#constructed textiles

Text

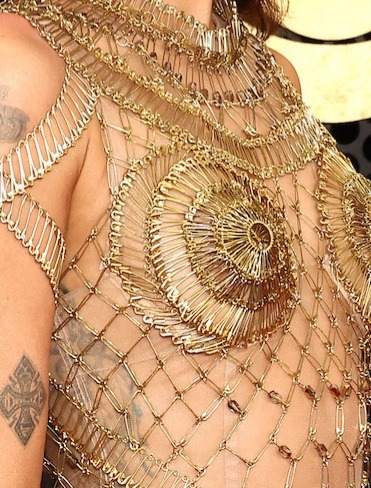

Miley Cyrus at the Grammys 2024, wearing Ancient Egypt-inspired net dress by John Galliano for Maison Margiela, constructed entirely from safety pins.

It took 675 hours of craftsmanship, using 14,000 safety pins.

This dress refers back to one from Galliano's Fall 1997 ready-to-wear collection.

#miley cyrus#red carpet#grammys 2024#grammys#fashion#maison margiela#john galliano#safety pin#net dress#naked dress#ancient egypt#constructed textiles#unconventional materials#2024#celebrity fashion#celebrity style#textile design#textiles#1990s#fashion history#1997#fw97#rtw#fall 1997#british designer

132 notes

·

View notes

Text

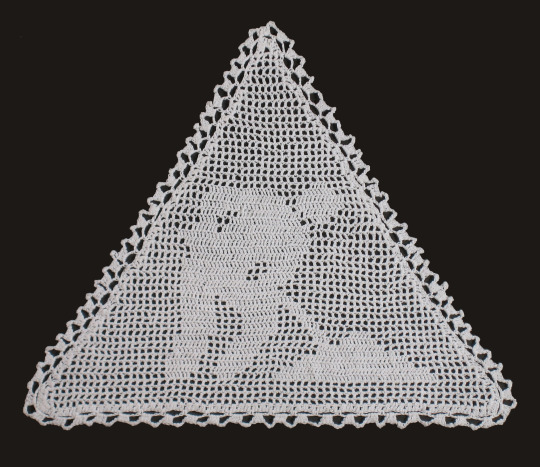

Nathan Vincent, Men Working | Doilies

#nathan vincent#doilies#crochet#textile art#construction#crochet art#fiber arts#filet crochet#southern gothic#⭒* ·˚ ☾ ⊹.#textiles

30 notes

·

View notes

Text

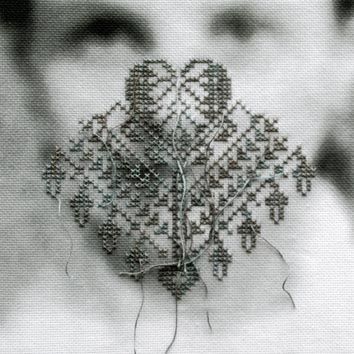

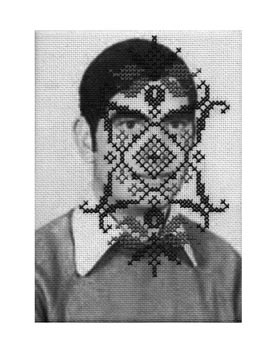

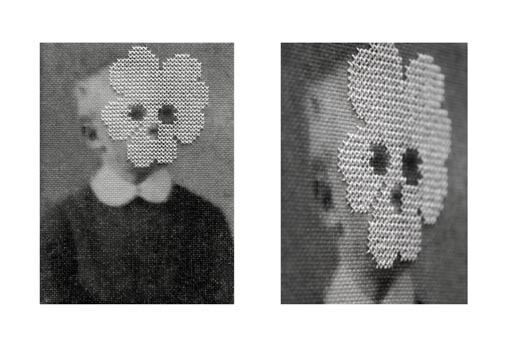

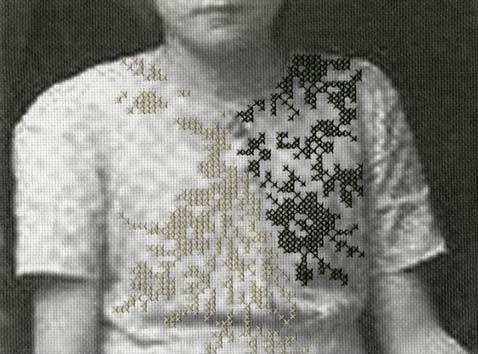

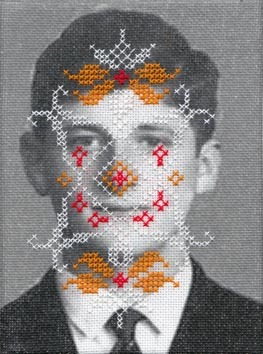

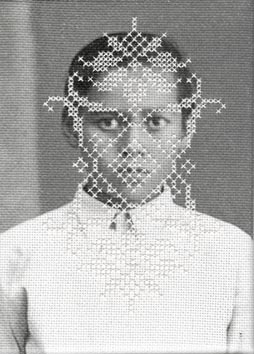

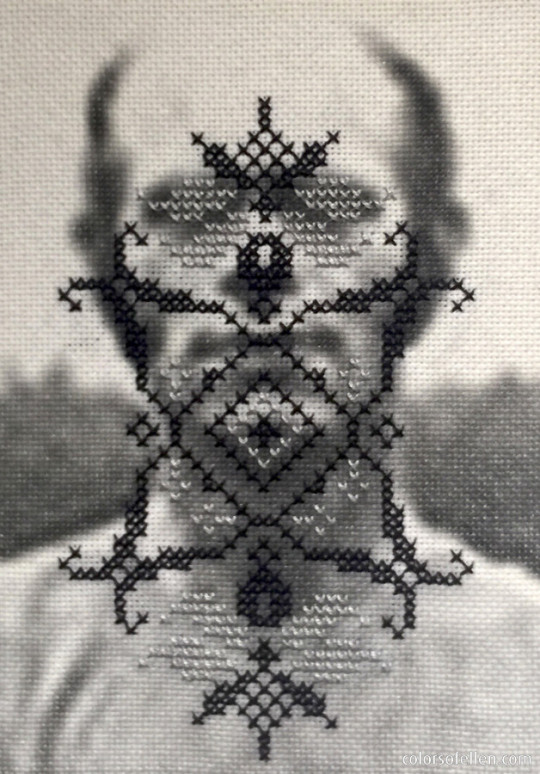

Hella van 't Hof

#artist#construction#art#textiles#textile art#embroidery#embroidery art#hella van 't hof#monochrome#conceptual art#sombre#thread#sewing

19 notes

·

View notes

Text

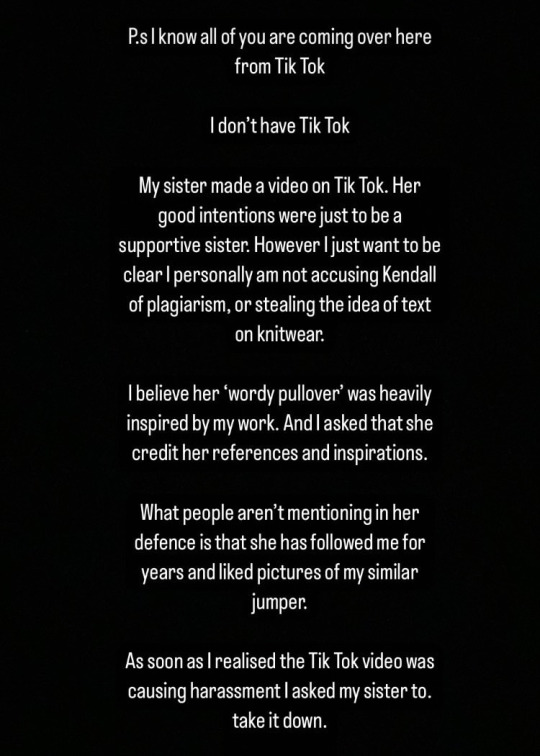

this just in: mandatory crediting of references and inspiration when you make art

#lmfao this is just getting stupid. a textile artist who heavily featured text in her work#needs to credit you for ‘inspiring’ her ???#from one poorly constructed sweater you posted TWO YEARS ago ??#im not accusing her of plagiarism i’m just accusing her of plagiarism#she liked my post so she must have stolen my idea rather than like….text in knitting being very popular and just looking like that

6 notes

·

View notes

Text

they don't know that the glued linen tube and yoke corselet hypothesis has been soundly discredited through closer reading of the sources....

#atm we think classical greek textile armour was PROBABLY twined.#there are surviving macedonian cuirasses which were iron core wrapped in cloth too. probably for heavy cavalry#and theres an extant scythian/sarmatian corselet of leather and iron scales.#animal hide corselets might have been used too.#but there are no references to glued construction within the relevant period and it would have been impractical on campaign#due to the potential for rot

1 note

·

View note

Text

Filo constructions workshop.

I've been really interested in crochet as a medium, I found this workshop really helpful and gave me a solid foundation for learning crochet. It gave me some ideas for future projects.

2 notes

·

View notes

Text

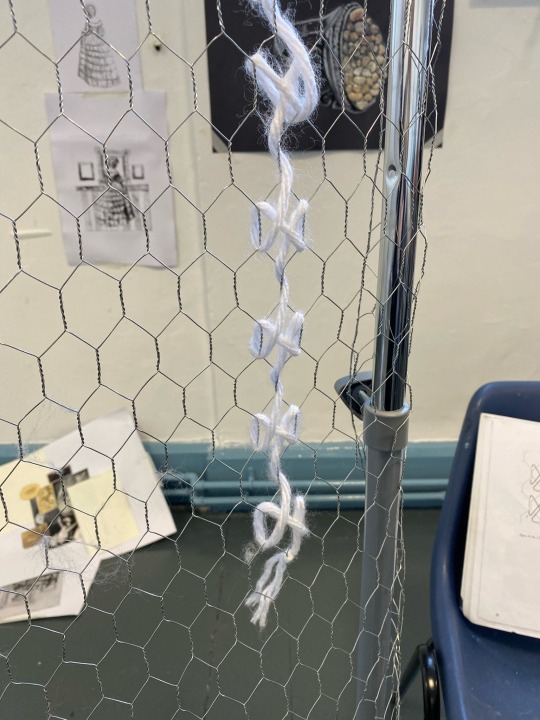

Filo Construction workshop

This morning I tried out the filo construction workshop with Giordanna which was great . Above I was trying out embroidery on net which I really enjoyed . I like to embroider on fabric in my spare time so it was fun to try it out on a larger scale . I also tried macrame and knitting which I found to be more difficult . I would definitely go to more embroidery workshops . At the moment I am looking at the biology of menstration while exploring temporary and this has given me the idea to maybe embroider something onto clothing items like cotton underwear .

3 notes

·

View notes

Text

Unlocking the Potential: Exploring Textile Printing Machines Market Trends

Introduction

In the dynamic world of textiles, printing plays a crucial role in adding value, enhancing aesthetics, and enabling customization. From apparel and home furnishings to automotive interiors and signage, printed textiles are ubiquitous in our daily lives. Behind the scenes, textile printing machines are at the forefront of innovation, driving the industry forward with advanced technologies, sustainable practices, and innovative applications.

In this comprehensive article, we will delve deep into the trends shaping the textile printing machines market, exploring digital transformation, sustainability initiatives, global market dynamics, and the future outlook.

According to the study by Next Move Strategy Consulting, the global Textile Printing Machines Market size is predicted to reach USD 17.78 billion with a CAGR of 5.2% by 2030.

Request a FREE sample, here: https://www.nextmsc.com/textile-printing-machines-market/request-sample

Digital Transformation: The Rise of Digital Printing Technologies

Digital printing has emerged as a game-changer in the textile industry, offering unparalleled flexibility, speed, and quality. Unlike traditional printing methods such as screen printing and rotary printing, which involve lengthy setup times and limited design capabilities, digital printing allows for the on-demand production of highly intricate designs with minimal setup requirements. This shift towards digitalization is transforming the way textiles are printed, enabling faster turnaround times, reduced waste, and enhanced customization options.

One of the key advantages of digital textile printing is its ability to accommodate short print runs and rapid design iterations, making it ideal for fast fashion brands and niche markets. With advancements in inkjet technology and software solutions, digital printers can achieve vibrant colors, sharp details, and smooth gradients, replicating complex designs with precision. Additionally, digital printing enables variable data printing, allowing manufacturers to personalize products with individualized text, graphics, or images.

In recent years, the adoption of digital printing technologies has surged across the textile industry, driven by factors such as increasing demand for customized products, growing e-commerce penetration, and advancements in digital ink formulations. Today, digital textile printers are capable of printing on a wide range of substrates, including cotton, polyester, silk, and even synthetic fabrics such as nylon and spandex. As digital printing continues to evolve, we can expect further improvements in print speed, color accuracy, and substrate compatibility, expanding the possibilities for innovation and creativity in the textile industry.

Sustainability Focus: Driving Environmental Responsibility in Textile Printing

Sustainability has become a key priority for stakeholders across the textile supply chain, from raw material suppliers to garment manufacturers and retailers. In response to growing environmental concerns and regulatory pressures, the textile printing industry is increasingly adopting sustainable practices and eco-friendly technologies to minimize its ecological footprint.

One of the primary areas of focus for sustainable textile printing is the development of water-based inks as an alternative to traditional solvent-based inks. Water-based inks contain lower levels of volatile organic compounds (VOCs) and hazardous chemicals, making them safer for both workers and the environment. Additionally, water-based inks are more easily recyclable and biodegradable, reducing the impact of printing waste on landfills and waterways.

Another sustainability initiative gaining traction in the textile printing industry is the use of eco-friendly substrates and materials. Manufacturers are exploring alternative fibers and fabrics derived from renewable sources such as bamboo, hemp, and organic cotton, which require fewer pesticides and chemicals in their production. Additionally, advancements in textile recycling technologies are enabling the reuse and repurposing of post-consumer and post-industrial textile waste, closing the loop on the circular economy.

Beyond ink and substrate choices, textile printing companies are also implementing energy-efficient manufacturing processes and investing in renewable energy sources to reduce their carbon emissions. From energy-efficient digital printers to solar-powered production facilities, sustainable energy solutions are helping textile printers minimize their environmental impact and contribute to a greener future.

Innovative Applications: Exploring New Frontiers in Textile Printing

The versatility of textile printing machines extends far beyond traditional applications such as apparel and home textiles. Today, printed textiles are finding innovative uses across a wide range of industries, from automotive and aerospace to healthcare and architecture. Advances in printing technologies and materials are unlocking new possibilities for creativity, functionality, and customization in diverse sectors.

In the automotive industry, printed textiles are increasingly used for interior upholstery, seat covers, and decorative trim, offering designers the flexibility to create unique patterns, textures, and color schemes. Digital printing enables automotive manufacturers to produce custom interiors tailored to individual preferences, enhancing the overall aesthetic appeal of vehicles, and differentiating them in the market.

Inquire before buying, here: https://www.nextmsc.com/textile-printing-machines-market/inquire-before-buying

Similarly, in the field of architecture and interior design, printed textiles are being employed for wall coverings, window treatments, and acoustic panels, transforming spaces with visually stunning and acoustically functional designs. Digital printing allows architects and interior designers to collaborate with textile printers to create bespoke solutions that meet their project requirements, whether it's a corporate office, hospitality venue, or residential space.

In the healthcare sector, printed textiles are playing an increasingly important role in patient care and medical device manufacturing. Antimicrobial fabrics, printed with specialized inks containing silver nanoparticles or other antimicrobial agents, are being used for hospital linens, uniforms, and wound dressings to help prevent the spread of infections and improve hygiene standards. Additionally, 3D-printed textile structures are being explored for applications such as tissue engineering, drug delivery, and wearable medical devices, opening up new possibilities for personalized healthcare solutions.

Global Market Dynamics: Exploring Regional Trends and Opportunities

The textile printing machines market is a dynamic and diverse landscape, shaped by regional trends, economic factors, and cultural preferences. While established markets such as North America and Europe continue to drive innovation and technological advancements, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth and market expansion.

In North America and Europe, the textile printing industry is characterized by a high level of automation, advanced digital printing technologies, and a strong emphasis on sustainability and product innovation. Manufacturers in these regions are investing in research and development to stay ahead of the curve and meet evolving consumer demands for eco-friendly and customizable products. Additionally, strategic partnerships and collaborations between textile printing companies and fashion brands are driving market growth and brand differentiation.

In contrast, Asia-Pacific and Latin America are emerging as key growth markets for textile printing machines, fueled by factors such as urbanization, rising disposable incomes, and a growing middle-class population. Countries including China, India, Brazil, and Mexico are witnessing a surge in demand for printed textiles driven by the booming fashion and apparel industries, increasing consumer awareness of fashion trends, and the growing popularity of e-commerce platforms. As a result, textile printing companies in these regions are ramping up production capacity, investing in infrastructure, and adopting advanced printing technologies to capitalize on market opportunities and gain a competitive edge.

Conclusion: Charting the Course for Future Success

As we look ahead to the future of the textile printing machines market, one thing is clear: innovation, sustainability, and globalization will continue to shape the industry landscape and drive market growth. Digital transformation will revolutionize the way textiles are printed, enabling faster turnaround times, greater customization, and enhanced creativity. Sustainability will remain a top priority for stakeholders across the supply chain, driving the adoption of eco-friendly materials, energy-efficient processes, and responsible manufacturing practices. And global market dynamics will present both challenges and opportunities for textile printing companies, as they navigate evolving consumer preferences, regulatory requirements, and competitive pressures.

By staying abreast of the latest trends and developments in the textile printing machines market, businesses can position themselves for success in this dynamic and competitive industry. Whether it's investing in digital printing technologies, implementing sustainable practices, or exploring new applications and markets, textile printing companies must adapt and innovate to thrive in an ever-changing business environment. As we unlock the full potential of textile printing machines and harness the power of innovation and sustainability, we can create a brighter future for the industry, our customers, and the planet.

0 notes

Text

Supplier of Air Ventilator in Kutch

Airwell Systems:

Airwell Systems is a prominent Manufacturer and Supplier of Air Ventilator in Kutch, Gujarat, India.

The company is proud to hold ISO 9001:2015 certification, ensuring adherence to industry standards.

Airwell Systems' air ventilators are designed to facilitate air passage and ventilation within warehouses. They operate by expelling air through a circular-shaped steel channel driven by fan action.

These ventilators harness wind energy to create airflow through centrifugal action. Rotating vanes generate centrifugal force, creating a low-pressure zone that effectively removes heat and pollutants while drawing in fresh air.

Airwell Systems manufactures ventilators using stainless steel and aluminum, providing corrosion resistance for extended longevity and durability.

The ventilators are available in various sizes and are competitively priced to suit different needs and budgets.

Key Features of Air Ventilators:

Temperature Regulation: Ensures optimal temperature control for improved comfort and productivity.

Variable Speed Control: Allows users to adjust the fan speed according to their ventilation needs.

Directional Louvers: Enables directing airflow to specific areas for targeted ventilation.

Automatic Operation: Operates automatically based on preset conditions or environmental cues.

Durable Housing: Constructed with robust materials to withstand harsh environmental conditions.

Remote Control or Smart Connectivity: Provides convenient control options for seamless operation.

Compatibility with Ducted Systems: Easily integrates with existing ducted ventilation setups for enhanced efficiency.

Timer Controls: Enables scheduling ventilation cycles for optimized energy usage.

Safety Features: Incorporates safety mechanisms to prevent accidents and ensure user protection.

Application Industries:

Pharmaceutical

Agro & food

Textile

Chemical

Steel & power plants

Industrial sheds

Paper & sugar mills

Infrastructure & construction

Service Coverage:

Airwell Systems Supplier of Air Ventilator in Kutch, Gujarat, India and surrounding areas, including Bhuj, Gandhidham, Anjar, Rapar, Mandvi, Bhachau, Mundra, Kandla, Nakhatrana, Abdasa, Lakhpat.

For detailed information and inquiries, interested parties can directly contact Airwell Systems.

Read the full article

#Abdasa#Agro&food#AirVentilatorinIndia#AirVentilatorinKutch#Anjar#Bhachau#Bhuj#ExporterofAirVentilator#Gandhidham#IndustrialSheds#Infrastructure&Construction#Kandla#Lakhpat#Mandvi#ManufactrerofAirVentilator#ManufacturerofofAirVentilatorinKutch#Mundra#Nakhatrana#Paper&SugarMills#Pharmaceutical#Rapar#SupplierofAirVentilator#SupplierofAirVentilatorinGujarat#SupplierofAirVentilatorinIndia#SupplierofAirVentilatorinKutch#Textile

0 notes

Text

#get creative#experimenting and developing#developing samples#playing with textiles#bright colours#brazil parrot#start of the construction

0 notes

Text

Celebration of the 2024 International Day of Forests.

Forests sustain us in countless ways – from clean air and water to food and medicine, income and livelihoods, and even sustainable fashion. Being near trees and forests can inspire creativity, reduce stress, and improve your mood.

The world's forests cover nearly one-third of all land, providing carbon storage and biodiversity habitat while building our resilience to withstand storms and other natural disasters. Yet despite all that they provide us, forests are often undervalued, and every year we continue to lose ten million hectares of forests.

Innovations in science and technology now make it possible for countries to use remote sensing, drone technology, and artificial intelligence to monitor the health of their forests for mapping and monitoring, tree planting, measuring carbon, and early wildfire detection.

At the same time, innovative forest products provide sustainable alternatives for construction materials, textiles, and new types of plastic and medical products. Exploring the possibilities for forest products in building our greener future is limited only by the breadth of our imagination. This is why the theme of this year's International Day of Forests on 21 March 2024, is "Forests and Innovation".

UN DESA's UN Forum on Forests Secretariat will organize a special event to celebrate the International Day on 21 March at UNHQ in New York. The event will feature senior UN and government officials, technical experts, and civil society, all sharing their perspectives on how we can promote innovation to help the world's forests. It will highlight the importance of implementing the UN Strategic Plan for Forests and achieving the Global Forest Goals by 2030.

Related Sites and Documents

International Day of Forests Webpage

Provisional Programme

Watch the celebration of the International Day of Forests 2024.

#forests and innovations#Global Forest Goals#sustainable forest management#sdg15#reforestation#unff#tree planting#innovative forest products#sustainable alternatives for construction materials#Sustainable alternatives for textiles#new types of plastic and medical products#panel discussion#United Nations Forum on Forests#undesa

0 notes

Text

Lil Nas X at the 2022 VMAs, wearing Harris Reed x Vivienne Lake

This is a black version of the Dolce & Gabbana x Harris Reed (x milliner Vivienne Lake) look Iman wore to the 2021 Met Gala.

#lil nas x#vmas#vmas 2022#mtv vmas#red carpet#fashion#harris reed#hat#millinery#vivienne lake#textiles#textile design#constructed textiles#celebrity style#celebrity fashion#queer designer

154 notes

·

View notes

Text

Nylon. In a fanstasy novel. In a not-our-world fantasy novel. I can't I fucking can't. Call it something made up, I dont care just doing call it fucking nylon.

I can not get a fucking handle on what level of technological advancement this world is meant to be at, but it sure as shit shouldnt be at fucking NYLON

#i never thought textiles would break world building#but it has#it fucking has#oh my god#just say you know nothing about clothing history or construction or where teztile come from#i dont mind modern textiles in this kinda fantasy! but you gotta be consistent!#but fucking nylon#jesus christ almighty#nylon but no cars#or any kind of radio communication#YES IM PETTY

1 note

·

View note

Text

Jesons Industries Limited is a leading manufacturer of specialty coating emulsions and water-based pressure-sensitive adhesives in India. The company was founded in 1999 and is headquartered in Mumbai, Maharashtra. Jesons Industries has a strong focus on research and development. The company has developed a number of innovative products that are used in a variety of industries, including packaging, paints, construction, and textiles

#Coating emulsions#Pressure sensitive adhesives#PSA#Tape and label#Packaging#Paints#Construction chemicals#Textiles#Polyurethane dispersion#Anti-viral#Anti-microbial#Leather#Paper#India#Mumbai#Jesons Industries Limited

0 notes

Text

Les multiples bienfaits du bambou : Santé, cuisine, cosmétiques, construction et textile

Le bambou, une plante asiatique versatile et polyvalente, est largement utilisé dans divers domaines tels que la santé, la cuisine, les cosmétiques, la construction et le textile. Ses nombreuses propriétés bénéfiques en font un choix privilégié pour de nombreuses applications. Cet article explorera les multiples bienfaits du bambou, mettant en évidence ses avantages dans chaque domaine…

View On WordPress

#bambou dans la construction#bambou dans la cuisine#bambou dans la santé#bambou dans le textile#bambou dans les cosmétiques

0 notes

Photo

Enclosed - Living Room

A large, formal living room with a tile fireplace, white walls, and a dark wood floor and brown carpet can be seen in the photo.

#scenic wall paper#estate#new construction#newport highboy cabinet#velvet sofa#antique textiles#bucks county

0 notes