#polyethylene

Text

1955 Bemis Bags and Products

#1955#bemis#poly#bag#golf#sales#polyethylene#plastic#vintage illustration#vintageadsmakemehappy#vintage magazine#vintage advertising#magazine#advertising#1950s#50s

59 notes

·

View notes

Link

One of the worst forms of plastic pollution may have met its match in the saliva of a humble worm.

Spanish researchers say they've discovered chemicals in the wax worm's drool that break down polyethylene, a tough and durable material.

The researchers say that one hour's exposure to the saliva degrades the plastic as much as years of weathering.

They hope the breakthrough will lead to new natural approaches to deal with plastic pollution.

They've discovered two enzymes in the liquid that can degrade polyethylene at room temperatures and believe it's the first time that such an effective agent has been found in nature.

Continue Reading.

883 notes

·

View notes

Text

Polyethylene waste could be a thing of the past

An international team of experts undertaking fundamental research has developed a way of using polyethylene waste (PE) as a feedstock and converted it into valuable chemicals, via light-driven photocatalysis.

The University of Adelaide's Professor Shizhang Qiao, Chair of Nanotechnology, and Director, Center for Materials in Energy and Catalysis, at the School of Chemical Engineering, led the team that published their findings in the journal Science Advances.

"We have upcycled polyethylene plastic waste into ethylene and propionic acid with high selectivity using atomically dispersed metal catalysts," said Professor Qiao.

"An oxidation-coupled room-temperature photocatalysis method was used to convert the waste into valuable products with high selectivity. Nearly 99% of the liquid product is propionic acid, alleviating the problems associated with complex products that then require separation. Renewable solar energy was used rather than industrial processes that consume fossil fuel and emit greenhouse gases."

Read more.

60 notes

·

View notes

Text

Plastic degradation by marine bacteria

“Plastic waste pollution on Singapore beach.” - via Wikimedia Commons

#this is what i’m studying for my undergraduate capstone so it’s very much on the brain for me rn#microbiology#plastic remediation#bioremediation#wikipedia#wikipedia pictures#nature#plastic pollution#pollution#environmentalism#environmental science#wikimedia commons#bacteriology#bacteria#marine bacteria#marine pollution#ocean pollution#ocean plastic#science#polyethylene#polypropylene#polyethylene terephthalate#pe#pp#pet#biofilm

7 notes

·

View notes

Text

High-Density Polyethylene Sheet

High-Density Polyethylene (HDPE) Sheets are known for their remarkable strength and chemical resistance. They are made from a flexible, long-lasting plastic resin. These sheets are used in many different industries, such as packaging, construction, agriculture manufacturing, outdoor furniture, playground equipment and more. Discover the lightweight nature of HDPE sheets that doesn't compromise on durability, making them an ideal choice for various projects. With a smooth surface and excellent impact resistance, HDPE sheets offer a reliable solution for both indoor and outdoor applications.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#hdpesheet#hdpesheetmanufacturer#hdpesheetsupplier#pp#polypropylene#plasticsheet#plastic#polyethylene#sheets#sheetmanufacturer#ecommerce#marketing#artwork#ppbag#branding#sales#commercial

1 note

·

View note

Link

This is fascinating: They’re using recycled PET soda bottles to create a new building material for prefab construction slabs; it’s PET foam insulation inside, with an impermeable skin, so it doesn’t need any exterior cladding, and is waterproof, so you don’t need shingles; you can just paint it. This could be revolutionary for building affordable homes that are energy-efficient, and much greener with less ‘virgin’ wood, CO2-intensive concrete, transportation of materials, etc.

17 notes

·

View notes

Text

Plastic degradation by biological systems with re-utilization of the by-products could be a future solution to the global threat of plastic waste accumulation. Here, we report that the saliva of Galleria mellonella larvae (wax worms) is capable of oxidizing and depolymerizing polyethylene (PE), one of the most produced and sturdy polyolefin-derived plastics.

Read more...

4 notes

·

View notes

Text

Navigating the Dynamics of the Global Polyethylene (PE) Market: Insights into Demand, Trends, and Future Prospects.!!

Polyethylene (PE) stands as a cornerstone in the world of polymers, demonstrating its versatility and indispensability across a myriad of industries. As a key player in the plastics market, the global polyethylene market is characterized by dynamic forces, evolving trends, and a constantly shifting landscape. This blog unravels the intricacies of the global polyethylene market, shedding light on demand drivers, market trends, applications, and future prospects.

Understanding Polyethylene:

Polyethylene a thermoplastic polymer, is renowned for its durability, flexibility, and chemical resistance. It is categorized into various forms, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE), each tailored to specific applications.

Demand Drivers:

Packaging Prowess: The packaging industry remains a significant driver for polyethylene demand. LDPE and LLDPE, with their flexibility and durability, find extensive use in packaging applications, including films, bags, and containers.

Construction Surge: The construction sector, with its continuous growth, propels the demand for HDPE in pipes, cables, and geomembranes due to its strength, corrosion resistance, and low weight.

Automotive Innovations: As the automotive industry embraces lightweight and durable materials, polyethylene, especially HDPE, is increasingly used in automotive components such as fuel tanks and interior parts.

Consumer Goods Manufacturing: The consumer goods sector leverages polyethylene for the production of various household items, ensuring a steady demand for LDPE and LLDPE in the manufacturing of containers, toys, and household products.

Market Trends:

Sustainable Solutions: With an increasing focus on sustainability, the market witnesses a rise in demand for bio-based and recycled polyethylene products, driving innovation and eco-friendly alternatives.

Technological Advancements: Ongoing research and development lead to the development of advanced polyethylene grades, offering improved performance characteristics and meeting the evolving needs of diverse industries.

Global Supply Chain Challenges: The polyethylene market is not immune to global supply chain disruptions, influencing prices, availability, and impacting the strategic decisions of businesses in the sector.

Applications Across Industries:

Polyethylene's versatility allows its application in a wide array of industries:

Packaging: LDPE and LLDPE dominate in flexible packaging solutions.

Construction: HDPE plays a crucial role in pipes, cables, and construction materials.

Automotive: HDPE contributes to lightweight and durable automotive components.

Consumer Goods: LDPE and LLDPE are pivotal in the manufacturing of various household products.

Future Prospects:

The global polyethylene market is poised for significant growth driven by increasing industrialization, urbanization, and a rising global population. The market's future will witness a confluence of sustainable practices, technological innovations, and a continual shift towards circular economies, making polyethylene a key player in the evolving landscape of materials.

Conclusion:

As an integral component of the plastics industry, polyethylene's widespread use and adaptability underscore its enduring significance. Navigating the global polyethylene market requires a keen understanding of demand drivers, market trends, and emerging applications, empowering businesses and stakeholders to make informed decisions in a dynamic and evolving landscape. The future promises both challenges and opportunities, positioning polyethylene as a resilient and vital material in the global market.

#PolyethyleneSupplyChain#SustainablePackaging#PolyethyleneMarketTrends#Polyethylene#PEApplications#PackagingMaterials#GlobalTrade#MarketResearch

0 notes

Text

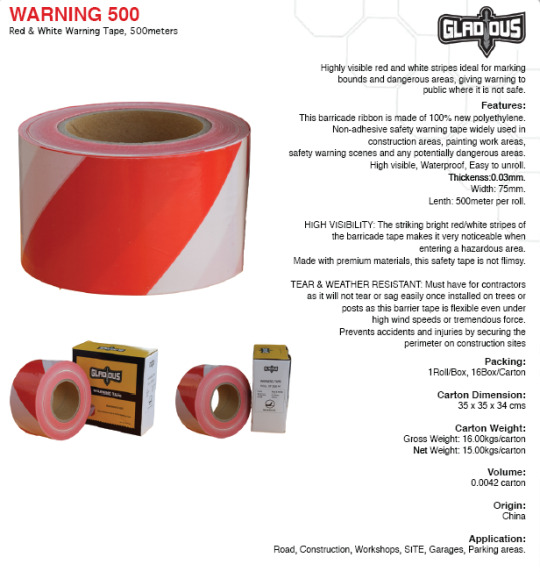

𝐖𝐀𝐑𝐍𝐈𝐍𝐆 𝟓𝟎𝟎 𝐑𝐞𝐝 & 𝐖𝐡𝐢𝐭𝐞 𝐖𝐚𝐫𝐧𝐢𝐧𝐠 𝐓𝐚𝐩𝐞, 𝟓𝟎𝟎𝐦𝐞𝐭𝐞𝐫

Highly visible red and white stripes ideal for marking bounds and dangerous areas, giving warning to public where it is not safe.

𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐬:

This barricade ribbon is made of 100% new polyethylene. Non-adhesive safety warning tape widely used in construction areas, painting work areas, safety warning scenes and any potentially dangerous areas. High visible, Waterproof, Easy to unroll.

Thickness:0.03mm.

Width: 75mm.

Length: 500 meter per roll.

#gladious#warningtape#500meter#red#white#protection#safetyfirst#barricade#ribbon#polyethylene#waterproof#highvisible

0 notes

Photo

Wax worm saliva contains enzymes capable of breaking down plastics

A team of CSIC researchers has discovered that wax worm saliva degrades plastic; a discovery with numerous applications for treating or recycling plastic waste. Back in 2017, the team discovered that this worm species (the lepidopteran Galleria mellonella) is able to break down plastic (polyethylene), and now they have discovered just how it does this: its saliva contains enzymes (pertaining to the phenol oxidase family) that can rapidly set off polyethylene degradation at room temperature. These enzymes are the first and only known enzymes capable of degrading polyethylene plastic without requiring pre-treatment, according to Federica Bertocchini, a CSIC researcher at the CIB-CSIC (Centre for Biological Research) who led the study. The results of the work, pending review, have been published in preprint in the BioRxiv online archive.

"For plastic to degrade, oxygen must penetrate the polymer (the plastic molecule). This is the first step in oxidation, which is usually a result of exposure to sunlight or high temperatures, and represents a bottleneck that slows down the degradation of plastics like polyethylene, one of the most resistant polymers," explains Bertocchini. "That is why, under normal environmental conditions, plastic takes months or even years to degrade," she adds.

"Now we have found out that enzymes in the wax worm's saliva perform this crucial step: they oxidize the plastic. This means they can overcome the bottleneck in the plastic degradation process and accelerate its decomposition," she adds.

Read more.

1K notes

·

View notes

Text

Heavy-Duty Poly Tarps | Tarp Supply Inc.® | For All Your Tarp Needs

Tarp Supply Inc.®'s Heavy-Duty Poly Tarps stand as a testament to durability and reliability. Crafted from high-grade polyethylene, these tarps are designed to withstand the toughest of conditions. With reinforced edges and heat-sealed seams, they offer exceptional strength and resistance against tears, making them ideal for safeguarding valuable equipment, covering outdoor spaces, or providing protection during transportation.

These heavy-duty poly tarps from Tarp Supply Inc.® boast weather-resistant features, including waterproofing and UV protection, ensuring resilience against rain, sun damage, and mildew. Engineered to endure harsh environments, they excel in both residential and industrial applications, standing firm against prolonged use and extreme weather conditions.

Available in various sizes and colors, these tarps cater to diverse needs, whether securing construction materials, sheltering outdoor furniture, or covering vehicles. Tarp Supply Inc.®'s commitment to quality ensures that their Heavy-Duty Poly Tarps provide dependable and long-lasting protection, making them a reliable choice for multiple applications across the USA.

0 notes

Text

#BIS Certification for Agro-Textiles Laminated Woven Orchard Protection Covers | IS 17731: 2021#LaminatedWovenOrchardProtectionCovers#woven#agrotextiles#biscertification#ISIlicense#indianstandardsonagrotextiles#farmers#protection#orchard#biscertificate#agriculture#polyethylene#is17731#textiles

0 notes

Text

@POLYETHYLENE Come here for ur quotation.

0 notes

Text

Thick growth in thin packaging: Ceresana Report on the World Market for Bioplastic Films

Wafer-thin films, often less than 1 millimeter thick, are one of the first areas of application in which bioplastics are able to establish themselves. Although casings made from petroleum products are still usually sold cheaper and in larger quantities, biobased materials such as starch or polylactic acid do not only offer a better public image regarding environmental awareness, but often also tangible advantages: Food packaging made from biodegradable plastics does not have to be disposed of at high cost, but can be composted; organic mulch films can simply be left on the field and plowed under. Ceresana has studied the global market for films made from bioplastics: The new market report forecasts that revenues will increase to around USD 14.2 billion by 2032.

Further information about the new market study “Bioplastic Films”: https://ceresana.com/en/produkt/bioplastic-films-market-report-world

#plastics#films#foils#packaging#import#export#manufacturers#production#producers#demand#consumption#polyethylene#PET#polypropylene#applications#bags#sacks#markets#bioplastics#BOPP#construction#agriculture#market study#market data

0 notes

Text

Ultra-High Molecular Weight Polyethylene: Major Things to Understand

Ultra-high molecular weight polyethylene (UHMWPE) is a distinctive thermoplastic polymer with remarkable mechanical and physical qualities. It is polyethylene with the same molecular as regular polyethylene. However, it has a higher molecular weight than polyethylene, which is commonly used. In this blog, let’s understand the major things.

People are living longer lives, particularly in emerging countries such as China and Japan, which are increasing requirements for medical services and UHMW implants. As a result of its advantageous characteristics and tensile strength. Many industries use it significantly, including electronics, automotive, industrial, and heavy equipment. As a result, these factors are anticipated to boost the market. In addition, according to a research report by Astute Analytica, the Global Ultra-High Molecular Weight Polyethylene Market is likely to rise at a compound annual growth rate (CAGR) of 14.7% over the forecast period from 2023 to 2031.

How are UHMWPE products made?

Polymerization:

The polymerization process is carried out at lower temperatures (66-90 °C) and pressures (0.4-0.6 MPa) utilizing a Ziegler-Natta catalyst, namely tri ethyl-aluminum (Al(C2H5)3) and titanium chloride (TiCl4). Polymerization occurs in a solvent, which is a mixed system containing ethylene gas, hexane solvent, and a catalyst. This system is utilized for heat and mass transmission.

Converting of UHMWPE powder to solidified form

UHMWPE is manufactured in powder form and needs to be consolidated at higher pressures and temperatures due to its high melt viscosity. It cannot move like lesser molecular weight polyethylene when heated above its melting temperature. As a result, several thermoplastic manufacturing methods, such as injection molding, blow molding, or screw extrusion are impractical for UHMWPE. Semi-finished UHMWPE is typically manufactured using a ram extruder and compression molding.

Processing:

Unlike LDPE and HDPE, UHMWPE has a high particle size that makes processing challenging. This is due to the large molecular mass and low rheological qualities (low flowability). As a result, polymers such as UHMWPE require high pressure and temperature to achieve proper plasticization.

UHMWPE is processed using one of two ways

Compression molding

Compression molding is a method of molding material into a constrained shape by the use of pressure and heat. Two phases follow this molding procedure. The first is preheating, while the second is pressurizing.

Ram extrusion

The ram extrusion procedure is used to make UHMW rods and tubing profiles. Gravity feeds UHMWPE powder into a chamber, and a hydraulic ram drives the powder from the chamber into the die. The die is the intended plastic shape, such as a specific diameter rod, profile shape, or exterior diameter tube, or inner diameter tube.

The Benefits of UHMWPE

UHMW Polyethylene polymer molecules have both crystalline and amorphous sections. This is known as the “Lamella” structure. The polyethylene chemical chain has a proclivity to rotate around the C-C bonds, resulting in chain folds. Folded of this cord, in turn, allows the molecule to create regionally organized, sheet-like regions called ‘Crystalline lamellae’. The crystallized lamellae are very small. As a result, it cannot be seen with the naked eye (since it is invisible).

Source: Ultra-High Molecular Weight Polyethylene: Major Things to Understand

#UHMWPE#Polyethylene#HighMolecularWeight#PolymerScience#MaterialScience#EngineeringMaterials#PlasticTechnology#IndustrialMaterials#AdvancedMaterials#PolymerProperties#MechanicalProperties#MaterialCharacterization#ApplicationsInnovation#MedicalPlastics#WearResistant#ChemicalResistance#PolymerResearch#PolymerApplications#EngineeringPlastics#MaterialInsights

0 notes