#plastic molds

Text

Application of 3+2 CNC Machining in Mold Making Factory

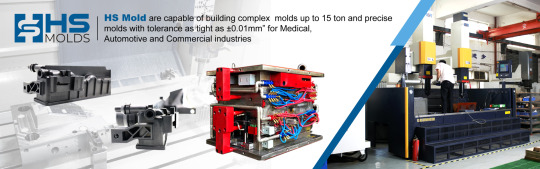

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

#PURPLE #POISONAPPLE #RESINPOUR time again! I'm loving this color combo so much... I'm using different embellishments for the back of these babies, but the #mirror will be just as magical! This color combo is giving me serious Regina vibes (if you've never watched one upon a time, do yourself a favor & check out our on Disney plus!) Adding this to my #etsysale this week!

💜 I miss this lady so much! Such a great show!

.

🍏 #linkinbio for my shops and blogs!

🍏 mold by @str8outtaglitter

.

💜

#resin#craft#resincraft#art#diaries#fangirllife#etsyseller#resinart#artistsoninstagram#shopsmall#snow white#disneybound#disney villains#poison apple#magic mirror#resin pour#process#so satisfying#artists on tumblr#plastic molds#restocking#once upon a time#ouat#oncer#oncer for life#evil queen#handcrafted#handmade#hand mirror

2 notes

·

View notes

Text

Plastic Structural Design 2 - Mold (Introduction)

Fer Read Series 1, please Plastic Structural Design 1—Materials.As a product structure or mechanical engineer, it is necessary to master basic understanding of injection molds. It can help you better develop products. Details are as follows:

1. Mold material selection and texture introduction

1.1. Selection of mold materials

Materials used in mold are mainly as shown in table below

Steel mill…

View On WordPress

#cold runner mold#Double parting surface injection mold#hot runner mold#injection mold#injection molding#injection molding process#injection molds#mechanical engineer#Mold base and design#mold factory#Mold guide system#mold materials#Mold positioning#mold structural parts#mold structure#mold structure design#mold surface treatment#molded parts#multi-cavity molds#parting surface#plastic molds#plastic parts#Plastic Structural Design#product design#product designer#Push block ejection mechanism#single-cavity mold#single-parting surface injection mold#Slider limit mechanism#slider splitting

0 notes

Text

How Customized Injection Molding Solutions Save Your Biotech Device Development by 80%

Introduction:

In the rapidly evolving landscape of biotechnology, the development of cutting-edge devices demands innovative solutions that not only meet stringent industry standards but also ensure efficiency and cost-effectiveness. One key aspect that plays a pivotal role in the biotech device development process is injection molding. This article delves into the significant impact of customized injection molding solutions on saving up to 80% of the development costs for biotech devices.

Precision Engineering for Complex Designs:

Customized injection molding allows for the precise replication of intricate and complex designs, a crucial requirement in the biotech industry where devices often have intricate geometries and tight tolerances. This level of precision ensures that the final product meets the specific needs of the biotech application, eliminating the need for costly revisions and adjustments in the later stages of development.

Material Selection for Enhanced Performance:

Biotech devices often require specialized materials to meet the stringent regulatory and performance criteria. Customized injection molding solutions enable the selection of materials that are not only compliant with industry standards but also enhance the overall performance of the device. This targeted material selection ensures durability, biocompatibility, and resistance to harsh environmental conditions, reducing the likelihood of failures and the need for redesigns.

Rapid Prototyping for Iterative Development:

The iterative nature of biotech device development demands quick turnaround times for prototypes and design modifications. Customized injection molding facilitates Rapid Prototyping, allowing developers to assess and refine their designs swiftly. This agility in the development process not only accelerates time-to-market but also significantly reduces costs associated with prolonged development cycles.

Cost-Efficient Production:

Traditional manufacturing methods often involve high tooling costs and lengthy lead times. Customized injection molding solutions, on the other hand, offer a more cost-efficient approach by minimizing

tooling expenses and allowing for large-scale production with shorter cycle times. This results in substantial cost savings, contributing to an overall reduction in the financial burden of biotech device development.

Streamlined Quality Control:

Ensuring the quality and consistency of biotech devices is paramount. Customized injection molding solutions enable the implementation of rigorous quality control measures throughout the manufacturing process. By maintaining tight control over key parameters, such as temperature, pressure, and material flow, manufacturers can produce high-quality components consistently, reducing the need for post-production inspections and rejections.

In conclusion, the utilization of customized injection molding solutions in biotech device development presents a transformative opportunity for companies to achieve substantial cost savings of up to 80%. From precision engineering and material selection to rapid Prototyping and cost-efficient production, these solutions empower developers to navigate the complexities of biotech innovation with greater flexibility and efficiency.

As you embark on your biotech device development journey, consider partnering with RPWORLD, a leading provider of customized injection molding solutions. With our expertise and commitment to excellence, we can help you realize significant cost savings while ensuring the precision and quality your project demands. Embracing customized injection molding is not just a strategic choice; it's a crucial step towards optimizing the development process and driving advancements in the biotech industry. Contact RPWORLD today and let's shape the future of biotechnology together.

0 notes

Text

Some product parts produced by injection molds

If you're looking for help with your plastic injection mould, this is a great place to start.

We welcome any of your new project for which we will be pleased to provide you our competitive offers.

Email:[email protected]

0 notes

Text

Safety Relief Valve Manufacturer in China

Shanghai Wuyue Pump & Valve Group is a professional breather valve, pressure reducing valve as well as Safety relief valve manufacturer in china. It is a high-tech enterprise specializing in technology development; product development and after-sales service in the field of pump and valve fluids. Visit our website to know more about safety relief valve supplier in china.

#safety relief valve manufacturer in china#Suppliers#Plastic Molds#Mold Parts#Manufacturers#Machining#Injection Mold

0 notes

Text

Three Categories Of Plastic Molds

Three categories of plastic molds

1. Plastic injection (plastic) mold

It is mainly a molding mold that is most commonly used in the production of thermoplastic parts. The processing equipment corresponding to the plastic injection molding mold is the plastic injection molding machine. The plastic is first heated in the barrel at the bottom of the injection machine. It is heated and melted, and then driven by the screw or plunger of the injection machine, it enters the mold cavity through the injection machine nozzle and the pouring system of the mold, and the plastic is cooled and hardened to form, and demolded to obtain the product. Its structure usually consists of forming parts, pouring system, guiding parts, pushing mechanism, temperature regulation system, exhaust system, supporting parts and other parts. The manufacturing materials usually use plastic mold steel modules, and the commonly used materials are mainly carbon structural steel, carbon tool steel, alloy tool steel, high-speed steel, etc. The injection molding process is usually only suitable for the production of thermoplastic products. The plastic products produced by the injection molding process are very wide, ranging from daily necessities to various complex machinery, electrical appliances, and transportation parts. It is the most widely used processing method in the production of plastic products.

2. Plastic Compression Mould

Including compression molding and injection molding two structural mold types. They are a type of mold mainly used to mold thermosetting plastics, and their corresponding equipment is a press molding machine. Compression molding method According to the characteristics of the plastic, the mold is heated to the molding temperature (generally 103°108°), then the measured compression molding powder is put into the mold cavity and the feeding chamber, the mold is closed, and the plastic is heated under high heat and high pressure. Soften the viscous flow, solidify and shape after a certain period of time, and become the desired product shape. The difference between injection molding and compression molding is that there is no separate feeding chamber. The mold is closed before molding, and the plastic is preheated in the feeding chamber and becomes a viscous flow state. Under the action of pressure, it is adjusted and squeezed into the mold cavity to harden and form. Compression molds are also used to form some special thermoplastics such as hard-to-melt thermoplastics (such as polyvinyl fluoride) blanks (cold pressing), resin lenses with high optical properties, slightly foamed nitrocellulose car steering wheels, etc. . The compression mold is mainly composed of cavity, feeding cavity, guiding mechanism, ejecting parts, heating system, etc. Injection molds are widely used in packaging electrical components. The materials used in the manufacture of compression molds are basically the same as injection molds.

3. Plastic extrusion die

A type of mold used to produce continuous-shaped plastic products, also known as extrusion molding head, is widely used in the processing of pipes, rods, monofilaments, plates, films, wire and cable cladding, profiled materials, etc. The corresponding production equipment is a plastic extruder. The principle is that the solid plastic is melted and plasticized under the conditions of heating and the screw rotation of the extruder, and is made into the same cross-section as the shape of the die through a die of a specific shape. Continuous plastic products. Its manufacturing materials are mainly carbon structural steel, alloy tools, etc., and some extrusion dies are also inlaid with wear-resistant materials such as diamond on the parts that need to be wear-resistant. The extrusion process is usually only suitable for the production of thermoplastic products, which is significantly different from injection molds and compression molds in structure.

0 notes

Text

Given that Belobog is so full of snow, I'm kinda sad we never get to see any snowmen anywhere. Like that would have made for such a cute bg decoration!

And I think it would be especially funny for Sampo to make them, not out of pure, innocent whimsy and joy, but like specifically to be a menace smzhnsjd

Like Gepard keeps finding little snowmen out around the frontlines. And normally he would just turn a blind eye to this like he does with other things (like the shitty amateur distillery no one thinks he knows about); war sucks, their own damn leader is trying to kill them and Gepard is treading water just trying to keep Cocolia from using his guards as cannon fodder. If his soldiers want to make some snowmen in their downtime, then they should be allowed that. God knows they've earned it.

BUT SOMEONE IS MAKING SNOWMEN THAT LOOK LIKE HIM, DAMMIT!!!

Gepard keeps finding them down the back alleys and more hidden parts of the frontlines! And they all have the same grumpy little face, with blue-painted rocks for eyes and sometimes even gold-colored bullet casings for hair! And he knows who it is the second he finds another little blue haired, green eyed snowman next to it! Fuckin' Koski is sneaking in here, and easily enough that he has the time to taunt him!

Gepard once found a little Snow Geppie with angry eyebrows and red roses stuck in its blushing cheeks that was handcuffed to a weapons rack, which was when he realized someone had pickpocketed his handcuffs. He punches the head clean off the little Snow Sampo nearby, only to discover that it is also holding his wallet, minus all the shield he'd had in it that morning. Gepard kicks it for good measure.

One time he found a little Snow Sampo offering roses to a little Snow Geppie, and he quickly knocked those over too before anyone else could see them or his red face. He swears he can feel Sampo snickering and mocking him nearby.

Sometimes, Gepard finds little Snow Sampos with tiny sacks thrown over their shoulders, all filled with items that are SUPPOSED to be in the depths of the guarded Silvermane storehouses. Sampo technically isn't even stealing anything, he's just showing Gepard that he could if he wanted to, and poor Gepard is going to pop an aneurysm.

Pela: Good morning, Captain. Have you been outside of your tent yet?

Gepard: No. ....Why.

Pela: No reason. Say, have you heard of any break ins recently?

Gepard: No, why.

And Pela holds open the tent flap and there's a ton of tiny little Silvermane Guards snowmen in tight neat rows, all with their little stick arms up in salute, and each one with an actual, stolen official helmet-mask.

Pela: You run a real tight ship out here, huh.

Gepard: (looooong weary muffled sigh as he drags a hand down his face)

#gepo#sampard#hsr gepard#hsr sampo#sampo koski#gepard landau#pelageya sergeyevna#hsr#honkai star rail#I love Sampo being petty as shit just to rile Geppie up fkdsajflasdj#like he is absolutely watching from somewhere hidden nearby and snickering to himself#of a related note I think Caelus and March 7th should be given those little plastic mold thingies that make rubber ducky-shapes in the snow#they go through the restricted zone and just leave them in random places#Gepard trying to conduct serious military business and up on the wall behind him are a row of rubber duckies judging the Guards fjklasjfkld

101 notes

·

View notes

Text

Liberal feminist observations of Barbie aren't entirely wrong. I think the doll as an aspirational vision of single womanhood instead of a tool to raise girls to be mothers does represent a culture shift. The problem is the claim that this was an altruistic feminist gesture, rather than an attempt to appeal to (and create!) a new consumer demographic. We could have the same discourse about LGBT pandering. I remember the rainbow Oreos ad from 2012 and thinking, whoa, can they do that? Drag me, but I was a teenager and the prospect was exciting. I still don't think it's wrong to say this reflected a shift in majoritarian opinion. But it's jarring that any old internet user can point out that this is just pandering, but we still get thinkpieces on the revolutionary feminist messaging of Mattel.

#if you want to reappropriate Barbie in a feminist way i won't say it's impossible. plastic can be molded into any shape.#but barbie is a toy with a button that makes her say 'math is hard'

185 notes

·

View notes

Photo

Nero always DID kinda look like a Ken doll to me... 🤔

321 notes

·

View notes

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

#DEMOLDING for my #chipndale TV #resinshaker 🙌🏾 puttimg this together for a buddy of mine.... can't wait to do the watch party for the upcoming movie!! Just a few more steps & this cutie will be finished...I can't wait!

📺

These TV shakers are so fun because I can put anything inside, & I'm so pumped to pay tribute to this classic! They just don't make em like they used to! The Disney afternoon after school block? That was solid television, man 🥰 I don't usually go in for these reboots right away, but this one looks solid (& hey, I loved the chipmunk movies 🤷🏾♀️)

🐿

Stay tuned for the next steps! Gotta paint the back of these transparencies white (makes the colors pop beautifully), then seal em inside the TV, fill it with sparkly bits, put plastic over the top, then seal that, before adding hardware & finishing the back 😅 the crafting struggle is real... but so worth it!

Check out my insta, my website & my etsy!

🐿 mold by @str8outtaglitter

#craft#resin#resincraft#art#diaries#fangirllife#etsyseller#resinart#artistsoninstagram#shopsmall#geek chic#geek gifts#disney gift#Disney crafts#resin shaker#demolding#plastic molds#chip and dale#rescue rangers#chip n dale rescue rangers#work in progress#process#watch party#host gift

0 notes

Text

Difference between injection mold and die casting mold

Gud Mould Industry Co., Ltd. is a professional manufacturer of plastic injection mold and die casting mould.In manufacturing industry, injection molds and die-casting molds are two key tools that play a vital role in production of plastic and metal parts. Although the two molds may look similar in appearance, they have significant differences in structure, working principles, operating conditions…

View On WordPress

#design of injection molding molds#design of mold#die casting machine#die casting mold#die-cast product#Difference between injection mold and die casting mold#injection mold#injection mold guide system#Injection molding cycle#injection molding machine#injection molds#plastic molds#plastic products#three-plate molds

0 notes

Text

"Nobody’s Perfect Chair" Collection,

Gaetano Pesce, published by Zerodisegno in 2003,

Polyurethane resin and molded plastic dyed in yellow, black and yellow, black and blue, green... mass.

Length : 19.69 in / 50 cm, Height : 35.43 in / 90 cm, Width : 17.72 in / 45 cm

#art#design#sculpture#furniture#seat#chair#forms#nobody's perfect#gaetano pesce#zerodisegno#2003#polyurethane#resin#molded#plastic#yellow#blue#red

40 notes

·

View notes

Text

Eastcom Technology provides Plastic Injection molds service.

We are a supplier of precision molds, if you have interests, I will be very appreciate.

0 notes