinctive body style that perfectly blends form and function.

With its sleek lines, muscular fenders, and well-proportioned silhouette, this truck exudes a confident and powerful presence on the road.

Whether cruising through city streets or tackling rugged terrains, the Chevy C10 turns heads and commands attention at every turn.

One of the standout design elements of the Chevy C10 is its signature grille.

The bold and instantly recognizable front grille accentuates the truck's aggressive stance, adding a touch of sophistication to its overall appearance.

It is a testament to Chevrolet's commitment to meticulous craftsmanship and attention to detail.

But it isn't just the exterior design that makes the Chevy C10 an icon.

Step inside, and you'll find a thoughtfully designed cabin that seamlessly combines style and comfort.

With its ergonomic layout, high-quality materials, and intuitive controls, the interior of the Chevy C10 provides a driver-focused experience like no other.

As a beloved classic, the Chevy C10 transcends trends and time.

Its design stands as a testament to automotive excellence, with each element carefully crafted to withstand the test of time.

Whether showcased at a car show or cruising down the highway, the Chevy C10 continues to captivate hearts and evoke a sense of nostalgia with its timeless appeal.

Quote:

"The Chevy C10 is an automotive masterpiece, embodying the perfect blend of bold design and timeless appeal. Its distinctive body style, signature grille, and attention to detail make it a sought-after classic in the world of trucks." - Car Enthusiast Magazine

Iconic Design Elements

Distinctive Body Style

Signature Grille

Thoughtful Interior

The sleek lines and muscular fenders give the Chevy C10 a powerful presence on the road.

The bold and instantly recognizable front grille accentuates the truck's aggressive stance.

The ergonomic layout and high-quality materials create a comfortable and stylish cabin.

The C10's design is a testament to Chevrolet's commitment to craftsmanship and attention to detail.

The signature grille adds a touch of sophistication to the overall appearance.

The driver-focused interior provides an intuitive and enjoyable experience.

Table: Iconic Design Elements of the Chevy C10

Performance and Power: The Chevy C10 Experience

Performance and Power: The Chevy C10 Experience by autoambiente.com

Unleashing the Potential

One of the defining characteristics of the Chevy C10 is its exceptional performance capabilities.

From the moment you step on the gas pedal, you can feel the raw power coursing through its veins.

The Chevy C10 is built to deliver an exhilarating driving experience that leaves a lasting impression.

The engine options available for the Chevy C10 are a testament to its performance-driven nature.

Whether you opt for the V8 or the inline-six engine, you can expect a thrilling ride that never fails to impress.

With its robust horsepower and torque, the Chevy C10 effortlessly combines strength and agility.

A Thrill Behind the Wheel

Behind the wheel of a Chevy C10, you'll immediately understand why this truck has earned a reputation for its performance prowess.

The responsive handling and precise steering make every turn and maneuver a thrill.

The acceleration is quick, propelling you forward with a surge of power that pushes you back into your seat.

The Chevy C10 is not just a truck; it's a true mechanical marvel that guarantees an unforgettable driving experience.

Versatility for Work and Play

While the Chevy C10's performance capabilities are undeniably impressive, its versatility goes beyond the open road.

For those who rely on their trucks for work, the Chevy C10 offers a potent combination of power and practicality.

It can tackle tough jobs with ease, effortlessly hauling heavy loads and towing with confidence.

Even when the workday is done, the Chevy C10 doesn't shy away from adventure.

Its powerful engine and rugged build make it equally well-suited for off-road excursions and weekend getaways.

So whether you're heading to the job site or embarking on a thrilling outdoor adventure, the Chevy C10 is the perfect companion.

Unleash the Power of a Legend

The Chevy C10 is not just a truck; it's a performance powerhouse that embodies the spirit of true American muscle.

With its exceptional power, outstanding handling, and versatile nature, this legendary vehicle continues to captivate enthusiasts and impress drivers around the world.

Experience the thrill of the Chevy C10 and unleash its unparalleled power today.

Customization and Personalization: Making It Your Own

Customization and Personalization: Making It Your Own by autoambiente.com

When it comes to the Chevy C10, customization and personalization options abound, allowing enthusiasts to create a truly unique and personalized vehicle.

Whether you want to enhance its performance, upgrade its interior, or give it a head-turning exterior makeover, the Chevy C10 offers endless possibilities for customization.

Exterior Customization:

One of the easiest ways to personalize your Chevy C10 is by giving it a fresh coat of paint.

Whether you prefer a classic vintage look or a bold, modern color scheme, the choice is yours.

From vibrant reds to sleek metallic finishes, the options are limitless.

Additionally, you can add unique touches to the exterior with custom badges, emblems, and decals.

These small details can make a big difference in creating a customized look that reflects your personal style.

Interior Upgrades:

The interior of your Chevy C10 is where you spend the most time, so why not make it as comfortable and stylish as possible?

Upgrading the seats, installing a modern audio system, and adding custom upholstery are just a few of the ways you can personalize the interior to suit your taste.

Performance Modifications:

If you're looking to take your Chevy C10 to the next level in terms of performance, there are numerous modifications you can make.

From engine upgrades to suspension enhancements, these modifications can transform your Chevy C10 into a high-performance machine that delivers exhilarating power and handling.

Aftermarket Accessories:

To truly make your Chevy C10 stand out from the crowd, consider adding aftermarket accessories.

From upgraded wheels and tires to custom grilles and body kits, these accessories can give your Chevy C10 a unique and aggressive look that turns heads wherever you go.

By customizing and personalizing your Chevy C10, you can create a vehicle that not only represents your individuality but also captures the spirit of this iconic truck.

Conclusion

The Chevy C10 is not just a truck; it is a cult phenomenon that has captivated enthusiasts for decades.

With its rich history, iconic design, and powerful performance, the Chevy C10 has earned its status as a cherished classic.

From its origins to its evolution through different generations, the Chevy C10 has remained timeless, attracting a dedicated following of fans.

Its distinctive body style, signature grille, and other design elements continue to turn heads wherever it goes.

But it's not just about looks—the Chevy C10 delivers on the road too.

With a range of engine options, impressive horsepower, and torque, it offers an exhilarating driving experience that enthusiasts crave.

Its versatility makes it suitable for both work and play, further enhancing its appeal.

What truly sets the Chevy C10 apart is the ability to make it your own.

With a world of customization and personalization options available, enthusiasts can transform their Chevy C10 into a unique expression of their personality and style.

Whether you're a long-time fan or discovering the Chevy C10 for the first time, it's undeniable that this truck has left an indelible mark in automotive history.

Its enduring allure and fervent following are a testament to its timeless appeal.

The Chevy C10 is more than just a truck—it's a legend.

FAQ

Why is the Chevy C10 considered more than just a truck?

The Chevy C10 has gained a cult following and become a phenomenon among enthusiasts due to its iconic design, timeless appeal, and powerful performance.

What is the history of the Chevy C10?

The Chevy C10 has a rich history that spans several generations.

It was first introduced in 1960 and remained in production until 2002.

Over the years, the Chevy C10 has undergone various updates and enhancements, making it a beloved classic among truck enthusiasts.

What makes the Chevy C10's design iconic?

The Chevy C10 features a distinctive body style that sets it apart from other trucks of its time.

Its signature grille, sleek lines, and attention to detail contribute to its timeless appeal, making it a highly sought-after classic.

How powerful is the Chevy C10?

The Chevy C10 offers impressive performance with a range of engine options to choose from.

Its engines are designed to deliver ample horsepower and torque, ensuring a thrilling driving experience.

Whether for work or play, the Chevy C10 provides the power you need.

Can I customize my Chevy C10?

Absolutely! The Chevy C10 offers a wide range of customization and personalization options.

You can choose from various paint colors, upgrade the interior with modern amenities, and even modify the performance with aftermarket accessories.

Make your Chevy C10 truly your own.

What is the enduring allure of the Chevy C10?

The Chevy C10's enduring allure lies in its timeless design, powerful performance, and the ability to customize it to fit individual preferences.

It has cemented its status as a cherished classic among enthusiasts and continues to captivate truck lovers to this day.

Read the full article

0 notes

Text

Revolutionizing Industries with Plastic Extrusion Products and Wholesale Bumpers

In today's fast-paced industrial world, plastic extrusion products and bumpers wholesale are playing pivotal roles. Manufacturers are pushing the boundaries of innovation to meet the diverse needs of various sectors, from automotive to construction. These products stand out for their durability, versatility, and cost-effectiveness, making them indispensable in numerous applications.

Plastic extrusion technology has opened up a world of possibilities. It allows manufacturers to create complex profiles with precision and efficiency. This process involves melting raw plastic and forming it into a continuous profile, offering endless possibilities in shapes and sizes. Industries rely on these extruded products for components like pipes, frames, and rails, which are essential in everyday operations.

The demand for bumpers, particularly in the wholesale market, reflects the need for safety and durability in vehicles and machinery. Suppliers are responding by offering a wide range of bumpers, designed to absorb impact and protect against damage. These products are not just limited to the automotive industry; they also find applications in warehouses, loading docks, and anywhere that requires protection against collisions.

Innovation doesn't stop at product design. Manufacturers are continually exploring new materials to enhance the performance and sustainability of their offerings. The use of recycled plastics and eco-friendly materials is becoming more common, aligning with global efforts to reduce environmental impact.

Customer service is at the heart of the industry. Suppliers of plastic extrusion products and bumpers wholesale understand the importance of meeting client needs with precision. They offer customized solutions, ensuring that each product fits the specific requirements of their applications. This approach has built strong partnerships across industries, fostering growth and innovation.

In conclusion, the industries of plastic extrusion products and bumpers wholesale are vital in driving innovation and efficiency across sectors. Their commitment to quality, sustainability, and customer satisfaction continues to make them indispensable partners in industrial success.

Source

0 notes

Text

Thermoplastic Polyolefins (TPO) Market Assessment: Current Status and Outlook

Thermoplastic Polyolefins (TPO) have emerged as a versatile and high-performance material in the realm of polymers, offering a wide array of benefits across various industries. This blog aims to delve into the global TPO market, providing insights into its market dynamics, key applications, emerging trends, and future prospects.

Understanding Thermoplastic Polyolefins (TPO):

Thermoplastic Polyolefins (TPO) are a blend of polypropylene (PP) and ethylene-propylene rubber (EPR) or ethylene-propylene-diene monomer rubber (EPDM). This combination results in a material with exceptional properties, including high impact resistance, flexibility, UV resistance, and chemical resistance.

Market Dynamics:

Automotive Industry Dominance: TPO finds extensive use in the automotive sector, where its lightweight nature, durability, and design flexibility make it ideal for exterior and interior automotive parts, including bumper fascias, body panels, and interior trim components.

Building & Construction Applications: The construction industry utilizes TPO for roofing membranes, siding, and decking due to its weatherability, UV resistance, and ease of installation, contributing to the market's growth in this sector

Consumer Goods Manufacturing: TPO is employed in the manufacturing of various consumer goods such as appliances, furniture, and recreational equipment, benefiting from its impact resistance, aesthetics, and moldability.

Packaging Solutions: TPO is increasingly used in packaging applications, including containers, films, and closures, owing to its sealability, chemical resistance, and recyclability, driving demand in the packaging industry.

Applications Across Industries:

Automotive: Bumper fascias, body panels, interior trim components.

Building & Construction: Roofing membranes, siding, decking.

Consumer Goods: Appliances, furniture, recreational equipment.

Packaging: Containers, films, closures.

Market Trends:

Sustainability Drive: The TPO market is witnessing a shift towards sustainable solutions, with a growing demand for bio-based and recyclable TPO materials to address environmental concerns and regulatory requirements.

Technological Advancements: Ongoing research and development efforts focus on enhancing TPO formulations, improving processing techniques, and exploring novel applications, fostering innovation in the market.

Customization and Specialty Grades: Manufacturers are offering specialized TPO grades tailored to specific industry needs, incorporating additives and modifiers to enhance performance characteristics and meet diverse application requirements.

Future Prospects:

The global Thermoplastic Polyolefins market is poised for significant growth, driven by its versatile applications, technological advancements, and increasing demand across industries. As industries continue to seek materials that offer a balance of performance, sustainability, and cost-effectiveness, TPO stands at the forefront as a solution for diverse applications.

Conclusion:

Thermoplastic Polyolefins have solidified their position as a versatile and high-performance material in various industries. Navigating the global TPO market requires a deep understanding of market dynamics, emerging trends, and the evolving needs of industries. With a promising future shaped by sustainability initiatives and technological advancements, TPO remains at the forefront of innovation in the polymer industry, offering solutions to meet the evolving demands of diverse applications worldwide.

#SustainableMaterials#PlasticManufacturing#BuildingMaterials#AutomotiveApplications#ChemicalIndustry#IndustrialMaterials

0 notes

Text

Unlocking Growth: The Dynamics of the Methylene Diphenylisocyanate (MDI) Market

Methylene diphenylisocyanate (MDI) is a key component in the production of polyurethane foams, coatings, adhesives, and sealants. This versatile chemical compound finds extensive applications across various industries including construction, automotive, electronics, and furniture manufacturing. The global MDI market has witnessed significant growth in recent years, driven by the expanding demand for polyurethane products and the increasing emphasis on energy-efficient solutions.

The growth of the MDI market can be attributed to several factors. Firstly, the construction industry plays a pivotal role, with MDI being extensively used in the production of insulation materials for residential, commercial, and industrial buildings. The rising construction activities, particularly in emerging economies, coupled with stringent energy efficiency regulations, are fueling the demand for MDI-based insulation materials.

Furthermore, the automotive sector is a major consumer of MDI, primarily for manufacturing lightweight and durable components such as car seats, dashboards, and bumpers. With the automotive industry shifting towards electric vehicles and adopting lightweight materials to improve fuel efficiency, the demand for MDI is expected to witness sustained growth in the coming years.

Moreover, the electronics industry is another significant end-user of MDI, utilizing it in the production of circuit boards, coatings, and encapsulants. The rapid technological advancements, especially in consumer electronics and telecommunications, are driving the demand for MDI-based materials that offer superior performance and protection against environmental factors.

Additionally, the furniture industry relies on MDI for producing flexible and rigid foams used in mattresses, cushions, and structural components. As the global furniture market continues to expand, particularly in developing regions, the demand for comfortable and durable furniture products is driving the consumption of MDI.

Geographically, Asia Pacific dominates the MDI market, owing to the rapid industrialization, urbanization, and infrastructural development in countries like China, India, and Southeast Asian nations. The region's robust manufacturing sector, coupled with the growing construction activities and automotive production, sustains the high demand for MDI.

However, challenges such as volatile raw material prices and environmental concerns regarding the use of isocyanates pose potential constraints to market growth. Nevertheless, advancements in production technologies, along with increasing investments in research and development, are expected to address these challenges and drive innovation in the MDI market.

In conclusion, the global MDI market is poised for continued growth, supported by the expanding applications across various industries, particularly in construction, automotive, electronics, and furniture manufacturing. As industries strive for efficiency, sustainability, and innovation, MDI remains a critical component in meeting the evolving demands of modern markets.

0 notes