#precast concrete system

Text

Magnetic Recess Members

Magnetic Recess Members, Lifting Recess, & Holding Plates

Dog Bone Pin Recess Members

Designed for the installation of the lifting pin anchors in a steel form using a one-piece urethane recess made to fit all standard size Dog Bone pin inserts. Available with an embedded magnetic base or just the urethane casing to put on a plate.

Description

Size

Part Number

Magnetic Dog Bone Recess Member

1…

View On WordPress

#bread loaf magnet#concrete formwork magnets#Formwork Shuttering Magnet#Insert magnets#Loaf Magnets#Magnet for Precast Formwork#Magnetic chamfer#magnetic formwork fixation#Magnetic Formwork System#magnetic plate#Magnetic Recess#Magnetic Recess Members#Magnetic shuttering systems#Precast concrete components#Precast Concrete Magnet#Precast Concrete Magnetic Formwork#precast concrete system#precast magnets#Shuttering Magnet Adapter#Shuttering Magnet Box#Shuttering magnet systems#Shuttering Magnets#shuttering magnets for precast#shuttering system#Shuttering systems

0 notes

Text

water & sewage Fuji Silver Tech

FUJI Silvertech s advanced precast drains and utility ducts, taking infrastructure to its next level with superior strength, durability, and speed

#precast solutions for water and sewage systems#precast concrete components#precast construction industry#Precast road solutions#Precast bridge components#Precast construction industry in India#Precast manufacturing

0 notes

Text

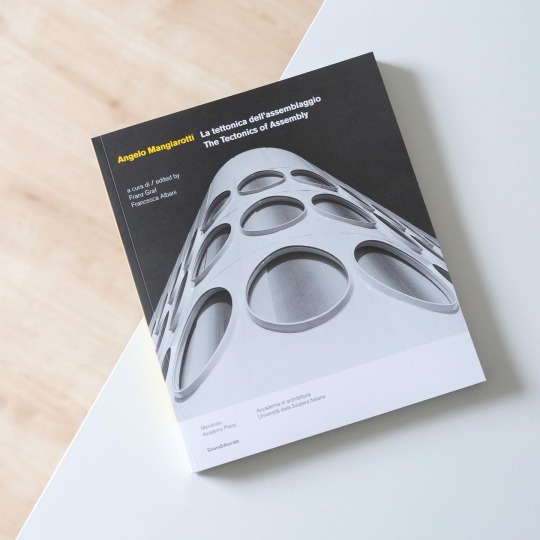

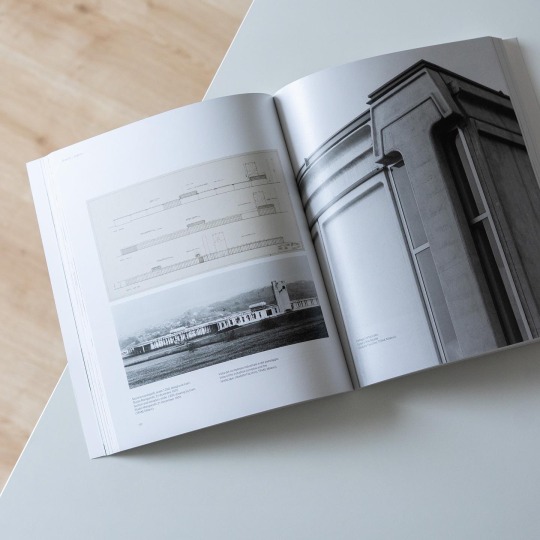

The ingenious work of Italian architect and designer Angelo Mangiarotti still remains somewhat under-appreciated outside of Italy which indeed is a shame in view of the sophisticated oeuvre he left. The latter is characterized by a poetic engineering that combines logical form and structural beauty that sets Mangiarotti’s buildings way apart from pure works of engineering. Throughout his career he worked on an architectural language of the assemblage consisting of vocabulary and grammar aligned with three key concepts: experimentation, gravity and module as Franz Graf and Francesca Albani explain in the introduction to the present volume they edited: „Angelo Mangiarotti - The Tectonics of Assembly“, published by Silvana Editoriale in 2015. These concepts, which relate to Mangiarotti’s sounding out of material capabilities and limitations, the main force in the trilithic system of simply supported precast concrete elements and the modular use of his structural inventions, can be explored further in the select but extensively documented catalogue of ten representative projects: structured along the aforementioned three concepts projects like the Elmag Factory in Lissone (1963-69) or Snaidero premises (1971-78) in Majano are presented in a brief explanatory text, design drawings, technical drawings, plans, models and photographs that provide an unusually comprehensive overview of the genesis of each project.

The two lengthy essays by the editors situate these works and Mangiarotti’s oeuvre in general within the postwar building culture of Northern Italy, his unique contribution to it and how it is perceived today. A more personal, close-up view on Mangiarotti’s practical work and design ethics is in turn provided by Kinue Horikawa who was one of the many Japanese architects and designers passing through the Milan office.

„Angelo Mangiarotti - The Tectonics of Assembly“ is a beautifully illustrated, concise and comprehensive introduction to the Italian master’s work and thinking and as such highly recommended!

29 notes

·

View notes

Text

AAC Blocks Making Plant Fully Automatic: Revolutionizing Construction with Efficiency and Sustainability

In the contemporary era of construction, sustainability and efficiency are paramount. As industries continually seek ways to reduce carbon footprints and enhance operational efficiencies, the adoption of advanced technologies becomes inevitable. One such revolutionary technology in the building materials sector is the fully automatic AAC (Autoclaved Aerated Concrete) blocks making plant. This article explores the operational mechanics, benefits, and economic implications of fully automatic AAC blocks making plants, painting a comprehensive picture of their impact on the construction industry.

Understanding AAC Blocks

Autoclaved Aerated Concrete (AAC) blocks are lightweight, precast foam concrete building materials that provide excellent structural integrity and insulation properties. AAC blocks are made from natural raw materials such as sand, lime, water, and cement, with an expanding agent that helps it to include millions of tiny air pores. Once cast, these blocks are subjected to high-pressure steam curing in autoclaves, which significantly enhances their mechanical properties.

Components of a Fully Automatic AAC Blocks Making Plant

A fully automatic AAC blocks making plant is a sophisticated assembly of various components that work in unison to produce high-quality AAC blocks. Key components of such a plant include:

Raw Material Handling System: This includes devices and conveyors for the storage, measuring, and transport of raw materials like sand, cement, lime, and aluminum powder, ensuring precise batching in the production process.

Mixing and Casting System: At the heart of the plant is the mixer where raw materials are combined to create the AAC slurry. The fully automated system ensures the slurry maintains a consistent quality, which is crucial for the final product's structural integrity.

Cutting Line: Once the slurry is set and partially cured, it is transported to the cutting line where it is sliced into precisely dimensioned blocks or panels using high-precision cutting machines.

Autoclave Curing: The cut blocks are then transferred to autoclaves for steam curing, which is a critical step to achieve the desired strength and lightweight characteristics of AAC blocks.

Packaging System: After curing, blocks are automatically packed and stacked, ready for shipment to construction sites.

Benefits of Fully Automatic AAC Blocks Making Plants

Enhanced Productivity: The automation of the AAC blocks manufacturing process significantly enhances productivity. A fully automatic plant can produce thousands of cubic meters of AAC blocks each day, far exceeding the output of manual or semi-automatic systems.

Consistent Quality: Automation minimizes human error, ensuring each AAC block meets stringent quality standards. This uniformity is crucial for safety and performance in building construction.

Reduced Labor Costs: The high level of automation reduces the need for a large workforce, thus lowering labor costs and minimizing human-related operational inefficiencies.

Energy Efficiency: AAC blocks themselves are energy-efficient materials, providing excellent insulation properties. Their production in a fully automated plant is also energy-optimized, reducing overall carbon emissions associated with construction materials.

Waste Reduction: The precise cutting and materials handling in an automated plant reduce waste significantly. Any waste generated during the manufacturing process can often be recycled back into production, further enhancing sustainability.

Economic and Environmental Impact

Adopting fully automatic AAC blocks making plants is not only a technical decision but also an economic and environmental one. Economically, these plants can deliver a quick return on investment due to reduced labor costs, increased output, and higher product quality leading to greater market demand.

Environmentally, AAC blocks contribute to sustainable construction practices. Their lightweight nature reduces transportation costs and emissions, and their insulative properties can lessen the energy required for heating and cooling buildings—a significant factor in reducing a building’s carbon footprint.

Challenges and Considerations

While the advantages are compelling, setting up a fully automatic AAC blocks making plant involves considerable capital investment. It also requires a steady supply of quality raw materials and a stable technological infrastructure to ensure uninterrupted and efficient production. Moreover, market dynamics such as demand fluctuation, competition from other building materials, and regulatory changes also play critical roles in the operational success of these plants.

Market Adoption and Future Outlook

The adoption of fully automatic AAC blocks making plants has been gaining momentum globally, particularly in regions with stringent environmental regulations and high demand for green building materials. Europe and Asia lead in adopting this technology, driven by growing environmental awareness and increasing urbanization. North America, too, is catching up as the shift towards sustainable construction materials gains traction.

The future outlook for AAC blocks is highly promising. As the construction industry increasingly focuses on reducing its environmental impact, the demand for AAC blocks is expected to rise. This trend is supported by ongoing improvements in automation technology, making the plants even more efficient and less costly to operate.

Investment in research and development is also key to overcoming current limitations, such as high initial setup costs and dependency on skilled labor for maintenance. Innovations in machine learning and predictive maintenance could further enhance operational efficiency, making fully automatic AAC blocks making plants an even more attractive investment for the construction industry.

Conclusion

The fully automatic AAC block making plant represents a significant advancement in building material production, aligning with global trends toward automation, sustainability, and efficiency. For stakeholders in the construction industry, investing in such technology not only boosts economic returns but also contributes to the broader goals of sustainable development. As the world moves towards greener construction practices, technologies like the AAC block making plant are not just beneficial but essential for future-proofing the industry.

0 notes

Text

Advancements in Precast Concrete Buildings Revolutionize Construction in India

India, with its burgeoning population and rapid urbanization, faces significant challenges in housing its citizens while maintaining sustainability and cost-effectiveness. In response to these challenges, the construction industry is increasingly turning to precast concrete buildings and houses as a solution. This innovative construction method offers numerous advantages, including speed of construction, enhanced quality, and reduced environmental impact. In this article, we explore the burgeoning trend of precast houses and precast concrete buildings in India, highlighting their benefits and potential impact on the country's construction landscape.

The Rise of Precast Construction in India:

Precast construction involves the manufacturing of building components such as walls, slabs, columns, and beams off-site in a controlled environment before transporting them to the construction site for assembly. In India, the adoption of precast construction techniques has been steadily increasing due to several factors.

Speed and Efficiency: One of the primary advantages of precast construction is its ability to significantly reduce construction time. Since precast components are manufactured off-site, construction can proceed concurrently at the project site, leading to shorter project durations. This accelerated construction process is particularly beneficial in addressing India's urgent housing needs and infrastructure demands.

Quality Assurance: Precast concrete elements are manufactured under controlled conditions, allowing for greater precision and consistency in quality compared to traditional cast-in-place methods. This results in structures with higher strength, durability, and resistance to environmental factors such as earthquakes and corrosion. In a country like India, prone to seismic activity in many regions, the structural integrity provided by precast concrete buildings is invaluable.

Sustainability and Environmental Benefits: Precast construction offers environmental advantages, including reduced material wastage, lower energy consumption, and minimized site disturbance. Additionally, the use of recycled materials in precast concrete production further enhances its sustainability credentials. As India endeavors to meet its sustainability goals and reduce carbon emissions, the adoption of precast construction aligns with these objectives.

Cost-Effectiveness: While initial investment in precast manufacturing facilities may be higher, the overall cost savings achieved through reduced construction time, labor expenses, and maintenance requirements make precast construction a cost-effective choice in the long run. Moreover, the scalability of precast production allows for economies of scale, driving down costs further as demand increases.

Key Projects and Initiatives:

Several notable projects across India exemplify the growing trend towards precast construction. From residential complexes and commercial buildings to infrastructure developments, precast concrete is increasingly becoming the material of choice for forward-thinking developers and contractors.

Affordable Housing: Government initiatives such as the Pradhan Mantri Awas Yojana (PMAY) aim to provide affordable housing to all by 2022. Precast construction plays a vital role in realizing this vision by enabling the rapid and cost-effective construction of housing units. Projects like the Dholera Special Investment Region in Gujarat showcase the scalability and efficiency of precast technology in large-scale housing developments.

Infrastructure Development: In infrastructure projects, such as bridges, flyovers, and metro rail systems, precast concrete components offer advantages in terms of speed of construction and minimized disruption to traffic flow. The Mumbai Metro Line 3 project, utilizing precast segments for tunnel lining and station construction, demonstrates the viability of precast technology in major urban infrastructure initiatives.

Future Outlook:

The future of precast construction in India appears promising, with growing awareness of its benefits and advancements in technology driving further innovation. As the industry continues to mature, we can expect to see greater collaboration between stakeholders, improved regulatory frameworks, and increased investment in precast manufacturing facilities. Additionally, innovations such as 3D printing of precast elements and the integration of digital technologies are poised to revolutionize the way buildings are designed and constructed in India.

Conclusion:

Precast houses and precast concrete buildings represent a paradigm shift in the construction industry, offering a sustainable, efficient, and cost-effective alternative to traditional building methods. In India, where rapid urbanization and infrastructure development are placing immense pressure on existing resources, the adoption of precast construction is not just a choice but a necessity. By embracing this innovative approach, India can address its housing shortage, enhance infrastructure resilience, and pave the way for a more sustainable built environment.

#precast homes india#precast houses#precast concrete buildings in india#precast building#precast construction

1 note

·

View note

Text

70 Ton Crane

Unveiling the Power and Versatility of the 70-Ton Crane: A Comprehensive Guide

Introduction

In the world of heavy machinery, cranes stand as towering symbols of power, precision, and efficiency. Among them, the 70-ton crane emerges as a formidable force, capable of tackling a wide array of lifting tasks with ease and finesse. In this comprehensive guide, we delve into the intricacies of the 70-ton crane, exploring its design, functionality, applications, and the myriad benefits it offers to various industries.

Understanding the 70-Ton Crane

At its core, a 70-ton crane is a robust piece of equipment engineered to lift and maneuver heavy loads weighing up to 70 tons. These cranes typically feature a lattice boom design, renowned for its strength-to-weight ratio and ability to extend to impressive heights while maintaining stability. The lattice boom consists of interconnected truss sections, providing the necessary strength to hoist heavy objects with precision.

Power and Performance

One of the defining characteristics of the 70-ton crane is its exceptional power and performance. Equipped with powerful engines and advanced hydraulic systems, these cranes boast impressive lifting capacities coupled with smooth and precise operation. Whether lifting heavy machinery on construction sites or handling oversized cargo at industrial facilities, the 70-ton crane delivers unparalleled performance, making light work of the most challenging lifting tasks.

Versatility Across Industries

The versatility of the 70-ton crane knows no bounds, as it finds application across a diverse range of industries. In the construction sector, these cranes are indispensable for erecting steel structures, placing precast concrete elements, and facilitating the assembly of towering skyscrapers. In the oil and gas industry, they play a vital role in lifting heavy equipment and materials on offshore platforms and in refinery operations. Moreover, the versatility of these cranes extends to infrastructure projects, shipyards, mining operations, and more, highlighting their adaptability to various environments and job requirements.

Advanced Features and Technology

Modern 70-ton cranes are equipped with a host of advanced features and technology, enhancing safety, efficiency, and productivity. From computerized load monitoring systems and precision controls to ergonomic operator cabins with panoramic views, these cranes prioritize user comfort and operational excellence. Additionally, many models feature telescopic booms, allowing for increased reach and flexibility in challenging work environments. With built-in safety features such as overload protection systems and stability controls, operators can work with confidence, knowing that the crane is engineered to prioritize their safety and well-being.

Environmental Considerations

In an era marked by growing environmental consciousness, the 70-ton crane stands out for its commitment to sustainability. Many modern models are designed with fuel-efficient engines and emission-reducing technologies, minimizing their carbon footprint while maximizing operational efficiency. Additionally, the use of recyclable materials in construction and the implementation of eco-friendly practices further underscore the industry's dedication to environmental stewardship.

Training and Certification

Operating a 70-ton crane requires specialized skills and training to ensure safe and efficient operation. Proper training programs, coupled with certification from accredited institutions, are essential for crane operators to gain the necessary knowledge and expertise. These programs cover a wide range of topics, including crane operation, safety protocols, load calculations, and maintenance procedures. By investing in comprehensive training, operators can mitigate risks, prevent accidents, and uphold industry standards of excellence.

Conclusion In conclusion, the 70-ton crane stands as a pinnacle of engineering excellence, combining power, versatility, and advanced technology to meet the evolving needs of various industries. From construction sites to industrial facilities, these cranes play a pivotal role in lifting heavy loads with precision and efficiency. As technology continues to advance and environmental considerations take center stage, the 70-ton crane will undoubtedly evolve to meet the demands of the modern world, reaffirming its status as a cornerstone of heavy lifting operations.

1 note

·

View note

Text

Importance of Tower Crane Hoists

Tower crane hoists play a critical role in the overall functionality and efficiency of tower cranes on construction sites. These hoists are responsible for lifting and moving heavy loads vertically, which is essential for various construction tasks. Here are several key reasons why tower crane hoists are important:

Lifting Heavy Materials: Tower crane hoists are designed to lift heavy materials and equipment to significant heights. This includes construction materials like steel beams, concrete panels, precast elements, machinery, and tools. Without efficient hoisting capabilities, construction progress would be severely limited.

Enhanced Productivity: By efficiently lifting and lowering materials, tower crane hoists contribute directly to increased productivity on construction sites. They streamline the process of moving materials from ground level to elevated positions, reducing the time required for manual handling.

Safety: Tower crane hoists are equipped with safety features to ensure the secure lifting and lowering of loads. Modern hoists are designed with advanced braking systems, overload protection, and fail-safe mechanisms to prevent accidents and ensure worker safety.

Versatility: Tower crane hoists can be adapted to lift different types of loads, ranging from bulk materials like aggregates to delicate components requiring precise positioning. This versatility allows for efficient handling of various construction tasks.

Reach and Height: Tower crane hoists enable construction projects to reach great heights, facilitating the construction of tall buildings and structures. The vertical reach of tower cranes is crucial for assembling high-rise buildings and installing structural components at elevated levels.

Site Accessibility: Tower crane hoists provide access to areas of the construction site that are otherwise challenging to reach. They can transport materials over obstacles or across large distances, optimizing site logistics and workflow.

Cost Efficiency: Tower crane hoists contribute to cost efficiency by reducing labor costs associated with manual material handling. They also help minimize downtime by expediting the movement of materials, tools, and equipment.

Operational Control: Tower crane hoists are operated by skilled personnel who have precise control over lifting operations. This control allows for accurate positioning of loads and ensures operational efficiency.

In summary, tower crane hoists are indispensable components of modern construction projects, enabling efficient lifting, positioning, and transportation of heavy materials and equipment. Their importance extends to improving productivity, enhancing safety, and facilitating the construction of complex structures with vertical reach requirements. Tower crane hoists are essential tools that contribute significantly to the success and efficiency of construction operations.

0 notes

Text

Cap Waterproofing & Drains Servicing In Southern Ontario

The structural integrity of bulkheads and seawalls is crucial for preserving waterfront property. Early detection of points by way of regular inspections, coupled with prompt motion on repairs, can save substantial time and money. We also mentioned Bilco basement doorways and the way installing this watertight possibility will definitely keep your basement freed from leaks and damages. Concrete sealants are another tool to look into, as they are straightforward to make use of and can successfully fill any gaps your basement bulkhead door may have. Soil loss around bulkheads and seawalls is a matter that will get worse.

Another thing you are able to do is to use a sealant across the cracks within the foundation wall. You also can install a gutter system to stop water from entering the basement via the roof. Most bulkheads are connected to a precast set of stairs that lead right into a basement. During the house constructing process, a black rubber seal is put between the inspiration wall and the bulkhead unit. Due to the design of bulkheads, the lack of weight holding them in place, and different components, motion occurs during the winter months and compromises the seal. The water and soils beneath the bulkhead freeze and thaw, causing the unit to move up and down.

Have it checked a couple of occasions in a year, and don’t delay if there are any repairs or replacements needed. There are many ways of preserving your basement dry, and considered one of them is waterproofing the bulkhead door. As explained earlier on this publish, a bulkhead will must be changed when it is worn out. Rust can cause a steel door to corrode creating areas that may allow water leaks, or a wood door can rot making it warp. Install the two bulkhead doors by sliding them into the hinge pins.

Typically, roofing firms may even present waterproofing services. Any plumbing leak, if not mounted in time, can deliver the homeowner lots of problems – from the dysfunction of the entire system to flooding the home. It is impossible to disregard such situations, so finding a certified specialist turns into the primary aim. At Superior Plumbing & Heating, we provide our shoppers a variety of services for every want, together with plumbing leaks repair in Toronto. The longer a leak goes uncontained, the more pervasive and extreme the ensuing moisture injury turns into.

The base soil on the dry side of your bulkhead is needed to supply help in opposition to the body of water pushing in opposition to it. Cavernous subgrades and weak soil can undermine the integrity of a bulkhead and trigger settlement at pedestrian walkways. Keep your waterfront property safe and protect landscaping by addressing soil loss and washout early with URETEK’s waterfront bulkhead repair. Water attacks a bulkhead by way of deteriorated joints, cracks, and repeated wave action like scouring. As water ebbs and flows it reaches into openings and pulls soil out into the bigger physique of water.

We satisfaction ourselves on meticulously examining your property’s soil circumstances and designing an answer that ensures the long-term outcomes that you simply anticipate. Additionally, weep holes are very important for permitting water to seep through the seawall, stopping built-up stress from causing structural failure. It’s necessary to periodically inspect these openings and make sure they’re not obstructed with debris, together with plant matter or sediment, for proper drainage. You can apply this solution with a sprayer or a rolling brush, making it a simple to use solution that won’t change the appearance no matter how you select to apply. This sealant additionally dries clear, making it perfect for those trying to create a more refined look whereas filling in their basement door gaps. Weatherstripping your bulkhead door is amongst the most popular methods to maintain unwanted leaks from build up in your basement.

Some setups use a return pump that is external to the tank and sump. Usually, with an exterior return pump, a bulkhead is used to attach the return pump to the sump by way of plumbing. When you partner with Rescon Basement Solutions for basement waterproofing or repair, you can be certain your project will be handled with the utmost precision and care. All of our solutions are performed by our own team of highly trained technicians, not subcontractors, whose work we backed with a one-year guarantee.

When it involves changing your basement bulkhead, one important issue to consider is the kind of door that most intently fits your needs. There are several forms of basement bulkhead doorways out there in the marketplace, every with its personal unique features and benefits. Every one of our jobs is finished before we move onto one other job. Most bulkhead repairs and replacements may be carried out in a few day’s time.

bulkhead repairs

This works much better than wood as wooden is definitely inclined to damage. Bulkhead seals are a self-lubricating agent that's designed to seal the bulkhead gaps for shafts. The primary objective of the seal is to protect the bulkhead from any kind of dirt leakage or damage so that your tonneau cover stays secure.

This gap seems automatically after installing the quilt as a result of drop of the bed liner. We have over 50 years of basis repair expertise and an impeccable status. Our aim is to make your project as seamless and headache-free as potential. We could have already carried out that very same concrete raising & leveling service for another person and simply not added it to our web site yet. At CAP Waterproofing & Drains we offer a extensive range of services suit your wants in business,iIndustrial and residential. Start your project at present & contact CAP Waterproofing & Drains.

#bulkhead waterproofing#bulkhead waterproofing repairs#bulkhead waterproofing repair services#bulkhead leak repair solutions#bulkhead repairs#bulkhead repair services#bulkhead fixing

1 note

·

View note

Text

Brick and Block Renovation Services in Cleveland Build Your Dream House

Brick and block restorations are timeless markers of quality and dependability in the building and home improvement industries. These adaptable materials provide a strong basis for altering rooms and realizing architectural aspirations in both historical sites and contemporary homes. We'll go into the realm of Brick and block renovations Gold Coast services in this blog, examining the knowledge, ingenuity, and commitment that go into these life-changing endeavors.

Craftsmanship and skill

A strong dedication to craftsmanship and skill is the foundation of our brick and block restoration services. Years of expertise and experience are brought to every project by talented masons and artisans, guaranteeing accuracy and excellence in every little detail. These experts have the know-how to manage a wide range of restorations with grace and proficiency, whether they're renovating historic structures with delicate brickwork or updating interiors with sleek block accents. The precise execution of every rehabilitation operation, from cutting blocks to laying bricks, from fixing mortar seams to strengthening buildings, demonstrates their attentive attention to detail.

Customized Solutions for Every Project

Brick and block restoration services by Brick Manufacturer in Gold Coast provide customized solutions to satisfy the particular requirements and tastes of every customer and project. When it comes to home remodeling, business restoration, or industrial refurbishment, skilled contractors work together with customers to comprehend their goals, constraints, and schedule. Every stage of the remodeling process, from original idea creation to final implementation, is meticulously planned and carried out to guarantee the best possible outcomes. These services are focused on providing revolutionary solutions that go above and beyond, whether it's improving curb appeal with a new brick facade, designing unique interior elements with ornamental blocks, or maximizing energy efficiency with insulated concrete blocks.

New Materials and processes

To improve effectiveness, sustainability, and performance, Brick and block renovations Gold Coast services are always utilizing new materials and processes. Modern building techniques, such modular brick systems and precast concrete blocks, speed up installation and cut down on building expenses and time. In addition, the use of energy-efficient components like high-performance brick veneers and insulated concrete blocks enhances the thermal efficiency and sustainability of refurbished buildings. Renovating services make sure they can provide clients with state-of-the-art solutions that seamlessly blend aesthetic appeal and functional excellence by keeping up with the most recent trends and advances in the business.

0 notes

Text

Precast Walls Prices in Hyderabad: A Comprehensive Guide

Introduction to Precast Walls

At Hyderabad Builders we apprehend the significance of precast partitions in building projects. Whether you are a house owner searching to decorate your property's aesthetics or a developer aiming for reasonably-priced and environment friendly solutions, precast partitions provide severa benefits. In this complete guide, we delve into the intricacies of precast walls Prices in Hyderabad, exploring their advantages, fee factors, and issues for selecting the proper choice for your needs.

Understanding Precast Walls

Precast partitions are prefabricated concrete factors manufactured off-site and transported to the building web site for installation. These partitions are forged in a managed environment, permitting for unique fantastic manipulate and customization in accordance to assignment specifications. With Hyderabad Builders you can assume premium-quality precast partitions tailor-made to your requirements.

Advantages of Precast Walls

Durability and Strength

One of the main benefits of precast partitions is their splendid sturdiness and strength. Constructed with awesome substances and bolstered with steel, precast partitions provide highest quality structural integrity, making sure durability and resilience in opposition to environmental factors.

Time and Cost Efficiency

By opting for precast walls, you can drastically limit building time and costs. Since these partitions are manufactured off-site, they reduce on-site labor necessities and speed up the development process. Additionally, the streamlined manufacturing system interprets to price financial savings except compromising on quality.

Versatility in Design

With precast walls, you have the flexibility to pick from a huge vary of designs, textures, and finishes to complement your architectural vision. Whether you pick a glossy present day aesthetic or a rustic appeal, Hyderabad Builders provides customizable options to go well with your fashion preferences.

Factors Influencing Precast Wall Prices in Hyderabad

Material Quality

The high-quality of substances used in precast wall manufacturing without delay influences the standard cost. At Hyderabad Builders we prioritize the usage of premium-grade concrete and metal reinforcements to make certain the best requirements of exceptional and durability.

Design Complexity

The complexity of the design, along with complex patterns, textures, and extra features, can impact the pricing of precast walls. Our group of skilled specialists collaborates with purchasers to create custom-made designs whilst optimizing cost-efficiency.

Installation Requirements

Factors such as website online accessibility, transportation logistics, and set up complexity can have an effect on the typical price of precast walls. With Hyderabad Builders you can believe our environment friendly set up system to decrease disruptions and maximize cost-effectiveness.

Quantity and Scale

The quantity of precast partitions required for your challenge and the scale of building play a large position in identifying the pricing. Hyderabad Builders affords aggressive pricing applications for initiatives of all sizes, making sure affordability besides compromising on quality.

Choosing the Right Precast Wall Solution

When deciding on precast partitions for your project, it is necessary to think about a number of elements to make an knowledgeable decision. At Hyderabad Builders our crew gives specialist education and help at some point of the choice process, making sure that you pick the most useful answer tailor-made to your precise desires and budget.

Conclusion

In conclusion, Hyderabad Builders affords premium-quality precast partitions in Hyderabad, tailor-made to meet the various desires of our clients. With a center of attention on durability, affordability, and diagram versatility, we attempt to supply excellent cost and pleasure with each project. Contact us nowadays to examine greater about our precast wall options and take the first step closer to reworking your building imaginative and prescient into reality

0 notes

Text

Magnetic Coil Loop & Locator Magnets

Magnetic Coil Loop & Locator Magnets

Magnetic Coil Thread & Ferrule Locators

Magnetic Coil Thread Protectors & Magnetic Ferrule Locators are made with a threaded steel stud. The base contains a strong neodymium magnet encased in a urethane shell. The base has a square recess machined into it to accommodate a 1/2″ ratchet driver for easy removal from concrete. Custom threading & stud lengths are…

View On WordPress

#Coil Loop Protector Magnet#concrete formwork magnets#Flat Base Magnet#Insert magnets#Magnet for Precast Formwork#Magnetic Coil Loop Inserts#Magnetic Coil Thread Protector#Magnetic Conduit Locators#Magnetic Ferrule Locators#Magnetic Formwork System#Magnetic PVC Locators#Precast concrete components#Precast Concrete Magnetic Formwork#precast concrete system#precast magnets#Radius Base Magnet#shuttering system

1 note

·

View note

Text

TMT Bars: Key to Sustainable & Energy-Efficient Buildings

Sustainable Steel, Sustainable Future: TMT Bars & Energy Efficiency

In recent years, there has been a growing emphasis on sustainability in the construction industry. As the world faces environmental challenges, it has become crucial to adopt practices that reduce the carbon footprint and promote energy efficiency in building projects. One essential component of sustainable construction is the use of high-quality TMT (Thermo-Mechanically Treated) bars. In this article, we will explore the significance of TMT bars in sustainable construction and the contributions of TMT Bars Manufacturers in Tamilnadu towards this endeavour.

Beyond Strength: The Link Between TMT Bars and Energy Efficiency

TMT bars, short for Thermo Mechanically Treated bars, are a type of steel reinforcement used extensively in construction. Traditionally known for their strength and durability, TMT bars from reputed manufacturers in Tamil Nadu offer an unexpected benefit: they contribute significantly to energy-efficient buildings.

Significance of Sustainable Buildings:

Sustainable buildings are designed to minimize their environmental impact throughout their lifecycle, from construction to operation and eventual demolition. These buildings incorporate eco-friendly materials, energy-efficient systems, and innovative design strategies to reduce energy consumption, conserve resources, and promote occupant well-being. By embracing sustainable practices, buildings can lower greenhouse gas emissions, improve indoor air quality, and mitigate the depletion of natural resources.

Contribution of TMT Bars to Sustainable Construction:

TMT bars are a critical component of reinforced concrete structures, providing strength and durability to buildings. However, their importance extends beyond structural support. TMT bars can contribute to sustainability in several ways:

Efficient Material Usage: TMT bars from reputable Tamil Nadu manufacturers boast higher strength and ductility, requiring fewer bars for the same integrity. This reduces material consumption and lowers the carbon footprint.

Energy-efficient Design: TMT bars enable longer spans and slimmer structural elements, facilitating open floor plans and maximizing natural light. Innovative techniques like precast concrete and modular construction further reduce energy consumption during building.

Durability and Longevity: Highly resistant to corrosion and fatigue, TMT bars ensure the longevity of reinforced concrete structures. Buildings constructed with TMT bars need less maintenance, reducing resource-intensive repairs and renovations and minimizing waste generation.

Recyclability: Made from recycled scrap steel, TMT bars are a sustainable choice. At the end of their service life, they can be easily recycled and reused, contributing to the circular economy and minimizing waste.

TMT Bars Manufacturers in Tamil Nadu:

Tamil Nadu is home to several leading TMT bar manufacturers known for their commitment to quality, innovation, and sustainability. These manufacturers employ advanced manufacturing processes, stringent quality control measures, and sustainable production practices to produce TMT bars that meet international standards and exceed customer expectations. By prioritizing eco-friendly materials, energy-efficient technologies, and responsible manufacturing practices, TMT bars manufacturers in Tamil Nadu are driving the transition towards sustainable construction in the region.

Continuous Innovation:

To meet the evolving needs of the construction industry and address emerging challenges, TMT bars manufacturers in Tamil Nadu invest in research and development initiatives aimed at innovation and improvement. Through ongoing research, these manufacturers explore new materials, technologies, and manufacturing processes to enhance the performance, durability, and sustainability of TMT bars. By embracing innovation, TMT bars manufacturers drive progress and promote the adoption of sustainable construction practices across the industry.

Collaboration and Knowledge Sharing:

TMT Bars Manufacturers in Tamilnadu actively collaborate with architects, engineers, builders, and other stakeholders to promote knowledge sharing and best practices in sustainable construction. Through seminars, workshops, and training programs, these manufacturers educate industry professionals about the benefits of sustainable building materials and techniques, encouraging widespread adoption and implementation. By fostering collaboration and knowledge sharing, TMT bars manufacturers contribute to the collective effort towards a more sustainable built environment.

Assessing the Environmental Impact:

TMT bars are instrumental in mitigating the environmental impact of construction endeavours. Through streamlined structural design and reduced material consumption, builders effectively lower the carbon footprint linked with manufacturing, transporting, and installing construction materials. Furthermore, the durability and lasting performance of buildings erected with premium TMT bars aids in conserving natural resources, curtailing the necessity for demolition and subsequent reconstruction efforts.

Building a Greener Future: The Ripple Effect of Sustainable TMT Bars

The benefits of using sustainable TMT bars from Tamil Nadu extend beyond the building itself:

Reduced Greenhouse Gas Emissions: By promoting energy efficiency and minimizing the need for reconstruction, sustainable TMT bars contribute to a reduction in greenhouse gas emissions, helping combat climate change.

Resource Conservation: The use of recycled content and energy-efficient production processes associated with sustainable TMT bars manufactured in Tamil Nadu helps conserve valuable natural resources.

Promoting a Sustainable Construction Ecosystem: The growing demand for sustainable TMT bars incentivizes the construction industry to adopt environmentally friendly practices throughout the entire building lifecycle.

TMT bars are more than just structural components; they are essential building blocks for sustainable and energy-efficient buildings. By choosing high-quality TMT Bars Manufacturers in Tamilnadu, builders and developers can create structures that not only withstand the test of time but also minimize their environmental footprint and contribute to a greener, more sustainable future.

0 notes

Text

youtube

Watch the American Climate Leadership Awards 2024 now: https://youtu.be/bWiW4Rp8vF0?feature=shared

The American Climate Leadership Awards 2024 broadcast recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by active climate leaders. Watch to find out which finalist received the $50,000 grand prize! Hosted by Vanessa Hauc and featuring Bill McKibben and Katharine Hayhoe!

#ACLA24#ACLA24Leaders#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental justice#environment protection#environmental health#Youtube

14K notes

·

View notes

Text

Understanding The Pressure And Loads On Concrete Formworks

In the realm of construction, concrete formwork plays a crucial role in shaping the structural integrity of buildings. However, understanding the pressure and loads exerted on formworks is imperative to avoid structural failures. Let's delve into the intricacies of calculating concrete pressure on formwork and navigating the various loads encountered during construction.

Calculating Concrete Pressure on Formwork:

To calculate concrete pressure on formwork, a precise formula is utilized: P = (hC) / A, where P represents the pressure in kN/m², h denotes the height of concrete in meters, C signifies the unit weight of concrete in kN/m³, and A represents the contact area of formwork in m². This formula serves as a vital tool in ensuring the stability and integrity of formworks under varying concrete heights and densities.

Understanding Formwork Loads:

Two primary types of loads are encountered during concrete formwork: Form Dead Loads and Form Live Loads. Form Dead Loads encompass the actual weight of forms along with the weight of fresh concrete. On the other hand, Form Live Loads include the weight of workers, equipment, and material storage. It's essential to consider these loads meticulously to ensure the structural integrity of formworks throughout the construction process.

Managing Concrete Height and Pressure:

The pressure exerted by concrete on formwork increases proportionally with the height of the formwork. For instance, pouring a 25-meter high wall entails significantly higher pressure compared to a 5-meter high wall. Understanding this correlation is paramount in designing formworks capable of withstanding varying concrete heights and pressures effectively.

Determining Form Pressure:

To design formworks effectively, it's crucial to determine the appropriate form pressure based on the rate of placement and concrete temperature during placement. Utilizing formulas or referencing tables can aid in determining the base value for lateral pressure, ensuring optimal formwork design and stability.

Mastering the intricacies of concrete formwork involves a comprehensive understanding of pressure and loads encountered during construction. By accurately calculating concrete pressure on formwork and considering formwork loads, builders can design and implement robust formwork systems that withstand the rigors of construction with ease. Whether it is basic to complex construction, modular to precast formwork system, or even just concrete slab drains, Nova formworks have mastered it all. Embrace the science behind formwork design and unlock the potential for safe and efficient construction practices with Nova.

0 notes

Text

Enhancing Infrastructure with Concrete Kerbs: The Foundation of Safe and Structured Roads

In the bustling network of roads and footpaths that crisscross our urban landscapes, there exists a crucial yet often overlooked element: concrete kerbs. These unassuming barriers play a vital role in delineating walkways from the rest of the road, providing structure, safety, and guidance to both pedestrians and motorists alike. At SVC, we understand the importance of concrete kerbs in enhancing infrastructure, and we're committed to providing high-quality solutions that meet the diverse needs of modern cityscapes.

Defining Boundaries:

Concrete kerbs serve as the silent sentinels of our streets, defining boundaries and guiding the flow of traffic with precision and efficiency. Whether it's separating sidewalks from roadways, directing water runoff to drainage systems, or providing a barrier between different sections of the road, these humble structures play a critical role in maintaining order and safety in our urban environments.

Ensuring Safety:

One of the primary functions of concrete kerbs is to enhance safety for pedestrians and motorists alike. By clearly delineating the edges of walkways and roadways, kerbs help prevent accidental veering off the road or sidewalk, reducing the risk of collisions and accidents. Additionally, they provide a visual and physical barrier, helping to keep pedestrians safe from vehicular traffic and vice versa.

Promoting Accessibility:

Concrete kerbs also play a vital role in promoting accessibility for individuals with mobility challenges. By providing a distinct edge to sidewalks, kerbs help wheelchair users and pedestrians with limited mobility navigate city streets with greater ease and confidence. Accessible infrastructure is not just a matter of convenience; it's a fundamental aspect of creating inclusive communities where everyone can participate fully in public life.

Custom Solutions from SVC:

At SVC, we understand that every urban environment is unique, with its own set of challenges and requirements. That's why we offer a range of concrete kerbs designed to meet the diverse needs of modern cityscapes. From standard straight kerbs to radius kerbs, sloped kerbs, and more, we provide custom solutions tailored to fit the specific demands of each project.

Building the Foundations of Tomorrow:

As cities continue to grow and evolve, the importance of well-designed infrastructure becomes increasingly apparent. Concrete kerbs may seem like small, insignificant elements of urban design, but in reality, they form the foundation upon which safe, structured, and accessible roads and footpaths are built. At SVC, we're proud to play a part in shaping the future of our cities by providing high-quality concrete kerbs that enhance the functionality, safety, and beauty of urban landscapes.

Contact-

Web - https://svc.com.au/products/civil/kerbing/

Mail - [email protected]

Ph - 1300 287 782

Address - 38 Japaddy Street,Mordialloc VIC 3195 AU

concrete kerbs, precast concrete kerbs, precast concrete

0 notes

Text

Talking about construction techniques and counts concrete is fine but it waste too much it's the biggest problem is it's weight it's too heavy and it will crush people but something happens I've seen lightweight panels be pushed off by fat middle-aged women when they're juiced out they get adrenaline and push it off it's not that heavy and those panels meet like are 13 which is Arizona and you put like a handle board on the inside and it has a seam but it's like a it's like one of those wallboard systems that you don't see the seam as much as a closure piece it snaps in that's really what you want is this other stuff is such a pain and you put all the stuff in the ceiling the wall outlets that's a an issue but they make them that are shallow and you run them down in a channel you make in the back of the panel believe it or not it look like 3/4 an inch they stick out a quarter but the cover covers that it's a little fashioned but it works and that system is very fast they use it in Arizona there's no reason to change it's precast and you go down there and you make your own plants and you take the land tons of land just required and you can make tons and tons of forms it's all sand if you can do it out in the sands and you can just shade it it's really not hard and just massive amounts of area can be used for panels you can stack them like a son said you just stick them up there and that's controlled in like huge huge warehouses that are like 10 stories high with huge racks and all modular you cast the foundations and you come back in a day and you put all the walls up and sometimes they can start the roof and they do trusses in their wood and some people put some steel in or cable we like to put a cabling and you can see it a lot of people do and they tie the roof down too with cables and to the concrete and it's really nice and it supports itself no they're bolted together and you have pieces that come off in an angle in that supports it and you have to prep for it to hook into the floor and they're very solid they're insulated they have a ton of strength and their bullet resistant 50 caliber bullet we'll go through the first layer and stop the second from 200 yards and nothing will do that and that's a copperhead and that's against The accidental and the roof is concrete slate usually and you can make factories now there's no reason you can't and to build a house now to take a month because we have to get the precast going so while you're there you start to precast you can build out of wood those will take a couple weeks you know they gain a couple weeks literally cuz the precast is so damn fast it really is ridiculous it just goes up and it's done and it's all measured and laid out in numbers you just bolts it all together and some welding it is so darn fast and the interior positions are metal they're just much straighter and easier to put up and use the panels 6 minutes versus hours I'll tell you this is the way to go utilities come to the floor or the ceiling air and electric through the ceiling usually water sewer through the floor and it's all in before the panels around it's real fast very very fast but right now wood is required or you're going to move something out there and yeah a continuous petrified wood and it's now extremely hard Stone ship that was made and then submers and became petrified and it's real old is extremely hard and a very big over 20 miles long and we know what it's for

Thor Freya

We're going to go on and start getting ready for the next phase of the operation and for tomorrow I'm very happy with what's going on and with my husband's who's helping me and holding me like you always tell us but he always does and yeah you tell us but I didn't say that so someone of ours did which is good and I'm very thankful for what he's been doing I like it

Hera

He helped him with the planet selection but he said this one here because it's iron and eventually they're going to need it and he said that and I get record of it and you'll remember

Thor Freya

I love him and it's because it's smaller and they're not going there yet cuz they're fighting over it this is great

Hera

We have a lot to talk about but this Phoenix project is going to save a lot of problems and headaches there's a whole bunch of products that are going to come out of there there's going to be a ton of vehicles and we need all of them and he's got a Baja car and that's Jack Black and he loves the damn thing and he's going to name it blackjack and he said you should make like a whiskey so he's suddenly decided something he's going to make a whiskey and a racing team and the vehicle it really works and boy that thing's going to fly it already does he made one and it worked the idea and he's going to start selling them and they're for the road or off road and it's a wonderful idea so we're getting ready to start working and these people are going to come up with businesses and the other groups too are going to be around there doing the same thing

Thor Freya

I usually helping in some way but Trump is turned into a booger snot and people keep telling him it's not big enough it's the empire was taken over which they are they'll have like five trillion ships and he golfs and he says oh no and we're going to hand it over trapped and stuff and he says yeah and it probably infiltrate using your method you got grossed out he has to check and it's gross. But this will get us hope we needed it bad and I can make the precast company and it says I should start and would frame for now and big apartments too out of both I'm trying my wood technique and you'll think that I knew what I was doing as a carpenter really I learned a lot from your father that's good to know and this technique you'll probably stop harassing me if he sees it to work and you will too if something to do like it cuts the time because you can either build it there and fly it up it cuts the time into like 1:30 and you can remember the condos I remember those you'll find it up and it was Houston and took a little longer but they had like the whole thing done before we're done the finishing and it only takes us like 3 or 4 days and now I understand what you're saying

Jack Black

Olympus

0 notes

Text

Supplier of Paver Tiles Making Machines in Madhya Pradesh

Akshar Precast Industries is a Manufacturer, Exporter, and Supplier of Paver Tiles Making Machines in Madhya Pradesh, India.

Akshar Precast Industries was founded in 2018. We are a prominent manufacturer specializing in semi-automatic fly ash brick machines, manual brick making machines, block making machines, paver block vibrating tables, cement brick making machines, and more.

The machinery used to manufacture paver tiles, which are concrete or clay tiles for outdoor surfaces.

These machines typically involve processes such as mixing raw materials, molding tiles into shape, and curing them to achieve strength and durability.

Paver Tiles Making Machines vary in size and complexity, ranging from manual or semi-automatic machines suitable for small-scale production to fully automated systems capable of high-volume manufacturing.

Applications:

Construction industry staple

Produces versatile pavers

Ideal for outdoor surfaces

Advantages:

Enhances production efficiency

Ensures consistent product quality

Lowers labor costs

Akshar Precast Industries is a Manufacturer and Supplier of Paver Tiles Making Machines in Madhya Pradesh and places like Bhopal, Jabalpur, Gwalior, Ujjain, Sagar, Dewas, Satna, Ratlam, Rewa, Katni, Singrauli, Burhanpur, Khandwa, Bhind, Chhindwara, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori.

Please get in touch with us if you would want further information.

Read the full article

#AksharPrecastIndustries#Betul#bhind#Bhopal#BlockMakingMachines#Burhanpur#CementBrickMakingMachines#Chhatarpur#Chhindwara#ConstructionIndustry#damoh#Datia#Dewas#Exporter#FlyAshBrickMachines#guna#Gwalior#itarsi#Jabalpur#katni#khandwa#Khargone#LaborCosts#MadhyaPradesh#Mandsaur#ManualBrickMakingMachines#Manufacturer#Morena#Nagda#Narmadapuram

0 notes

Text

youtube

Watch the 2024 American Climate Leadership Awards for High School Students now: https://youtu.be/5C-bb9PoRLc

The recording is now available on ecoAmerica's YouTube channel for viewers to be inspired by student climate leaders! Join Aishah-Nyeta Brown & Jerome Foster II and be inspired by student climate leaders as we recognize the High School Student finalists. Watch now to find out which student received the $25,000 grand prize and top recognition!

#ACLA24#ACLA24HighSchoolStudents#youtube#youtube video#climate leaders#climate solutions#climate action#climate and environment#climate#climate change#climate and health#climate blog#climate justice#climate news#weather and climate#environmental news#environment#environmental awareness#environment and health#environmental#environmental issues#environmental education#environmental justice#environmental protection#environmental health#high school students#high school#youth#youth of america#school

15K notes

·

View notes