#Railway Parts Manufacturing

Text

Understanding the Role of Materials in Railway Parts Manufacturing

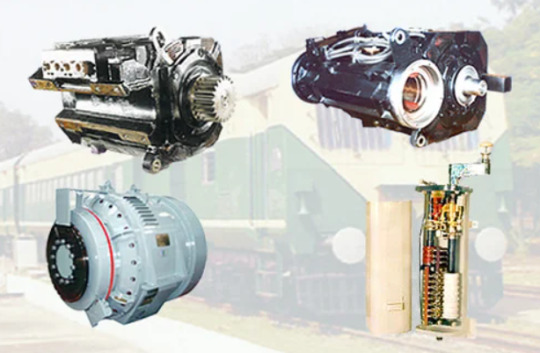

The manufacturing of railway parts is a complex and intricate process that requires a deep understanding of various elements, particularly when it comes to critical components like crankshafts. A fundamental aspect that significantly influences the performance and reliability of railway engines is the choice of materials used in their construction. In this blog, we will delve into the crucial role of materials in the manufacturing of railway parts, with a specific focus on crankshafts.

Crankshafts, being essential components of any railway engine, play a pivotal role in converting reciprocating motion into rotational motion, powering the wheels and propelling the locomotive forward. The efficiency, durability, and overall performance of the engine heavily rely on the properties of the materials employed in crafting the crankshaft. By exploring the relationship between crankshaft manufacturing and materials, we can gain valuable insights into how residual stress, manufacturing technology, and material selection impact its performance.

To comprehend the significance of these aspects, we will analyze the diagram showing the intricate design and composition of a crankshaft, shedding light on how specific materials are strategically utilized in various sections to optimize strength, weight, and stress distribution.

Join us on this informative journey as we unravel the mysteries behind the selection of suitable materials, the effects of residual stress on performance, and the latest manufacturing technologies shaping the railway industry. Understanding the interplay between materials and the manufacturing process is vital for ensuring safe, efficient, and reliable railway operations in the modern era.

Role of Materials in Railway Parts Manufacturing

The railway industry is a cornerstone of modern transportation, and the efficiency and safety of railway systems heavily depend on the quality and durability of the components that make up the intricate network. One critical aspect of railway part manufacturing is the selection and utilization of appropriate materials. This holds true particularly for components like crankshafts, which play a pivotal role in the functioning of locomotive engines. In this discourse, we delve into the nuances of crankshaft manufacturing, the significance of materials, and the impact of manufacturing technologies on the final product.

Crankshaft Manufacturing: An Overview

A crankshaft is an essential mechanical component in the engine of a locomotive, responsible for converting reciprocating motion into rotational motion. As the engine pistons move up and down, the crankshaft translates this linear motion into the circular motion needed to drive the wheels. Given the high stresses and loads involved, crankshaft materials must exhibit superior mechanical properties to ensure reliable performance and longevity.

Material Selection for Crankshaft Manufacturing

The choice of materials for crankshaft manufacturing is a critical factor that directly affects the component’s performance and service life. Traditionally, materials like cast iron were used due to their robustness and ease of manufacturing. However, advancements in materials science have led to the adoption of more sophisticated materials, such as forged steel and even specialized alloys.

Forged steel offers improved strength, fatigue resistance, and better impact properties compared to cast iron. Its homogeneous structure, achieved through controlled manufacturing processes, ensures consistent material properties throughout the crankshaft. Moreover, specialized alloys, like nodular cast iron, provide a balanced combination of tensile strength, ductility, and fatigue resistance. The right choice of material depends on factors such as the engine’s power output, operational requirements, and the desired service life of the crankshaft.

Role of Materials in Performance

The materials used in crankshaft manufacturing significantly influence the overall performance of the engine. The mechanical properties of the material dictate its ability to withstand the cyclic stresses and high loads that occur during engine operation. High-strength materials contribute to enhanced durability, minimizing the risk of catastrophic failures that could disrupt railway services.

One crucial aspect to consider is residual stress. During the manufacturing process, various techniques such as heat treatment and surface finishing can induce residual stresses in the material. Residual stresses can impact fatigue life, leading to premature failures. Proper material selection, combined with controlled manufacturing processes, can help mitigate the negative effects of residual stress, ensuring a longer lifespan for the crankshaft and the engine as a whole.

Managing Technology’s Influence

Advancements in manufacturing technology have brought about substantial improvements in the quality and precision of crankshaft manufacturing. Computer Numerical Control (CNC) machining, for instance, allows for intricate shaping and accurate dimensioning of crankshafts. CNC technology not only enhances the final product’s geometry but also plays a role in optimizing material usage, reducing waste, and improving overall efficiency.

Furthermore, the use of finite element analysis (FEA) has revolutionized the design and validation of crankshafts. FEA enables enterprises to simulate real-world operating conditions and predict how different materials will behave under various loads and stress conditions. This simulation-driven approach empowers manufacturers to refine material selection and manufacturing processes before physically producing the component, ultimately saving time and resources while ensuring optimal performance.

The Visual Representation of Crankshaft Material

A diagram shows the cross-section of a crankshaft, highlighting the layered composition of the material. The outer layer, often composed of a hardened alloy, provides resistance against wear and surface fatigue. Beneath this layer, the core material exhibits a balance between strength and ductility, allowing it to withstand the bending and torsional stresses imparted by the engine’s operation. The careful selection of materials for both layers is crucial in ensuring the crankshaft’s reliability and longevity.

The role of materials in railway parts manufacturing, particularly in components like crankshafts, cannot be overstated. The choice of materials directly impacts the component’s performance, durability, and overall reliability. With the ever-evolving landscape of materials science and manufacturing technologies, businesses and manufacturers have a wider array of options to choose from, enabling them to optimize the design, fabrication, and performance of railway components. As the industry continues to evolve, a deep understanding of materials and their behaviour will remain pivotal in shaping the future of railway transportation.

Conclusion

In conclusion, the role of materials in railway parts manufacturing, particularly in the context of crankshafts, holds paramount importance in ensuring the efficiency, reliability, and safety of railway engines. The manufacturing of crankshafts demands a deep understanding of materials, their properties, and the impact of manufacturing technologies on their performance. By carefully selecting suitable materials and employing advanced manufacturing techniques, you can create crankshafts that optimize engine efficiency, reduce emissions, and enhance overall performance.

The significance of material selection in crankshaft manufacturing lies in achieving a delicate balance between strength, durability, and weight. High-performance materials, such as steel alloys, continue to play a crucial role, while advancements in material science continually present opportunities for further innovation.

Additionally, considering factors like residual stress is essential for ensuring the long-term reliability and safe operation of railway engines. Proper management of residual stress during manufacturing processes is critical to prevent premature failure and maintain the structural integrity of the crankshaft.

Visual representations, such as diagrams, provide invaluable insights into the complex design and material distribution within the crankshaft. These diagrams aid in making informed decisions during the manufacturing process, leading to the production of high-quality crankshafts that can withstand the rigors of railway operations.

As the transportation industry advances, a deep understanding of the interplay between crankshaft manufacturing, materials, and technology will continue to drive progress in the field. Embracing innovative materials and manufacturing techniques will pave the way for more efficient, environmentally friendly, and reliable railway systems, contributing to a sustainable future for rail transportation.

0 notes

Text

Evolution of EMD Traction Motors: From Early Models to Modern Innovations

Railway transportation has been a cornerstone of global mobility for centuries, and at the heart of locomotive propulsion lies the traction motor. Over the years, Electro-Motive Diesel (EMD) traction motors have undergone a remarkable evolution, transitioning from early models to modern innovations that have revolutionized the efficiency, reliability, and sustainability of rail transport. This journey of innovation reflects the relentless pursuit of excellence in engineering and the commitment to meet the evolving needs of the railway industry.

The story of EMD traction motors begins in the early 20th century when pioneering engineers sought to develop propulsion systems capable of delivering the power and torque required to propel heavy trains across vast distances. The earliest EMD traction motors were characterized by their simplicity and ruggedness, designed to withstand the rigors of continuous operation in harsh railway environments. These early models laid the foundation for the subsequent advancements that would shape the future of rail transport.

One of the key milestones in the evolution of EMD traction motors came with the introduction of direct current (DC) traction technology. DC traction motors offered improved efficiency and control over locomotive operations, allowing for smoother acceleration, deceleration, and better traction on varying track conditions. This technological leap paved the way for the widespread adoption of EMD traction motors in locomotives around the world, solidifying their reputation for reliability and performance.

As the demands of the railway industry continued to evolve, so too did EMD traction motors. The transition from DC to alternating current (AC) traction technology marked a significant turning point in the evolution of locomotive propulsion systems. AC traction motors offered several advantages over their DC counterparts, including higher power density, improved efficiency, and greater flexibility in controlling locomotive performance. EMD embraced this shift towards AC traction technology, developing innovative motor designs that further enhanced the capabilities of modern locomotives.

In recent years, the focus of EMD traction motor innovation has shifted towards sustainability and environmental stewardship. With growing concerns over climate change and air pollution, there has been a concerted effort to reduce the carbon footprint of rail transport through the development of more energy-efficient and environmentally friendly propulsion systems. EMD has responded to this challenge by incorporating cutting-edge technologies such as regenerative braking and hybrid propulsion systems into their traction motor designs, allowing locomotives to recover and reuse energy during operation, thereby reducing fuel consumption and emissions.

Furthermore, advancements in materials science and manufacturing techniques have enabled EMD to produce traction motors that are lighter, more compact, and yet more powerful than ever before. By leveraging lightweight materials such as aluminum and composite alloys, EMD has been able to achieve significant reductions in the weight and size of traction motors, resulting in improved efficiency and performance while reducing the overall environmental impact of locomotive operations.

Another area of innovation in EMD traction motors is the integration of digital technologies and predictive maintenance solutions. By equipping traction motors with sensors and onboard diagnostics, EMD has enabled locomotive operators to monitor the health and performance of their equipment in real-time, allowing for proactive maintenance and troubleshooting to prevent costly breakdowns and maximize uptime. This shift towards predictive maintenance not only improves the reliability and safety of railway operations but also reduces maintenance costs and enhances the overall efficiency of locomotive fleets.

Looking ahead, the future of EMD traction motors is filled with promise and potential. As rail transport continues to evolve in response to changing market dynamics and technological advancements, EMD remains committed to pushing the boundaries of innovation to meet the evolving needs of the railway industry. Whether it's through the development of more energy-efficient propulsion systems, the integration of advanced digital technologies, or the adoption of sustainable manufacturing practices, EMD traction motors will continue to play a vital role in shaping the future of rail transport for generations to come.

In conclusion, the evolution of EMD traction motors from early models to modern innovations is a testament to the ingenuity, perseverance, and commitment of engineers and innovators in the railway industry. Through decades of relentless innovation and technological advancement, EMD traction motors have transformed the landscape of rail transport, driving progress, and propelling locomotives into the future. As the demands of the railway industry continue to evolve, EMD stands ready to meet the challenges of tomorrow with innovative solutions that will shape the future of rail transport for generations to come.

0 notes

Text

The market of railway parts manufacturers in India

Industry Overview

India has the fourth-largest railway network in the world, just behind the US, Russia, and China.

This huge market requires a constant supply of spare parts and components.

Advanced composite component manufacturers such as Rockman AC are supplying the most advanced railway components.

The railway parts manufacturers in India are growing rapidly to meet this demand.

Growth factors

The growth of the railway parts manufacturing industry is driven by

The government's focus is on infrastructure development.

Increasing demand for railway as a mode of transportation.

Quality of components supplied by the third-party manufacturers.

Key components manufactured with advanced composites

Several body components and parts are manufactured with advanced composites:

Composite car bodies are now very common, especially in high-speed trains.

Composite interior panels are lighter and more durable.

Bogies get extra strength and rigidity with advanced composites.

Composite braking components are lighter, heat resistant, and durable.

Composite doors and windows are energy efficient, corrosion resistant, and durable.

For more information on railway parts manufacturers in India visit: https://rockmanac.com/

0 notes

Text

Sujan Industries stands out as a premier railway parts manufacturer in India, offering a diverse range of railcar components, rubber springs, rubber pads, and more.

0 notes

Text

LancerFab is a reliable manufacturer and supplier of railway parts in India. With rich experience in manufacturing railway products that are critical to the sustenance and development of the railways, we offer Indian railway parts and Indian railway metro parts to the railway sector in the country.

#metal fabrication#sheet metal fabrication#railway equipment manufacturers#railway parts manufacturer#metro rail & railway parts manufacturer#metro rail parts manufacturer#railway parts manufacturer of India#metro rail and railway parts supplier

0 notes

Text

Driving the future of Indian railways: Precision-engineered railway parts manufacturers in India.

The company was established in 2013 with a vision to provide world class high quality standards OEM equivalent railway replacement spare parts for ALCO Locomotive, EMD Locomotive, G.E. Locomotive, WABCO (Exhauster/Compressor Parts, Air Brake Parts). The company deals in New & Reconditioned Parts.

#railway parts manufacturers in India#rail parts manufacturers in India#alco 251 engine parts#emd locomotive parts#alco locomotives parts#wabtec locomotive parts

0 notes

Text

Members of an ethical hacking group called Dragon Sector, including Sergiusz Bazański and Michał Kowalczyk, were called upon by a train repair shop, Serwis Pojazdów Szynowych (SPS), to analyze train software in June 2022. SPS was desperate to figure out what was causing "mysterious failures" that shut down several vehicles owned by Polish train operator the Lower Silesian Railway, Polish infrastructure trade publication Rynek Kolejowy reported. At that point, the shortage of trains had already become "a serious problem" for carriers and passengers, as fewer available cars meant shorter trains and reduced rider capacity, Rynek Kolejowy reported.

Dragon Sector spent two months analyzing the software, finding that "the manufacturer's interference" led to "forced failures and to the fact that the trains did not start," and concluding that bricking the trains "was a deliberate action on Newag's part."

According to Dragon Sector, Newag entered code into the control systems of Impuls trains to stop them from operating if a GPS tracker indicated that the train was parked for several days at an independent repair shop.

The trains "were given the logic that they would not move if they were parked in a specific location in Poland, and these locations were the service hall of SPS and the halls of other similar companies in the industry," Dragon Sector's team alleged. "Even one of the SPS halls, which was still under construction, was included."

The code also allegedly bricked the train if "certain components had been replaced without a manufacturer-approved serial number," 404 Media reported. [...]

404 Media noted that Newag appeared to be following a common playbook in the right-to-repair world where manufacturers intimidate competitor repair shops with threatened lawsuits and unsubstantiated claims about safety risks of third-party repairs. So far, Dragon Sector does not appear intimidated, posting its success on YouTube and discussing its findings at Poland’s Oh My H@ck conference in Warsaw.

211 notes

·

View notes

Text

ANALYSING Q!SLIME'S FINAL BIRTHDAY GIFT [12/08/2023]

With the addition of the underground railway within the mines of q!Slime's Eggxile base, the choices on the birthday build (from the lead-up, the threshold, to the house itself) adds so much on to q!Slime's character as well as gives hints on the bigger picture of the Federation and the new wave of codes.

Prior to today's Birthday stream, the two significant builds in Eggxile are the Altar to Lil J and the Basement - two builds that represent q!Slime's religious devotion and his familial devotion respectively.

I did an analysis comparing the two in another post HERE as a Part 1 - big recommend to read through that one before this one when you can!

This time I'll be going into detail specifically about the underground railway and how it represents q!Slime's 'devotion' to the island itself and the Federation.

long rambling ahead be careful

[EXPLANATION UNDERCUT]

PREVIOUS KNOWLEDGE:

Quick SparkNotes summary about Slime's way of building:

Slime's builds are simplistic, symmetrical layouts (preferably circular)

Comprised of mostly local, easy to obtain/manufacture materials

A lot of flora interior

NO security, little-to-no input from the Create-mod

These characteristics were derived from the similarities between Slime's existing builds of the Altar and the Basement. The uncanniness of the Birthday Build is that it is an extension NOT built by Slime, but instead is the Federation's attempt to imitate his style and forcibly insert itself into his life.

We can presume that this is the Federation's doing and by extension JuanaFlippa's current identity by the context clues during the scavenger hunt. The main giveaway being the location of the START placed at the QSMP Dinner Hall: the first sightings of the Egg Codes and the location of Gegg's assassination. The detail of the FIRST CLUE as well being Slime's train ticket to the island supports this theory in assumption that it was the Federation that both brought the original 17 residence to the island and is currently withholding the tickets themselves.

The scavenger hunt goes as planned, all in all directing Slime back to his Eggxile base. (Note the poster being placed IN FRONT of the school's only exit)

THRESHOLD BETWEEN THIS WORLD AND THE NEXT:

Not much of Slime's actual base is touched in the scavenger hunt other than the nook in the Basement Slime had originally designed to be JuanaFlippa's area. Here it is decorated with the carpet, two chairs, and two presents. Everything before that (lamps including) was made by Slime.

After Slime collects what he believes is the last of the presents the lamps in the Basement are progressively removed directing him to the only other light in room being the black wool platform and chest. These lamps were destroyed NOT turned off. The contents of the chest read as follows:

Hostile architecture is defined as a design strategy to purposefully guide or restrict movement (targeting mostly the homeless. it sucks). And by limiting Slime's vision here is the first of many examples of the Federation restricting Slime's movement as the path progressively becomes more and more forced.

From here to the mine entrance Slime is still given a physical choice whether or not to follow the light. This is the Federation's way in giving Slime the illusion of free choice. 'You chose to follow the light' 'You chose to break that wall in the mines' 'You chose to activate the train carriage'

The train carriage and its small, difficult to move around, interior being the last direct choice Slime makes. It locks him inside and sends him on a trip that goes no where but down, deeper into the mines.

It's worth noting that originally these mines originally belong to Slime. He made this entrance and he was able to freely explore any part of these caves. What the train carriage does is give Slime a strict path to follow and a very limited window to look through - no straying from the path here. Look only where the Federation tells you to.

Given the connection between codes and trains, symbolically this can also represent Slime's gradual spiral (the shape of the tracks) into hell - the madness that is the island led on by the Federation.

JUANAFLIPPA'S HOUSE:

The road ends at a small house at the very bottom of the lush caves. It's a nice house! Supposedly trying to replicate the arched partition walls in the Basement... But not quite perfectly imitating his style of build. The giveaways being its asymmetry and the choice of materials: a variety of different wood types, most NOT local to Eggxile (also the fake house just looks prettier wwww)

Here's the two houses for comparison (Slime's house is an 8x8 block square)

Stylistically, the vibe of this house given the location and purpose remind me of that one Cold War bunker in Las Vegas. An underground mansion designed to look like the outside world - a secluded, controlled paradise for a family to live in.

The confirmation that the underground house being a facade becomes clearer the deeper Slime explores the inside.

Normal interior. Normal kitchen. Normal table: 4 chairs (like the outside bonfire), 3 mugs (Slime, Mariana, Juanaflippa). Shelves like Slime's old house in Sacapuntas. A passageway in the wall leading to Juanaflippa's room.

All these things portraying the life Slimeriana and Juanaflippa could have lived. A happy family tucked under from all the dangers of the outside, far far away from the world. Until you look deeper into the cracks only to find out it was all fake, there is nothing back there. A mockery in disguise of a gift.

THE FEDERATION AND SLIME:

Prior to the birthday stream with the assassination of Gegg, Slime had initially come to terms that Juanaflippa was well and truly dead and had told ElQuackity (a member of the Federation) that he no longer had any attachments to the island, and because of that would try to be himself.

The Federation responded to this twice: the first being ElQuackity offering a position to work with them and ElQuackity win the Elections (this fails as ElQuackity is assassinated by q!BBH); the second being this birthday stream.

So far the Federation has not destroyed anything Slime has built but instead added on top of it. These decisions both give Slime a reason to stay on the island whilst pushing him to do things aligned with the Federation's goals shown by the gifts he gets in the scavenger hunt (Ghillie suit, landmines, grappling hook, dark metal ingots).

Interestingly the 2nd prize during the scavenger hunt is quite literally called the CHARLIE Flag and is the nautical symbol for YES. While the purpose of this flag is for whatever mission the Federation is about to send Slime on, this is also metaphorical as the only response Slime can give right now is YES.

Additionally the flag metaphor could be applied on the controls at the beginning of the tracks: Red flag both socially and in Nautical terms (BRAVO) meaning danger/carrying dangerous cargo.

These are literal red flags in the world in the architecture that are warnings to Slime that once he 'agrees' to these terms and conditions, life for him will only get more dangerous with no way in turning back. Deliberate decisions made by the Federation in guise of Slime's actions and the places he's impacted in the world.

In the end, Slime is a product of the early QSMP and how its history shapes a person and is represented physically by the builds he makes. By the interference of the new tech and prettier structures, the Federation overwrites Slime's creations against his will, creating a world unfamiliar to him - blending what is the truth of the past with the new, augmented present. In another context, change like this can be a good thing - but in this circumstance presents itself as an invasive decision into Slime's private life. This is the Federation forcibly applying itself as one of Slime's priorities in sacrifice of rewriting everything Slime has gone through.

#stufff rambles#long post#slimecicle#qsmp#qsmpblr#qsmp analysis#qsmp spoilers#wish I could add more research on more cultural/historic symbolism tho this what comes to mind at the moment#Something else I wanted to add (idk where itd go) being Slime's healing arc sharing similarities w/ the Orpheus and Eurydice story#He keeps going to the end holding onto hope until the very end where he turns around to lose everything and damning everyone#this story visually being when Slime tries to run after Juanaflippa suddenly losing sight of her

375 notes

·

View notes

Text

Traintober 2023: Day 1 - Free Day

Preservation on Sodor:

Sodor must be one of the most interesting places to look at when it comes to railway preservation, if not also road, sea and air preservation. For starters, the island’s railways are all still primarily run by vintage steam traction – but there’s also Harold, who is in his 60s or 70s at this point, Bertie the bus (who is nearing 100), Trevor and Terrence and George – not to mention the fact that the island seems to continue to have antique ships within its waters, including steam ships and fishing trawlers.

But of course, I want to focus on the railways – and in particular how Sodor must be the British hub for heritage railways, museums and other attractions. For starters, Sodor has by far the largest heritage railway system in the world for its size, with over 80 miles of mainline, several branchlines, a narrow-gauge railway, a mountain railway and a miniature gauge railway. It also has a massive fleet of engines – 80 by the Reverend’s count on the NWR alone – making it possibly the single largest working heritage railway in the UK, if not Europe. This would instantly attract many preservationists wishing to run their locomotives, meaning that mainline excursions and visitors would be a frequent sight on the island. This in turn would bring in tourists, who would make money for the NWR and the railway the engines belong to, as well as helping the Fat Controller if one of his enignes is unable to work. It would also give us as railfans the chance to see unique motive power on a variety of trains - like a Coronation Class pulling a slow goods, or a Hughes Crab on a China Clay train - things we don't get to see anymore.

Furthermore, Sodor is home to Crovan’s Gate Works, the largest steamworks of its kind in Britain. For its influence, I am going to turn to 60163 Tornado. When Tornado was built, her boiler had to be manufactured in Germany because there was just no one in the UK able to produce a boiler of the type, while the superheater header needed to be attempted by three foundries before it was assembled correctly. Crovan’s Gate Works, which is able to maintain a full fleet of engines including Gordon – who is also an A1 with many similarities – would have been able to do both in a far timelier manner. The same would go for all locomotive repair programs in the UK. Crovan’s Gate would either host locomotives or manufacture parts for them, becoming a hub for preservation across the country. Engines like Stepney or Green Arrow would be able to be overhauled at the Works, rather than be taken out of service. This would effect how many steam engines are in working order in Britain, if not Europe, as the refurbishment time would be significantly shortened - something that is compounded if said locomotive shares any components with a Sodor engine - like Talyllyn, Dolgoch, Flying Scotsman or any of the Black 5s, Panniers or Autotanks in preservation.

This brings me on to the last point: International Tourism. Sodor must be one of the most visited locations in Britain in this universe. For starters, there’s all the fans of the book and TV series (which are both canon and referenced in the books). This means that Sodor would have tens of thousands of families coming to the island from around the world annually to see the ‘Eight Famous Engines’ or the ‘Steam Team’, bringing in a massive amount of revenue for hotels, local businesses and the railways themselves. But there would also be the railfans who come with the aforementioned railtours, as well as international railfans who want to see steam in action in a mainline setting – something nearly impossible anywhere on the planet. Sodor has at least one airport (and probably two, considering in real life there is an airport on Walney Island near the real-life Vickerstown), six ports connected to the NWR, and a rail and road link to the UK. The island has the infrastructure to handle the flocks of tourists, and this would in turn benefit much of the rest of Northern England. This would majorly benefit the preservation world by bringing in funding for Sodor, which is in turn able to fund things like track upgrades, or overhauls for engines beyond their own railway. It also gives other railways a good place to promote themselves, as Sodor has a guaranteed market for tourists who may travel to these other railways.

You cannot understate how much these books have done for Sodor, and for railway preservation as a whole.

So, Sodor is at the very least a centre for preservation in the UK, with railtours, overhauls and masses of international tourists – but it’s also where a lot of engines were likely rescued from. We see it in Oliver and Douglas, but engines know of Sodor and its safety. I can imagine an alternate universe in which engines keep turning up throughout the 1960s, being brought to safety on Sodor and then sold to heritage railways, being overhauled at Crovan’s Gate before moving to their new homes. Sodor would act as an intermediate in this era, being able to do the paperwork to preserve engines due to its position in the national network while also being aligned with the cause of the heritage railways. Sodor is a safe haven for steam, and this would have a significant impact on its position as a preservation hub for the UK.

Back to the Master Post

#railway series#weirdowithaquill#thomas the tank engine#railways#traintober 2023#railway preservation#rambles

95 notes

·

View notes

Text

StEx in real life Part 2: Coaches

As per the last StEx irl post, these do not match up perfectly. They're simply the closest I can find to what we see in the show despite the frequent inconsistencies/lack of information, with a few of my own headcanons sprinkled in.

Pearl: Pennsylvania Railroad balcony observation car

This is such a perfect match. Pearl doesn't always have a confirmed origin company, but on her Vegas/Tour outfit she wears the Pennsylvania Railroad logo on her belt. She's likely an open observation car due to the railing on her neckline, which fits the bill for this coach.

Dinah: American dining car

The coach in the photo is a Wabash car, but really any dining car from an American passenger service would fit Dinah (I picked this one for the colour). In English-speaking productions she's typically portrayed with a Southern accent, but this doesn't automatically dictate which company built her as accents can change over time.

Buffy: LNER buffet car

Buffet cars are an increasing rarity (at least here in Britain), with most being replaced but buffet trolleys instead. But dedicated buffet cars certainly used to be a thing, and I think this one fits Buffy very well. I imagine she was sold off to America, and acquired her New York accent there.

Ashley: Four-wheeled 1st class smoking car

Ashley to me has always screamed "vintage" in her design, she looks like she's made of polished wood and she's likely the oldest of the coaches still in service. She's also 1st Class (based on her placement in the train), so this particular coach fits her perfectly. I imagine she's been modified and had a gangway connection fitted though, to couple up with the more modern coaches.

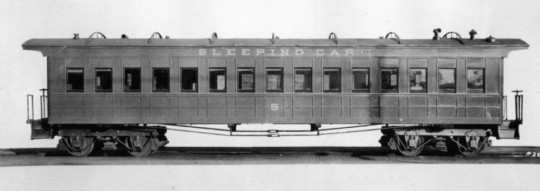

Memphis Belle: Pullman sleeping car

This one is just outright fact, as Memphis Belle explicitly tells us both her class and her manufacturer. Which company she worked in service for is another matter, but in one version of her lyrics she claims to have been bought by Cornelius Vanderbilt, who owned a lot of railways.

Brandi: 1st class parlour car

Whilst to my knowledge "bar car" is not a dedicated coach class, Belle/Brandi nicely fits a lounge car; she has a posh, elegant design, and lounge cars are often fitted with bars. She's also first class, as indicated by her train placement, which matches her stylish design.

Carrie: Combine luggage/passenger car

Whilst Carrie is only ever stated to be a luggage van, I think it's possible she's a combine, fitted with a passenger section as well as luggage compartment. She's likely part of Control's express train, and a combine would allow for more passengers. Plus her design just fits this idea to me.

23 notes

·

View notes

Text

I adore the steelworks gang, like more than I've seen other people express online.

First of all...

My little icon Lexi.

They have been known and initially regarded for their silly voices and jolly nature but I don't often see people looking into why they do it. Like their voices make them more wild than Marion who's generally loved by some fans but they also do it in spite of themselves. They and Theo did an entire upbeat song about how much they are failures to railway engineering with lyrics like:

"We're experiments gone bad

in other words whoever designed us must be mad."

These are not the words of someone with self esteem in how funny they are! They even showed them actually depressed when saying 'We can't do anything.' for the final time in the special.

And anyone who knew how long it took for more in-your-face LGBT+ representation in 2018 She-Ra will know that if this special just came out three or four years later, we might've had proper gender-fluid Lexi representation.

As for Theo...

He is still a pure little bean and I feel the ambiguity of his design makes it all the more reason for him to feel bad about his design. I don't know what about his design warranted gigantic cogs on his sides but we don't know what went on in whatever workshop he was built at. For all we know he could've had the Henry treatment, having been dumped on the doorstep on the first desperate railway executive needed an engine, as a last ditch effort for a dying manufacturer.

As for him being on the spectrum, I can still see it in his behaviour. Lexi was truly not gender fluid but once you've met one autistic person, you've met one autistic person.

And some characteristics are visible in him.

His unintentional bluntness. "Are you being scrapped?"

His tics and stutters.

His shakes in excitement, if you were to count it as stimming.

And who's to say he's not limited to physical disabilities? He and Lexi, depending on how successful you can view it having designs as unique as them on British rails, are the perfect ones to have given the body language they were adamant on giving all the engines back then.

Him being so gentle and anxious is generally adorable, so yeah, not so much to say about his actual personality.

Speaking of not much to say, not much to say on Merlin either, at least nothing that people haven't said already. We all know how awesome he is.

Beresford is MY MAN!

Beresford just wants a friend guys. He said in his own song that he was always ignored by engines who just want to get a job done. No time to chat with him. Loneliness can drive him mad. It is kinda sad that his appearance in Royal Engine was not only a sign of the further appearances these characters could've had but how it was also kinda a rehash of the scene we got in his last appearance, so maybe an episode of his own where he learnt to make friends properly would've been fun.

Ah well, at least he got some friends in another life.

And what can I say about Hurricane?

Keeping it real, working with steel.

Since 1902

He is such a chill guy, that while his companion might've had a lot of hard labour in mind for Thomas, he seems so genuine in wanting to take Thomas in while still acknowledging his terrible position. He could've done with standing up to Frankie though.

But whatever, that's meant to be a part of his character, and he was voiced by the chad Jim Howick no less.

It's so funny when people say he sounded like a member of the royal family when he's played kings before.

And then there's Frankie.

Oh my god I adore her so much. Her manipulation being legitimately intimidating at the best times, especially when she's actually chasing Thomas down in the dead of night, her musical style bribing him into working for her, her VA's performance capturing all of her personality through line delivery perfectly.

Everything about her class, her demeanour, most of her lines makes me so curious about her whole life.

How is she running this steelworks better than the human manager of the works if there even is one? How are the human workmen so ok with her doing this? How did the other engines before Thomas get into doing her work? How did they get out? How did Hurricane stay with her for this long, let alone not encourage some potential friends of his to work with her? Was she indirectly responsible for Hurricane surviving as long as he did to still be a tank engine after she was built? Why didn't the railways surrounding this fictional steelworks not agree with this most likely non-existent human manager not just agree to get a lot of their engines to transport steel from their works? What did Frankie do? What are you hiding from us!?

The whole mystery surrounding her and her apparently feeling put-down and apparently not evil at heart according to her character profile and her role in the book 'Delivery at the Docks' makes her potential crimes such a goldmine for story potential that I really want to delve into very soon.

And yeah, that's what I have to say on them in canon. All beautiful characters that I feel need more recognition on a regular basis.

#thomas the tank engine#thomas and friends#ttte lexi#ttte theo#ttte beresford#ttte merlin#ttte hurricane#ttte frankie#she ra and the princess of power#catradora#all engines go

14 notes

·

View notes

Text

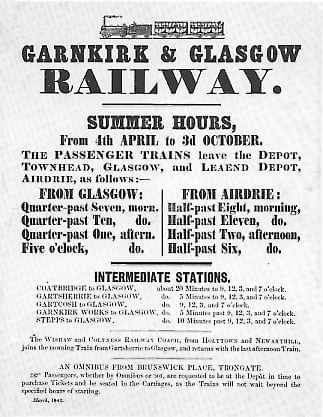

Scotland's first passenger railway, the Glasgow and Garnkirk Railway opened on 27th September 1831.

The line was originally run as a goods service, funded by Charles Tennant & Co manufacturers, with horse-drawn coal trucks operating along the 4ft 6in Scotch Gauge line.

The line allowed coal to be transported into Glasgow from the Monkland Coalfields, whilst avoiding the Monkland Canal with its high charges. The Caledonian Railway took over the line in 1845, and in 1921, the line became part of the London, Midland and Scottish Railway.

20 notes

·

View notes

Text

Behind the Scenes: Exploring the Manufacturing Process of Railway Parts

The smooth and efficient operation of railways relies on a multitude of components and parts working together seamlessly. From locomotives to tracks and signaling systems, every aspect of rail transportation depends on precision-engineered parts that meet strict standards of quality and performance. In this blog, we'll take a closer look behind the scenes and explore the intricate manufacturing process of railway parts.

Design and Engineering:

The journey of manufacturing railway parts begins with design and engineering. Teams of skilled engineers and designers collaborate to develop detailed specifications and drawings for each component. They consider factors such as material selection, mechanical properties, structural integrity, and performance requirements to ensure that the parts meet the demanding needs of the railway industry.

Using advanced computer-aided design (CAD) software, engineers create digital models of the parts, incorporating intricate details and dimensions with precision. These digital models serve as the blueprint for the manufacturing process, guiding every step from prototyping to production.

Material Selection and Procurement:

Once the design phase is complete, the next step is material selection and procurement. Railway parts are often subjected to harsh operating conditions, including high temperatures, heavy loads, and dynamic forces. Therefore, selecting the right materials is crucial to ensure the durability, reliability, and longevity of the parts.

Railway parts manufacturers carefully evaluate various materials, such as steel, aluminum, cast iron, and composite alloys, considering their mechanical properties, corrosion resistance, and cost-effectiveness. Once the materials are selected, they are sourced from reputable suppliers and undergo stringent quality control measures to ensure compliance with industry standards and specifications.

Machining and Fabrication:

With materials in hand, the manufacturing process moves to machining and fabrication. Modern machining techniques, such as computer numerical control (CNC) machining, allow for precise shaping, drilling, and finishing of railway parts with high efficiency and accuracy.

Skilled machinists operate CNC machines to mill, turn, grind, and drill raw materials into intricate shapes and profiles according to the specifications outlined in the digital designs. Advanced cutting tools, abrasives, and machining strategies are employed to achieve tight tolerances and surface finishes that meet the stringent requirements of railway applications.

In addition to machining, fabrication processes such as welding, bending, and forging may be employed to produce certain railway parts. Welders use specialized techniques to join metal components together, while fabricators use presses, brakes, and other equipment to form and shape materials into the desired configurations.

Heat Treatment and Surface Coating:

After machining and fabrication, some railway parts may undergo heat treatment to enhance their mechanical properties and improve performance. Heat treatment processes, such as annealing, quenching, and tempering, alter the microstructure of the materials, increasing hardness, strength, and toughness as needed.

Following heat treatment, railway parts may also undergo surface coating or finishing processes to protect against corrosion, wear, and environmental damage. Coating methods such as painting, powder coating, anodizing, and plating provide a protective barrier that extends the lifespan of the parts and ensures long-term durability in service.

Quality Assurance and Testing:

Quality assurance is a critical aspect of the manufacturing process for railway parts. Manufacturers implement rigorous inspection and testing procedures to verify the quality, accuracy, and performance of each component before it leaves the production facility.

Skilled inspectors use a variety of techniques, including dimensional measurement, visual inspection, non-destructive testing, and material analysis, to ensure that railway parts meet the specified requirements and standards. Any deviations or defects are identified and addressed promptly to maintain the highest levels of quality and reliability.

In addition to in-process inspections, railway parts may undergo functional testing to validate their performance under simulated operating conditions. This may include mechanical testing, such as load testing and fatigue testing, as well as environmental testing, such as temperature cycling and vibration testing, to ensure that the parts meet the demanding requirements of railway applications.

Assembly and Integration:

Once the individual components are manufactured and inspected, they are ready for assembly and integration into larger systems or assemblies. Skilled technicians and assemblers carefully assemble the parts according to engineering drawings and specifications, using specialized tools, fixtures, and equipment.

Assembly may involve fitting together multiple components, connecting electrical and mechanical interfaces, and ensuring proper alignment and functionality of the final assembly. Quality checks and tests are conducted at each stage of assembly to verify that all components are properly installed and functioning as intended.

Finally, the assembled railway parts are packaged, labeled, and prepared for shipment to customers or installation at railway sites. From locomotive engines to track components and signaling systems, each part plays a vital role in ensuring the safe, reliable, and efficient operation of railways around the world.

In conclusion, the manufacturing process of railway parts is a complex and intricate journey that involves meticulous planning, precision engineering, and rigorous quality control. From design and material selection to machining, testing, and assembly, every step is carefully orchestrated to produce parts that meet the demanding requirements of the railway industry. Through innovation, technology, and expertise, railway parts manufacturers continue to push the boundaries of what is possible, driving progress and excellence in railway transportation.

0 notes

Text

Chapter 3. Economy

How will exchange work?

There are many different ways exchange could work in a stateless, anti-capitalist society, depending on the size, complexity, and preferences of the society. Many of these are far more effective than capitalism at ensuring a fair distribution of goods and keeping people from taking more than their fair share. Capitalism has created a greater inequality in access to resources than any other economic system in human history. But the principles of capitalism that economists have indoctrinated the public to accept as laws are not universal.

Many societies have traditionally used gift economies, which can take many different forms. In societies with a modest amount of social stratification, the wealthier families maintain their status by giving gifts, holding lavish feasts, and spreading their wealth; in some cases, they risk the wrath of the others if they are not generous enough. Other gift economies are barely or not at all stratified; the participants simply disown the concept of property and give and take social wealth freely. In his diary, Columbus remarked with amazement that the first indigenous people he encountered in the Caribbean had no sense of property, and gave willingly of all they had; indeed, they came bearing gifts to greet their strange visitors. In such a society, no one could be poor. Now, after hundreds of years of genocide and capitalist development, many parts of the Americas have some of the starkest wealth gaps in the world.

In Argentina, poor people initiated a massive barter network that grew enormously after the economic collapse in 2001 rendered capitalist forms of exchange unworkable. The barter system evolved from simple swap meets into a huge network involving an estimated three million members trading goods and services — everything from homemade crafts, food, and clothing to language lessons. Even doctors, manufacturers, and some railways participated. An estimated ten million people were supported by the barter network at its peak.

The barter club facilitated exchange by developing a credit/currency system. As the network grew, and the capitalist crisis deepened, the network was beset by a number of problems, including people — often from outside the network — stealing or forging the currency. Several years later, after the economy stabilized under President Kirchner, the barter club shrank, but still retained a huge membership considering it was an alternative economy in the country that was once a model for neoliberal capitalism. Rather than giving up, remaining members developed a number of solutions to the problems they had encountered, such as limiting membership to producers so the network is only used by those who contribute to it.

Contemporary anarchists in the US and Europe are experimenting with other forms of distribution that transcend exchange. One popular anarchist project is the “free store” or “give-away shop.” Free stores serve as a collection point for donated or scavenged items that people no longer need, including clothes, food, furniture, books, music, even the occasional refrigerator, television, or car. Patrons are free to browse through the store and take whatever they need. Many accustomed to a capitalist economy who come into a free store are perplexed by how it could possibly work. Having been raised with a scarcity mentality, they assume that since people profit by taking stuff and do not profit by donating, a free store would quickly empty out. However this is rarely the case. Countless free stores operate sustainably, and most are overflowing with goods. From Harrisonburg, Virginia, to Barcelona, Catalunya, hundreds of free stores defy capitalist logic on a daily basis. The Weggeefwinkel, Giveaway Shop, in Groningen, Netherlands, has operated out of squatted buildings for over three years, opening twice a week to give away free clothes, books, furniture, and other items. Other free stores hold fundraisers if they have to pay rent, which would not be an issue in a completely anarchist society. Free stores are an important resource for impoverished people, who either are denied a job by the whims of the free market or who work a job, or two or three, and still can’t afford clothes for their kids.

A more high-tech example of free exchange is the relatively mainstream and wildly successful Freecycle Network. Freecycle is a global network originally formed by an environmental nonprofit group to promote giving away items that might otherwise end up in the trash. As of this writing they have over 4 million members grouped into 4200 local chapters, spread through 50 countries. Using a website to post items wanted or items available to give away, people have circulated prodigious quantities of clothing, furniture, toys, artwork, tools, bicycles, cars, and countless other goods. One of the rules of Freecycle is that everything has to be free, neither bartered nor sold. Freecycle is not a centrally controlled organization; local chapters set themselves up based on the common model, and use the website on which the model is based.

However, as it does come from a liberal nonprofit group without revolutionary aspirations nor any critique of capitalism and the state, we can expect Freecycle to have some problems. In fact, the organization accepts corporate sponsorship from a major recycling company and advertises on its website, and the chairperson has arguably slowed the spread of the Freecycle idea by attacking various member groups or copycat websites with lawsuits, or threats thereof, for trademark infringement; also by collaborating with the notoriously authoritarian Yahoo! Groups to shut down local chapters for not adhering to organizational rules concerning logo and language. Naturally, in an anarchist society there would be no lawsuits for trademark infringement and one chairperson would not be able to tyrannize a network that was maintained by millions of people. In the meantime, Freecycle demonstrates that gift economies can function even within jaded, individualistic Western societies, and can take new forms with the help of the internet.

#anarchism#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#anarchy#anarchists#libraries#leftism#anarchy works

7 notes

·

View notes

Text

Sujan Industries stands out as a premier railway parts manufacturer in India, offering exclusive railcar components, rubber springs, rubber pads, and more.

0 notes

Text

Victorian Warhammer Alternate Universe - Second batch of the Primarchs.

And here are the texts @sonofdorn-vii wrote for them:

(making a cut because very long post)

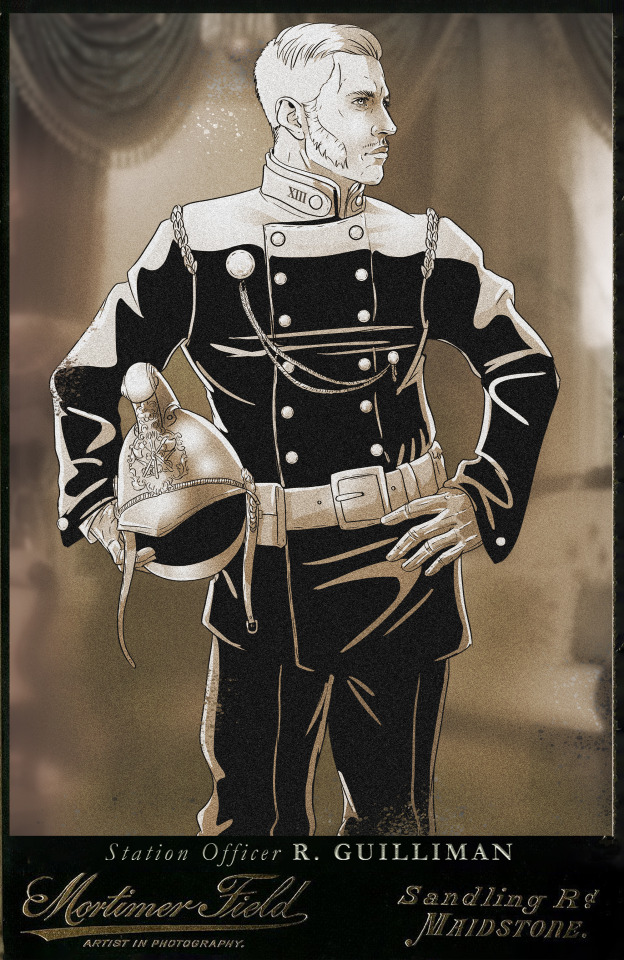

Guilliman, the fire-chief

Station Officer Guilliman is an exceptional firefighter. A solid rule follower, Young Rob decided not to join his father in the army, instead has devoted himself to helping others. Fire Station Thirteen is run with clockwork efficiency, though his men are occasionally sneered at behind their backs for seeming so eager to please him. When alone, Guilliman laments always feeling late to the party, and wishes perhaps he could be more proactive in preventing disaster from striking in the first place, rather than just cleaning up the mess.

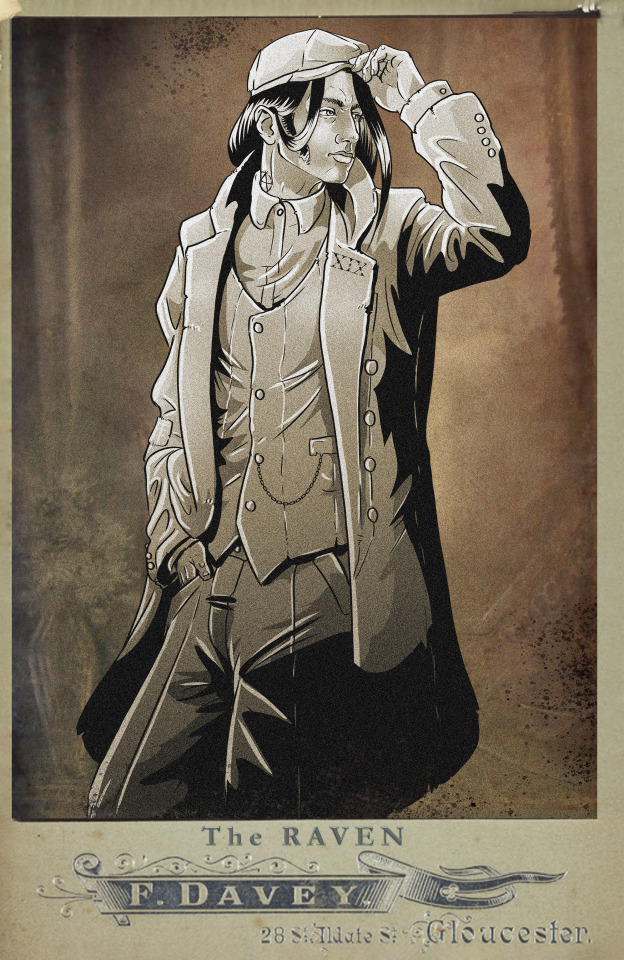

Corvus

Known to the authorities only as 'The Raven', Corvus Corax is a wanted man. A coal miner since early childhood in the deepest pits of Yorkshire, Corvus has seen first hand how the class system benefits the rich at the expense of the working poor. After discussion of forming a workers union lead to the murder of his father at the hands of the mine owner, Corvus vowed that the system would change, even if it must be forced to. Since then, he has committed many acts of sabotage; generating fear and disgust among the richest land owners and is wanted by police forces across the Kingdom

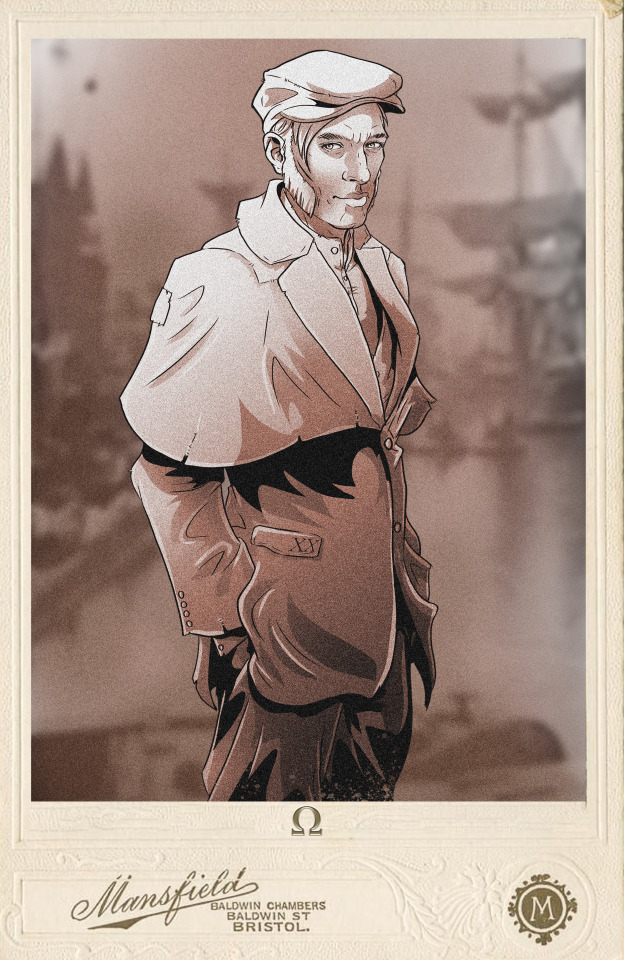

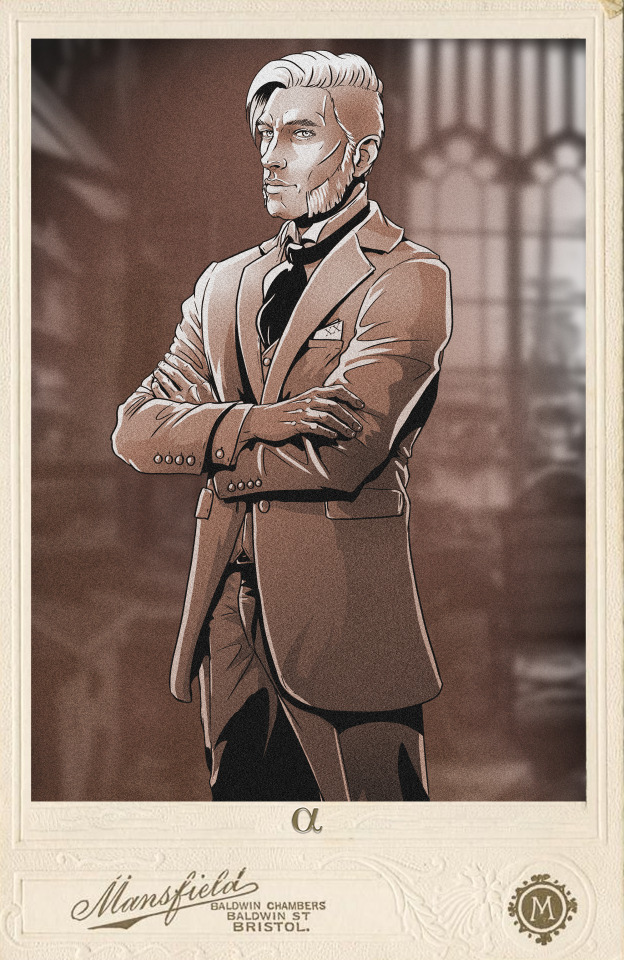

Alpharius/Omegon

Alpharius Omegon is a poor bootblack, plying his trade on the streets of Cardiff. Good at his job; liked, but unnoticed by most of his wealthy patrons, Alpharius has learned that overheard information is often far more valuable than his physical skill for a man who knows how to use it. Alpharius Omegon is also a wealthy shipping magnate, based in Cardiff Docks, who's uncanny knowledge of his competitor's business dealings have often given him an advantage over them in bidding for contracts. Knowing which rival is addicted to chasing the dragon or who has an unhealthy interest in fresh young cadavers can lead to business opportunities of all kinds...

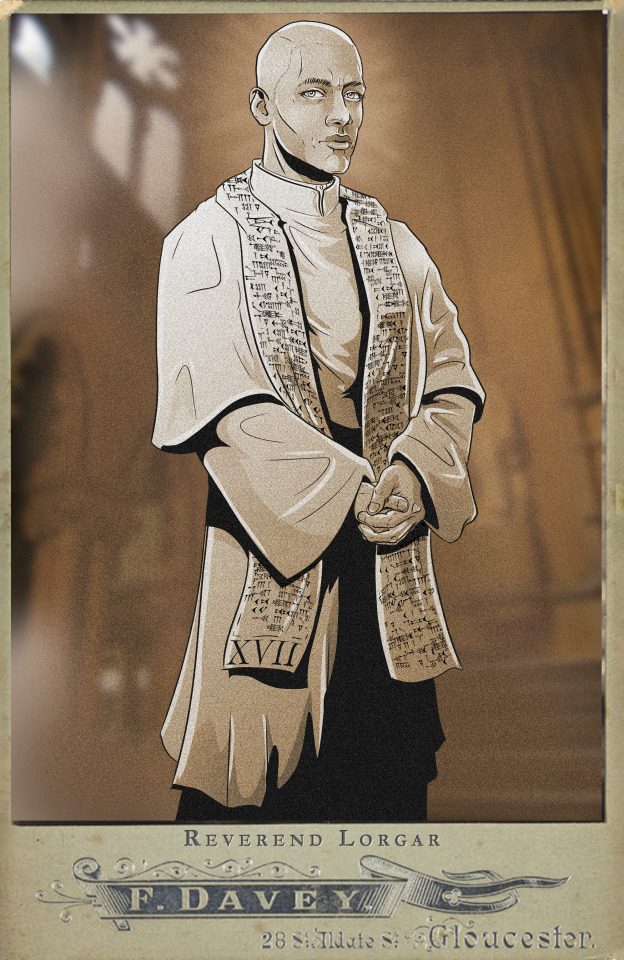

Lorgar

The Very Reverand Lorgar Aurelian is an Anglican minister from the Home Counties. Once a young military padre, he left the service after several tours of Darkest Africa, having seen great and terrible deeds done in the name of the King. His easygoing and approachable manner make him instantly likable, while his small stature leave him unitimidating to those who encounter him. His work with war orphaned boys on the streets of London have earned him many unquestioningly loyal followers, stirred into righteous action by Lorgar's inspiring sermons and prolific writings.

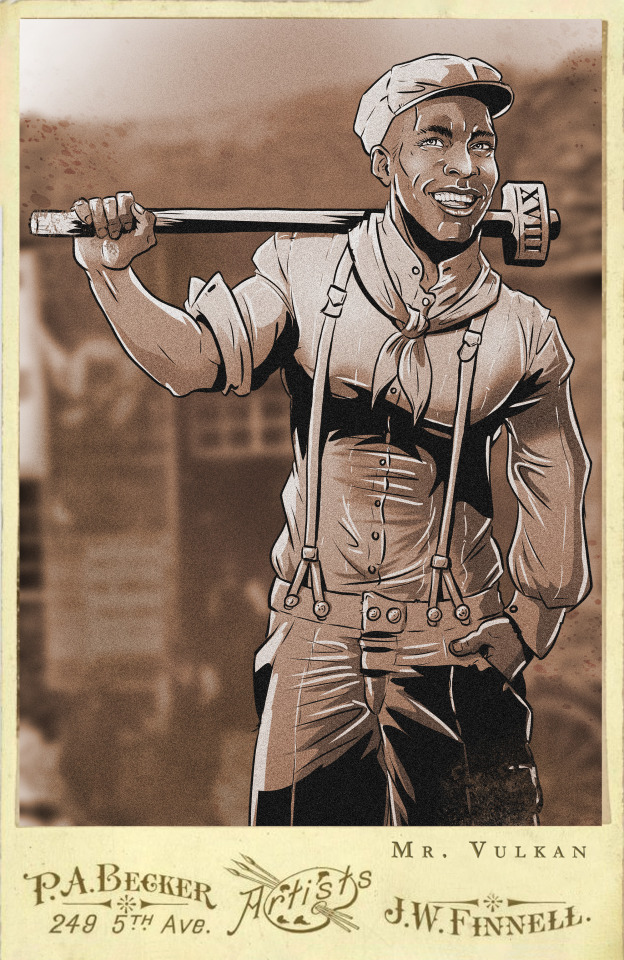

Vulkan

Foreman Victor Vulkan runs one if the many forges in the county of South Yorkshire. His affinity with molten metal has lead him to no small fame across the country as a weapons manufacturer, as well as a significant contributor to the railway network of the Kingdom. Young Vulkan was adopted by his father, a Yorkshire Steelworker, from the West Indies and studied in the Steel City of Sheffield. They also travelled together to Essen in the Ruhrgebiet and as far afield as the Empire of Japan learning new and old smithing techniques. His jovial manner and support of his men and their families lead him to aid in the formation of one of the country's earliest Trade Unions. The colour of his skin, unusual in the Kingdom, has lead less enlightened citizens to be wary of him but his booming laugh and kindly nature immediately puts those he encounters at ease...

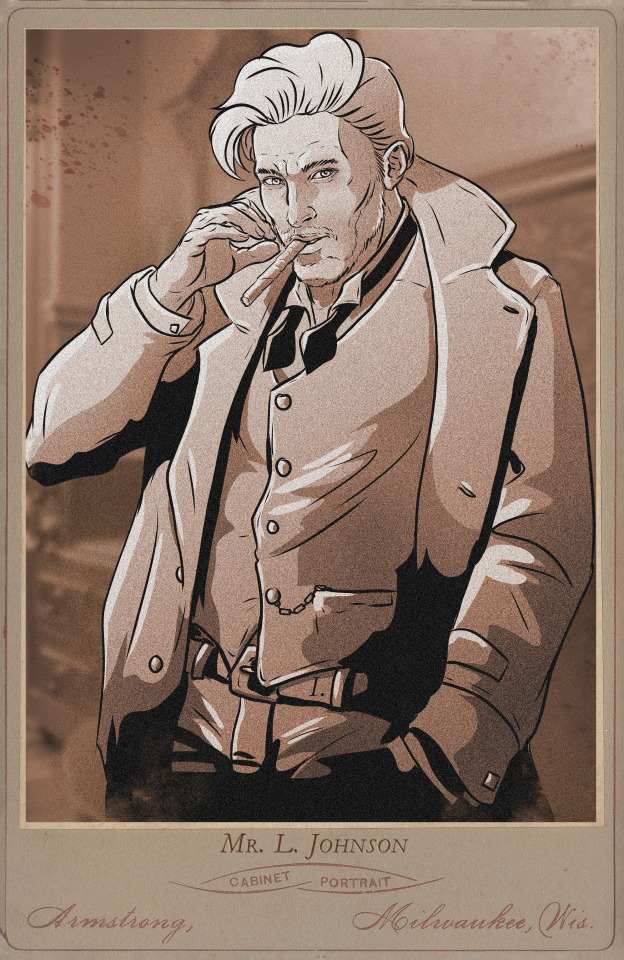

Lion

Mr Lionel Johnson hails from the ex colony of North America. His blonde hair, dazzling white smile and genial manner make him a perfect guest at dinner parties this season. When you're noticed by 'The Lion' it feels like the sun is shining on your face, like you're the only one in the room. His tales of the West are fascinating to Europeans, earning him much attention and favour with the stuffy British establishment, however HIS part in these tales is always unclear. He wears a pair of six shooters on his hips and those lucky enough to witness a demonstration are dumbfounded by his superb skill. Some say he is late of the US Cavalry, and learned his trade hunting Natives for sport, some say he's a small town Sheriff, used to being the Law wherever he goes. Where he actually acquired these weapons and the affinity he has with them is a question of much debate in Society, however his real past is currently cloaked in mystery...

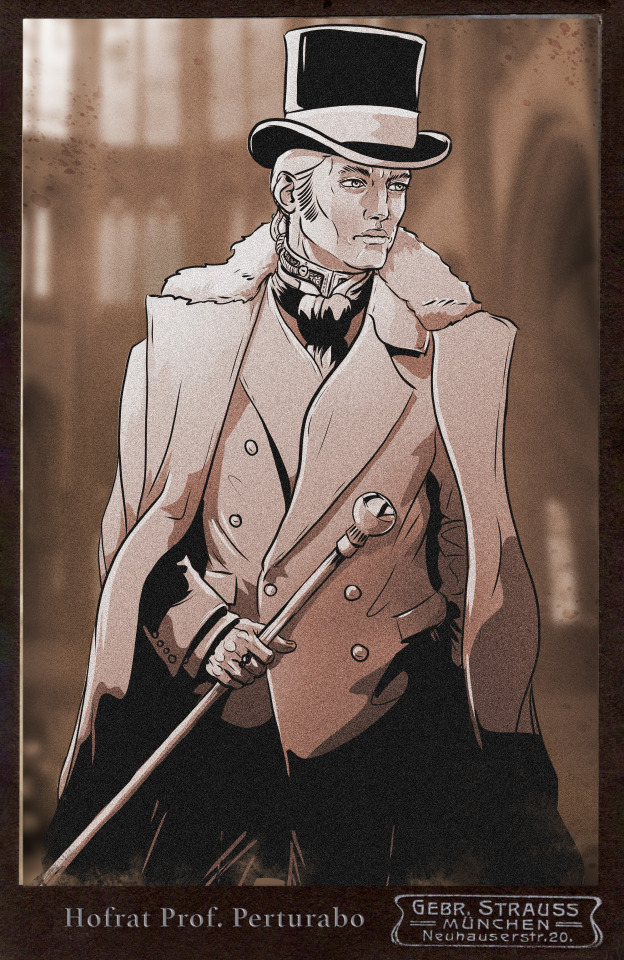

Perturabo

Perturabo is a prussian architect of astounding skill. His cathedrals and palaces cover the Kingdom and beyond, preferred of all the aristocracy of Europe. His wonderous creations however belie his cold and calculating mind. His visions, though of great beauty, are the product of his intense desire to be recognised as the best in his field, serving only his own advancement. The artistry involved is merely a tool to be used, a way of gaining recognition. He feels nothing for his creations, most of them he's never seen beyond the drawing board, discarding as many as one in ten as substandard to his exacting specifications. His ultimate goal is unclear, but his need to ingratiate himself with the elite of Europe, by any means necessary, is a powerful motivator...

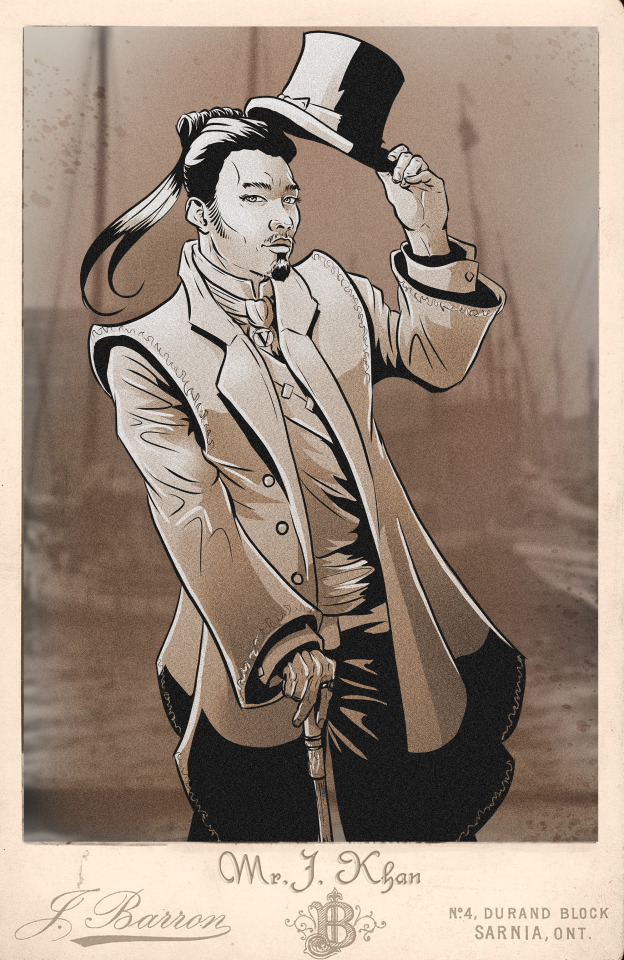

Khan

Jaghatai Khan claims to have the fastest ships in the known world. Marked with his personal Lightning Sigil, his cutters ship linen from India, ink from China and coffee from the West Indies at record breaking speeds. Using his considerable resources, Jaghatai can import the best feeds and supplements to support his other passion; horse racing. From imbibing ginger to twitches made from whalebone, he'll try anything to make his horses faster. A thoroughbred from his own personal stables, White Scar, will compete against the King's horse, Custodian, at Cheltenham in the spring. Little is known about how a poor boy from the steppes of Asia became one of the most powerful Trade Envoys in the world, but any that meet him are immediately charmed by his amiable nature. Generous with time and coin, the Great Khan, as he's named in quiet whispers, has made quite the impression in Society circles, even catching the eye of a certain notorious Viscount on occasion...

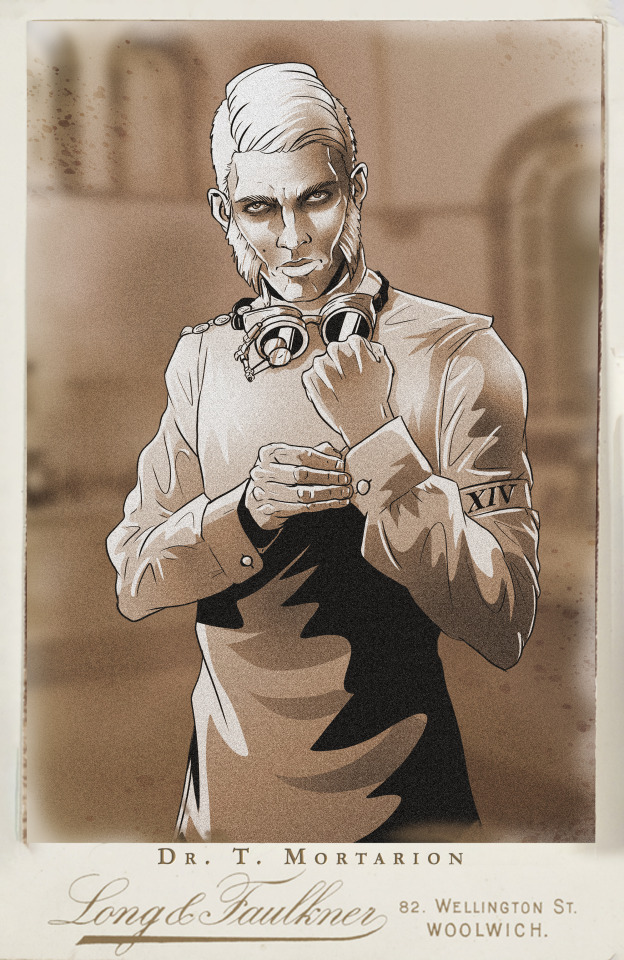

Mortarion

Timothee Mortarion is a respiratory specialist at St Barts in London. After his brother died of complications due to Asthma, young Mortarion dedicated his life to science. Using cutting edge (literally) methods, the serious young doctor has developed techniques using inhalation of various aerosolised substances to strengthen and enhance the lungs of many young homeless patients. His success rate is the cause of some debate in the medical community however, his cures seem to kill as many unfortunates as they save...

I'll repost the first batch with their texts (not all of them have texts, since we started giving them backstories a while after I began drawing. but I'm sure my wonderful wordsmith-friend will write something up for the missing ones, too).

#Warhammer#Alternate Universe#Victorian AU#Victorian Alternate Universe#Primarchs#Horus Heresy#Adeptus astartes#Mortarion#Jaghatai Khan#Perturabo#Lion El'Johnson#Vulkan#Lorgar Aurelian#Lorgar#Alpharius#Omegon#Corvus Corax#Guilliman

233 notes

·

View notes