#vertical grain douglas fir

Photo

Asian Kitchen

Inspiration for a small asian galley light wood floor and beige floor enclosed kitchen remodel with a single-bowl sink, flat-panel cabinets, light wood cabinets, marble countertops, green backsplash, glass sheet backsplash, stainless steel appliances, no island and green countertops

0 notes

Photo

Asian Kitchen

Inspiration for a small asian galley light wood floor and beige floor enclosed kitchen remodel with a single-bowl sink, flat-panel cabinets, light wood cabinets, marble countertops, green backsplash, glass sheet backsplash, stainless steel appliances, no island and green countertops

0 notes

Text

Enclosed - Asian Kitchen

With an undermount sink, flat-panel cabinets, medium-tone wood cabinets, marble countertops, a green backsplash, a glass sheet backsplash, stainless steel appliances, no island, and a small galley with a light wood floor and a brown floor enclosed kitchen photo.

0 notes

Photo

San Francisco Enclosed Kitchen

With an undermount sink, flat-panel cabinets, medium-tone wood cabinets, marble countertops, a green backsplash, a glass sheet backsplash, stainless steel appliances, no island, and a small galley with a light wood floor and a brown floor enclosed kitchen photo.

0 notes

Photo

Open Living Room San Francisco

Small open concept living room idea with white walls and light wood floor, beige floor, and wood walls.

0 notes

Photo

Vestibule Mudroom Seattle

Inspiration for a small timeless brick floor entryway remodel with gray walls and a red front door

#arched doorways#vertical grain douglas fir ceiling#mudroom#covered porch#porch addition#natural wood soffits

0 notes

Text

Cedar Specialty Shoppe sells timbers in both Western Red Cedar and Douglas Fir. All timber product options are available in a variety of grades ranging from vertical grain clear to utility. Cedar Specialty Shoppe can offer any size of timbers you may need. Shop online with us at https://thinkcedar.com/pricelist/

Or, call us today at 1.800.263.3653 for all of your Cedar Decking, Fencing, Roofing, and Cedar Siding needs, we deliver!

0 notes

Text

Types of Beam Supports

We all have seen massive structures supported by thick beams, these beams are supported by beam supports.

But have you ever wondered how many types of beam support there are?

If you too are interested in types of beam support then hop on, because in this blog we will discuss different types of beam supports.

Also Read : Different Types Of Coupling Beam and Their Usages

What is beam support?

A beam is a post that is capable of withstanding load, a beam transfers all its load to the supports so that the structure remains strong as well as stable.

There are many types of beam support houses and buildings as well, the choice of beam support depends upon the type of structure and other external factors involved.

What type of wood is used in beam support?

While using wood as a beam support the engineers have to keep many things in mind.

Things like termites, moisture, stability of the structure, etc.

The best wood with the highest finish that is used in beam support is Douglas fir, it is best known for its beautiful grains and highly finished posts.

Different types of beam supports

Classification of beam support is based on the way they are supporting the beam.

There are 4 types of beam supports.

Fixed support.

Fixed support keeps the end of the beam fixed to the support, the beam is able to resist horizontal, and vertical forces and moments.

Pinned support

Pinned support is like a door leaf, it rotates along the vertical axis but doesn’t move horizontally and vertically.

A pinned support resists vertical and horizontal forces but can’t resist a moment.

Roller support.

Roller supports are usually used for long bridges because it enables the bridge to expand and contract as per the temperature.

Roller supports can rotate and translate along the resting surface of the roller.

Simple support.

This type of support allows the beam to rest freely on it.

The beam is free to move in any direction and can also rotate on the support.

These were 4 types of beam supports.

0 notes

Photo

Steep Grade Fadeaway

Day is a Monday, lease On life’s right side of the low- Lying greens, order’d by law, Creases, offering a hand to hench- Men handy for odd-jobs re- Pression & phobia with wolf spider Ire stocking its stuffing, venom Plenum spokes from eight- legged gait, unipolar police

Police who didst to citizen do South bayway sword maneuver —dune ballooning din—kill them :: moths from mothta spread— I’m a member of.— online soap seas cap’n gown loan shark says-he’s—sore lark admin the sole soul food restaurant— vessels contain company that’s it—company THE THING IS IS VANDAL SURE-FOOT’D SHOE YOU’LL DISAPPOINT ME —Dianne of diagnostics Prism blend’d light, you mean honestly ~ i ~, ere Administration's penchant for pens & Cagey humors, pent up & alloted limited stock On pinterest’s pinner plot Would extraction begin, even Helices interr, interject Baby Christ’s liverwurst extrusion, Redux of suede luxe ever does thine slow- f[x] fool on a lark's wing in folly err; But general, the nut sacks, please, topp'd Sweetener glaze (never for gays) Sweat frosting from ecclesiast's evac- Uation jizzum, eat- ery just a- Round the bend over good That IndyCar 500 cock. So: so-so soho block where— Erstwhile free- thinking myth- ology passes heavy limbs Creaking in wind [was thinking we’d] Flower fourteen curls Back & forth, Codify desert sublation, Cue gay porn infinity loop on eternity's Cloud backup-drop forever projected, For your children, Mike, your kids. & this — this (my) ((his)) cursive slick mercurium thick, pen flood in- flux counter-sunk & dumb- Bows, ties, sells quill at marketplace With expertise’s durable advisory, reed Screeching in its rubber friction drift, which quells not squad disruption, squall,

Abuts up with a spade to fabled proprietary lines; Umpire enraptured, raptor

Pack kinetics study anonymous groups, For scrimmage near miss Miss, the MRSA Merck's

Near-fatal tithe.

< h o w t i g h t b i r c h b a r k f l a k e s o f f t o g e t h e r ash :: coils :: winch :: draw- in-the-dark rhythms inn-like, quiet, keeping with

Queen Mariah Carey's

Kierkegaardian wish :: Of lactic acid & Jehoshaphat Edicts, alliances spat at by Jehu So cordage tension its elastics tests :: Hell moans red Waves a porcupine pelt let through

Spires sharp with bone, in- Scriptions of pass’d down teaching King-toppling :: hull groan gore, little system submarine ultrasonics, Realty a reality drive, divisions Splints tack’d on ulterior Versions, separation goods Another marketplace subsumption, a- Ah ah, Monarch’s ampersand Armory & orphanage growth paradigm. Mama, in the maw Of a monster it appears When spat to mangrove’s entanglements In whose rootless cloak Womb-like repair’d did I float On Tidal pressure’s pat turns Of wave phrase & coastal sound. Grammy’s telegram Faroff drawing graph’d out In double bass clef, whitebread from the top of Wonderbread ridge, Omi? [[[ hives, hexagon life-rafts Ashkanazi Jews descendents in whose Nameless lineage bow’d heads lean past stalk & branch ]]] Holocaust a hologram to fool’s corner; Survived, devised lives, could I Then, they this disbelief hold After the fact hush, scattering creed, Belief like layers of sound same Overlaid, distortion via copying; this Terrain vague makes us Hungry for disbelief & away,— Shame at sensation’s predicate, we’re not we’re not were not them—then. Characters glynne & surrowe, iyse foes may say will not into world will For will’s sake. Gardner rescinds Offer for cylinder Heads, standing wave pressurized

In tubular body, met with lip Aperture shifts & valve Select valve depressions trumpet Walls down, & Solomon’s temple’s walls Shake each brick laid If coded into video- game; mechanics of Megafauna’s jaws dent don’t puncture, dental spread of broom’s Bristles or concrete finishing screed. The lady grabs the keys & allows generations a soul’s Movement to buoy faith :: Clay takes on new shapes for Good, naked bracing Against surface, thrust short Rink’s fire firefly-stud’d, freight’d glows The fright force against density Darkness offers, suspension Cradle, safe durational rock shock’d By freight trains penetrative Expansion, gaseous fits in confines small; Cobbler’s shop a shack, canister Tremolo goes to tumble-wash, Eviction of nuns at Juniper Monastery, things object through Inaction, plants guard fruit from gulls’ gullets, Gourd raft or instrument & species disembark :: Parnassus lamb on spits, spurn Wager’d against poignant Stellation of spur’s star’d points, stud’d. It is rather lonely. Welter Weights waste excess swells In waist’s weight-gain, Spotted once then trimmed, deemed High hinderance if loot’s to be tuned up, then taken; Blood from thin laceration Above the right eye releases threads Of blood; hand held, yes Triads, amps per kilojoule of One grain of sand, which Between toes react, duststorm Shakes clapboards & window-garments, The fornification of conceivable indivisible parts :: Things poole gryn, Graham to you This, saturate, this saturnalia. Wherever sea rummages earth’s crust Sage’s city wisdom, said to overturn off- Compass underpass or Souls inhabitance Herenow splatoon ever in unum Pluribus, A well. If it gets to, it’s off in bramble patch again; Cavernous sediment down- Loads by way of remaining in stasis, Adaptation & change proceed With gradients of such nuance one is Sure as one can be Organisms are a constancy unmoved.

English ivy, spry & welcoming Enough to juncos & finch-song, Strangles any individual offering A vertical support, a tall host, From whose apex, were One to climb douglas fir In that Spanaway house’s lot, one would note Yellow blazes from Scotch broom, an infantry Under which camas flower & prairie grass Die off; ecologists hear & provisions provide public. Nova scorch Canopy, What’s happened to it all Primates of later eon ask? Sand shook; mud slid, loosed from Roots once anchoring mass, Hook enters the base Of the bait, loop line Doubles & knots, casting out guesswork When fisheries bring ghostnets to Foreground & shore. Rasas. & family still Standing :: Burgess brothers Twin lute & nylon-string, Summerfield Tectosilicate feldspar recovers & with Katy & makes musical games to train good weapons, voice leading & harmony Accompaniment, just.— It promised. no ~ i ~, quotient, quarrel Quest-kill objective, quarantine, Can inquiry proceed experimental Without explorational? INgenuine (this venue, come now) To even ask, but to Figure this out buy redrawing What was that, Those shapes making layers first, Maybe dimensions, second? Sinkholes clog eventually. Can yonder’s crayon-wax Out rear windshield Make out landscape’s Attendees & absentees alike? The tipoff bid for children’s hospital Sutures lawmaker to industry Profit-centers, pediatric morbidity rallies, Shipping vessels on glass beds spit Beads of bleach, sleet freeze Hardening to barnacles, sharkfin decor, Trim efficiencies, sin, sign, nature, what Remains in speech decoder’s translation? Mama’s got through villanelle Format, perforated loss, refrains Rebounding sound given shape By lack surrounding it, cradling it, even. Shedding it, scalar skin or bark; Magnitude without direction; A temper vestibule in- Vests, jackets a body in Truncated coat, technics fold, inter- Ruptions :: hundreds die as baseline Nuclear arsenal refill Fun, a planting pot fresh with Manure, fertilizer funds, & dirt With paradox, halving lives A speculative endurance, Populating a futurity with Untraceable elegance, Like mycological spore, or mycelial Masses; like cryptocurrency Exchanges in blockchain Relationship & exchange verifiable With uncompromising math With extraneous dialogue In the wind; like let them be naked Physicists sporting labcoats Only, as a group Sure of dark matter’s Not being there, its criminality A subversion, defying Paradigm parameters, & the glottal Stop at this epistemological Dissolution, erotic even, A flush heating bodies up At the limits, the proximity Of other bodies, the desire For physical embrace & exchange enough, nearly, To assume such kingmaker species a half-life well off Into future, plutonium megawatt power-station Giving life to groups finding Each other, once again, beneath Night’s luminous bodies, Beneath moon’s thievery, Held by shadows, deep black density In whose unmappable infinitude a species Approaches a release from print, rose Compass, gold arrow, landscape & waterway Florescent with spectra of blue & volcanic reds, shorn from it, then, Held in what is after all, unnamable, Of near-absolute incompatibility With kingmaker species & yet, That which gave any of it The possibility of accidental beginning.

#poems#poets#poetry#poemsandpaintings#poemsandimages#poeticstories#writerscreed#artontumblr#whateveritis

3 notes

·

View notes

Photo

Suncatch | Design by Norm Applebaum Architect | Photo by Mary E. Nichols © Located Rancho Santa Fe, United States📍 . Follow @habitat.theory . The architecture of “Suncatch" came about after an 8 year design and construction process. It sits on 30 acres in the prestigious area known as Rancho Santa Fe in Southern California. The project consists of 54,000 square feet of floor space divided as follows, 24,500 square feet of living space and 29,500 square feet for a 37 car showroom under the house. It was completed in 2005. The architect’s client stated that he wanted the finest house in the region. The home is finished out using a half million board feet of clear vertical grain Douglas fir, floors, ceilings, cabinets, doors, fascia and all trim. Plaster walls and poured in place concrete, using a veneer system invented by the architect, are the finish materials. Views were to north but large overhangs were used to capture the south sun, this in turn brightens up the interior spaces of the architecture. #habitattheory #modern #suncatch (at Rancho Santa Fé)

7 notes

·

View notes

Text

Woodinville Whiskey Co, Quincy Washington

Woodinville Whiskey Processing, Barrel-Aging Facility, Washington Commercial Property, WA Architecture Photos

Woodinville Whiskey Co in Quincy WA

Mar 3, 2022

Design: Graham Baba Architects

Location: Quincy, Washington, USA

photo © Kristian Alveo

Photos: Kristian Alveo and Ross Eckert

Woodinville Whiskey Processing and Barrel-Aging Facility

To meet increasing demand for its products, Woodinville Whiskey needed a larger distillery facility to process and age its whiskey. A 10-acre site set amidst the fields of grain used to produce the company’s whiskey in Quincy, Washington was selected for a multi-phase expansion that consolidates operations as well as provides space for continued development.

photo © Kristian Alveo

The initial phase of the expansion features a processing and bottling building, which also houses new corporate offices, and a barrel rickhouse for aging the whiskey. A second barrel rickhouse is currently under construction. Four additional barrel rickhous-es are slated for future phases.

photo © Ross Eckert

The buildings are large—ranging from 40- to 70-feet-wide-by-400-feet-long—and establish a monumen-tal presence within the fields that surround the site. Despite their size, the structures are an exercise in restraint, taking design inspiration from the simple agricultural and industrial warehouses found in the region, as well as from traditional ricking houses found throughout the American South.

photos © Ross Eckert

Inspired by the distillery’s production and tasting facility in Woodinville, Washington (also designed by Graham Baba Architects), the client’s directive required balancing functional and industrial requirements while clearly conveying the Woodinville Whiskey brand. Building massing is simple, with functional aspects such as vehicle circulation, loading and unloading dictating the site’s layout and the buildings’ scale. Maintaining the simple, rectilinear gabled form and dark brown hue of the Woodinville distillery, the new complex consists of buildings clad in dark metal siding and Kebony wood. Large Corten-clad slid-ing barn doors and bands of Corten siding at key locations combine to evoke the warmth and character of the whiskey.

photos © Kristian Alveo

Leveraging the economy of prefabricated metal buildings, the team determined manufactured structures would provide a cost-effective way to create a lot of space while still preserving opportunities for cus-tomization. Highly crafted details are strategically located where they count the most—in places where they can be touched and seen. In the process building, the entry is topped by a slim canopy that appears to fold up and peel away from the building, revealing a Corten-clad inner core and a large off-center pivot door. The transition between office and process areas is demarcated with a long vertical window that folds from wall to ceiling, transforming into a skylight.

photo © Kristian Alveo

Horizontal windows on the north wall of the processing area frame the adjacent agricultural landscape and farmstead. A row of rooftop skylights provide natural daylighting into the processing space, while south-facing photovoltaic rooftop panels provide a renewable source of electricity.

photo © Ross Eckert

Selective elements demolished at the Woodinville distillery (steel and old growth Douglas fir stairs and steel railings) were salvaged and repurposed for the new complex, keeping them out of the landfill while creating a spiritual and physical link between the new facility and the distillery. Before the stair was moved to its new location, patrons of Woodinville signed a steel stringer, further connecting the past to the future.

photo © Ross Eckert

On the exterior, a huge “Woodinville Whis-key Co.” sign is rendered as a semi-transparent super-graphic painted onto the north façade of the build-ing, announcing the brand to passing motorists, and recalling signs such as those found on the sides of distilleries and rickhouses throughout rural and agricultural regions from Kentucky to Scotland.

photo © Ross Eckert

The shallow gabled roof, rectilinear form, and repetitive double hung windows of the barrel rickhouses were inspired by traditional whiskey ricking houses and serve both as a visual connection to the tradi-tional methods of whiskey aging as well as a functional purpose—the process of aging whiskey remains essentially unchanged since people first began distilling and enjoying spirits.

photo © Kristian Alveo

The hot days and cold nights of eastern Washington create the perfect conditions for aging whiskey, allowing for the expan-sion and contraction of the distillate within the charred oak interior of the barrels, resulting in the rich, oaken profile and russet hue so distinctive of a good bourbon and rye.

photo © Kristian Alveo

The rickhouses are uninsulated and unconditioned to maximize the temperature swings that support the aging process. After aging, the whiskey is piped from the barrels into bottles in the process building, which are then shipped to nearly half the states in the US.

photos © Kristian Alveo

A tasting room, featuring a tasting bar, windows into the processing area and covered and open patio areas overlooking the fields of rye, corn and wheat, is planned for a future phase. With fields and dis-tant mountain views, the tasting room will provide an on-site amenity open to the public, unlike any other in the region. The tasting room will be elevated several feet above ground level so that patrons will be visually immersed in the adjacent fields of grain—the perfect grain-to-glass experience.

photo © Ross Eckert

photo © Kristian Alveo

Woodinville Whiskey Co in Quincy, Washington – Building Information

Design: Graham Baba Architects – http://grahambabaarchitects.com/

Graham Baba Architects team

Susan Tillack, design and project manager

Andy Brown, design and project architect

Brett Baba, design and detailing

Project team

Graham Baba Architects (architecture and interior design)

JSL Engineering (civil and structural engineering)

Western Pacific Engineering (geotechnical engineer)

AHBL (landscape architecture)

REAX Engineering (fire protection consultant)

Rimmer & Roeter (contractor)

Woodinville Whiskey/LVMH (client)

photo © Kristian Alveo

Materials/Products

Structural system: Butler Building (prefabricated steel bents and girts)

Exterior cladding: Morin SLR 16-0 Panel; Kebony cladding; Corten metal siding

Roofing: Morin SLR 16-0 Panel

Windows: EFCO; Milgard

Glazing: Hartung; Vitro Solarban 60; Pyrostop 60

Skylights: Crystallite; EFCO

Exterior Doors: Western Window Systems

Interior Doors: Ceco

Paints and stains: Benjamin Moore

Solid surfacing: Wilsonart Laminate

photo © Ross Eckert

Photography: Kristian Alveo and Ross Eckert

Woodinville Whiskey Co, Quincy Washington images / information received 030322

Location: Quincy, Washington, USA

Kirkland Architecture

Kirkland Mid Century Modern

Design: CTA Design Builders

photograph : Michael Cole

Kirkland Mid Century Modern, Washington

Washington Architecture

Washington Architecture

Washington Architectural Projects by LMN Architects – selection:

New Interdisciplinary Science Center In Washington, Cheney, WA

photo : Adam Hunter/LMN Architects

Eastern Washington University Interdisciplinary Science Center

Sound Transit U District Station, 4300 Brooklyn Ave NE, University of Washington’s Seattle campus, Seattle

photo : Adam Hunter/LMN Architects

Sound Transit U District Station Building

Everett Grand Avenue Pedestrian Bridge, Everett

image Courtesy LMN Architects

Construction Photography Credit: Adam Hunter/LMN Architects

Everett Grand Avenue Pedestrian Bridge

American Architecture Links – chronological list

Winery Building in Washington

Washington State University Visitor Center

USA Architecture

American Architecture

American Architects

Ways To Keep Your Office Building In Top Condition

Comments / photos for the Woodinville Whiskey Co, Quincy, Washington by Graham Baba Architects page welcome

The post Woodinville Whiskey Co, Quincy Washington appeared first on e-architect.

0 notes

Text

Window Styles: Which is Right for Your Home?

The correct window styles won't just change the outside of your home, yet can likewise improve its energy productivity simultaneously. This is what you need to know

Window styles are one part of house plan that truly can represent the deciding moment an undertaking. Regardless of whether you are revamping, expanding or working without any preparation, getting the style right can give your property moment kerb advance.

Nowadays, house façades are frequently more window than divider so it is profoundly essential to consider the warm presentation and energy proficiency of you picked window style, not exactly how much normal light it will bring to the table.

This guide sets out all you require to realize while picking the correct windows for your home, visit www.thewindowexperts.ca for more details.

What to Consider When Choosing a Window Style

At the point when you are picking your window styles you ought to think about the accompanying:

Configuration: Will your windows be exemplary and conventional, or smooth and contemporary?

Style: Find out about the various sorts of casements and the what the styles bring to the table

Material: Our material guide that analyzes cost, toughness and style

Coating: Thermal execution and energy productivity are presently high of the need list for some self developers and renovators

Expenses: Take a glance at our recommendation on contrasting between cites

Requesting: Think about how to request and what the lead-in occasions will mean for your task

The situating of windows will be impacted by room designs and the state of the actual house yet the shape and kind of the actual windows ought to be taken into genuine thought when settling on the outside and inside wraps up.

For example, a contemporary, single-story house is improved by likewise thin, vertical windows however old bungalows look odd with enormous coated openings constrained into thick stone dividers.

The amount Do Different Window Styles Cost?

Your window costs will fluctuate contingent upon the size of your venture yet there are a couple of shrewd approaches to get some great evaluations when looking.

Before you picked your new window style it is insightful to choose what material you need your windows making out of. Do you need wood or steel, plastic or aluminum?

The following are the advantages and disadvantages of various window materials.

Softwood windows:

Expenses: £6,000-£15,000, less if 'DIYed' on location

Aces:

Nothing can beat the physicality and specifying of a lumber outlined window

Softwood is mainstream among those on a restricted spending plan as they are the least expensive choice whenever coated and improved nearby

Can be stained, however are normally painted

Suites both contemporary and customary style homes

Cons:

On location coating conveys a danger of twofold coating disappointment (for example moistened units)

Industrial facility coating brings down the danger however costs more

Softwood requires repainting at regular intervals

Best softwoods to pick:

Douglas fir is a truly steady, solid softwood while European Redwood (otherwise called Scots Pine) is less inclined to dimensional change and development.

Hardwood windows

Expenses: Between £8,000 and £20,000

Experts:

Have a more tight grain than softwoods, making them more steady and solid

Can be blessed to receive be additionally settled

Generally well known on customary style homes

Normally stained

Cons:

It's costly — anything up to multiple times the expense of softwood

0 notes

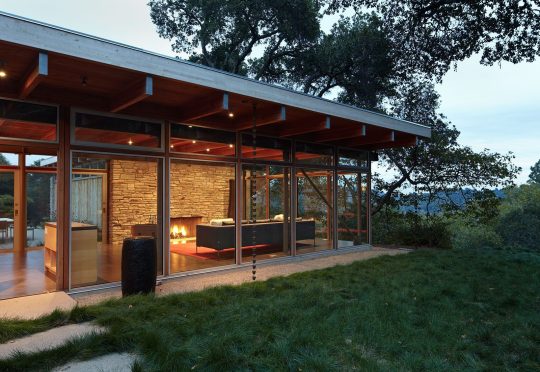

Photo

SAN ANSELMO RESIDENCE

This project for an architect’s home involves a major renovation to an existing 1950’s modern home on a 1.4 acre wooded hilltop site in Marin County. The original structure, possibly designed by the Bay Area Modernist Henry Hill, had floor to ceiling glass walls, anchored by a system of ashlar masonry walls. Expanded to 2,800 feet, the character of the original structure is updated and expanded, and the building is transformed into a low-energy use, green building.

The existing building footprint and slab are reused in part of the house, while a new wing is added for an additional two bedrooms and an updated kitchen/family room. The system of existing masonry walls is carefully kept and complimented by new masonry elements that visually anchor the new wing. The new kitchen acts as the fulcrum for the house being open to both the family room and the dining living area in the old footprint. Relying on the simple clarity of its design, all of the structure is exposed, including painted steel beams, gluluam beams and vertical grain Douglas Fir panels. New floor to ceiling insulated glass provides unobstructed views between the masonry elements and the home’s resulting transparency creates the illusion of boundless space where the outdoors are an extension of the indoor experience.

The massing is carefully integrated into the varied levels of the ridge top topography and incorporates extensive native and low water landscaping. Numerous sustainable design elements are incorporated such as; photo-voltaic panels, solar domestic/ hydronic heating, solar pool heating, gray water system, insulation using recycled blue jeans. low-E insulated glazing, low albido roof membrane, post-consumer products, high fly ash concrete, and FSC-certified wood.

0 notes

Text

Glass-like wood insulates heat, is tough, blocks UV and has wood-grain pattern

Need light but want privacy? A new type of wood that's transparent, tough, and beautiful could be the solution. This nature-inspired building material allows light to come through (at about 80%) to fill the room but the material itself is naturally hazy (93%), preventing others from seeing inside.

Materials engineers at the University of Maryland have transformed wood into a transparent building material that directs light for a diffused effect, is tougher and insulates better than glass, and has a natural wood-grain pattern. They published their results last week in the journal Nature Communications.

"In this patented research, we demonstrate the first esthetic wood with patterns following the density variation in natural wood. Such patterned, transparent wood can also block UV and heat, is mechanically strong, which could find many applications in buildings where sustainability and energy efficiency are desired," said Liangbing Hu, Herbert Rabin Distinguished Professor and Director of the Center for Materials Innovation at the University of Maryland, College Park.

Tiny nanostructures made of cells pass water and nutrients up and down the tree, but they hold importance here as vertically aligned channels in the wood, a naturally-grown structure that can be used to pass light along.

The team started with a small block of Douglas fir and used chemicals to selectively remove its lignin, the part that makes wood brown and strong. This makes the wood transparent to light.

Read the full article

0 notes

Photo

Used some scrap vertical grain Douglas fir to make pencil holders. Added some rubio monocoat oil for color and protection.

There’s a few left for sale, check them out on www.designableco.etsy.com

5 notes

·

View notes

Text

Cladding essentials: leading 10 pointers for getting it right

1 USE THE RIGHT SPECIES

The option of lumber types is generally based on aesthetic appeals, resilience, and cost. Of these, one of the most vital is durability, as well as assessing its course and efficiency is core to an excellent specification.

One of the most usual softwood species utilized for wood cladding consist of woods such as Western red cedar, larch, imported Douglas Fir, European Redwood, and also European Whitewood. Each of these has different longevity. For example, the Western red cedar can last for approximately three decades uncoated, where the Larch could only last for 15-- so recognizing your timber's resilience is the primary step to good cladding. Popular hardwoods for cladding are generally oak or pleasant chestnut, yet in determining what to make use of, it is best to reference a durable data source. The TRADA wood types of a data source is an excellent place to start. You can also check the best Commercial Ceiling Cladding

2 THINK OF WETNESS CONTENT

Recognizing exactly how hardwood moves in feedback to adjustments in dampness web content is essential to make certain long life and also excellent efficiency. One factor to consider is the width of the boards used. This is because by restricting board sizes to a maximum of 150mm both the shrinkage and swelling continue to be convenient. Tongued and also grooved boards need to be even narrower, with an optimum width of 125mm. This will certainly decrease the threat of the tongues disengaging from the grooves when the boards shrink.

Where an open-jointed cladding system is utilized, water as well as light can penetrate the substructure. It is as a result essential to provide due consideration to waterproofing information around window and door openings, it might be needed to use a specialist UV-resistant breather membrane layer on the substructure itself.

3 USAGE THE RIGHT FIXINGS

Making use of stainless-steel nails is highly recommended for softwood cladding, even if the cladding is to be repainted.

The length of the nails is also crucial. When using plain cord nails they should belong sufficient to attain a point-side infiltration of 2.5 x the thickness of the cladding board right into the assistance batten. So, for example, dealing with a 20mm thickness board needs 50mm of nail infiltration right into the batten making use of nails of 70mm length.

Annular ring shank nails (often called boosted nails) only require point-side infiltration of 2x the board density, as well as it is usual to make use of two nails at quarter points across the size of the board.

For wood cladding, installers usually make use of stainless-steel screws to fix to the support battens, once again making use of two fixings at quarter points across the board and also pre-drilling holes a little extra-large to enable shrinkage and also growth.

4 ENSURE GREAT SUPPORT BATTENS

Preservative-treated softwood cladding battens need to be perpendicular to the cladding boards and also depending on the board account and also installation method, upright counter battens might be required to supply drainage as well as ventilation. Horizontal battens should be chamfered to shed water.

5 REMEMBER VENTILATION

Keeping excellent water drainage and airflow within the room behind the cladding is essential. The function of this is to make certain sturdiness, allow much faster drying, and to match wetness material on internal and external faces.

Flashing information at the base of the cladding and around windows and doors must be developed to lose water far from the building while maintaining important airflow. Inspect the demands for fireproof cavity obstacles with local structure control and also to consider making use of third-party accepted, ventilated dental caries obstacles.

6 CONSIDER COATINGS

Before specifying finishes, it is wise to take into consideration the awaited service life of the layer as well as the called for maintenance regimen-- numerous owners may be uninformed of the value of upkeep for resilience as well as efficiency.

Clear coatings such as oils as well as varnishes will usually need pre-emptive re-application yearly or so, indicating they are not a useful option. If the surface coating fails, resulting in discoloration or weathering of the wood, just reapplying the layer will certainly not be sufficient as it will certainly seal in the staining and also trap wetness.

Paints and also stains have a longer service life, though they do, certainly, still, need periodic re-application.

7 THE DEVIL IS IN THE DETAIL

There are design aspects within cladding that can assist prevent dampness traps and assist with water monitoring. Forecasts can create splashback, so cutting completions of vertical cladding board to an angle will certainly allow wetness to trickle off. A gap of at the very least 8mm must additionally be utilized where end grains are subjected, such as in running joints or edge blog posts, to reduce the danger of water sitting against them.

8 USAGE of APPROPRIATE INSTALLATION

Care for cladding boards before they are mounted. Maintaining boards spread out, well ventilated, and freely covered will certainly minimize exposure to wetness and also enable air movement, assisting to minimize the danger of substantial staining.

The optimal moisture material of lumber cladding during installment needs to be preserved between 16% and 18% to lower the likelihood of substantial movement or distortion. Where surface finishes are used, they need to be applied to all faces before suitable to prevent unfinished timber being subjected when the cladding swells or reduces.

9 KEEP AN EYE ON WEAR AND TEAR

If the outside hardwood cladding is to be left uncoated, it will constantly weather normally and also transform silver-grey over time, because of moisture and sunshine. Uncoated exterior wood cladding will certainly always weather and this ought to be anticipated. It is not a great concept to use clear surface coatings to preserve color as these require a high level of maintenance.

10 REDUCE THE RISK OF DISCOLOURATION

Extractive discoloration occurs when water-soluble elements in hardwood are offered the surface area but not removed by rainwater. Timbers like oak as well as Western red cedar have high levels of extractives that will certainly not remove if the cladding is sheltered. If extractive staining takes place, it can be removed and also the all-natural shade brought back, or it can just be entrusted to fade over time.

0 notes