#custom machine parts china

Text

MxmParts, a trusted CNC machining parts supplier from China, specializes in offering a comprehensive Swiss Type CNC Machining service for precision machine parts. With advanced CNC lathes such as combination Mill Turn CNC and Swiss type CNC lathe, MxmParts provides a wide range of precision machining capabilities, ensuring the production of small and large machined parts with the highest level of accuracy.

MxmParts offers the machining of various materials, including but not limited to steel and brass, through their precision CNC turning service. Their commitment to crafting parts that meet the highest standards ensures that customers receive quality machined parts that align with their specifications.

The Swiss Type CNC Machining service by MxmParts caters to industries requiring precision machine parts, including but not limited to automotive, aerospace, medical, and electronics. Through their expertise in precision CNC turning, MxmParts serves as a reliable supplier for companies seeking high-quality machined parts for diverse applications.

For further details and inquiries about the Swiss Type CNC Machining service for precision machine parts, provided by MxmParts from China, you can visit their official website at [mxmparts.com](https://www.mxmparts.com/) or get in touch with them directly through their contact information.

For more information, MxmParts can be reached at [[email protected]](mailto:[email protected]).

Using ChatG : Unlimited AI Chatbot

Entire Chat Link: www.brutusai.com/c/ycAzPJnaPSYTCODnfnvTy004sZu1/064a4be4-3010-4718-b874-4204f94d9709

#Swiss Type CNC machining China#china supplier#cnc turning#CNC parts China#precision CNC Turning parts#precision machine parts#precision turned parts#precision CNC machining#precision CNC Turning#mxmparts#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#steel Parts machining#ball Studs

0 notes

Text

Precision Engineering: Exploring China Custom Machining and Machining Parts

China Custom Machining and China Machining Parts are the cornerstones of precision engineering and manufacturing. At Sage Metal Parts, these solutions converge to provide tailor-made components and parts that redefine quality and innovation.

0 notes

Text

Everything You Need to Know About Plastic Injection Manufacturers in China

Want to prepare some computer accessories, then the plastic injection mold manufacturers can help you. Hsmolds.net is one of the best plastic injection mold manufacturers in China. Contact them now!

#mold parts#machining#suppliers#injection mold#mold manufacturers in china#custom plastic injection molding

0 notes

Text

Shortly before noon on Aug. 19, 2023, a Russian cruise missile sliced past the golden onion domes and squat apartment blocks of the Chernihiv skyline in northern Ukraine. The Iskander-K missile slammed into its target: the city’s drama theater, which was hosting a meeting of drone manufacturers at the time of the attack. More than 140 people were injured and seven killed. The youngest, 6-year-old Sofia Golynska, had been playing in a nearby park.

Fragments of the missile recovered by the Ukrainian armed forces and analyzed by Ukrainian researchers found numerous components made by U.S. manufacturers in the missile’s onboard navigation system, which enabled it to reach its target with devastating precision. In December, Ukraine’s state anti-corruption agency released an online database of the thousands of foreign-made components recovered from Russian weapons so far.

Russia’s struggle to produce the advanced semiconductors, electrical components, and machine tools needed to fuel its defense industrial base predates the current war and has left it reliant on imports even amid its estrangement from the West. So when Moscow launched its full-scale invasion of Ukraine in February 2022, major manufacturing countries from North America, Europe, and East Asia swiftly imposed export controls on a broad swath of items deemed critical for the Russian arms industry.

Russia quickly became the world’s most sanctioned country: Some 16,000 people and companies were subject to a patchwork of international sanctions and export control orders imposed by a coalition of 39 countries. Export restrictions were painted with such a broad brush that sunglasses, contact lenses, and false teeth were also swept up in the prohibitions. Even items manufactured overseas by foreign companies are prohibited from being sold to Russia if they are made with U.S. tools or software, under a regulation known as the foreign direct product rule.

But as the war reaches its two-year anniversary, export controls have failed to stem the flow of advanced electronics and machinery making their way into Russia as new and convoluted supply chains have been forged through third countries such as Kazakhstan, Turkey, and the United Arab Emirates, which are not party to the export control efforts. An investigation by Nikkei Asia found a tenfold increase in the export of semiconductors from China and Hong Kong to Russia in the immediate aftermath of the war—the majority of them from U.S. manufacturers.

“Life finds a way,” said a senior U.S. intelligence official, quoting the movie Jurassic Park. The official spoke on background to discuss Russia’s evasion of export controls.

Some of the weapons and components analyzed by investigators were likely stockpiled before the war. But widely available Russian trade data reveals a brisk business in imports. More than $1 billion worth of advanced semiconductors from U.S. and European manufacturers made their way into the country last year, according to classified Russian customs service data obtained by Bloomberg. A recent report by the Kyiv School of Economics found that imports of components considered critical for the battlefield had dipped by just 10 percent during the first 10 months of 2023, compared with prewar levels.

This has created a Kafkaesque scenario, the report notes, in which the Ukrainian army is doing battle with Western weapons against a Russian arsenal that also runs on Western components.

It is an obvious problem, well documented by numerous think tank and media reports, but one without an easy solution. Tracking illicit trade in items such as semiconductors is an exponentially greater challenge than monitoring shipments of conventional weapons. Around 1 trillion chips are produced every year. Found in credit cards, toasters, tanks, missile systems, and much, much more, they power the global economy as well as the Russian military. Cutting Russia out of the global supply chain for semiconductors is easier said than done.

“Both Russia and China, and basically all militaries, are using a large number of consumer electronic components in their systems,” said Chris Miller, the author of Chip War: The Fight for the World’s Most Critical Technology. “All of the world’s militaries rely on the same supply chain, which is the supply chain that primarily services consumer electronics.”

Export controls were once neatly tailored to keep specific items, such as nuclear technology, out of the hands of rogue states and terrorist groups. But as Washington vies for technological supremacy with Beijing while also seeking to contain Russia and Iran, it has increasingly used these trade restrictions to advance broader U.S. strategic objectives. For instance, the Biden administration has placed wide-ranging prohibitions on the export of advanced chips to China.

“At no point in history have export controls been more central to our collective security than right now,” Matthew Axelrod, the assistant secretary for export enforcement at the U.S. Commerce Department, said in a speech last September. U.S. National Security Advisor Jake Sullivan has described export controls as “a new strategic asset in the U.S. and allied toolkit.”

Russia’s ability to defy these restrictions doesn’t just have implications for the war in Ukraine. It also raises significant questions about the challenge ahead vis-à-vis China.

“The technological question becomes a key part of this story and whether or not we can restrict it from our adversaries,” said James Byrne, the director of open-source intelligence and analysis at the Royal United Services Institute, a British think tank.

In the Russian city of Izhevsk, home to the factory that manufactures Kalashnikov rifles, shopping malls are being converted into drone factories amid a surge in defense spending that has helped the country’s economy weather its Western estrangement. Arms manufacturers have been urged to work around the clock to feed the Russian war machine, while defense is set to account for one-third of the state budget this year.

“We have developed a concept to convert shopping centers—which, before the start of the SMO [special military operation], sold mainly the products of Western brands—to factories for assembly lines of types of domestic drones,” Alexander Zakharov, the chief designer of the Zala Aero drone company, said at a closed event in August 2022, according to the Russian business newspaper Vedomosti. “Special military operation” is what the Russian government calls its war on Ukraine. Zala Aero is a subsidiary of the Kalashnikov Concern that, along with Zakharov, was sanctioned by the United States last November.

Defense companies have bought at least three shopping malls in Izhevsk to be repurposed for the manufacture of drones, according to local media, including Lancet attack drones, which the British defense ministry described as one of the most effective new weapons that Russia introduced to the battlefield last year. Lancets, which cost about $35,000 to produce, wreaked havoc during Ukraine’s offensive last year and have been captured on video striking valuable Ukrainian tanks and parked MiG fighter jets.

Like a lot of Russia’s weapons systems, Lancets are filled with Western components. An analysis of images of the drones published in December by the Washington-based Institute for Science and International Security found that they contained several parts from U.S., Swiss, and Czech manufacturers, including image processing and analytical components that play a pivotal role in enabling the drones to reach their targets on the battlefield.

“The recurring appearance of these Western products in Russian drone systems shows a keen dependence on them for key capabilities in the drone systems,” the report notes. Lancets are not the only drones found to contain Western components. Almost all of the electronic components in the Iranian Shahed-136 drones, which Russia is now manufacturing with Iranian help to use in Ukraine, are of Western origin, a separate analysis published in November concluded.

Early in the war, the Royal United Services Institute analyzed 27 Russian military systems, including cruise missiles, electronic warfare complexes, and communications systems, and found that they contained at least 450 foreign-made components, revealing Russia’s dependence on imports.

One of the principal ways that Russia has evaded Western export controls has been through transshipment via third countries such as Turkey, the UAE, and neighboring states once part of the Soviet Union. Bloomberg reported last November that amid mounting Western pressure, the UAE had agreed to restrict the export of sensitive goods to Russia and that Turkey was considering a similar move. Kazakh officials announced a ban on the export of certain battlefield goods to Russia in October.

Suspected transshipment is often revealed by striking changes in trade patterns before and after the invasion. The Maldives, an island chain in the Indian Ocean that has no domestic semiconductor industry, shipped almost $54 million worth of U.S.-made semiconductors to Russia in the year after the invasion of Ukraine, Nikkei Asia reported last July.

Semiconductor supply chains often span several countries, with chips designed in one country and manufactured in another before being sold to a series of downstream distributors around the world. That makes it difficult for companies to know the ultimate end user of their products. This may seem odd—until you realize that this is the case for many everyday products that are sold around the world. “When Coca-Cola sells Coca-Cola, it doesn’t know where every bottle goes, and they don’t have systems to track where every bottle goes,” said Kevin Wolf, a former assistant secretary for export administration at the U.S. Commerce Department.

While a coalition of 39 countries, including the world’s major manufacturers of advanced electronics, imposed export restrictions on Russia, much of the rest of the world continues to trade freely with Moscow. Components manufactured in coalition countries will often begin their journey to Moscow’s weapons factories through a series of entirely legal transactions before ending up with a final distributor that takes them across the border into Russia. “It starts off as licit trade and ends up as illicit trade,” said a second senior U.S. intelligence official, who spoke on condition of anonymity.

The further items move down the supply chain, the less insight governments and companies have into their ultimate destination, although sudden changes in behavior of importers can offer a red flag. In his speech last September, Axelrod, the assistant secretary, used the example of a beauty salon that suddenly starts to import electronic components.

But the Grand Canyon of loopholes is China, which has stood by Moscow since the invasion. In the first days of the war, U.S. Commerce Secretary Gina Raimondo warned that Washington could shut down Chinese companies that ignored semiconductor export controls placed on Russia. Last October, 42 Chinese companies were added to export control lists—severely undercutting their ability to do business with U.S. companies—for supplying Russian defense manufacturers with U.S. chips.

But as the Biden administration carefully calibrates its China policy in a bid to keep a lid on escalating tensions, it has held off from taking Beijing to task. “I think the biggest issue is that we—the West—have been unwilling to put pressure on China that would get China to start enforcing some of these rules itself,” said Miller, the author of Chip Wars.

A spokesperson for the U.S. Commerce Department’s Bureau of Industry and Security (BIS) said: “Due to the restrictions imposed by the United States and key allies and partners, Russia has been left with no choice but to spend more, lower its ambitions for high-tech weaponry, build alliances with other international pariah states, and develop nefarious trade networks to covertly obtain the technologies it needs.

“We are deeply concerned regarding [Chinese] support for Russia’s defense industrial base. BIS has acted to add over 100 [China]-based entities to the Entity List for supporting Russia’s military industrial base and related activities.”

Export controls have typically focused on keeping specific U.S.-made goods out of the hands of adversaries, while economic and financial sanctions have served broader foreign-policy objectives of isolating rogue states and cauterizing the financing of terrorist groups and drug cartels. The use of sanctions as a national security tool grew in wake of the 9/11 attacks; in the intervening decades, companies, government agencies, and financial institutions have built up a wealth of experience in sanctions compliance. By contrast, the use of export controls for strategic ends is relatively novel, and compliance expertise is still in its infancy.

“It used to be that people like me could keep export controls and sanctions in one person’s head. The level of complexity for each area of law is so intense. I don’t know anyone who is truly an export control and sanctions expert,” Wolf said.

Export controls, experts say, are at best speed bumps designed to make it harder for Russia’s defense industrial base to procure Western components. They create “extra friction and pressure on the Russian economy,” said Daniel Fried, who as the State Department coordinator for sanctions policy helped craft U.S. sanctions on Russia after its annexation of Crimea in 2014. Russia is now paying 80 percent more to import semiconductors than it did before the war, according to forthcoming research by Miller, and the components it is able to acquire are often of dubious quality.

But although it may be more cumbersome and expensive, it’s a cost that Moscow has been willing to bear in its war on Ukraine.

Western components—and lots of them—will continue to be found in the weapons Russia uses on Ukraine’s battlefields for the duration of the war. “This problem is as old as export controls are,” said Jasper Helder, an expert on export controls and sanctions with the law firm Akin Gump. But there are ways to further plug the gaps.

Steeper penalties could incentivize U.S. companies to take a more proactive role in ensuring their products don’t wind up in the hands of the Russian military, said Elina Ribakova, a nonresident senior fellow at the Peterson Institute for International Economics. “At the moment, they’re not truly motivated,” she said.

Companies that run afoul of sanctions and the Foreign Corrupt Practices Act, a U.S. federal law that prohibits the payment of bribes, have been fined billions of dollars. Settlements of export control violations are often an order of magnitude smaller, according to recently published research.

In a speech last month, Axelrod said the United States would begin issuing steeper penalties for export control violations. “Build one case against one of the companies extremely well, put out a multibillion-dollar fine negotiation, and watch everybody else fall in line,” Ribakova said.

And then there’s the question of resources. BIS has an annual budget of just $200 million. “That’s like the cost of a few fighter jets. Come on,” said Raimondo, speaking at the Reagan National Defense Forum last December.

The agency’s core budget for export control has, adjusted for inflation, remained flat since 2010, while its workload has surged. Between 2014 and 2022, the volume of U.S. exports subject to licensing scrutiny increased by 126 percent, according to an agency spokesperson. A 2022 study of export control enforcement by the Center for Strategic and International Studies recommended a budget increase of $45 million annually, describing it as “one of the best opportunities available anywhere in U.S. national security.”

When it comes to enforcement, the bureau has about 150 officers across the country who work with law enforcement and conduct outreach to companies. The Commerce Department has also established a task force with the Justice Department to keep advanced technologies out of the hands of Russia, China, and Iran. “The U.S. has the most robust export enforcement on the planet,” Wolf said.

But compared with other law enforcement and national security agencies, the bureau’s budgets have not kept pace with its expanding mission. The Department of Homeland Security has more investigators in the city of Tampa, Florida, than BIS does across the entire country, Axelrod noted in his January speech.

On the other side, you have Russia, which is extremely motivated to acquire the critical technologies it needs to continue to prosecute its war. The Kremlin has tasked its intelligence agencies with finding ways around sanctions and export controls, U.S. Treasury Undersecretary Brian Nelson said in a speech last year. “We are not talking about a profit-seeking firm looking for efficiencies,” the second senior U.S. intelligence official said. “There will be supply if there is sufficient demand.”

18 notes

·

View notes

Text

Export Import Products List

Exporting and importing products is a major part of the global economy. In 2022, the value of global merchandise trade was over $28 trillion. This means that businesses and consumers all over the world are exchanging goods and services on a massive scale.

There are a wide variety of products that are exported and imported, but some of the most common include:

Agricultural products: This category includes food crops, such as wheat, rice, and corn, as well as livestock and animal products, such as meat, dairy, and eggs.

Chemicals: This category includes a wide range of products, such as petrochemicals, pharmaceuticals, and fertilizers.

Electrical machinery and equipment: This category includes products such as generators, motors, and computers.

Food and beverages: This category includes processed foods and drinks, as well as fresh produce.

Machinery and equipment: This category includes products such as machine tools, engines, and construction equipment.

Manufactured goods: This category includes a wide range of products, such as textiles, clothing, and electronics.

Minerals and fuels: This category includes products such as crude oil, natural gas, and coal.

Other goods: This category includes products that do not fall into any of the other categories, such as furniture and toys.

Textiles and clothing: This category includes products such as yarn, fabric, and garments.

Transport equipment: This category includes products such as cars, trucks, and airplanes.

The specific products that are exported and imported vary from country to country. For example, the United States is a major exporter of agricultural products, machinery, and equipment, while China is a major exporter of manufactured goods and electronics.

Factors to Consider When Choosing Export Import Products

There are a number of factors that businesses should consider when choosing which products to export or import. These factors include:

Demand: Is there a strong demand for the product in the target market?

Competition: How much competition is there for the product in the target market?

Profitability: Is the product profitable to export or import?

Regulations: Are there any regulations that restrict the export or import of the product?

Logistics: How will the product be transported to and from the target market?

Benefits of Exporting and Importing Products

There are a number of benefits to exporting and importing products. For businesses, exporting can help to increase sales and profits, and it can also help to diversify the business's customer base. Importing can help businesses to access products that are not available domestically, and it can also help businesses to reduce costs.

For consumers, exporting and importing can help to lower prices and increase the availability of goods. For example, consumers in the United States can buy fresh produce from all over the world, and they can also buy electronics and other manufactured goods at lower prices because of imports.

Conclusion

Exporting and importing products is a vital part of the global economy. It helps businesses to grow and consumers to save money. If you are considering starting an export import business, there are a number of resources available to help you get started.

#Export Import Products List#export import products#export import data#exporter#bussiness#export#import#importers

2 notes

·

View notes

Text

UHMWPE lining sheet,road mats,soccer rebounder board.plastic cut to size....

Dezhou New Origin Rubber&Plastic CO.,Ltd. is located at the China polyethylene engineering plastic products intensive center, Dezhou City, close to Beijing and Tianjin City. We are engaging in the engineering plastics from 1996.

Kelly Wei

Sales Manager

Email:[email protected]

Cell:+86 17705445030

Whatsapp: +86 17705445030

Website:www.dz-neworigin.com

Our plastic products cover a full range from semi-finished sheets to various machined parts, including CNC machining parts, injection molding parts, marine fender pads, lining sheet, temporary road mats, outrigger pads, synthetic ice rink, curling lanes, cutting board,soccer rebounder boards, as well as plastic irregular machinery parts, which are widely used in marine system, mining, construction, events and projects, sports, food and machinery industries. Which have been exported to United States, United Arab Emirates, India, Russia, Australia, Ukraine, Lithuania, Peru, Germany, Spain Saudi Arabia, South Africa etc. All the customers give good appreciation to our products.

2 notes

·

View notes

Text

What do they like more in Russia: tea or coffee?

Have you ever wondered what people like more in Russia: tea or coffee? I will not torment and immediately give a short answer to this question - tea in Russia is the most popular drink after water. But why is that?

If you tell without unnecessary information - it happened historically. Tea was brought to Russia at the beginning of the XV century from China, but to be more precise - from Siberia. The peoples of Siberia at that time had been drinking tea for a long time, as they were in close contact with China, at the same time, Russia was exploring and capturing Siberia, and that's when the Russian people learned about this outlandish drink.

On the one hand, this drink was accepted at the very top. What Muscovite, even in the 17th century, did not want "like in the best houses"? On the other hand, all those people who somehow ended up in Siberia and communicated with the locals, adopted their customs. The interpenetration of cultures is such a thing. So over time, poor people also began to drink tea. And gradually tea became a common drink.

Over time, tea drinking became a tradition - such gatherings were arranged for as much as half a day. Be sure to arrange a feast so that you can show generosity and brag about pickles and delicacies that are in the house. So, by the way, they came up with lemon tea. In Europe, lemon is used more to add piquancy to sauces, salad dressings, etc. And now take a look here:

-Here I have flower tea (that is, from tips), here I have overseas fruits, here's something else…

-Tea and fruit? Well, let's try it.

Those who were not up to chic and revelry, but there was no wealth, they bought samovars. And they drank, even if not "family", but ordinary tea, but they drank the same.

Those who could not afford it, they warmed themselves with tea in taverns. Moreover, they did not take money for boiling water there. So it was possible to order one teapot and take a long time to heal it. And the tavern is a very different audience.

In general, tea is not only a favorite drink of Russians, it is an integral part of Russia and its traditions.

Coffee appeared in Russia much later. The fashion for coffee was introduced after the Emperor Peter I. He discovered the drink during a trip to Holland in 1697. It was sold in pharmacies as a remedy for all diseases. After returning home, Peter I ordered all his subjects to drink coffee.

However, it is difficult to imagine a Russian person without a cup of coffee in the morning. There are a lot of coffee shops in Russia and they are leading on foreign chains, and their own, and there are a lot of them in Russia: CoffeeWay, Cofix, One Price Coffee, Surf Cofffee, Coffee Like and others.

Russians also fell in love with foreign coffee brands, for example: Starbucks, Costa Coffee, Dunkin' Donuts, Krispy Kreme and others.

But Russians do not know how to appreciate coffee as much as tea. Many people don't even have coffee machines at home and they drink instant coffee. I can't say that about myself, coffee is my favorite drink, after water, of course. I can safely drink 3 cups of coffee a day and it won't be enough for me.

Well, I'm saying goodbye to you! My name is Max, I live in Moscow and tell you about the peculiarities of life in Russia! See you soon! By the way, what do you like more: tea or coffee?

4 notes

·

View notes

Text

my generation, part 1

Everything was different when I was a kid.

There was no such thing as a colour television or a personal computer, and the internet hadn’t been invented. If you wanted music, there was the ‘wireless’ or what my grandmother referred to as a gramophone and the rest of us called a record‐player. Discs were vinyl — twenty‐ minute‐a‐side LPs and smaller, three‐minute‐a‐side 45s — and musicians recorded them on two‐ or four‐track reel‐to‐reel tape. The first portable transistor radio was sold in the USA just two months after I was born, but neither eight‐track stereo nor videocassettes were even imagined yet. MTV was launched when I was in my twenties, not long before the first compact disc and the cellular mobile phone. ‘Touch‐tone’ phones with digital keyboards turned up in the USA in the early ’60s. Until then, every phone used slow, rotary dialling. International voice communications were carried only on terrestrial cables, not relayed through satellites, and you still had to ask an operator to connect a call. Facsimile machines — we hadn’t yet learnt to call them faxes — were the size of a coffee table, with a bit‐rate that transmitted a single typewritten page in ten minutes. Even time was analogue. I was a teenager when the first digital watch, the Pulsar, with its bulky, faux‐gold casing and red LED display, went on sale. There were no microwaves, no pocket calculators and no game consoles (arcade games were large and electro‐mechanical, like pinball machines). Credit cards were for the rich — Diner’s Club, Carte Blanche and American Express — and there were no bank cards, no automatic teller machines, and no point‐of‐sale processors. A bank’s customer records were still kept in a file drawer. Your signature was your main form of ID.

It’s a sure sign that you’re growing old when you start to talk about how things used to be. I’m a Baby Boomer, born almost at the mid‐point of a generation whose first members were conceived just before the end of World War II. We came of age in the ’60s, in time for a few of us to be drafted into the first large‐scale deployment of Australian and American soldiers to Vietnam. We were the first generation to be raised in the suburbs, in the identikit, planned estates of low‐rise apartments and brick‐veneer houses that spread like a blight from the edges of Western cities during the economic boom of the ’50s, and the first whose experience of the world was to be shaped not by direct experience, but by mass media. We were also the first to be immersed in a media‐driven culture of consumerism. Ask a Boomer about their earliest childhood memory, and chances are they’ll tell you about a TV show.

Now we’re the first generation to reach old age within this new millennium — the oldest of us turn sixty this year — and, unlike our parents and grandparents, maybe unlike our own children, we’re reluctant to let go of our youth. If anything, we reject ageing altogether, marketing to ourselves the idea that it’s just a state of mind: with the right science and medicine (preferably synthesised within a viable consumer product), a healthy diet, regular exercise and a little hybrid spirituality, we might be able to live forever.

Don’t trust anyone over thirty. This was the unifying sentiment behind the barricades we built between previous generations and us during the ’60s. It didn’t just inspire the raucous anthems of post‐Beatles rock groups like The Who — People try to put us d-down/ Just because we get around/ Things they do look awful c-c-cold/ I hope I die before I get old — it became the underpinning of a societal upheaval that, in many ways, was as subversive in its bid for power and ideological unity as the Great Proletarian Cultural Revolution conceived by Mao Zedong in China at about the same time. And yet, by the end of the ’60s, before any of the Boomer generation had actually reached thirty, there were few among us who felt a part of it any more. We had learnt not to trust anybody, and there was a tacit resolve to extend the barricades so that we were insulated from not just the generations that preceded us, but the generations that would follow as well. Popular culture had become synonymous with youth — although it only really became known as youth culture with the launch of MTV, the source of a whole new vernacular for mass media and marketing — and we were determined not to let it be pried from our grasp, even when our youth was done.

Baby Boomers didn’t invent youth culture. We weren’t even the first to recognise the economic and social power that youth had begun to acquire, almost inadvertently, in the decade or so after World War II — how could we have been, we were infants, if we were born at all? The sudden demographic up‐welling that spilled across the USA, Western Europe and Australasia to become a surging counter‐current of new attitudes and ideas was unarguably a singularity of the ’60s, but the source of it was actually a generation whose own youth was muted by the uncertainty and hardships of the Great Depression and World War II. Rock’n’roll, the twentieth century’s great, twisted take on an ancient Bardic tradition, was the invention of the Silent Generation. From the hellfire performers who emerged from the God‐fearing rural ghettoes of the former Confederacy states — among them, Chuck Berry, Jerry Lee Lewis, Buddy Holly, Roy Orbison and Elvis Presley — to unsettle the consciousness and sexual mores of ’50s America’s too‐tightly wrapped middle class, to the younger, working‐ class, urban Englishmen who hero‐worshipped them and went on to form bands — The Beatles, The Rolling Stones, The Yardbirds, The Animals and, in Australia, The Easybeats — that would eventually overshadow, if not outlast, even Elvis’s unprecedented fame, none was a Baby Boomer.

The ’50s was the first decade in modern history in which youth laid claim to a discrete identity of its own, and instigated a cultural, social, sexual, political and economic revolution that, half a century later, has yet to run its course. Never before had youth gained the upper hand in a developed society — let alone, as it has turned out, held on to it for over half a century. The allure of youth has haunted the middle‐aged of every generation, but you only have to look at movies produced before the ’50s to see that, in the popular imagination, youth used to be what today’s Baby Boomer demographers might describe as ‘aspirationally older’: Bacall chasing Bogart, not the other way around, until James Dean came along. They wanted more than just acceptance by an older generation: they wanted admission to what was presented as its more responsible, rational and coherently structured society — they couldn’t wait to grow up.

Again, the tectonic cultural shifts that disrupted this had nothing to do with Baby Boomers. These began with the frustrated restiveness of the Silent Generation, and the times’ nagging apprehension of an intensifying Cold War between the West and the then Soviet Union, with its sombre, ever‐present nuclear threat of MAD, or mutually assured destruction. There were also fateful connections made, with what was to become a generational inclination to apophenia, between what were, on the surface, a series of apparently disparate events in the decade between 1950 and 1960 — among them, the American witch‐hunts for communist sympathisers between 1950 and 1954, incited by the cynical, ambitious and corrupt Republican senator Joseph McCarthy, the emergence of an Afro‐American civil rights movement, and the defiant Montgomery Bus Boycott in 1955, inspired by the refusal of a middle‐aged black woman Rosa Parks to give up her seat on a segregated public bus in Alabama, USA, led by a young black minister (another member of the Silent Generation), Martin Luther King, the launch of the first living creature — a dog named Laika — into space in 1957 aboard the Russian Sputnik 4, or the foundation of the Campaign for Nuclear Disarmament in England in 1958 (when the oldest Baby Boomers were just adolescents) by the elderly Bertrand Russell, Victor Gollancz and J.B. Priestley, and the middle‐aged Michael Foot and E.P. Thompson. (This last event prompted the designer and artist Gerald Holton to create the peace symbol — a simple, upside‐down trident based on the semaphore signals for the letters ‘N’ and ‘D’; in a world cluttered by graphics and logos, it endures as one of the 20th centuryʹs most recognisable and best understood icons.

In North America, Western Europe and even Australia, the twenty‐ and thirty-somethings of the Silent Generation were increasingly ready to break with traditional social orders: in their eyes, the so‐called Greatest Generation that went before them had done nothing but drag them through economic chaos and war (albeit in pursuit of the worthy ideal of creating a better world), then marginalise them in the aftermath. Nearly a decade of economic growth spurred by the postwar reconstruction of Europe and the demand it created for North America’s industries — and Australia’s natural resources — had given the Silent Generation economic independence, while prolonged peace and prosperity had encouraged it to invest in leisure, despite the slightly puritanical disapproval of older, more frugal generations. As the 63‐year‐old British Prime Minister Harold Macmillan admonished his fellow Conservatives in a 1957 speech, “Most of our people have never had it so good.”

Maybe we over‐estimate the impact of a twenty‐one‐year‐old Elvis in his first nationally broadcast TV appearance in 1956, but his hyper‐sexual posture and sardonic disdain (mirroring James Dean’s character, Jim Stark, in Nicholas Ray’s now‐ classic film Rebel Without A Cause, released the year before) channelled perfectly the pent‐up desire of the Silent Generation to get up into the face of its elders. Rock’n’roll, James Dean and the reckless swagger of Jack Kerouac’s semi‐fictional Dean Moriarty in the novel On The Road, which was published in 1957 and became an unexpected best‐seller, were the iconic foundations of a very real cultural identity that would gather momentum over the next decade.

It was an identity that Baby Boomers would usurp and, with the unseemly disregard that was to become a generational trait, eventually ‘productize’ and exploit — as they would so many others.

Sexual intercourse began

In nineteen sixty-three

(which was rather late for me) –

Between the end of the Chatterley ban

And the Beatles’ first LP.

Philip Larkin, from Annus Mirabilis

Even in 1967, when Britain’s repressed poet laureate appropriated the title of a seventeenth century John Dryden poem for his own celebration of a year of miracles – in which the commercial introduction of the oral contraceptive pill in the USA coincided with The Beatles’ first hit records there – it was impossible not to be struck by the irony that, as in the Dryden poem, the year in question was as remarkable for its awfulness as for its chronicle of achievements: 1963 was the year 70,000 British supporters of the Campaign for Nuclear Disarmament marched from the Atomic Weapons Research Establishment in Aldermarston to London, and American networks shocked their prime‐time TV audiences with footage of a Vietnamese monk setting fire to himself in a Saigon street. It was the year British spy Kim Philby sought asylum in Moscow, and the Soviet cosmonaut Valentina Tereshkova became the first woman to voyage into space aboard Vostok 6. It was the year Betty Friedan published the first feminist best‐seller, The Feminine Mystique, revitalising the American women’s movement, and Richard Neville, Martin Sharp and Richard Walsh published the first issue of the Australian satirical magazine Oz. It was the year Martin Luther King, delivered his most famous speech — I have a dream — to more than a quarter of a million people from the steps of the Lincoln Memorial in Washington DC. It was the year one of the most popular US Presidents in history, John F. Kennedy, was gunned down in the back seat of an open‐topped limousine during a motorcade through Dealey Plaza, in downtown Dallas, Texas.

It was a year of lost innocence, in every sense. The last of the Silent Generation turned eighteen, not then old enough to vote or to drink, but old enough to be drafted into the military.

It was probably a Baby Boomer who came up with the hoary old line that if you can remember the ’60s, then you weren’t there. The Silent Generation and the Baby Boomers shared their cheap alcohol, cannabis, psilocybin and LSD, but the context of their experience of those years was different. “There was a pissed‐offness about the ’60s that gets covered over by flower power now, but it was an angry time,” American playwright and actor Sam Shepard recalled in an interview with The Guardian this year. Today, the NRMA resorts to nostalgie de la boue to advertise its insurance policies to aging Baby Boomers — speckled monochrome newsreel footage of us dancing in the mud at some long‐forgotten rock festival — but that decade began not with peace and love but with France testing an atomic bomb in the Sahara, the U.S. deploying 3,500 American troops in Vietnam, the Soviet Union shooting down an American U‐2 spy plane, and the East Germans beginning the construction of the Berlin Wall. For the Silent Generation, whose childhood and adolescence had spanned a prolonged economic depression and a world war, the escalation of the Cold War and the imminent threat of nuclear annihilation tainted their perception of the early ’60s and incited a dark, jittery sense of déjà vu.

As it turned out, 1963 was a pivotal year. It marked the beginning of what would become an acute divergence between the attitudes of the Silent Generation and the Baby Boomers. By then, the Silent Generation had had enough. When their best‐loved poet – a geeky Jewish kid from Hibbing, Minnesota, Robert Zimmerman, who had reinvented himself as Bob Dylan and earned enough agit‐prop credibility to sing for the March on Washington for Jobs and Freedom, the occasion for Martin Luther King’s memorable address – scored a commercial and emotional hit with his generational anthem, The Times They are A-Changin’, the times already had.

By the early ’60s, the Silent Generation had the economic clout — not to mention a determination inspired by a childhood in which their parents’ attention had been distracted, if not lost completely, in the pervasive tensions of the war — to change the existing order of society, to make it different if not necessarily better. If any generation could be said to have given the late twentieth century its social conscience, it was the Silent Generation. Over the next twenty years, its influence on public attitudes to issues such as the proliferation of nuclear arms, the war in Vietnam, civil liberties, racial and sexual equality, gay rights and the abuse of political power (specifically, the Nixon presidency and its collapse under the weight of the Watergate scandal) was so constant and deeply felt that we took it for granted.

When, inevitably, the Silent Generation grew tired of the fight, no other generation stepped up to take its place. Quite the opposite. Nowadays, in a post‐9/11 world, Baby Boomers appear to be almost complicit with the erosion of civil rights, the increasing, covert surveillance of public and virtual spaces, the rejection of accountability by elected governments and the oppressive atmosphere of intolerance that are the antitheses of everything the essential spirit of the ’60s – its vibe – was supposed to be about.

Except it never was.

As the hardened ex‐con played by an aged ’60s icon, Terence Stamp, in the 1999 Steven Soderbergh film The Limey recalls: “Did you ever dream about a place you never really recall being to before? A place that maybe only exists in your imagination? Some place far away, half‐remembered when you wake up. When you were there, though, you knew the language. You knew your way around. That was the ’60s. [Pause] No. It wasn’t that either. It was just ’66 and early ’67. That’s all.”

The so‐called Summer Of Love in Haight‐Ashbury, San Francisco in 1967 embodied the hippie ethos of ‘turn on, tune in, and drop out’ — a phrase coined by the psychologist and high‐profile advocate of better living through psycho‐ pharmacology, Timothy Leary — but the idyll was less than the season itself.

In 1966 as a million people gathered along Sydney’s streets to welcome Lyndon Baines Johnson, the first US president to visit the country — they had been exhorted to ‘Make Sydney gay for LBJ’, which, from the perspective of today’s sexually more enlightened age, gave a whole new meaning to Harold Holt’s infamous election slogan, ‘All the way with LBJ’ — 10,000 anti‐war protesters fought a pitched battle with the city’s police, prompting the NSW Premier Rob Askin to order his chauffeur to “drive over the bastards”. Neither peace nor love were to be found anywhere by 1968. When a performance by a rock group, The MC5, at the Democratic National Convention in Chicago degenerated into a full‐scale riot, the then mayor of the city, Richard J. Daley authorised “whatever use of force necessary” to quell the situation. Much the same orders had been given (at about the same time) to the commanders of the Warsaw Pact tanks that rolled into Prague in Czechoslovakia, to suppress what Moscow portrayed as an uprising (even it was really just a badly managed attempt at social and economic reform) and, three months earlier, to French riot police, les Compagnies Républicaines de Sécurité, when over a million striking students and other protesters took to the streets of Paris.

In 1969, the Woodstock Music and Art Festival, held on a dairy farm in upstate New York, billed itself as “three days of peace and music” — and it was, probably, for most of the half a million people who turned up there — but four months later, at a festival at Altamont Raceway Park in Northern California, a gang of Hell’s Angels hired as security by the Rolling Stones stomped an eighteen‐year‐old African‐American boy to death in front of the stage.

Whatever illusions we still had about the live‐and‐let‐live, love‐the‐one-you’re‐with attitude of the ’60s were lost or abandoned at the bitter end of the decade. Peace and love were as dead as Wyatt and Billy after the rednecks shot‐gunned them off their motorcycles in the final frames of Easy Rider.

In 1970, a company of National Guards opened fire on 2,000 students protesting the American invasion of Cambodia on the campus of Kent State University in Ohio. Four students, including two women, were killed and nine were injured. Ten days later, police, supported by the National Guard, opened fire on protesting students at Jackson State University in Mississippi. Two were killed and twelve were injured. It appeared that the emergence of a cohesive, politicised youth counter‐culture had shaken up the status quo enough that the first reaction of those charged with maintaining it — the vestigial guardians of the Great Generation, the unambivalent defenders of the moral high ground and the guys who had fought the last ‘good’ war for us — had been to try, quite literally, to kill it. “They’re worse than the brown‐ shirts and the communist element and also the nightriders and the vigilantes,” the Republican governor of Ohio, James Allen Rhodes, said of the Kent State protesters in a fit of indignant hyperbole at a press conference, just twenty‐four hours before the fatal shootings. “They’re the worst type of people that we harbour...I think that we’re up against the strongest, well‐trained, militant, revolutionary group that has ever assembled in America.”

The oldest of the four Kent State students killed was twenty, the youngest nineteen. Unsurprisingly, two of these Baby Boomers had had no part in the protest at all. They were walking from one lecture to another.

Part one of three.

First published as part of a single essay in Griffith Review, Australia, 2006.

#babyboomers#generationaldivides#the60s#youthculture#rocknroll#culturewar#vietnam#summeroflove#postwar

3 notes

·

View notes

Text

youtube

CNC Lathe Machining, a pinnacle of precision engineering, transforms raw materials into finely crafted components. At the forefront of technological innovation, our CNC Lathe Machining service at China Ming Xiao Manufacturing is dedicated to shaping your ideas into reality. From intricate details to seamless finishes, our advanced machinery ensures unparalleled accuracy, making us the go-to choice for those who demand precision in every turn. Elevate your projects with the excellence of CNC Lathe Machining – where precision meets craftsmanship.

#CNCMachining #PrecisionParts #GlobalManufacturing #cnclathemachining #customparts

#CNC Lathe Machining#CNC Lathe Turning#CNC Turning#mxmparts#china metal parts#china supplier#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#Youtube

0 notes

Text

Pavel's pride: 45 years of the inaugural flight of the Su-27

Fernando Valduga By Fernando Valduga 07/10/2022 - 6:28 PM in History, Military

The year 2022 marks the 45th anniversary of the inaugural flight of the prototype Su-27 fighter developed by the Sukhoi Experimental Design Bureau, which marked the birth of the famous Su-27/Su-30 fighter family.

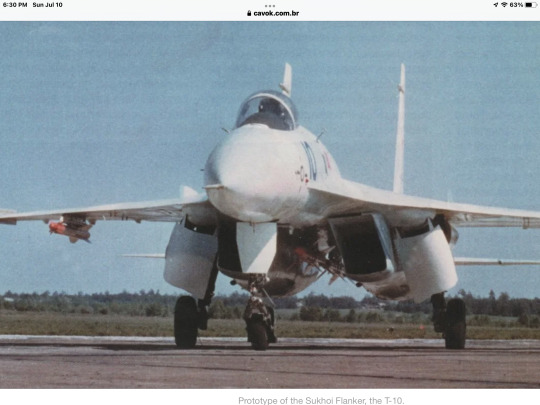

Prototype of the Sukhoi Flanker, the T-10.

In the 21st century, the Su-27/Su-30 became one of the most requested fighters in the world: they were purchased by Angola, Belarus, Venezuela, Vietnam, India, Indonesia, Kazakhstan, China, Malaysia, Uganda and other countries. Much of the credit for this should go both to aircraft designer Pavel Osipovich Sukhoi and to the team of his incomparable Design Bureau, who managed to obtain a technically perfect formula for the overall success of the Sukhoi brand.

"Aerial superiority is a key factor in any confrontation. That's why we pay close attention to the development of new advanced platforms. At the same time, the Su-27 has become a technologically innovative machine and the parent of a whole family of exceptional aircraft: the Su-30, Su-34 and Su-35. Today, these jets are the mainstay of the Russian Aerospace Forces and carry out missions successfully even under especially adverse conditions on a daily basis. This is a vivid demonstration of our technological capabilities," said Vladimir Artyakov, first deputy director general of Rostec State Corporation.

Su-30SM.

Currently, Russia's family of Sukhoi high-performance heavy duty aircraft systems offered for export is represented by aircraft of the 4+/4++ generation, the Su-30SME, Su-34E and Su-35.

"Rosoboronexport has delivered about 700 Su-27/Su-30 combat aircraft abroad since 2000. In 2021, the company's order book was replenished with new contracts for the supply of Su-30SMs," said Alexander Mikheev, Managing Director of Rosoboronexport (part of Rostec State Corporation). "In the last 10 years, the share of aircraft supplies in Russia's total arms exports has stood at 40-50% and even exceeds this number today. Currently, our partners greatly appreciate the fact that engines, avionics, weapons, systems and components in Russian combat aircraft are exclusively manufactured in Russia. This ensures the independence of purchasing countries from unfair actions taken by third countries. In addition, an open architecture of avionics and weapons systems, implemented in Russian fighters, allows foreign customers, with the involvement of the Sukhoi Design Bureau, to integrate some of the national systems and weapons thrown from the air into them."

Su-34.

The Russian Aerospace Forces are the largest operator of Sukhoi combat aircraft. According to the Russian Ministry of Defense, Su-30SM and Su-35 aircraft can effectively intercept air targets and attack military installations with guided weapons with precision at low, medium and high altitudes. Its airborne equipment allows the use of air weapons with maximum precision. According to the fighter pilot "Hero of Russia" Major Viktor Dudin, the Su-35 is a perfect fighter.

Su-35.

The Su-35 is a powerful 4++ generation aircraft system that incorporates fifth-generation fighter technologies. The Su-35 handles the full range of hunting missions at a wide altitude and speed envelope. A large number of hardpoints allow the use of up to 12 medium-range air-to-air guided missiles or 6 air-to-surface missiles in one sort. Its powerful on-board radar can detect aerial targets over long distances (up to 350 km). The Su-35 also effectively engages ground (surface) targets, including without entering the enemy's air defense zone. In addition, the Su-35 is able to control a group of planes in the air, acting as an AWACS aircraft.

Main advantages of Su fighters:

super maneuverability that gives an advantage in approximate air combat, allowing the Sukhoi aircraft to stop retaliatory missile attacks;

powerful missiles and rockets plus a 30 mm automatic cannon;

autonomous base and in-flight refueling capacity;

Open architecture of avionics and weapons systems.

Su-30MKI of the Indian Air Force.

One of the most notable ?? Foreign Su-30 fighter operators is India, where the licensed Su-30MKI fighter production program, which make up the backbone of the country's Air Force, has been successfully implemented. Rosoboronexport, under the Make in India program, is ready to provide additional kits completely disassembled for the assembly of the Su-30MKI and carry out joint work on its modernization, including the integration of the latest air weapons, avionics, etc. At the same time, the existing portfolio of aviation projects allows the company to develop technological cooperation globally in a wide range of areas.

The fighters will be demonstrated this year at the ARMY-2022 International Military and Technical Forum.

Tags: Military AviationRussiaSu-27 FlankerSukhoi

Previous news

Airbus delivers the 7,000th Ecureuil helicopter

Next news

Super Hornet falls into the sea from the USS Harry S. Truman in the Mediterranean

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in a specialized aviation magazine in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

3 notes

·

View notes

Text

Precision Engineering: Exploring China Custom Machining and Machining Parts

In the world of manufacturing and precision engineering, China Custom Machining and China Machining Parts from Sage Metal Parts stand as pillars of innovation and precision.

China Custom Machining: Tailored Precision

China Custom Machining is the art of crafting bespoke components with utmost precision. Here's why it plays a pivotal role in modern manufacturing:

1. Tailored Solutions

Custom machining offers the flexibility to create parts that are tailor-made to meet the specific needs of various industries, from aerospace to automotive.

2. Precision and Quality

Advanced CNC machining techniques ensure the highest levels of precision and quality in every component produced.

3. Innovation and Efficiency

Custom machining drives innovation by enabling the creation of complex parts and streamlining production processes.

China Machining Parts: The Building Blocks of Industry

China Machining Parts are the unsung heroes behind the machinery and devices that power our modern world. Here's why they are indispensable:

1. Versatility

Machining parts come in a vast array of shapes and sizes, making them suitable for diverse applications, from medical devices to industrial equipment.

2. Quality Assurance

They are manufactured with rigorous quality control measures to ensure reliability and longevity in various operational environments.

3. Collaborative Advancements

China machining parts manufacturers collaborate with industries to create cutting-edge components that push the boundaries of innovation.

In Conclusion

China Custom Machining and China Machining Parts are the cornerstones of precision engineering and manufacturing. At Sage Metal Parts, these solutions converge to provide tailor-made components and parts that redefine quality and innovation.

1 note

·

View note

Text

Tips for Designing Custom Plastic Injection Molding with Injection Mold Suppliers China!

Injection molding is a process of producing custom plastic parts with the help of Injection Molding Services China. It is one of the most efficient and cost-effective methods of manufacturing plastic components. Injection molding is used for a wide range of applications, such as automotive, medical, and consumer products, to name a few. The process involves the injection of molten plastic material into a mold, allowing the plastic to take the shape of the mold and harden.

When it comes to designing custom plastic parts injection molding, there are several tips that you should keep in mind. These tips will help you get the best results and ensure that your custom plastic parts injection molding process runs smoothly. Here are some of the tips you should consider when working with Injection Mold Suppliers China:

1. Determine the Material: The first step in designing custom plastic parts injection molding is to determine the material that you will be using. Different types of plastic have different characteristics, so you need to make sure that you select the right material for your application. Your injection mold supplier China can help you select the appropriate material for your project.

2. Choose the Right Injection Mold Supplier: It is important to choose an experienced and reliable injection mold supplier in China. You should research their past projects, customer feedback, and other metrics to determine the best supplier for your project.

3. Design the Mold: Once you have chosen an injection mold supplier, you need to design the mold. It includes deciding on the size, shape, and other details of the part. It is crucial to work closely with your injection mold supplier to ensure that the mold is designed correctly.

4. Account for Shrinkage: Plastic tends to shrink after it is injected into the mold. To ensure that your parts come out correctly, you need to account for this shrinkage when designing the mold. Your injection mold supplier can help you account for this issue.

5. Consider Secondary Operations: Depending on the complexity of the part, you may need to perform secondary operations. These can include machining, painting, or other processes. If you are planning on performing these operations, you need to ensure that the mold is designed in such a way that it can be performed easily.

Following these tips can help to ensure that your Custom Plastic Injection Molding process runs smoothly and efficiently. Working with an experienced injection mold supplier in China can help you get the best results.

#Custom Plastic Injection Molding#Injection Mold Suppliers China#Injection Molding Services China#injection mold#machining#mold parts#manufacturers#plastic parts#business#plastic molds#Mold Parts

1 note

·

View note

Text

CNC Machine Shop

Fuson Precision Machining is a leading CNC precision machine online service shop based in China. We certificated ISO9001-2015,we aim to help our clients grow. For more information call us at +86 15920434778.

1 note

·

View note

Text

Why are centrifugal pumps with wide application in industry?

Centrifugal pump plays a crucial role in the industrial operation of oil and gas, power production, water treatment, and other areas. At the same time, this series of pumps enjoys a good reputation for its high efficiency, reliability and wide range of applications. The following article will explain why electric centrifugal water pumpare widely used in industry.

Wide-Ranging Applications

The centrifugal pump with great versatility is adaptable for various industrial applications to convey a wide range of fluids including oil, water, chemicals and slurry. When you use this machine in your mining and beneficiation processes, it can effectively and quickly process corrosive and abrasive materials. The centrifugal pump is an ideal choice for the mining industry due to its specially designed to withstand slurry transport.

Reliable Operation

Generally speaking, the industrial sector often requires durable and continuous operation of equipement. We designed the centrifugal pumps for sale with robust construction and exceptional dependability that will effectively deal with harsh environments with temperature and high pressure. Compared with other series pumps, centrifugal pump has less maintenance time and steps due to its simple design and fewer moving parts. In other words, the use of centrifugal pumps will reduce downtime and save money in your industrial facilities for continuous production.

Increased Production Capacity

Self priming centrifugal pump made by Shenghui adopt energy-efficient design for the reduction of power consumption and operations costs in your industries. The development of technology has led to the development of high-pressure slurry pumps and vertical centrifugal pumps, effectively improving production efficiency. Using the centrifugal pump convey the liquid over long distances or to higher elevations while using less energy because the pumps have the design of higher operating pressure.

Productive Conveying

The capacity of high pressure centrifugal pump to transport fluids effectively is one of the major factors contributing to their widespread use in industrial environments. In order to provide a high flow rate, the pump converts into kinetic energy to operate by converting mechanical energy. Liquids may pass through a rotating impeller in centrifugal pumps thanks to their design, which produces centrifugal force. Therefore, the centrifugal pump is perfectly suitable for industrial applications where liquids must be moved continuously because it will handle enormous volumes of fluids, such as chemical manufacturing plants.

Industrial centrifugal pumps are indispensable role in industrial environments because of their working efficiency, wide application, smooth operation. You can use this machine for mining, water treatment, oil and gas, and various industries to transport a broad range of fluids.

As one of the professional manufacturers and producers in China, Shenghui company has been producing and developing pumps for more than ten years, with a professional research team and machines. Our company's success is based on specializing in the manufacture of high quality pumps, the implementation of innovative technology and the provision of excellent customer service. If you need centrifugal pumps for industrial use, we can provide you with reliable and professional centrifugal pumps according to your needs, please contact us immediately!

0 notes

Text

Medical Sheet Metal Fabrication

In the modern medical industry, sheet metal products are an indispensable part. Medical device sheet metal product processing is an important manufacturing process that can provide high-quality medical equipment and appliances for hospitals and medical institutions, and provide better healthcare services for patients.

The application of medical device sheet metal processing is very wide, mainly involving medical equipment, medical devices, medical appliances and other fields. Sheet metal processing technology can manufacture medical devices of various shapes and sizes, such as operating tables, surgical lamps, surgical instrument racks, etc. These devices can help doctors perform surgeries and treatments more effectively. Medical sheet metal products can also be used to manufacture medical equipment, such as stretchers, wheelchairs, beds, etc. These tools can provide a more comfortable nursing environment and help patients recover.

Medical Metal Parts Manufacturing Capabilities

The advantage of medical sheet metal product processing is its precision and reliability. As an experienced sheet metal factory in China, we follow the strict quality control system, use well trained engineers and workers, use state of the art equipment to ensure our sheet metal parts have the best precision and accuracy.

We have decades of experience in manufacturing sheet metal parts for medical industry. Because of its complexity in design and aesthetics in appearance, medical device has high requirements on factories, and almost all processes will be involved, such as laser cutting, CNC bending, precision stamping, deep drawing, welding, surface treatment, etc. We already have a deep understanding of medical devices and can meet our customers' quality requirements.

How Yixing Technology Produce Medical Metal Parts

How to make medical device can be mainly divided into below four parts:

Part 1: Cutting Materials

Laser cutting is one of the most common cutting methods in sheet metal processing. Firstly, according to the size specifications of the finished sheet metal parts, stainless steel and other sheets are laser cut into the required dimensions for backup. This process is collectively referred to as cutting.

Part 2: Bending

Bending is the process of CNC bending the finished material according to the size specifications of the sheet metal workpiece. It will be prepared for the next step of sheet metal welding. Take patient transfer device as example, the main parts are square tubes. We use press brake or pipe bending machine to do the precise bending.

Part 3: Welding

Welding can be divided into two methods: manual welding or robot automatic welding. It is a process of welding finished materials based on the cut, bent or formed sheet metal parts. It is combining two or more types of the same or different types of sheets. Shanghai Yixing Technology can do TIG and MIG welding. Material selection and welding quality is the most important because it will influence the load bearing capacity and whether the machine can do straight line rolling. We pay attention on every detail.

Part 4: Surface Treatment

There are many surface treatment we can do such as sandblasting, anodization, polishing, powder coating, electrophoretic paint, hot-dip galvanizing, electroplating or others. For the patient transfer device, the main surface treatment is powder coating. The minimum coating thickness is more than 60um and we do 100 grid test and salt spray test to check the adhesion and corrosion resistance.

Patient transfer device is a complicated design and more process will be involved which is not listed above like riveting, threading, printing, heat treatment, assembly with motors and other plastic parts and hammock.

0 notes

Text

Automotive Coolant After Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Coolant After Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Coolant After Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Coolant After Market is experiencing robust growth driven by the expanding globally. The Automotive Coolant After Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Coolant After Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

The automotive coolant aftermarket is an important part of the automobile industry that has been gaining significant traction in recent years and is projected to grow in the coming years.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/107968

Key Strategies

Key strategies in the Automotive Coolant After Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Coolant After Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Coolant After Market.

Major Automotive Coolant After Market Manufacturers covered in the market report include:

BASF SE (Germany), Exxon Mobil Corporation (U.S), TotalEnergies (France), Royal Dutch Shell PLC (U.K.), Valvoline LLC (U.S), Motul S.A. (France), Castrol Limited (U.K.), Sinopec Lubricant Company (China), and Petroliam Nasional Berhad (Petronas) (Malaysia).

The automotive coolant aftermarket is an important part of the automobile industry that has been gaining significant traction in recent years and is projected to grow in the coming years. The demand for more technologically advanced vehicles demands advanced cooling and, thus, demand for aftermarket high-quality, effective coolant products

Trends Analysis

The Automotive Coolant After Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Coolant After Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Coolant After Market Solutions.

Regions Included in this Automotive Coolant After Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Coolant After Market.

- Changing the Automotive Coolant After Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Coolant After Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Coolant After Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Automotive Coolant After Market?

► Who are the prominent players in the Global Automotive Coolant After Market?

► What is the consumer perspective in the Global Automotive Coolant After Market?

► What are the key demand-side and supply-side trends in the Global Automotive Coolant After Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Coolant After Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Coolant After Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Automotive Coolant After Market#Automotive Coolant After Market Share#Automotive Coolant After Market Size#Automotive Coolant After Market trends#Automotive Coolant After Market Growth

0 notes