#crankshafts

Text

Quality Engine Parts for Reliable Performance | TGP India

Explore a wide range of engine parts at TGP India. From pistons to crankshafts, find high-quality components to ensure optimal performance and durability for your engine.

0 notes

Text

Understanding the Role of Materials in Railway Parts Manufacturing

The manufacturing of railway parts is a complex and intricate process that requires a deep understanding of various elements, particularly when it comes to critical components like crankshafts. A fundamental aspect that significantly influences the performance and reliability of railway engines is the choice of materials used in their construction. In this blog, we will delve into the crucial role of materials in the manufacturing of railway parts, with a specific focus on crankshafts.

Crankshafts, being essential components of any railway engine, play a pivotal role in converting reciprocating motion into rotational motion, powering the wheels and propelling the locomotive forward. The efficiency, durability, and overall performance of the engine heavily rely on the properties of the materials employed in crafting the crankshaft. By exploring the relationship between crankshaft manufacturing and materials, we can gain valuable insights into how residual stress, manufacturing technology, and material selection impact its performance.

To comprehend the significance of these aspects, we will analyze the diagram showing the intricate design and composition of a crankshaft, shedding light on how specific materials are strategically utilized in various sections to optimize strength, weight, and stress distribution.

Join us on this informative journey as we unravel the mysteries behind the selection of suitable materials, the effects of residual stress on performance, and the latest manufacturing technologies shaping the railway industry. Understanding the interplay between materials and the manufacturing process is vital for ensuring safe, efficient, and reliable railway operations in the modern era.

Role of Materials in Railway Parts Manufacturing

The railway industry is a cornerstone of modern transportation, and the efficiency and safety of railway systems heavily depend on the quality and durability of the components that make up the intricate network. One critical aspect of railway part manufacturing is the selection and utilization of appropriate materials. This holds true particularly for components like crankshafts, which play a pivotal role in the functioning of locomotive engines. In this discourse, we delve into the nuances of crankshaft manufacturing, the significance of materials, and the impact of manufacturing technologies on the final product.

Crankshaft Manufacturing: An Overview

A crankshaft is an essential mechanical component in the engine of a locomotive, responsible for converting reciprocating motion into rotational motion. As the engine pistons move up and down, the crankshaft translates this linear motion into the circular motion needed to drive the wheels. Given the high stresses and loads involved, crankshaft materials must exhibit superior mechanical properties to ensure reliable performance and longevity.

Material Selection for Crankshaft Manufacturing

The choice of materials for crankshaft manufacturing is a critical factor that directly affects the component’s performance and service life. Traditionally, materials like cast iron were used due to their robustness and ease of manufacturing. However, advancements in materials science have led to the adoption of more sophisticated materials, such as forged steel and even specialized alloys.

Forged steel offers improved strength, fatigue resistance, and better impact properties compared to cast iron. Its homogeneous structure, achieved through controlled manufacturing processes, ensures consistent material properties throughout the crankshaft. Moreover, specialized alloys, like nodular cast iron, provide a balanced combination of tensile strength, ductility, and fatigue resistance. The right choice of material depends on factors such as the engine’s power output, operational requirements, and the desired service life of the crankshaft.

Role of Materials in Performance

The materials used in crankshaft manufacturing significantly influence the overall performance of the engine. The mechanical properties of the material dictate its ability to withstand the cyclic stresses and high loads that occur during engine operation. High-strength materials contribute to enhanced durability, minimizing the risk of catastrophic failures that could disrupt railway services.

One crucial aspect to consider is residual stress. During the manufacturing process, various techniques such as heat treatment and surface finishing can induce residual stresses in the material. Residual stresses can impact fatigue life, leading to premature failures. Proper material selection, combined with controlled manufacturing processes, can help mitigate the negative effects of residual stress, ensuring a longer lifespan for the crankshaft and the engine as a whole.

Managing Technology’s Influence

Advancements in manufacturing technology have brought about substantial improvements in the quality and precision of crankshaft manufacturing. Computer Numerical Control (CNC) machining, for instance, allows for intricate shaping and accurate dimensioning of crankshafts. CNC technology not only enhances the final product’s geometry but also plays a role in optimizing material usage, reducing waste, and improving overall efficiency.

Furthermore, the use of finite element analysis (FEA) has revolutionized the design and validation of crankshafts. FEA enables enterprises to simulate real-world operating conditions and predict how different materials will behave under various loads and stress conditions. This simulation-driven approach empowers manufacturers to refine material selection and manufacturing processes before physically producing the component, ultimately saving time and resources while ensuring optimal performance.

The Visual Representation of Crankshaft Material

A diagram shows the cross-section of a crankshaft, highlighting the layered composition of the material. The outer layer, often composed of a hardened alloy, provides resistance against wear and surface fatigue. Beneath this layer, the core material exhibits a balance between strength and ductility, allowing it to withstand the bending and torsional stresses imparted by the engine’s operation. The careful selection of materials for both layers is crucial in ensuring the crankshaft’s reliability and longevity.

The role of materials in railway parts manufacturing, particularly in components like crankshafts, cannot be overstated. The choice of materials directly impacts the component’s performance, durability, and overall reliability. With the ever-evolving landscape of materials science and manufacturing technologies, businesses and manufacturers have a wider array of options to choose from, enabling them to optimize the design, fabrication, and performance of railway components. As the industry continues to evolve, a deep understanding of materials and their behaviour will remain pivotal in shaping the future of railway transportation.

Conclusion

In conclusion, the role of materials in railway parts manufacturing, particularly in the context of crankshafts, holds paramount importance in ensuring the efficiency, reliability, and safety of railway engines. The manufacturing of crankshafts demands a deep understanding of materials, their properties, and the impact of manufacturing technologies on their performance. By carefully selecting suitable materials and employing advanced manufacturing techniques, you can create crankshafts that optimize engine efficiency, reduce emissions, and enhance overall performance.

The significance of material selection in crankshaft manufacturing lies in achieving a delicate balance between strength, durability, and weight. High-performance materials, such as steel alloys, continue to play a crucial role, while advancements in material science continually present opportunities for further innovation.

Additionally, considering factors like residual stress is essential for ensuring the long-term reliability and safe operation of railway engines. Proper management of residual stress during manufacturing processes is critical to prevent premature failure and maintain the structural integrity of the crankshaft.

Visual representations, such as diagrams, provide invaluable insights into the complex design and material distribution within the crankshaft. These diagrams aid in making informed decisions during the manufacturing process, leading to the production of high-quality crankshafts that can withstand the rigors of railway operations.

As the transportation industry advances, a deep understanding of the interplay between crankshaft manufacturing, materials, and technology will continue to drive progress in the field. Embracing innovative materials and manufacturing techniques will pave the way for more efficient, environmentally friendly, and reliable railway systems, contributing to a sustainable future for rail transportation.

0 notes

Text

Are you hearing engine noise? It might be time to replace your vehicle’s timing chain.

Timing chains ensure that the timing of camshafts and crankshafts is right. As time goes on, the chain may stretch. The timing guides can also wear out, causing noise.

There is no set mileage for when the timing chains need to be replaced. This frequency depends on the vehicle, type of engine, and what the manufacturer recommends. Some vehicles have timing belts – or wet belts, in the case of Ford Fiestas.

The belt can start to shred and the fibers will get stuck in the oil pump pickup, causing a low oil problem. So, newer engines may not look like they have a timing belt but they do.

#new timing chain#timing chains#steve's auto repair and tire#prince william county virginia#crankshafts#camshafts

0 notes

Link

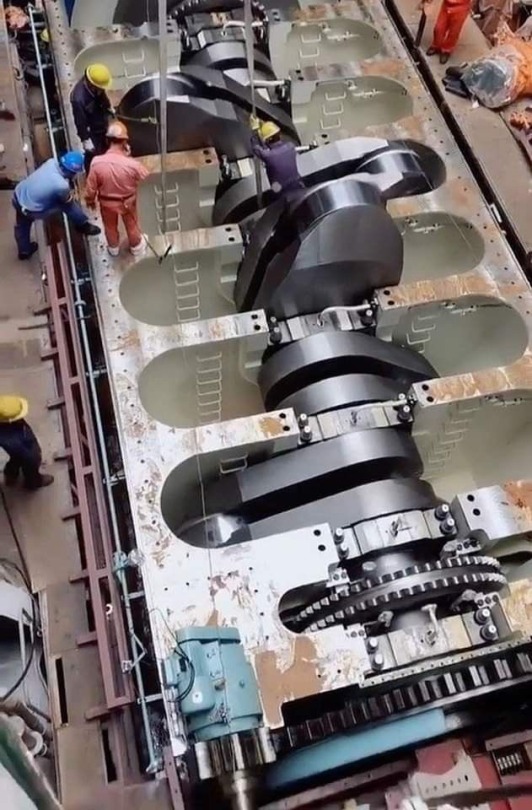

Our skilled specialists conduct Sulzer Z 40/48 crankshaft repair placed on the vessel. It has been determined that the Sulzer Model Z 40/48's crankpin is damaged, and to make the necessary crankshaft repair, grinding and polishing must be executed. You can contact us at [email protected], 0124-4251615, or +91-9810012383 to know more about our crankshaft repair services and receive additional information.

#sulzer z 40/48 crankshaft on vessel#crankshaft grinding#crack repair#grinding of crankshaft#crankshaft grinding and repair#in situ grinding crankpins#Crankshaft grinding machine manufacturer#crankshaft repair services#crankshafts#onsite crankshaft grinding machine#Crankshaft Grinding Machine#insitu crankshaft grinding machine#crank shaft grinding machine#machine

0 notes

Text

We provide onsite grinding journals and crank pins services for high capacity engine installed on vessel or land base. We gave comprehensive services for crankshaft grinding to metal stitching of broken engine components . If you want to know more about grinding crankshafts and journals here you connect with us at [email protected], 0124-4251615, or +91-9582647131.

#crankshaft grinding#insitu crankshaft grinding repair#crankshaft grinders#crankshaft repair#crankshafts#caterpillar crankshaft repair#main journal grinding#crankpin and main journal#crankshaft journal crankpin grinding#polishing crankshaft journals#onsite machining of crankshaft#crankshaft repair services#onsite repair services#grinding journals and crank pins

0 notes

Text

Maximizing Diesel Crankshaft Life: 5 Proven Methods

Maximizing Diesel Crankshaft Life: 5 Proven Methods

The Importance of Diesel Crankshaft Life

The diesel engine is a workhorse in the industrial sector, powering heavy machinery, transportation vehicles, and generators. The crankshaft, the heart of the engine, converts the reciprocating motion of the pistons into rotational motion, driving the transmission and other components. The durability and reliability of the diesel crankshaft are critical for the engine’s performance and productivity. In this article, we will discuss five proven methods to maximize diesel crankshaft life.

Method 1: Proper Lubrication and Maintenance

The proper lubrication and maintenance of the diesel engine are essential for the longevity of the crankshaft. The crankshaft and bearings require a constant supply of oil to reduce friction and wear. The oil should have the correct viscosity and additives to withstand high temperatures and pressures. A regular oil change and filter replacement schedule should be followed, and the oil pressure and temperature should be monitored regularly.

Method 2: Balancing and Dynamic Analysis

The diesel crankshaft’s balance and dynamic characteristics are crucial to prevent vibration, noise, and premature failure. The crankshaft must be balanced statically and dynamically to ensure that the mass distribution is uniform and the center of gravity is aligned with the rotation axis. The dynamic analysis evaluates the crankshaft’s natural frequencies, mode shapes, and critical speeds to avoid resonance and fatigue failure.

Method 3: Surface Hardening and Heat Treatment

The surface hardness and strength of the diesel crankshaft can be improved by surface hardening and heat treatment processes. The induction hardening, nitriding, and shot-peening are some of the methods used to increase the wear resistance, fatigue strength, and corrosion resistance of the crankshaft. The heat treatment processes, such as quenching and tempering, normalize, and annealing, can improve the mechanical properties and eliminate residual stresses.

Method 4: Material Selection and Design Optimization

The material selection and design optimization of the diesel crankshaft can significantly affect its life and performance. The material should have high strength, toughness, and fatigue resistance, such as forged steel, ductile iron, or titanium alloys. The design should consider the stress concentration, fillet radius, oil supply, and bearing clearance to minimize the stress and deformation. Computer-aided design and finite element analysis can help optimize the design and reduce the development time and cost.

Advancements in Diesel Crankshaft Technology

The advancements in diesel engine technology have led to the development of new materials, manufacturing processes, and design techniques that can further improve the diesel crankshaft’s life and performance. The use of advanced alloys, such as nickel-based superalloys, composites, and nanomaterials, can enhance the mechanical and thermal properties of the crankshaft. The additive manufacturing and create complex geometries and reduce the material waste. The digital twin and artificial intelligence can monitor the crankshaft’s condition, predict the failure, and optimize the maintenance schedule. By implementing these methods and technologies, the diesel crankshaft’s life can be maximized, reducing downtime, and increasing productivity

Cylinder Liner

Engine Piston Crown

Cylinder Cover

from Decho Marine Services

Decho Marine Services (China) Tingting

+86 159-6706-1188

[email protected]

0 notes

Text

Rica venida en la boca de Tzelli pop

Ebony and redhead anal fucked in bdsm

Fucking Big Boobs Teacher After Tuition Class

Messy bottom taking dick for the first time

Teen sucks old small cock

Uber Lyft Rideshare Blowjob Hero Legend

Lustful fat mature hooker fucks her big snatch with a dildo

Puta Manda Un Video Caliente

Petite ebony teen slammed in the kitchen

Christy Mack Big Tit Babe Enjoys Huge Cock

#Bunsen#chevalet#Sonja#curling#that-a-way#getaways#urinalyses#nonet#Baconian#jury-packing#Waters#crankshafts#prorealism#sermon#overinhibited#Geullah#guests#horahs#awarrant#armigeral

0 notes

Text

vessel crank

117 notes

·

View notes

Text

“He was the most optimistic person I have ever known. He just thought things were gonna work out. And he didn’t have a particularly easy life… he just had this incredible optimism. In fact, as an older man I took him I took him to visit some of his World War II friends, Charlie Cruikshank, “Crankshaft” … and there was another guy, Danny, one of his World War II friends … and I asked that guy was he always this positive? Was he always this optimistic? Even way back during the war? And Danny said ‘Yeah, it used to drive us crazy’.”

— Rebecca Hutchinson, youngest daughter of Harry Crosby, during an interview with the Indie Magazine Podcast

#they also called him Mr.Wonderful because whenever you asked how he was he would say wonderful#Harry Crosby#mota#masters of the air#real mota#Rebecca Hutchinson#podcast#quotes#interview#Harry Crosby is precious#charles cruikshank#crankshaft#cruikshank#if you know who Dan is let me know because I have no clue

43 notes

·

View notes

Text

Masters of the Air (2024)

My most random MOTA-crush is just Crank in the background being cute and supportive of his fellow flyboys.

49 notes

·

View notes

Text

I've been busy at this, here's the characters from Terra Nimbus/Levetania.

CRANKSHAFT

AURORA

ROBIN

LARKIN

I don't know if I should include the sky plushlings here or just compile all the different kinds into one post. I can work that out another time.

#fantasy life#fantasy life 3ds#Fantasy Life Art Reference#art reference#Crankshaft doesn't have eyes so you aren't missing much from this angle#RIP any of my FL Robin stans out there but I nearly forgot he existed#I have more but I'll wait until tomorrow to avoid clogging the tabs

20 notes

·

View notes

Text

Exploring Different Types of Crankshafts and Their Applications

Welcome to our blog post on the fascinating world of crankshafts and their diverse applications in various engines. A crankshaft is a vital component of any engine, responsible for converting reciprocating motion into rotational motion. It serves as the backbone of an engine, facilitating the transfer of power from the pistons to the drivetrain. The world of crankshafts is incredibly vast, encompassing different types and functions tailored to specific engine requirements. Engine builders and enthusiasts alike recognize the significance of choosing the right crankshaft type for optimal performance. In this article, we will delve into the realm of crankshafts, exploring the different types available and shedding light on their applications.

Crankshafts come in a range of designs, each serving a distinct purpose based on the engine’s intended use. Understanding the various crankshaft types is crucial for engine builders, as it allows them to tailor the engine’s characteristics to meet specific performance goals. The primary function of a crankshaft is to convert the reciprocating motion of the pistons into rotational motion, which drives the vehicle or powers machinery. Achieving this transformation involves the collaboration of multiple components, including the connecting rod and crank pin, which play crucial roles in the overall system.

Engine builders often opt for fully-built crankshafts or those with specific modifications to suit the engine’s needs. These crankshafts undergo meticulous design and engineering processes to ensure optimal performance, durability, and efficiency. The selection of the appropriate crankshaft type depends on factors such as the engine’s intended application, desired power output, and the desired torque curve. With the vast array of crankshaft types available, from cast iron to forged steel, it’s essential to understand their strengths, limitations, and specific applications.

In this article, we will explore different types of crankshafts and their applications across various engines. We will discuss the distinguishing features of each crankshaft type, highlighting their advantages and disadvantages. Whether you are an engine enthusiast seeking to expand your knowledge or an engine builder aiming to optimize performance, this comprehensive guide will provide valuable insights into the world of crankshafts and help you make informed decisions when it comes to selecting the most suitable crankshaft for your specific needs. Let’s dive into the intricacies of crankshaft types and uncover the secrets behind their incredible functionality in the realm of engines.

Exploring Different Types of Crankshafts and Their Applications

Crankshafts are a vital component of engines, responsible for converting the reciprocating motion of the pistons into rotational motion. They serve as the backbone of an engine, facilitating the transfer of power from the pistons to the drivetrain. The world of crankshafts is incredibly diverse, with different types and functions tailored to specific engine requirements. Engine builders and enthusiasts recognize the significance of choosing the right crankshaft type for optimal performance. In this article, we will explore the various types of crankshafts and shed light on their applications across different engine

#1 Understanding Crankshaft Types and Functions

Crankshafts come in a range of designs, each serving a distinct purpose based on the engine’s intended use. The primary function of a crankshaft is to convert the reciprocating motion of the pistons into rotational motion. This conversion is essential for driving the vehicle or powering machinery. Achieving this transformation involves the collaboration of multiple components, including the connecting rod and crank pin, which play crucial roles in the overall system.

Engine builders often have the option of choosing fully built crankshafts or those with specific modifications to suit their engine’s needs. Fully built crankshafts undergo meticulous design and engineering processes to ensure optimal performance, durability, and efficiency. The selection of the appropriate crankshaft type depends on factors such as the engine’s intended application, desired power output, and the desired torque curve.

#2 Different Types of Crankshafts

Cast Iron Crankshafts

Cast iron crankshafts are commonly found in older engines or engines designed for heavy-duty applications. Cast iron provides excellent strength and durability, making it suitable for engines that experience high stress and loads. However, cast iron crankshafts can be heavier than other types, which may affect the engine’s overall weight and performance.

Forged Steel Crankshafts

Forged steel crankshafts are a popular choice for high-performance engines. They are created through a forging process that involves shaping the crankshaft under extreme heat and pressure. This manufacturing technique enhances the strength and durability of the crankshaft, making it capable of withstanding higher RPMs and torque. Forged steel crankshafts are often found in sports cars, racing engines, and performance-oriented applications.

Billet Crankshafts

Billet crankshafts are machined from a solid block of high-quality steel or aluminium alloy. This manufacturing method allows for precise customization and optimization of the crankshaft’s design. Billet crankshafts are commonly used in custom-built engines, where specific performance requirements need to be met. They offer excellent strength, reliability, and flexibility to achieve desired engine characteristics.

Nitrided Crankshafts

Nitriding is a surface-hardening process that involves diffusing nitrogen into the outer layer of the crankshaft. This treatment improves the crankshaft's wear resistance and reduces the risk of surface fatigue. Nitrided crankshafts are commonly used in engines that operate under high temperatures and experience high combustion pressures, such as turbocharged or supercharged engines.

#3 Applications of Different Crankshaft Types

Automotive Engines

Automotive engines vary in their requirements, depending on factors such as vehicle type, intended use, and desired performance characteristics. Cast iron crankshafts are often found in heavy-duty trucks, where strength and durability are crucial. Forged steel crankshafts are commonly used in sports cars and high-performance vehicles, where the engine needs to withstand high RPMs and torque. Billet crankshafts find their place in custom-built engines, allowing engine builders to achieve specific performance goals.

Racing Engines

Racing engines demand exceptional performance and reliability. They require crankshafts capable of withstanding extreme stresses and high RPMs. Forged steel crankshafts are a popular choice in racing engines due to their strength and durability. Billet crankshafts are also highly sought after in professional racing, as they offer precise customization options to meet the specific requirements of different racing disciplines.

Industrial Engines

Industrial engines power a wide range of machinery, including generators, pumps, and heavy equipment. These engines often operate under heavy loads and prolonged periods of use. Crankshafts for industrial engines are typically chosen based on their strength, durability, and resistance to wear. Cast iron or forged steel crankshafts are commonly used in industrial applications, depending on the engine’s power requirements and expected workload.

Conclusion

Crankshafts are a crucial component in the world of engines, facilitating the conversion of reciprocating motion to rotational motion. The choice of the right crankshaft type is essential for achieving optimal performance, durability, and efficiency in different engine applications. Cast iron, forged steel, billet, and nitrided crankshafts each have their advantages and are tailored to specific engine requirements. Whether it’s for automotive, racing, or industrial engines, understanding the different crankshaft types and their applications allows engine builders to make informed decisions and achieve the desired engine characteristics. By delving into the intricacies of crankshafts, we uncover the secrets behind their incredible functionality and their significant role in powering our world.

#Crankshafts#crankshaft types#reciprocating motion#engine builder#crank pin#fully built#connecting rod

0 notes

Text

Mechanics. Inside of a WWII Allison aircraft engine.

#yzshot#travel#allison#aircraft engine#aviation engine#wwii#black and white photography#black and white#gears#crankshaft#machinery#engine#motor#power#cutaway

8 notes

·

View notes

Link

For grinding and polishing of crankshaft onsite all the required tools and machines are provided. Through use of a specially designed compact onsite grinding machine we are capable of undertaking crankshaft grinding on vessel without involving dismantling of the shaft from the entablature. Get detailed information through contacting us at [email protected], 0124-4251615, or +91-9582647131.

#grinding and polishing of crankshaft#crankshaft grinding on vessel#crankshaft grinding#grinding of crankshaft#Crankshaft grinding machine manufacturer#crankshaft grinding and repair#crankshaft repair services#crankshafts#in situ grinding crankpins#onsite diesel engine repair#onsite repair services#onsite grinding and polishing#grinding and repair#Insitu Crankshaft Repair of MAN B&W#crack repair#Crankshaft Grinding Machine#onsite crankshaft grinding machine#insitu crankshaft grinding machine

0 notes