#cobot

Text

Test - The original file of the board test

Welcome to contact me if you are interested.

Your satisfactory, our mission.

Email : [email protected]

7 notes

·

View notes

Photo

Beat Lippert, “Pierre et le Cobot,” 2021,

On an invitation from Ripopée,

Installation for ‘Art au Centre Genève’ Exhibition.

Art au Centre Genève takes place from the 25th November, 2021 to the 6 March, 2022, inviting you to discover a constellation of works by 20 artists, brought together by 10 exhibition curators.

The concept is simple. Each artist has a shop window at their disposal that is visible to the public 24 hours a day, 7 days a week. The 20 pieces are spread throughout the heart of Geneva and reveal the singularity and diversity of contemporary artistic creation.

This urban itinerary can be undertaken alone or with others, and free guided tours will also be organized on select dates. Keep your eyes peeled!

©Thomas Maisonnasse

#art#installation#beat lippert#pierre#cobot#ripopée#artaucentre#genève#conceptual#conceptualart#artifacts#windows#retail#shop window

15 notes

·

View notes

Text

Advantages Of Cobots

The benefits of collaborative robots extend far beyond just increased productivity and improved quality. You can checkout our dedicated blog for more details.

Patvin Cobots- https://www.patvin.co.in/capabilities-overview/cobots/

1 note

·

View note

Text

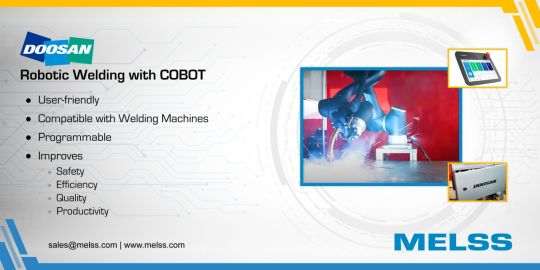

Welding has been a vital process of industrialization for more than a century now. It has evolved from human operation of welding machines to automation with robotics today. Many renowned brands have welding units compatible with COBOT's – improving safety levels, efficiency, quality and productivity.

MELSS brings you COBOT's from Doosan which have wide applicability – from welding to assembly. Welding is not an EOAT but it is a system comprising the Doosan COBOT, a welding power source, a welding torch and a welding table.

The Doosan COBOT for welding is user-friendly with welding parameters being set in the HMI, COBOT movement being programmed in the COBOT panel, data transfer between COBOT and power source using standardized interface and spark on/off via COBOT HMI.

For more: https://zurl.co/7Drk

0 notes

Photo

A new cobot has been developed, one that operates with a degree of autonomy and intelligence never before seen. The Collaborative Robotics Corporation has raised $30M in order to deploy this new cobot into factories and other industrial settings. It is said that the cobot is able to learn and evolve, adjusting its behavior to better suit the needs of its environment. The possibilities are endless, and the future of robotics is looking very bright.

0 notes

Text

How Automated Warehouse Picking Solution Works?

Warehouse robotics semi-robotic technologies are used in automated picking, also known as autonomous warehouse picking, to facilitate the work of human pickers. Automated order picking systems save sorting times, improve picking routes, and enable precise picking and packaging while reducing walking times. Robotic automation is being adopted by businesses across a variety of sectors, including e-commerce, manufacturing, retail, transportation, consumer products, food and beverage, pharmaceuticals, and more, to optimize warehouse operations and streamline picking and sorting procedures.

One of the more challenging warehouse and fulfillment-related operations to automate is order picking because, in some situations, it requires acute perception that, until recently, technology was unable to supply. Order picking can now be automated using technology such as robotic vision, intelligent pathfinding, picture recognition, and others.

When it comes to software and hardware automation solutions, warehouses nowadays have a wide variety of providers to select from. Understanding the current requirements and trouble spots at the facility in question is the first step in creating the ideal automation strategy. Next, a vendor offering a solution with added value should be sought out. There are several points which you have to look upon for understanding the working of automated warehouse picking.

Setting Up Picking Stations- Creating front-of-warehouse picking stations is one of the activities that robots and automated conveyors are particularly good at. In order to bring the necessary quantity forward into the warehouse, where people or robots can more readily acquire them, automated processes retrieve the necessary goods from the back of the warehouse, in bulk and case-pack storage regions.

Pallet Picking- Pallets are used during periods of high demand or when annexation zones have been set up to temporarily store high-consumption commodities. Assisted picking shuttles are used in this sort of robotic picking to remove items from the front or top of pallets.

Rebinning- General order picking is done by warehouse robots from case packs and small-SKU product libraries. They then package the orders for shipping and shuttle them automatically to the shipping area. Typically, manipulator arms on robots made for these jobs feature cushioned grippers at the end and many axes of motion for optimum reach and flexibility.

Collaborative Robots- Co-bots, Collaborative robots or accompany human order pickers and offer pacing assistance as well as aisle and bin navigation. Even though they don't really handle the products, these robots enable quicker and more accurate picking.

Softwares- The cornerstone of this web of robotic and automated technologies is automated software, sometimes known as software robots. The majority of this is now performed automatically by software robots, as opposed to when humans used to support the flow of information from the e-commerce channel, such as a storefront, to the warehousing team. Modern enterprise-planning and warehouse-management software suites may easily assign pick pathways to humans or robots and automatically locate product storage sites.

0 notes

Text

The most important steps of robots in ancient and modern history

#history#unimate#shakey#cobot#robotdog#robot#automation#industrialautomation#robotics#artificial intelligence

0 notes

Link

#ehr#robots#robotics#health it#health tech#electronic health records#cobot#nursing#nursing shortage#burnout#hospitals

0 notes

Text

The vision system looks for the caught object

Welcome to contact me if you are interested.

Your satisfactory, our mission.

Email : [email protected]

WhatsApp:+8613345915461

#cobot #robot #kernal #automation

0 notes

Text

Global Collaborative Robot (Cobot) Market Insights and In-Depth Analysis 2022-2030

With the advancements in technology, robotics is becoming available at a price that suits the pockets of even smaller as well as bigger companies. All thanks to the development of low-cost components, which have paved way for theupsurge of the collaborative robots or cobots .Collaborative robots are intended to collaborate with humans at work sites, and hence making automation a trouble-free job for businesses of all sizes. By now, cobots have been seen as a game-changer for a wide variety of applications.

Why cobots over traditional robots?

The new robotics technology is outdoing the weighty, daunting robots usually locked in the cages for security reasons. Now, it’s time to make use of cobots in those heavy industrial tasks! These robots are quite affordable, safe, and flexible to deploy. They are programmed to work in collaboration with humans and not under humans—unlike traditional robots. With these advanced-automated robots, you can forget the cages and make way for proper communication with them.

To Download a Comprehensive PDF Sample of Collaborative Robots (COBOT) Market Click here!

Here are some benefits of cobots over traditional robots.

1. Boosts accuracy and quality

A collaborative robot is more or less like an associate and can take care of any of the complex, sensitive task. Unlike traditional robots, collaborative robots are skilful enough of lifting up an item and handing it over to a person.

A tangible example of this is a car assembly line in which one cobot assembles a wheel and the other works on fixing the bonnet, whereas human staff works alongside on other important tasks. In this case, quality and accuracy both are enhanced.

2. Allows to concentrate on the core jobs

In a workplace, cobots can be assigned to carry out heavy or very low value-added tasks. This helps in shifting the focus of technicians on core business tasks and add value to the business.

Thus, human intelligence can be applied on other important parts of the production line.

3. Offers safe company

As cobots are functioned to work in co-operation with human coworkers, they are armed with features that allow smooth collaboration. One example of such a robot is the Baxter robot developed by Rethink Robotics. This robot is built using detection sensors, which helps it to understand where its coworkers are at a particular moment.

Also, Baxter is functioned to instantly halt its work if it signifies any kind of threat for an individual nearby. This eradicates the necessity to setup protected enclosures, as the cobot’s safety features are deliberate to function among human workers.

4. Highly scalable and flexible

Cobots can be easilyprogramed, whereas traditional robots demand computer programming abilities. Moreover, cobots are good learners. For instance, while explaining a new task to the Baxter, the operator just needs to perform the required actions using the robot’s arm. The cobot will then remember these actions and repeat them. This innovative learning-by-doing method is a tactic that any non-technical operators can easily learn and implement.

5. Easy on the pocket

Cobots are reasonably priced, hence they must not be restricted to a single task. Instead, they can be incorporated into several projects, making them much more profitable.

They can be effortlessly reprogrammed, relocated (by placing them on a mobile base) and redeployed at varied stages in the production cycle.

6. No need of safety barricades

With cobots there is no need of cages to maintain human safety, as these robots are fitted with cameras and sensors that constantly scan their surroundings. Every time they come across a human, they stop!

Request to Customize (Benefit of 10%OFF) Report of Collaborative Robots (COBOT) Market

The bottom line

From industrial manufacturing sites, PLC automation to offices, these collaborative equipment can manage a variety of tasks including packing of merchandises, palletising, assembling, machine tending, and many more.

Looking at high levels of flexibility, usually smaller size, easy mobility, and low weight of cobots it is clear that they are an ideal choice for performing a variety of tasks and several types of automation services.

#Collaborative Robot (Cobot) Market#Collaborative Robot (Cobot)#Collaborative Robot#Cobot#Robot#Assembling#Application#Technology#Automotive#Electronics#Metals & Machining#Plastics & Polymers#Furniture & Equipment#Healthcare

0 notes

Text

People who only view the Singularity as some robot animal pet

Read the tags before you come at me

#dbd#dbd singularity#dbd hux#hux a7 13#lemme clarify#this cobot did not become sentient and think itself better than humanity and create a full body for its purpose#just to be told to go play fetch#like that is a robot man#yeah i want to pet his head too but it doesn't mean he's gonna kill a bird and bring it to me#everybody is entitled to their own interpretation obviously#but i just think hux is an amazing Frankenstein's monster-esque character who only gets seen as a dog

9 notes

·

View notes

Text

Deploying COBOT's is an innovative new way by which restaurants today handle the growing demand from more customers.

Made for food-grade materials and handling both hot oils and wet surfaces, the Doosan E-Series COBOT's help restaurants and other businesses in the Food & Beverage (F&B) industry to meet the increasing volumes of business.

Doosan Robotics E Series COBOT's help improve safety through vision systems and sensors by detecting defects, contaminants and foreign objects in food. Easy programmability makes signature dishes easy to create, and ensures uniform taste of dishes over time. Not to mention repetitive tasks such as packaging, sorting and assembly, and time-consuming jobs like cutting vegetables, are all easily performed - resulting in increased productivity and efficiency.

For more info: https://zurl.co/CmBr

0 notes

Text

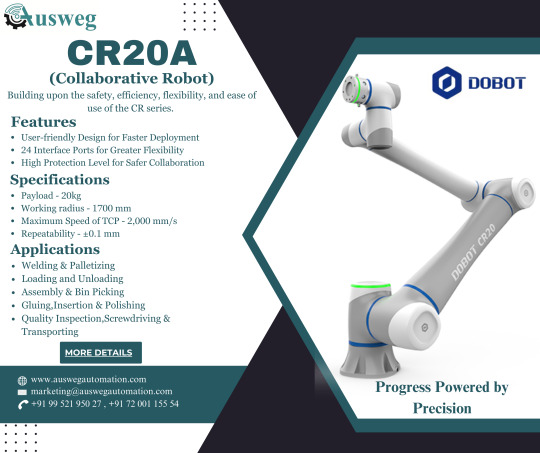

DOBOT CR20A

Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com

[email protected]

+91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes