#double parting surface injection molds

Text

Relationship between injection molds and injection machines is explained clearly at once

Injection mold is installed on injection machine. When designing an injection mold, in addition to mastering injection molding process, you should also have a comprehensive understanding of relevant technical parameters of selected injection machine to ensure that designed mold is compatible with injection machine used.

1. Classification and models of injection machines

1. Classification of…

View On WordPress

#angle injection machines#Classification of injection machines#double parting surface injection molds#horizontal injection machines#injection machine#injection mold#injection molding process#injection pressure#injection volume#mechanical clamping mechanism#molded plastic part#multi-cavity injection molds#plastic injection molding#Relationship between injection molds and injection machines#single parting surface injection molds#thermoplastic parts#thermosetting plastic parts#vertical injection machines

0 notes

Text

Comparison of metal processing techniques for several laptops computer casings

Casting Laptop Cases

Casting is a kind of metal thermal processing technology mastered by human beings earlier, and it is one of the modern mechanical processes. Because the casting blank is almost shaped, it achieves the purpose of free machining or a small amount of machining, which reduces the cost and reduces time to a certain extent.

Metal casting is to inject molten metal into a hollow mold made of high-temperature resistant material, and then condense to obtain a product of the expected shape; the obtained product is a casting.

Classification of casting

1. Gravity Casting

It refers to the process of injecting molten metal into the mold under the gravity of the earth, also known as casting. The molten metal is generally manually poured into the gate, and the product is obtained by filling the cavity with the molten metal by its own weight, exhausting, cooling, and opening the mold.

Gravity casting has the advantages of a simple process, low mold cost, fewer internal pores, and heat treatment, but at the same time, it has disadvantages such as poor compactness, slightly weaker strength, not suitable for producing thin-walled parts, low surface finish, low production efficiency, and high cost.

2. Die Casting Laptop Case

Under the action of high pressure, liquid or semi-liquid metal fills the die-casting mold (die-casting mold) cavity at a high speed, and is formed and solidified under pressure to obtain a casting.

ᅠ

High-pressure casting can quickly fill the mold, the production efficiency is extremely high, the product has good compactness, high hardness, good surface finish, and can produce parts with relatively thin wall thickness; at the same time, due to the use of high-pressure air for filling, more gas is involved in the interior, which is easy Pores are formed inside the product, so it is not possible to perform heat treatment (the internal gas will expand during heat treatment, resulting in defects such as bulges or cracks in the product) and post-machining with excessive processing (avoid penetrating the surface dense layer to expose subcutaneous pores, cause the workpiece to be scrapped).

However, the ordinary aluminum die-casting process has the problem that it is difficult to process a smooth aluminum oxide film. The reason is that silicon is added to the raw material in order to improve fluidity so that it flows over all areas of the mold. Therefore, if you are coloring an aluminum die casting, it may lose its high-end feel after painting because it looks like plastic.

Forging Laptop Cases

Forging is one of the metal pressure processing methods. It refers to a processing technology that uses pressure to change the shape of metal raw materials to obtain forgings with certain mechanical properties, certain shapes, and sizes.

Classification of forging

1. Hammer or Smith Forging

Hammer forging or blacksmithing use the same method, heating the workpiece to the forging temperature, and forging between the flat hammer and the drill plate; small pieces can be called iron forging by hand; large pieces must use a steam hammer (Steam Hammer), as follows picture. Among them, the working object is placed between the drill plate and the plane hammer. As for the structure of the steam hammer, it depends on the forging capacity. The light one is a single-frame type, and the heavy-duty one is a double-frame type.

2. Drop Hammer Forging

The difference between drop forging and plane forging is that the hammer of drop forging has a cavity, and the workpiece is subjected to two pressures or impact forces and then undergoes plastic deformation according to the shape of the cavity. As shown in the figure below, in order to ensure that the flow energy of the metal is reliable and sufficient, the forging is often divided into several stages, and the change of each stage is gradual to facilitate the control of the flow direction. As for the number of stages, it depends on the shape of the forging and size, metal enforceability, and workpiece dimensional accuracy requirements.

3. Press Forging

Pressure forging is a forging method in which the metal is extruded in the mold with slow pressure. Since the metal is under force for a long time, the extrusion effect not only acts on the surface of the forging but also on the central part of the workpiece. Therefore, can achieve the effect of internal and external uniformity, and the quality of its products is better than that of hammer forging.

The use of forging in the notebook computer shell process can effectively reduce the time of CNC so that the cost is relatively low, and an aluminum alloy with an aluminum content of more than 95% can be selected for anodic oxidation. Manufacturing process: First obtain the thicker structural parts of the mobile phone through forging and pressing; then CNC mills off the unnecessary parts; NMT obtains metal + plastic integrated structural parts; anodizes the surface; finally glues the antenna cover.

4. Upset Forging

Rough forging or end pressure forging is usually aimed at forging or shaping one end of a uniform long rod. The long rod is clamped in the mold, one end is heated to high temperature, and along its axial direction, and then the end is pressurized. , to make it forged or shaped.

5. Roll Forging

Take two non-100% round rollers as an example (with a diameter reduction rate of 25~75%, and the rest can be cut into grooves as required), feed the rod material into it and clamp it, and then continue to rotate. Roll the rod material to reduce the diameter and push it forward; when the roller turns to the opening position again, the rod material can be drawn back to the original position for the next round of rolling, or sent to another groove Do another construction.

Stamping laptop case

Laptop shell stamping is a metal cold treatment processing method, also known as cold stamping or sheet metal stamping, with the power of stamping equipment, the metal sheet is directly formed by force in the mold, and the stamped parts are widely used in electronic products, Auto parts manufacturing, and household appliances manufacturing.

Applicable material: suitable for most metal sheets, especially suitable for aluminum sheets, carbon steel sheets, stainless steel sheets, magnesium sheets, copper sheets, and zinc sheets.

Stamping laptop case process:

1. Fix the metal sheet of the laptop case on the mold table

2. The upper punch falls vertically so that the metal material of the laptop casing is formed under force inside the mold

3. The punch rises, and the parts are taken out to wait for the next trimming and grinding process. The whole process takes about 1s-1min.

One of the direct benefits of stamping is cost savings. It does not need nano-injection molding, it can be anodized directly after polishing, and mass production can climb quickly; but the disadvantage of this technology is that the upper and lower ends of the fuselage must be spliced with plastic. Can't make complex internal structures, and can only be used as front and rear covers.

CNC | CNC Machine Tool

CNC is commonly known as a "numerical control machine tool", that is, an automatic machine tool controlled by a program. The control system can logically process programs with control codes or other symbolic instructions, and through computer decoding, the machine tool can perform the prescribed actions, and a piece of original metal plate can be processed into the desired shape through long-term precision machining. shape.

CNC metal one-piece molding, that is, Unibody one-piece body molding process. It was first used in Apple's iPod, iPad, and MacBook, and finally realized in the iPhone5 generation, leading to the frenzy of all-metal mobile phones.

The iPhone 5 and 6 are integrally formed of aluminum alloy, that is, the fuselage and the frame are processed by CNC from a whole piece of aluminum alloy. At the end, choose injection molding and other partitions.

In order to obtain a higher-quality appearance, surface treatments such as anodizing, sandblasting, and polishing will also be carried out to achieve unique colors and smooth touches.

0 notes

Text

What Are the Classification of Injection Mold Processing?

https://www.gmmoldtech.com/what-are-the-classification-of-injection-mold-processing.html

What Are the Classification of Injection Mold Processing?

Ⅰ. The plastic injection mold processing

Injection molding is a relatively common manufacturing method of industrial products in machining processing. This processing technology obtains the required shape by processing rubber and plastic. There are many types of injection mold processing. In the process of processing, the processing technology should be selected according to the requirements of the injection product.

Ⅱ. The classification of plastic injection mold processing

1. Single parting surface injection mold

When the mold is opened, the movable mold and the fixed mold are separated, so that the plastic part is taken out, which is called a single parting surface mold. This processing method is the simplest of the plastic injection mold and molding. It can be divided into single-cavity injection molds or multi-cavity injection molds according to the design. It is widely used in today's production.

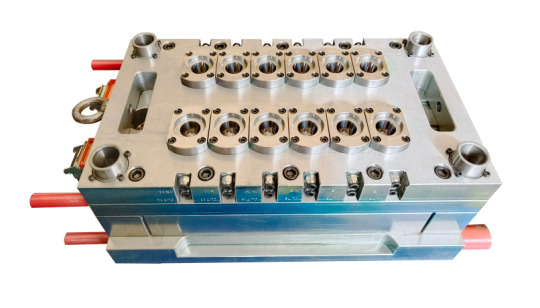

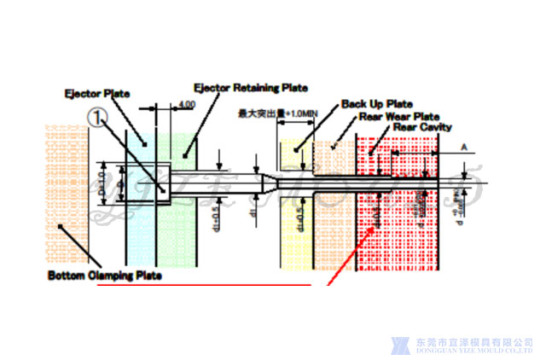

2. Double parting surface injection mold

Double parting surface injection molding has two parting surfaces. Compared with single parting surface injection molds, double parting surface injection molds have a movable intermediate plate in the fixed mold part, so this type of injection mold is called three-plate injection mold. It is most commonly used for single-cavity or multi-cavity molds with point gate feeding.

3. Injection mold with lateral parting and core pulling mechanism

When the plastic part has a side hole or a side depression, it needs to be formed with a core or slider that can move laterally. After injection molding, the movable mold will move down for a certain distance, and then the inclined surface of the bending pin fixed on the fixed template forces the slider to move outwards. At this time, the push rod of the ejection mechanism pushes the plastic part to take off from the core.

4. Injection mold with movable forming parts

Due to some special structures of plastic parts, injection molding will be required to be set into movable injection molded parts, such as movable punches, dies, movable inserts, movable threaded cores or shaped rings. During demolding, it can be moved out of the mold together with the plastic part and separated from the plastic part.

5. Automatic thread unloading injection mold

For plastic parts with threads, when automatic demolding is required, a freely rotatable thread core or ring can be set on the mold, and the mold opening action or the rotation mechanism of the injection molding machine can be used to drive the thread core or the threaded ring rotates and the plastic part comes out.

6. Runnerless injection mold

Runnerless injection mold refers to the method of adiabatic heating of the runner to keep the plastic between the nozzle and the cavity of the injection molding machine in a molten state, so that there is no condensate in the pouring system when the mold is opened and the plastic part is taken out.

7. The injection mold of the demoulding mechanism on the fixed mold

In the injection mold, the demolding device is installed on the side of the movable mold, which is of great help to the ejector device in the opening and closing system of the injection molding machine. In actual production, because of the shape limitation of some plastic parts, leaving the plastic parts on the side of the fixed mold is more helpful for forming.

0 notes

Text

Knowledge sharing about flip top cap mould

Introduction of flip top cap mould

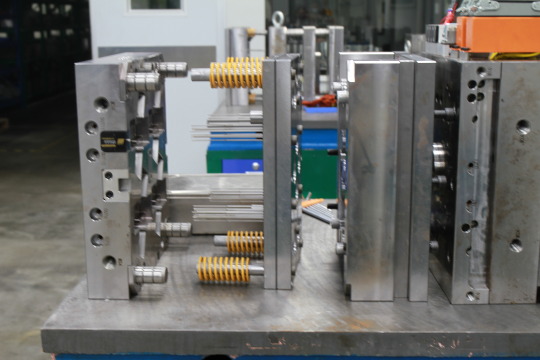

Flip top mold core and cavity with insert design. Very hard steel is used for the core and cavity. Such as S136, 2316, H13, etc. Detail steel will depend on cap design, cap material and customer requirements. But all these die steel hardness can be processed to HRC48-HRC52.

Flip top mould runner system

Clamshell mold runner systems can be hot runner and cold runner. Details depend on the cap design. Cold runner subs gates are suitable for flip caps and gate markings are allowed on the side of the cap. Usually the gate is located in the open area of the cap, so that the injection can be balanced, and the gate mark can be hidden under the top cap. Hot runner systems are becoming more and more popular in injection molds because of their better heating efficiency and no plastic material wasted in the injection molding process. And clamshell molds with hot runner systems can achieve shorter cycle times. The hot runner gate mark is usually on the top surface of the clamshell body, and the same position is the cold runner three-plate mold structure.

Flip top cap mould design process

Clamshell mold drawings are another important thing. Clamshell mold quality starts with mold drawings. The mold structure and mold size are determined by the drawings. Gragon Mold's focus on mold drawings ensures that clamshell mold projects get off to a good start. According to customer requirements, we can provide CMM inspection of key mold components such as inserts, cavity inserts and core inserts.

Advantages of flip top cap mould

1. The butterfly hinge design is very particular, flexible and not easy to break.

2. We use Moldflow analysis to simulate the entire injection process to ensure that qualified products are injected during mass production.

3. High-performance hot runner system with German heating components ensures uniform melt flow and pressure in all cavities.

4. The heat of each cavity is independently controlled to ensure uniform temperature.

5. Standard interchangeable mold components.

6. All parts are processed by high-precision CNC equipment, and the tolerance is below 0.02mm.

7. The core and cavity are made of high-hardness steel, with double anti-corrosion, high precision and long mold life.

8. Each cavity and core has an independent cooling system, which can shorten the production cycle.

9. The special water pipe design eliminates leakage and water marks on the preform.

10. The company logo of the cap can be easily replaced by changing the cavity.

11. The mold parts can be DME, HASCO or other standards, which is convenient for customers to find replacement parts in the market.

12. We can provide CMM to inspect the key parts of the mold, such as inserts, cavities and cores.

13. The clamping system can be designed according to customer requirements.

14. The mold guarantees long life, more than 5 million times.

Dragon Mold is an expert in plastic clamshell molds, providing multi-cavity solutions for shampoos, lubricants, confectionery, and more.

Flip top cap mould Supplier

Dragon mould has accumulated rich experience in various clamshell molds from 1 cavity to 72 cavity, such as shampoo clamshell mold, lubricating oil clamshell mold, condiment clamshell mold, double safety ring clamshell mold, etc. The innovation of multi-cavity technology enables the flip-top mold to meet the needs of high speed and high production capacity.

We design, manufacture and export high quality clamshell moulds for customers from all over the world. And we have "DRAGON MOLD QUALITY STANDARD" to control the quality of each mold from design to shipment. Our company's mission is to help our customers achieve superior production capabilities at extremely low cost. If you have any need for flip top moulds, please feel free to contact us.

0 notes

Text

Interlude - The Maw

A blacksmith would have taken different steps. Forge the blade, give it a handle, wrap the handle. Something like that, at least. Thankfully she was able to skip most of that by designing a mold and taking extraordinary care in its production. A perk of being smart, as she figured it.

The metal was nearly ready. It wasn’t the colour of anything she’d seen back on Azeroth, instead shedding four different glows at once. They overlapped and intertwined because nothing here was ever simple. Ilandreline wasn’t one for metaphors, but even she could recognize this one: four ores, wildly distinct, that could only be properly alloyed through the use of a fifth. Naturally the alloy was stronger than any of them independently. Also it was a bastard to work with.

She fed the ingots into the crucible, watching as the forge’s heat quickly liquefied the elethium. A pull of the lever and it drained into the waiting mixture, which one more movement injected into the waiting mold. That had been the real work, creating the exact negative space needed inside a block of solid stone. Not just any stone, of course, but the kind that wouldn’t melt in a furnace designed to bind souls to metal. Getting pieces of the Black Empire was hard enough even before one crossed into the realms of the dead.

Once the mixture had filled the block, Ila grasped it with the tongs she’d liberated from the soulforger whose workspace she now used. Steadiness was required to keep the metal from sloshing out or the whole thing from upending. Her movements were slow and deliberate, never jerking. A device was only as good as its craftsmanship; she intended this one to be her masterpiece.

Typically one would quench using a specific liquid. Fresh water, salt water, olive oil, certain beverages made by the dwarves… what one used depended on the desired outcome and the materials involved. For this it was something a bit more unusual. The Maw had recently become the destination for a great deal of anima drawn from the spirits being repented in Revendreth. This made for a sharp, hungry quench, which was precisely what she needed. She lowered the discomfiting block of slick stone into the roiling crimson, listening to the violent hissing as the alloy took shape.

Once the soul-steam had cleared and the little barrel was minutes removed from its moment of boiling, she fished the mold out with her borrowed tongs. "This better have worked," she muttered, mostly to externalize the worry. Better out than in, that sort of thing. "Only one way to find out."

Placing the black brick on the anvil nearby, she inspected every side for cracks or gaps. The only one she could find was the little hole where she'd added the molten metal, so… maybe it had happened? Picking up the hammer she'd made for just this purpose, Ilandreline closed her eyes and sought the resonance. It was so much easier now than that first time. That was how she'd survived the darkest path into the Shadowlands, and ever since she'd found herself increasingly aware. Now it was almost as easy as making saltpeter; not necessarily fast, but a simple task for the experienced. She felt for her core, dove into it, releasing her perceptions through the nightpurple veins bordering reality.

The Black Empire remnant was anything but dark now. Even the Maw's dolorous half-light caused a reaction, oil-slick scintilla flaring across the infinitesimal pockmark surface. In a way, it sang. Not like a voice, but a tuning fork, a frequency of sensation manifesting multitudinous waves into singular tone. Where her family's faith resided she felt the echo of kinship. Reaching through herself, she grasped the thread of the stone's structure and pulled.

In a sweater, such an act would have been the destruction of order that caused its unraveling. The bedrock of those who dwelt between the stars was made differently, however. What she had done manifested as an ordering matrix, leaching the inherent structural chaos out, snapping the minerals into some kind of grid. Gripping tightly through the depths of her soul, Ilandreline raised the hammer high and swung.

The hardened shadowghast strikeface tolled as it impacted the ruthlessly ordered block. The sound was brutal in its discordance, an archetypal resonance of shattered chains. What was held tightest become most undone; the black stone crumbled to dust, its forced structure inverted until it could no longer hold together.

Ilandreline felt her entire self ringing as she set the hammer aside. The reverberations rattled through her bones, trying to unmake her as thoroughly as she had the old gods' relic. But she was a Glimmerbow, born of those dark blessings, the ancient primordial unmakers' essence suffusing the deepest fibers of her being. The resonance traveled through her, unable to find an outlet to erode, equally unable to escape until she opened her mouth.

She didn't scream; this wasn't pain. Instead she had become an accidental echo chamber, an acoustic amplifier not unlike the elegant curves of a bell. From inside her structure rang the peal of uncreation. Open-mouthed she exhaled it into the stygian plains, unable to cease until the note was spent. Unable to hear, she could still feel the rigid structure of forge beside her eroding beneath the reciprocal action to what she had done.

As suddenly as it began, the moment ended, buckling her knees. Reflex alone allowed the elf to catch herself, weak-legged and bent over the anvil, eyelids only now able to pry themselves apart. Unsteady, Ila exerted her focus once more, willing herself to stay standing. As she did so, refusing to acknowledge the possibility she might collapse, she examined her work.

Atop a fine pile of utterdark sand lay a blade. It was a single piece, cast-forged, with a tapering, triangular blade emerging from one edge of a metal-wrought vertebra. Opposite the blade extended the cylindrical smoothness of bone, flaring into a double-knobbed pommel. It was far more beautiful than she'd expected, or perhaps that was the wrong word. Elegant? Fitting. This was a blade made with purpose, for someone very specific, and such certainty was apparent in its aesthetics.

"Almost done." Her voice was hoarse though she didn't realize it. She hardly knew she'd spoken, what with the ongoing ringing in her ears, and the way structures sounds such as speech fell apart in the fading wake of the hammer blow.

Ilandreline forced her legs to stillness, stood straight atop them once more. Grasping the weapon's handle -- she would wrap it with aged linen later, to give it the feel of something found in an ancient mausoleum -- she turned its stiletto point toward herself. Her other hand moved to expose an expanse of pale flesh, against which she set the blade.

"Freely given," she murmured, the spoken fraction of a larger recitation mostly contained within her mind. "A gift for another, made with intent. A part of me to carry with you." It was almost embarrassing to say it. Hearing herself speak so openly brought heat to her cheeks, but it wasn't so bad to shake her from her plan. Not after coming so far.

Shutting her eyes, Ilandreline exhaled slowly. Her free hand rested along the cold curves of the pommel. Freely given. Lungs fully empty, she braced herself and pushed.

The blade slid in more easily than she'd expected, quickly piercing through skin and fat and muscle. Farther and farther she guided it until the change in resistance signified she'd reached her goal. Just the barest movement more, pricking the exterior of her still-beating heart. Now the hard part.

Pulling the blade back out was the most excruciating experience of her life. It was a tool of purpose, to pierce through barriers and bring an end. To remove it without having killed was to deny it that fulfillment, and so the blade fought her every fraction of the distance. Blood -- her blood -- flowed over its pyramidal smoothness, slicking everything, trying to undo her efforts and allow the blade to feast on her life. Gritting her teeth, she looped a finger through the hole in the center of the guard, using the extra leverage to force the dagger out of her flesh entirely.

Slamming the bloodied weapon back on the anvil, Ila scrambled to the forge. There she snatched up the last of the prepared tools, a length of featureless iron, brilliantly glowing from the infernal heat. "Fuck, this was a stupid idea." Laughing at herself, she pressed the white-hot implement against the triangular piercing in her breast, allowing her rasping scream to drown out the sound of flesh cauterizing.

She didn't know how much time elapsed between keeping herself from bleeding to death and when she was able to stand again. It didn't matter, not really. The important thing was Loira's gift was finished. Complete, even. Totally worth it… but if she loses it I'm gonna kill her.

Chuckling at that, Ilandreline scraped herself together. Time to get out of here before the Covenants' assault wavered and the Jailer's forces had time to look for things like wayward elves with bad ideas. She took another quick look at her handiwork as she vacated the premises. There was no trace of her blood any longer, though she didn't remember wiping it clean, and every now and then the faint ghost light would reflect off a fleck of gleaming darkness. Sand in the blade? No, not sand; the dust of the Black Empire. Absorbed somehow following the sanguine consecration. Curious, but probably not a big deal. She hadn't felt anything strange, and her instincts were usually good about that sort of thing.

"Thanks for the help!" she told the forge's previous user, stepping over its hollow corpse. The spiked helmet that had been something like a head was mangled beyond recognition, as if repeatedly bashed by some kind of heavy blunt object. Ilandreline hefted her oversized wrench, rested it on her shoulder, and set off. Hopefully the blood loss wouldn't slow her down too much. It would be a shame to die before she could actually give Miss Winford her present.

(( Tagging for mentions of @ms-winford ))

8 notes

·

View notes

Text

How Are Colored Contact Lenses Made?

The contact lens is a device worn in the eye to correct vision, although some people wear colored contact lenses to enhance or change their eye color. The thin plastic lens floats on a film of tears directly over the cornea. For some forms of eye disease, contact lenses correct vision better than conventional spectacles. Many people prefer contact lenses over glasses for cosmetic reasons, and active sports enthusiasts prefer contact lens because of the freedom it provides them. There are basically three types of lenses: soft, hard, and gas-permeable. Soft contact lenses are usually more comfortable to wear, but they also tear more easily than hard contact lenses. Hard lenses also tend to "pop" out more frequently. Gas-permeable lenses are a compromise between the hard and soft, allowing greater comfort than hard lenses but less chance of tearing than soft lenses. Contacts are usually worn during the day and taken out every night for cleaning. Extended-wear lenses allow users to leave in their contacts for longer periods of time, even when they're sleeping. More recently, one-a-day contact lenses are gaining popularity among lens wearers. These contacts are worn for only one day and thrown away, eliminating the hassle of cleaning them every night.

Raw Materials

The raw material for contact lenses is a plastic polymer. (A polymer is a blend of materials created by linking the molecules of different chemical substances.) Hard contact lenses are made of some variant of polymethyl methacrylate (PMMA). Soft contact lenses are made of a polymer such as poly hydroxyethyl methacrylate (pHEMA) that has hydrophilic qualities, that is, it can soak up water and still retain its shape and optic functions. The science of lens material is always being updated by lens manufacturers, and the specific material of any contact lens may differ depending on the maker.

The Manufacturing Process

Contact lenses may be produced by cutting a blank on a lathe, or by a molding process. The forming of the lens involves shaping the plastic into specified curvatures. The major curves of the lens are named the central anterior curve (CAC) and the central posterior curve (CPC). The CAC refers to the overall curve of the side of the lens that faces out. This outer contour produces the correct refractive change to fit the patient's visual needs. The CPC is the concave inner side of the lens. This conforms to the measurements of the patient's eye. Usually these two curves are formed first, and the lens is then called semi-finished. The lens is deemed finished when peripheral and intermediate curves are formed, and the edge is shaped.

Molding method

1 Molding the lens can be carried out in several different ways. The lenses first developed in Prague were spin-cast. Three different fluids were poured into open rotating molds. The outside curvature of the lens was shaped by the mold, and the inside curvature was formed according to the speed of the rotation of the mold. The centrifugal force of the spinning mold led to the polymerization of the fluids so that the molecular chains linked to form the required hydrophilic plastic. A more reliable mass-production Contact Lens method is injection molding. In injection molding, the molten plastic is injected into the mold under pressure. Then the lens is removed from the mold and cooled. The lens is then finished on a lathe. It is also possible to produce lenses entirely through molding, that is, they need no lathe cutting. This is a recent development, made possible through highly automated, computer controlled mold production.

Lathe process

2 The initial forming of the lens can also be done by cutting on a lathe. First a blank is made. The blank is a circle only slightly larger than the size of the finished lens. This can be cut from a plastic rod, or stamped from a plastic sheet. Next the blank is fastened to a steel button with a drop of molten wax. The button is then centered on a lathe, which begins to spin at high speed. A cutting tool, which may be a diamond or a laser, makes concave cuts in the blank to form the CPC. Indicators on the lathe measure the depth of the cuts to guide the lens operator.

The button holding the blank is next moved to a lapping machine. The lapping machine holds the blank against a lapper, which is a revolving disk coated with an abrasive compound. The shape of the lapper matches the CPC of the lens. The lapping machine spins the blank in one direction, and the lapper in the other. It also moves the blank in a small figure eight motion. The abrasion polishes the lens surface.

The polished lens is then mounted on a steel shaft called an arbor. The end of the arbor has been ground to match the CPC so the lens will fit on the shaft. The arbor is installed in a lathe, and the operator makes convex cuts in the lens to form the other major curve, the CAC. Now this side of the lens is polished, and the lapper is modified to fit the convex CAC. When this second side of the lens is polished, the lens is considered semi-finished.

Finishing

3 The contact lens requires several more curves to be ground before the lens will fit exactly on the patient's eye. The final curves are the peripheral anterior and posterior curves and the intermediate anterior and posterior curves, which govern the shape of the lens nearest and next-nearest the edge. The lens is mounted on an arbor again by suction or with double-sided tape. The arbor is installed in the lathe or grinding machine. These shallower cuts may be ground with emery paper or cut with a razor blade. The diameter of the lens may also be trimmed at this time.

Quality control

4 Quality control is very important for contact lenses, since they are medical devices and they must be custom fit. The lenses are inspected after each stage of the manufacturing process. The lenses are examined under magnification for anomalies. They are also measured by means of a shadow graph. A magnified shadow of the lens is cast on a screen imprinted with a graph for measuring diameter and curvature. Any errors in the lens shape show up in the shadow. This process may be automatically performed by computer.

Packaging

5 After the lens has passed inspection, it is sterilized. Lens are boiled in a mixture of water and salt for several hours to soften the lens. Next, the lens are packaged. Standard packaging for lenses is a glass vial, filled with a saline solution and stoppered with rubber or metal. The hydrophilic material of soft contact lenses soaks up the saline solution, which is similar to human tears, and becomes soft and pliable. The lenses in this state are ready to wear.

The Future

The material for contact lenses is the subject of much research. Scientists are investigating different chemical recipes that may give plastic more desirable characteristics. One polymer currently being researched is a silicon-oxygen compound called siloxane. Siloxane forms a thin, flexible film and admits oxygen through to the eye 25 times better than current standard soft lenses. There are disadvantages to this compound, however: siloxane does not wet easily and it attracts lipids (fats) to its surface, causing it to cloud. Researchers have found a way to add flourine molecules to the siloxane compound, causing the material to resist lipids. Then they chemically attach a wetting agent, which changes its molecular shape when boiled in a saline solution, so that the material can soak up water like traditional soft lens. This material may ultimately lead to extended-wear contacts that can be worn for weeks at a time.

Researchers are also investigating new polymers that can be used for sclera lenses. For most people, comeal lenses are the norm, but the large sclera lenses are useful for patients with severely damaged corneas. Depending on the eye problem, some patients cannot regain their sight without a corneal transplant, but sclera lenses may help patients avoid eye surgery. Sclera lenses rest on the white part of the eye and form a vault over the cornea itself. This space over the cornea is filled with artificial tears, which serve to smooth out the cornea's damaged surface. In the past, sclera lenses have been uncomfortable because they do not allow enough oxygen to the eye, but investigations into new materials are focusing on more oxygen-permeable lenses.

Material for oxygen-permeable lenses has also been experimented on the space shuttle Endeavour. The designers of the experiment believe that micro-gravity conditions would promote a lens material that repels debris better and processes oxygen more effectively than polymers made in traditional labs. If commercially feasible, a new generation of contact lenses may be manufactured in space.

3 notes

·

View notes

Text

The residual stress of the blow molded bottle body is relatively high

The size of the plastic bottle (especially the neck thread size) has high precision, and it is easier to ensure the uniformity of the bottle wall thickness as required, and the bottle body specifications are uniform. The flat-bottomed double rounded bottom structure is mostly used for large-volume plastic bottles, which can better withstand the pressure from the inside of the bottle.The development trend of the external shape and size of the injection blow molding bottle.1 mm. For example, the height dimension error of 40-60 mL bottles should be controlled within ±0.

Blow molding can form products with complex, irregular and integral shapes. Physical and chemical performance test of medical plastic bottles: The main items of physical and chemical performance test of plastic bottles Kitchen Storage Cabinets Suppliers are heavy metal test, non-volatile residue test, ignition residue test, reducing substance test, sealing performance test, oscillation performance test, Water vapor permeability test, abnormal toxicity test and bacterial culture test, etc.

But from the general requirements of plastic bottles, the appearance quality should have a uniform milky white color, no obvious color difference, the surface of the bottle body should be smooth and flat, no deformation and obvious scratches, no trachoma, oil stains, etc.5 to 2 mm, and the current thickness tends to increase. Bottle appearance inspection: The appearance inspection of plastic bottles mainly includes the overall shape of the bottle body, surface tone, gloss, appearance quality and other quality characteristics that can be perceived by human vision.

Due to the high pressure of the melt in the mold cavity of the parison (10-40 MPa), the residual stress of the blow molded bottle body is relatively high, and the clamping force required by the parison mold is high. In extrusion blow molding, an extruder head is used for molding. The basis of appearance quality inspection is to formulate different appearance defect standards according to the different defects of various parts of the plastic bottle.

Generally, the plastic bottles produced by the same equipment, the same raw material and molding method should be stored in a constant temperature room at 23°±2° for a certain period of time before measurement, and under stable process molding conditions, compare the appearance of the product Appearance measurement is carried out on the reference dimensions of various parts of the design drawing.

1 note

·

View note

Photo

Industrial technology mainly involves smelting, casting, forging, welding, heat treatment, physical and chemical testing, etc., supplemented by knowledge of mechanical processing and computer design. Most people now know that stainless steel precision casting, also known as investment casting wax film casting, is widely applicable to various castings. However, in the casting process, it will also inevitably encounter a series of problems.

The first problem about the solution of the hammer jamming: In production, we should often measure the temperature to avoid excessive temperature of the hammer head and barrel and also select high-quality impurity-free alloy materials to avoid impurities sticking to the hammer head.

The second problem happens when the injection gun is stuck in the gooseneck. When the device is at room temperature, try to turn the hammer, if it can’t turn, then replace the barrel and remove the hammer. If you want to quickly solve the stuck problem, it is best to replace the material tank.

The third problem is that dozens of molds are impossible. It will take a few minutes to continue punching. See if there are any bright spots on the top. If all parts are gray, then the nozzle may be clogged. You should properly increase the nozzle temperature, reduce the nozzle knocking time by 0.1 to 0.2 seconds, and close the fixed mold cooling water slightly.

The fourth problem is on how to solve the problem of easy cracking of thin-walled die-casting products. This problem may be due to material problems, poor mold settings or improper selection of process parameters. Pls try to control the proportion of scrap products not to exceed 30%. If it is too long and the wall thickness is about 3 seconds per millimeter, the ejection delay is not very long, which is 0.5-2 second.

The fifth problem: the material is too hard, and the tool is easy to wear.

The sixth problem is on the black spots when polishing aluminum alloy die casting solutions: reduce the concentration of spraying agent, change to other spraying agent, or increase the blowing time after spraying.

The seventh problem is on metal splash solution in the die casting process: reinstall the mold; increase the clamping force and adjust the die casting machine to keep the moving fixed plate parallel; increase the support plate on the moving mold to improve the mold Stiffness.

The eighth problem is on flow pattern generation solution after die-casting anodizing: spraying, uneven walking of injection oil, inappropriate high-speed switching position, or excessive copper ion content in the oxidation tank will cause flow pattern problems, so spraying And injection oil can be evenly dispersed, not concentrated in local areas, or set high-speed switch position to reduce shortages. Casting phenomenon.

The ninth problem is about the solution of the die-casting mold adhesive: check whether the mold temperature is normal, reduce the casting temperature and mold temperature of the alloy liquid properly; check whether the release agent ratio is abnormal, try to replace the release agent; debug the surface of the sprayed part , And carefully polish the nitride mold to prevent damage. The surface nitriding layer forms more throwing sticking phenomenon; improve the design structure of the casting system to avoid the continuous corrosion of the cavity wall or the core by the alloy liquid; modify the mold cooling system; adjust the die casting process parameters, appropriately reduce the injection speed, shorten the double Speed travel.

www.bonlycasting.com

Email:[email protected]

welcome your consults for any casting parts.

1 note

·

View note

Text

Plastic Structural Design 2 - Mold (Introduction)

Fer Read Series 1, please Plastic Structural Design 1—Materials.As a product structure or mechanical engineer, it is necessary to master basic understanding of injection molds. It can help you better develop products. Details are as follows:

1. Mold material selection and texture introduction

1.1. Selection of mold materials

Materials used in mold are mainly as shown in table below

Steel mill…

View On WordPress

#cold runner mold#Double parting surface injection mold#hot runner mold#injection mold#injection molding#injection molding process#injection molds#mechanical engineer#Mold base and design#mold factory#Mold guide system#mold materials#Mold positioning#mold structural parts#mold structure#mold structure design#mold surface treatment#molded parts#multi-cavity molds#parting surface#plastic molds#plastic parts#Plastic Structural Design#product design#product designer#Push block ejection mechanism#single-cavity mold#single-parting surface injection mold#Slider limit mechanism#slider splitting

0 notes

Text

On idizwadidiz by Alexandre Galmard

http://kinet.media/diopter/on-idizwadidiz

A new ‘demolition of the wall’ (of language) has brought itself to the Ground [zu Grunde gehen], then back as a background. Isiah Medina. Every plus is a passing through the event-horizon, a projection of the concept of concept which, driven to be unwritten and ceasing to be what it is by an unnatural reverse to natural plane, challenges concepts on another basis than the one of philosophical articulation, outlining the contours of the world of thought. There is a crossing of threads from which this work stems : philosophical concepts and artificial languages are toys, and their geometries, figuration, animation and interaction multiply their dialectics and change the way we think worlds are made.

As a foundation kit, a trans-world toolbox to share with fellow makers and thinkers, an about-face to a ground-zero, idizwadidiz's‘textless punctuation’ is a sort of ‘concept-script’ whose ideography registers itself into an articulated rebus. More than encrypting a formal methodology for content-breaking, it rather breaks from old moulds by breaking from the molded idea of the mould itself. If we must break from the despotism of fixed grammatical rules at every point, against the idea that each composition has its own mould, one point at least must break with this idea by dealing with the most absolute form of despotic formalism.

The obverse position rendered here is subtraction for the very purpose of unconstraining thought to a position, of unconstraining the concept to a lens of truth, to an epistemological go-between which would render the world ingurgitable. The point is not so much that, if one were to show it all, artistic creativity would be compromised. Rather, the desire to see it all always already inscribes the Idea into the intimate domain of placement, whose lack of split intelligibility fortifies it into a perishable appearance. What is not-all-there is not a lack of explicit sources to retrace, but the impasse of the real from which you do not come back scot-free, from which you do not come back at-all. You can see it all without the necessity of an absolutely codified contextual structure ready to topple, without which it would be ‘like turning round hopelessly in some obscure labyrinth’. As Grothendieck puts it (regarding mathematics), you do not read, you listen.

By reflecting upon both epistemic transactions, between abstract things and concrete ideas, and their typological axiomatization, one goes through a sort of brachylogical sabotage, the very destructive step towards a re-foundational grounding of all parameters, of the conceptual and the not-so-conceptual brought to appear in other ways than they were made or thought to exist, and doing so by unconstraining the conceptual to an effect and the understanding to an affect : from ‘having or not having’ to ‘having or being’, that which ‘presupposes the subject as always already having a generative capacity’ shifts into that which 'takes into account how the subject itself emerges through the substance’s auto-scission’. Thinking is this montage whose Idea of montage is always-already a Montage of ideas, and ‘what is already there in the process of knowledge is taken from being, and not from the idea’.

(0)

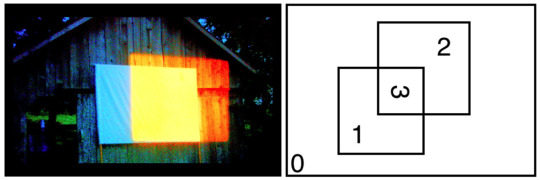

An empty screen appears. A ‘compulsion to repeat’ chops the opening shot, beginning over and over, acting as its own absolute self-reference : A is A, which, being repeatedly posited, differs from itself; a reminder that substance always-already splits itself intermittently. The original black frame is pre-ontological while the screen is the Void proper, its failure of being something other than nothing, or rather, a nothing which is counted for, just like the ground floors marked ‘0’. The black frame leaves its place for its negative correspondent, the white empty sheet.

This is closely followed by the appearance of another form of nothingness, a projection, a ‘shadowy double’, which plays the pre-roll countdown. This is at once the countdown of the beginning of the roll, and the reference that we already have begun to count. The two unaligned empty squares marks the difference of A’s voided being and A’s appointed there. The out-of-jointness from frame to screen, from picture to movie, as seen throughout, disrupts their identification with one another.

Once the logical projection meets the ‘ontological ground’, at this stopping point to the adjustment of the two, the co-incidence, the moment they superpose each other, the non-excluded middle, becomes the intersection of a union, a mark of their conflation, giving the shared part a space of its own (which will in turn burst into solid colors). This third term is at once the Two’s representative and its disordering into a blind spot, the passage from ‘there is no relationship’ to ‘there is a non-relationship’, its very own display.

(1)

The game of apprehending and comprehending the ‘completely identical and the completely different’, between both animation and inanimation, relies on playing their very own identities and differences with and against each other in order to conceivably and inconceivably register their transitions. If you take 'Envers' in F is a •reverse• in E, some fundamental laws of thought are written down, then reversed in correspondence with the axioms prescribed. The dynamic range is used to picture the cancelling out of the maximal and the minimal with no other way, fading to black or manually pushing and pulling the exposure, cancelling out the background formed of water and skyscrapers. To rely on such grounds, discernment must be the basis by which one perceives a space for neither full white nor full black, since both flattens out, evens out. Complementarity of logic and geometry is the opening of the movie – the union drawing – and its ending – an extended logical square diagram shown on top of a computer screen as a continuation of paint.

This is expanded in idizwadidiz : invariants transacting between similarity and dissimilarity unfold in accordance to how they are cut together and with which predicaments, drawing positional and oppositional relations out of strength. We thus depart from the ontological grounding of the count to a full scale dynamical geometry, that is, of the discernment, in the presentation, of the continuous and discontinuous orchestration of the interpenetrability of the same and the other (from 16mm green water to video of green synthetic grass, for example). Forms shift within a precise palette between shapes and dimensions, flatness and depth (circle, square / sphere, cube), from its support (film, video / drawing, CGI) up to its editing structures, the cutting (normative / transgressive – with a singular cut-to, with shot/counter-shot, with its acceleration into flicker, with a superposition, etc.). The body of idizwadidiz works through its web : after having backed up from nothing, the move between opposition and ‘n-opposition’ is the one between the very distinctions it posits – flatness and depth, interior and exterior, inward and outward, implicit and explicit, symmetrical and asymmetrical, real and artificial, between the ‘what’ and the ‘how’ –, binding the count point by point via raccords of site and sight, between conceptual mappings and points of representation.

(2)

In the diagram drawn, a chain bites its tail, the head, colored in orange, is the One, while the tail, colored in blue, is the Multiple. The One/Orange is the world-view, the representation of a set which collects all into a singular intensity.

This element is presented both as ‘CGI-earth’ and ‘16mm-globe’, both extending from the flat surface of the diagram into a three-dimensional object from which one may circle around, from which many perspectives are available, allowing to be counted in what is being worked through, the out-of-experience body. The world as logo is the rationality which extirpates itself from the icons of ratiocination, from the circumvention of ‘what there is’ to the articulated making of a renewed representative accuracy, the universality of new forms of accuracy.

The Multiple/Blue presents the expansion of the particular, the unifying continuous scanning of its ground, as the very immersion within the element that was lost by looking at the world from a global focal point. The solid blue from the iMessage screen, the empty space for text to the homogeneous set of the ocean can be read as this singularity which stands out of the totality, the exception of the ocean being the drop of water that is drinkable rather than a singular addressless message drowned in the indefinite depth of communication.

This game of univalences and multivalences is finally formalized in the very shape of the frame, in its convex or concave bend. Each stretch forging an object whose framework is being framed and systematically worked through via the spacing out of the cut.

The transgression of some pre-patterned and programmed transitions requires in fact that the transitions be fully rendered, then re-injected into the project. Collections turn into sets when multiple timelines, bound with the use of various presets, are rendered-as-one : modifications are glued in, frozen, and can be reprogrammed as being-cut. This is the ‘how’ of the recoil of the frame, not only turning it into a floating flat-screen, using cubic transitions and other pre-sets, but mostly by cutting and superposing them, playing them against each other, transitioning between a variety of increments in order to obtain dynamisms impossible within the same base, reconfigurating the preconfigured modes of configuration.

(3)

The decapitated couple (the bathroom divide), already painted as being torn from their respective bodies, being representative of their own inherent disjunction, are paired by being parred. The rime is simple, we all do not fit our bodies. A ‘bi-sexed body’ always-already splits itself in the working through of the impossibility to cope with its own predisposition. This left/right exchangability of the body turns to one-sided heads, two flat green circles that are subliminally pictured as the same, flashing away, tied by the bokeh which focuses back into its real form, the common ‘separated interior’ which ends up being a buoy, a systematic and ‘underlying oppositional backbone’ made so that our ships don’t get lost or worse, sink.

First, the impossibility of each sides to appear without what stands them apart, the vue d'ensemble which includes the gender divide, is resolved by a subtractive priming. Second, the fast flickering signals, through the accelerated shot/counter-shot, the inability for each sides to properly overlay (at least materially). And third, each dot, being the punctuation of their own inherent gap, can only meet outside of sides, that is, in the mark of their identity being ‘out there’ (like the undetermined ‘objet u’ of love) : from ‘bokeh’ to its focus on ‘buoy’.

From the impossibility of a One to emerge from difference (the flicker with the inverted positions), to the impossibility to have a One for the parts that are the same (the flicker with the two heads), we move to the signaling of the buoy. From the ‘finitude of desire’ to the ‘eternity of drive’, from the excluded middle, the ‘parallax gap’ between the two from which no synthesis is possible, we move to the permanently revisable formula : Spirit is a buoy.

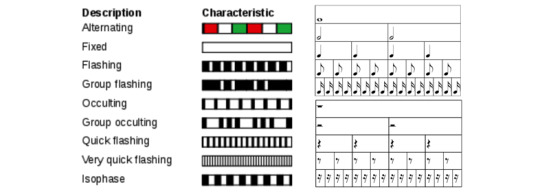

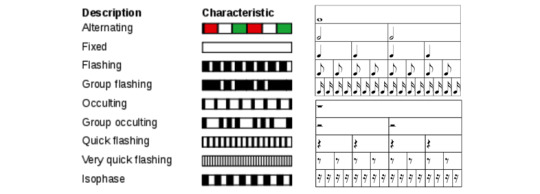

A mapping with the light characteristics chart (the navigational maritime signalization system) forms subtle shifts between the normative function of editing patterns and their dynamical rhythmic compositional tour-de-force.

In the buoy sequence, the steady navigational signaling breaks from the irregularities and twitches of the flicker. The formal synchronization of the cut with a separated entity regularizes the irrational cut-flow between positions, breaks out of the repetitive cuts between the law (the gendered separation of bathrooms) and its transgression (the stroboscopic flickering). Similarly, in the scene where the vignette flashes at every marking of dots of water, it is the marking on the cement which, as the law of cut, controls the vignetting of the frame, so when the marker gets included in its own count, pointing the act of pointing, a new dimension beyond the law opens up as the axis shifts. The proliferation of dialectics through their particular continuities (ideas, to copies, to models, to representations, to forms) is compelled by the cut to rupture, from itself and by itself, by disjoining ‘the place of the Other from any insistence of same-others’.

Finally, the cut is torn between flickers of void and intervals of infinities. The dynamic condensation of this shot/counter-shot generates the stereoscopic vision, just like the thaumatrope (or trauma-trope) : two stasis traverses the same motion and opens thus a new synthesized image of stasis whose ‘simulated simultaneity’ is something like an afterimage, an ‘afternature’. The totality of the ramified network of oppositions, contracted in the shift of this eternity-coin does not rely on the inception’s ever-spinning totem, where at every take the stakes are the same. Rather, the untenable invariant whose purpose takes form by playing forms and nonforms against each other, makes us ‘traverse the fantasy’ whose trajectory is rationally constructed by montage.

So what may finally lie beyond phenomenological description and conceptual prescription? By replacing ‘the object and its identity by the system of its perspectives, the functor’, IM registers a ‘dialectics of formalization’ whose impulse, challenging the classical thinking of the image by tearing down the ‘classical image of thought’, expands from contextual strings of pro-grammatical operations within an enrolment of body-volumes by subverting the motion study into the study of thought's very own motion, a motion ‘without arrows or bodies’, a ‘(meta)stasis of the conditions of a motion study itself’, a ‘metalogic of one's logic of theorization’.

This has only been a highly volatile and non-exhaustible investigation into idizwadidiz, I wish for and know that the best of many more dots are to be connected and entertained. Less than its ‘subjective glorification’, like the ones of the last century; a passion for the indexation of its consequences. If there is only one oeuvre for the next hundred years, it is it.

Bibliography :

Alain Badiou. Being and Event serie (1988, 2006, 2018)

Ray Brassier, Transcendental Logic and True Representings (2016)

Olivia Lucca Fraser. L'éclat de la dialectique dans les courts-circuits de la syntaxe: Hegel, Petersen, Girard (2012)

Isiah Medina. On 'Demolition of a Wall' & Summertime Reflections on Cinema (2017)

Alessio Moretti. The Geometry of Logical Oppositions (2009)

Reza Negarestani. Intelligence and Spirit (2018)

Fernando Zalamea. Synthetic Philosophy of Contemporary Mathematics (2012)

Slavoj Zizek. Absolute Recoil: Towards A New Foundation of Dialectical Materialism (2006)

12 notes

·

View notes

Text

wadiz:idizwadidiz?

by Alexandre Galmard

A new ‘demolition of the wall’ (of language) has brought itself to the Ground (’zu Grunde gehen’), then back as a background. Isiah Medina. Every point is a passing through the event-horizon, a universal projection of the concept of concept driven to be unwritten, ceasing to be what they are by reversing back to their natural space, challenging them on another basis than the one of philosophical articulation, outlining the contours of the world of thought. There is a crossing of threads from which this work stems : philosophical concepts and artificial languages as toys, their geometries, their blueprints, their figuration and animation, their interactions, transgressions and fantasies; and the multiplication of their dialectics to understand what they are and how they may be, changing the way we think worlds can be made in a systematic manner. As a foundation kit, a toolbox to share with fellow makers and thinkers, an about-face to a ground-zero which is never fully it ('Kindergarten'), idizwadidiz is ‘textless punctuation’, a sort of 'concept-script' whose ideography extends from the index which registers itself in its own immanent unraveling into an articulated and complex rebus which, more than staging a formal methodology for content-breaking, breaks from old molds by breaking from the molded idea of the mold itself, casting away the cast, engaging the whole media into a process of unlearning. If we must break from the despotism of fixed grammatical rules at every point, such that each composition has its own mold, one point at least must break with this idea by dealing with the most absolute form of despotic formalism. Here we have the marvel of marvels, extimacy demarking itself from the passing through of ascents and descents, through the formal-concept that emerges from the background of immanent abstractions.

If one lacks the proper language, should an effort be made to be able to see it all? Wouldn't it be denying that something can be thought without the thought with which it was conceived to affirm that Isiah's movies are indiscernible without its bibliography? The point is not so much that, if we were to show it all, artistic creativity would be compromised (clearly it isn't). Rather, the desire to see (truths) always already inscribes the Idea into the intimate domain of placement. The obverse position rendered here is subtraction for the very purpose of unconstraining thought to a position, of unconstraining the concept to a lens of truth, to an 'epistemological intermediary' which would render the world ingurgitable. What is shown is not lacking its sources because it is heavily censored, it is heavily censored because you do not come back scot-free from wanting to see it all. You cannot see it all without compromise, without an absolutely subtracted codified contextual structure without which it would be 'like turning round hopelessly in some obscure labyrinth', tracking down sensible intensities. By reflecting upon both epistemic transactions (between abstract things and concrete ideas) and their typological axiomatization, one goes through a sort of brachylogical sabotage, the very destructive step towards a re-foundational grounding of all parameters, of the conceptual and the not-so-conceptual brought to appear in other ways than they were made or thought to exist without reducing the conceptual to an effect, nor understanding to an affect : from 'having or not having' (concepts) to 'having or being', that which 'presupposes the subject as always already having a generative capacity' shifts into that which 'takes into account how the subject itself emerges through the substance's auto-scission', thinking thought as always-already a structured ideal, and whose Idea shifts from the affect of the subject in the effect of a truth to the effect of the subject in the affect of a truth.

(0)

As a contraction of words into one, the title, being a negation of Leibniz's "what is not a being, is not a being", presenting its inverted form and taking into account abstractness in its most concrete sense, is the grand investigation of a being of negation, 'there is no peace even in the Void'.

An empty screen appears. A 'compulsion to repeat' chops the opening shot, beginning over and over, acting as its own absolute self-reference, its principle of identity : A is A, which, being the same and posited twice, differs from itself, splits itself from itself, jump-cuts self-referent identities being re-injected into themselves as a constant reminder that substance always-already splits itself intermittently. The original black frame is pre-ontological while the screen is the Void proper, its failure of being something other than nothing, or rather, a nothing which is counted for, just like anglosaxon groundfloors marked '1'. The black frame leaves its place for its negation, the white empty sheet. This is closely followed by the appearance of another form of nothingness, an empty projection, a 'shadowy double', which plays the pre-roll countdown. This is at once the announcing of the beginning of the roll, and the retroactive referent that we already have begun to count. The two unaligned empty squares are an exemplary distinction between A's voided being and A's appointed there. The out-of-jointness from frame to screen, from picture to movie, as seen throughout, disrupts their identification with one another. Once the logical projection meets the ontological socle, a third term is created. This is 88:88's undertitle : '––:––, –'. Or : 'onto, logy, –'. The third term is what comes out of the intersection of a union, the very mark of their conflation (which in turn will burst into solid colours). At this stopping point to the adjustment of the two, the co-incidence, the moment they superpose each other, the (thus non-excluded) middle becomes intersected, giving the shared part a space of its own. This third term is at once the Two's representative and its disruption into a blind spot, the passage from 'there is no relationship' to 'there is a non-relationship', its very own display.

(1)

If you take 'Envers' in F is a •reverse• in E, some fundamental laws of thought are written down : negation (reverse), minimal, maximal – excluded middle, double negation; the track is reversed in correspondence with the axioms written before us. The dynamic range is then used to picture the cancelling out of the maximal and the minimal, with no other way, fading to black or manually pushing and pulling the exposure on Porphyry's tree (as I like to call to it) cancelling out the background formed of water and skyscrapers. To rely on such grounds, discernment must be the basis by which one perceives a space for neither full white nor full black, neither maximal nor inexistent (since both indiscerns and flattens form). Complementarity of logic and geometry is the opening – the union drawing – and the conclusion – an extended logical square diagram shown on top of a computer screen as a continuation of paint.

This announces the logico-geometrical expansion of idizwadidiz. Invariants transacting between similarity and dissimilarity unfold in accordance to how they are cut together and which predicaments do they pose, drawing positional and oppositional relations, 'movement from place to place, and change from color to color'. The colour palette symbolically reduced to a logical square (but ranging through all the intricate middle-zones throughout) could give : orange, blue / red, green. Notice how each side of the palette mixed with its respective inverse results in chromatic neutrality, grey on grey.

Notice also the black or white backgrounds and flickers which render the space of the frame. We thus depart from the ontological grounding of the count to a full scale dynamical geometry, that is, of the discernment, in the presentation, of the continuous and discontinuous interpenetrability of the same and the other (from 16mm green water to video of green synthetic grass, for example). Forms shift between, shapes, flatness and depth (circle, square / sphere, cube), from its support (film, video / drawing, CGI) up to its editing-structures, indicating how an opposition is treated by the cut (continuity, contingency / regularity, irregularity – with a singular cut-to, with shot/counter-shot and its acceleration to flicker, with a superposition), and so on. The body of idizwadidiz works its vast web of things; after having backed up from nothing, the move between opposition and 'n-opposition' is the one between the very distinctions it posits – flatness and depth, interior and exterior, inward and outward, implicit and explicit, symmetrical and asymmetrical, real and artificial, stratas of various states of the same, between the 'what' and the 'how' –, binding the count point by point and drawing from the raccord of site and sight as the dialectics of universality and particularity, alternating between both conceptual formalization and points of representation.

(2)

In the diagram drawn, a chain bites its tail, the head, coloured in orange, is the One, while the tail, coloured in blue, is the Multiple. The One (Orange) is the world-view, the representation of a set which collects all into a singular intensity, earth.

This element is presented both as 'CGI-earth' and '16mm-globe', both extending from the flat surface of the diagram into a three-dimensional object from which one may circle around, from which all perspectives are available, a 'cognitive mapping' which allows to situate ourselves within what is being worked through, the out-of-body experience. The logo of the world is a logos, a rationality which extirpates itself from the meanders of ratiocination, from what there is to its circumvention and articulation as an idea, re-making it into a renewed representative accuracy, a world-brain. The Multiple (Blue) presents the expansion of particularity as the very form of the presentation, the immersion within the element that is lost when looking at the world from a global focal point, and provides the unifying continuous scanning of its ground.

The solid blue from the iMessage screen, the empty space for text to the homogeneous set of the ocean (yet only a partial image, just like the 16mm globe, both sides already being diagonal to the present dialectical split) can be read as this singularity which stands out of the totality, the exception of the ocean being the drop of water that is drinkable (Hugo’s La source tombait du rocher), the very space for reason, the singular addressless message drowned in the indefinite depth of communication. Nowhere is it said that things are going to get more and more (conceptually) digestible.

The dialectics of the universal and the particular, the global and the local, extended out of colour-matching, is formalized in the very shape of the frame, in its inward or outward bend. Each without the other would be its own proper relapse.

The transgression of some pre-patterned and programmed transitions requires in fact that the transitions be fully rendered, then reinjected into the project. The necessity of the export/import into render-files to achieve such cuts is quite telling. Collections turn into sets when the multiple, bound with the use of various presets, is rendered-as-one : modifications are glued in, frozen, and can be reprogrammed as being-cut. This is how the recoil of the frame may be understood, not only by turning the frame into a floating flat-screen, but by using cubic transitions and other pre-sets, by cutting and superposing them on top of each other, transitioning between them, being incremented to obtain unprecedented dynamisms impossible within the same timeline, transgressing the classical modes of transgression of the 'art of transition'. Beyond the compass-view and the three-dimensional mapping, transgressing the pre-determined ways we transform what is, we arrive at a stabilization following a unique process of harvested intelligibilities : the buoy, the 'underlying oppositional backbone' which necessitates no solid ground (since it floats, it oscillates) in order to operate the shift between universal principles corresponding to particular forms and their conceptual polymorphy, generating thus new dialectical pictures of thought.

(3)

The decapitated couple (the bathroom divide), already painted as being torn from their respective bodies, being representative of their own inherent disjunction, are paired by being parred.

The rhyme is simple, we all do not fit our bodies. From the metonymic fluctuations between binary and plurality, the movie condenses the field of possibles back to sexual difference. This 'bi-sexed body' always-already splits itself in the working through of the impossibility to cope with one's own predisposition. This left/right exchangability of the body turns to one-sided heads, two flat green circles that are forcibly and subliminally pictured as the same, flashing away, tied by the bokeh which focuses back into its real form, the 'separated interior' which ends up being a buoy, a system made so that our ships don't get lost or worse, sink. The fast flickering does not signal the indistinguishability of both sides; it rather takes a step further, not proving the very identicality between them, but proving the inability for the contradiction to overlay (at least materially), its impossibility to appear at once without what stands it apart, other than through the vue d'ensemble which includes the gender divide. In other words, they meet outside of sides, in the indeterminate bokeh (Badiou's 'objet u'; recall Isiah's movie (∃u) [u ≤ f and u ≤ m] which formulates a love encounter and pictures the series of decisive points which awaits the lovers). From the impossibility of a One to emerge from difference (the flicker with the inverted positions), to the impossibility to have a One for the parts that are the same (the flicker with the two heads), we move to the signalling of a third term. From the 'finitude of desire' to the 'eternity of drive', from the excluded middle, the 'parallax gap' between the two from which no synthesis is possible, we move to the formula : Spirit is a buoy.

A mapping with the light characteristics chart (the navigational maritime signalization system) – that can be extended upon : solid colours in alternating flicker of orange and blue, a variety of sequences with black or white, regular or irregular (according to their grouping together) of cuts, and so on – forms subtle shifts between the systematicity of editing patterns and their dynamical rhythmic composition.

In the buoy sequence, the steady navigational signalling breaks from the irregularities and saccadation of the flickers, the formal synchronization with a separated entity regularizes the irrational cut-flow between positions, breaking out of the vicious cycle between Law (the gendered separation of bathrooms) and its transgression (the stroboscopic flickering). Similarly, in the scene where the vignette flashes at every marking of dots of water, it is the actual marking on the cement which, as Law, controls the vignetting of the frame, so when the marker gets included in its own count, pointing the act of pointing, a new dimension opens up as the axis shifts. Finally, there is a recondensation in the ambiguous figure of the cut, torn between the 'flicker of the void' and the 'infinite of intervals'. How do we apprehend the continuity and discontinuity between the illusion of both animation and inanimation as that which renders visible the 'material inferential transitions' between the two, the very form of their distinction in the passing into each other? Conception and transformation; the dynamic condensation of this shot/counter-shot generates the stereoscopic vision, a static image made out of two by retinal persistence (static -> movement -> stabilization), like the sides of a same coin, the thaumatrope (or as I call it, the traumatrope), the 'synthesis of world and spirit that offers the most sublime certainty of the eternal harmony of existence' whose 'simulated simultaneity' is something like an afterimage. Finally, the totality of the ramified network of oppositions is contracted in the shift of this eternity-coin, the inception's ever-spinning totem, where at every take the stakes are the same.

So what do cuts form? With or without the morphological variety of fades, incrustation, superposition (negativity's dilution). With or without the untenable invariant whose purpose takes form by playing these forms and nonforms against each other, by 'traversing the fantasy'. Yet if cuts unrestrict themselves to breaks made out from the substance's finite limitations, being neither a fold nor a stretch, if they do not appear in other ways than through blended losses, pure substanceless gaps, then, as Grothendieck puts it (for mathematics), you do not read, you listen. Listen to it like a birdsong, so that cuts be silent symphonies – recall Lacan's wordplay between J'ouis, 'I hear', and Jouis, 'enjoy' – which justifies the piece being silent (other than the two pinches which rime with the pre-count roll, as a mark of a prolonged beginning), already acquiring distance over the indistinction of sense and understanding. There is a non-continuity between the image's field of possibilities and the cut proper, such that cuts emerge neither solely from the elements of the sets, nor as a purely intentional act, 'what is is birthless and deathless'. In other words, how do we think away from continuity as neither an identification of image qua life and cuts qua death, nor as its transitory mode? If we reverse the metaphor of light and take the image as being imperfect insofar as cuts come leaking through like a flare over a closed shutter, how will we think beyond the self-instantiation of the particular interior it breaches through?

idizwadidiz's transits are an exemplary case of a 'dialectics of formalization' whose impulse, challenging the classical thinking of the image with the 'classical image of thought', does not restrict itself to arbitrary stratification, to contextual strings via pro-grammatical operations, nor simply to an enrolment of body-volumes. So what may finally lie beyond phenomenological description and conceptual prescription? From the replacement of 'the object and its identity by the system of its perspectives, the functor', Isiah responds : 'Is it possible to do a motion study without arrows or bodies, but to study the 'motion' or (meta)stasis of the conditions of a motion study itself?'

43 notes

·

View notes

Text

Introduction of metal belt buckle types

There are many types of metal belt buckles. Many people are very picky when choosing. They don't know which metal belt buckle is better. In fact, each metal belt buckle has its own characteristics. Let us find out together.

There are several kinds of buckles for metal belts

Belt buckle, also known as belt head or belt buckle head, is a hardware accessory on the front end of the belt, used to decorate and fix the entire belt. Changes in belt trends are largely caused by hooks and buckles. The shape and size of the hook and buckle also show the charm of men, the pin buckle belt shows the fashion and masculinity of men, and the buckle shows the calmness and roughness of men.

Pin buckle: Divided into five categories: single pin buckle, double pin buckle, Japanese-style buckle, plate buckle, and automatic buckle.

Single-pin buckle: Black, maroon, brown, and brown single-pin buckle belts are stress-free when paired with formal wear, and you can enjoy casual occasions.

Double pin buckle: The belt is more casual, unless the color is particularly calm (such as black), it is generally not recommended to match the double pin buckle belt with formal wear.

Buckle: The belt buckle material has a strong atmosphere of local tyrants, especially those golden buckles, which are favored by middle-aged uncles.