#water recycling

Text

"Namibia is the driest country in Sub-Saharan Africa, and home to two of the world’s most ancient deserts, the Kalahari and the Namib. The capital, Windhoek, is sandwiched between them, 400 miles away from the nearest perennial river and more than 300 miles away from the coast. Water is in short supply.

It’s hard to imagine life thriving in Windhoek, yet 477,000 people call it home, and 99 per cent of them have access to drinking water thanks to technology pioneered 55 years ago on the outskirts of the city. Now, some of the world’s biggest cities are embracing this technology as they adapt to the harshest impacts of climate change. But Namibia leads the way.

How did this come about? In the 1950s, Windhoek’s natural resources struggled to cope with a rapidly growing population, and severe water shortages gripped the city. But disaster forced innovation, and in 1968 the Goreangab Water Reclamation Plant in Windhoek became the first place in the world to produce drinking water directly from sewage, a process known as direct potable reuse (DPR).

That may sound revolting, but it’s completely safe. Dr Lucas van Vuuren, who was among those who pioneered Windhoek’s reclamation system, once said that “water should not be judged by its history, but by its quality”. And DPR ensures quality.

This is done using a continuous multi-barrier treatment devised in Windhoek during eight years of pilot studies in the 1960s. This process – which has been upgraded four times since 1968 – eliminates pollutants and safeguards against pathogens by harnessing bacteria to digest the human waste and remove it from the water. This partly mimics what happens when water is recycled in nature, but Windhoek does it all in under 24 hours...

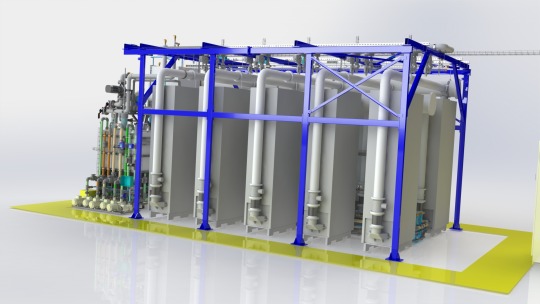

Pictured: These ultrafiltration membranes help to remove bacteria, viruses and pathogens. Image: Margaret Courtney-Clarke

“We know that we have antibiotics in the water, preservatives from cosmetics, anti-corrosion prevention chemicals from the dishwasher,” Honer explains. “We find them and we remove them.”

Honer adds that online instruments monitor the water continuously, and staff ensure that only drinking water that meets World Health Organisation (WHO) guidelines is sent to homes. If any inconsistencies are detected, the plant goes into recycle mode and distribution is halted until correct values are restored.

“The most important rule is, and was, and always will be ‘safety first’,” says Honer. The facility has never been linked to an outbreak of waterborne disease, and now produces up to 5.5m gallons of drinking water every day – up to 35 per cent of the city’s consumption.

Namibians couldn’t survive without it, and as water shortages grip the planet, Windhoek’s insights and experience are more important than ever.

Interest from superpowers across the globe

In recent years, delegations from the US, France, Germany, India, Australia, Singapore, and the United Arab Emirates have visited Windhoek seeking solutions to water shortages in their own countries.

Megadrought conditions have gripped the US since 2001, and the Colorado River – which provides 40 million people with drinking water – has been running at just 50 per cent of its traditional flow. As a result, several states including Texas, California, Arizona and Colorado are beginning to embrace DPR.

Troy Walker is a water reuse practice leader at Hazen and Sawyer, an environmental engineering firm helping Arizona to develop its DPR regulations. He visited Windhoek last year. “It was about being able to see the success of their system, and then looking at some of the technical details and how that might look in a US facility or an Australian facility,” he said. “[Windhoek] has helped drive a lot of discussion in industry. [Innovation] doesn’t all have to come out of California or Texas.”

Pictured: The internal pipes and workings of Namibia's DPR plant. As water becomes scarcer in some parts, countries are looking to DPR for solutions. Image: Margaret Courtney-Clarke

Namibia has also helped overcome the biggest obstacle to DPR – public acceptance. Disgust is a powerful emotion, and sensationalist ‘toilet to tap’ headlines have dismantled support for water reuse projects in the past. Unfortunately, DPR’s biggest strength is also its biggest weakness, as the speed at which water can re-enter the system makes it especially vulnerable to prejudice, causing regulators to hesitate. “Technology has never been the reason why these projects don’t get built – it’s always public or political opposition,” says Patsy Tennyson, vice president of Katz and Associates, an American firm that specialises in public outreach and communications.

That’s why just a handful of facilities worldwide are currently doing DPR, with Windhoek standing alongside smaller schemes in the Philippines, South Africa and a hybrid facility in Big Spring, Texas. But that’s all changing. Drought and increased water scarcity worldwide are forcing us to change the way we think about water.

Now, the US is ready to take the plunge, and in 2025, El Paso Water will begin operating the first ‘direct to distribution’ DPR facility in North America, turning up to 10m gallons of wasterwater per day into purified drinking water – twice as much as Windhoek. San Diego, Los Angeles, California, as well as Phoenix, Arizona are also exploring the technology."

Of course, DPR is not a silver bullet in the fight against climate change. It cannot create water out of thin air, and it will not facilitate endless growth. But it does help cities become more climate resilient by reducing their reliance on natural sources, such as the Colorado River.

As other nations follow in Namibia’s footsteps, Windhoek may no longer take the lead after almost six decades in front.

“But Windhoek was the first,” Honer reminds me. “No one can take that away.”"

-via Positive.News, August 30, 2023

#namibia#africa#desert#water shortage#water conservation#dpr#potable water#water recycling#clean water#drought#united states#colorado river#science and technology#sanitation#good news#hope

2K notes

·

View notes

Text

article pic: A rooftop wetland on the Salesforce Transit Center in San Francisco filters wastewater from sinks and showers for reuse.

#good news#nature#science#climate change#environmentalism#environment#conservation#waste water treatment#water#water reuse#water recycling

88 notes

·

View notes

Text

#sustainability#climate change#footprints#save water#conservation#sustainableenergy#renewableenergy#plants#waterfootprint#watertrade#water recycling#reuse water#water conservation

0 notes

Text

small-scale desalination

MIT makes some bold claims for a cheap, small scale desalination system.

The researchers estimate that if the system is scaled up to the size of a small suitcase, it could produce about 4 to 6 liters of drinking water per hour and last several years before requiring replacement parts. At this scale and performance, the system could produce drinking water at a rate and price that is cheaper than…

View On WordPress

1 note

·

View note

Video

Have a cool factory tour with us, fascinating rainwater harvesting modular tank workshop

#rainwatercollecting#rainwatertank#rainwaterharvesting#rainwatercollection#rainwater barrel#rainwater harvesting#rainwater collection#water storage tanks#water storage#water recycling#water reuse#sewage#sewage treatment#sewarage#sewerage system#rainwater pool#rainwater pond#underground pond#drain water#drainage#modular tank#tank modules#factory tour#workshop tour#factory direct#underground pool#green projects

0 notes

Text

Cuidado del agua

El desperdicio de agua es actualmente uno de los mayores problemas de la sociedad, principalmente en las grandes urbanizaciones. De acuerdo con un informe de Unicef de 2019, uno de cada tres personas en el mundo no tiene acceso al agua potable; en tanto, mil niños perecen todos los días por la falta del recurso.

Aquí la pregunta como ahorrar y salvar el agua. Cuidar el agua es responsabilidad de todos, por eso te invitamos a que atiendas las siguientes recomendaciones para un mejor uso y aprovechamiento del vital liquido. Además estos consejos te pueden ser de utilidad no sólo para el cuidado del agua, sino también del medio ambiente y la economía familiar.

¿Como ahorrar agua?

Lavabo

Mientras te lavas, no dejes correr el agua, coloca un tapón en el lavabo y llénalo.

Cierra la llave del agua mientras te cepillas los dientes; de esta manera, una familia de cinco personas puede ahorrar hasta 40 litros de agua al día.

Enjuaga y limpia tu navaja de afeitar en un recipiente, no lo hagas con agua corriente.

Escusado

Procura instalar escusados de bajo consumo, éstos emplean 6 litros por descarga.

Vigila periódicamente el estado de tu escusado, para que no haya derrames o fugas.

Acumula varias descargas antes de tirar el agua.

Regadera

Toma duchas más breves y cierra las llaves mientras te enjabonas o aplicas champú.

Aprovecha el agua que al principio sale fría, en lo que se calienta. Puedes acumularla fácilmente en una cubeta y utilizarla después en el escusado, o para lavar, regar, etc.

Si el agua tarda mucho en salir caliente, es mejor cambiar la colocación del calentador o aislar térmicamente la tubería.

Instala algunos de los dispositivo ahorradores de agua que existen en el mercado.

Fregadero

No permitas goteo al cerrar las llaves, remplaza los empaques cada vez que sea necesario.

Remoja y enjabona todo de una vez, sin tener la llave abierta y sólo ábrela para el enjuague final.

Instala un "aereador", es un dispositivo barato y fácil de colocar. Así ahorrarás bastante agua.

Para hacer cubos de hielo, usa moldes o charolas de plástico flexibles, lo que te permitirá removerlos con facilidad sin tener que ponerlos bajo la llave del agua para despegarlos.

Al lavar verduras usa un recipiente lleno y lava de una vez todas las que vas a limpiar. Si las lavas en el fregadero, coloca el tapón.

Usa poca agua para cocinar verduras. El sabor y el valor nutritivo se pierden junto con el agua.

No tires el agua que utilizaste para cocer vegetales. Con ella puedes preparar sopas.

Lavadora

Talla a mano las partes muy sucias para evitar dobles o triples lavados.

Usa la lavadora de ropa sólo con cargas completas, a menos que tenga ajustes para usar menos agua.

Si el agua del enjuague final no contiene detergente se puede utilizar para regar, lavar, etc.

Jardín

Riega sólo cuando sea necesario. Hazlo muy temprano o después de que se ponga el sol, para evitar la evaporación.

Riega justo de manera que el agua alcance a infiltrarse hasta las raíces de las plantas.

Aprovecha el agua de lluvia diseñando captaciones adecuadas. Esta es la mejor agua para las plantas.

Reduce la evaporación del riego cubriendo el suelo del jardín con tierra de hojas.

Reutiliza el agua de la tina y del lavado de tinacos, en el riego del jardín, limpieza de pisos, etc.

Al regar con aspersores, ubícalos y ajusta los grados de giro para no regar partes pavimentadas o que no lo necesiten.

Emplea mangueras con boquilla ajustable y si las dejas solas usa un sistema de control por tiempo.

En época de estiaje corta el pasto pero no lo barras, esto evita la evaporación.

No cortes el pasto muy al ras. La altura conveniente es entre 5 y 8 cm. para contribuir a que las raíces se mantengan sanas, permitir que el suelo tenga sombra natural y retener la humedad.

En época de sequías no desperdicies agua en el pasto que se puso amarillo, está inactivo y revivirá cuando haya lluvia normal.

Tinacos y cisternas

Desinféctalos y límpialos periódicamente. Normalmente no hay necesidad de vaciarlos para este tipo de operaciones, tal como sucede con las albercas.

Automóviles

Usa cubeta y jerga en lugar de manguera para no desperdiciar agua cada que limpias el auto.

Apoya el desarrollo de servicios públicos de lavado que “rehusan” el agua. Esto quiere decir que utilizan agua tratada.

Recomendaciones generales

Repara o reporta cualquier fuga que observes en la casa, calle u oficina.

Promueve productos y emplea procesos industriales que no propicien la deforestación de bosques, para evitar erosiones del terreno y preservar la recarga de agua al subsuelo.

Vigila que las llaves de agua queden siempre bien cerradas después de usarlas.

1 note

·

View note

Text

"...this unit, called a OneWater System, will be installed in the basement, where its collection of pipes will take in much of the hotel’s graywater — from sinks, showers, and laundry. The system will clean the water with membrane filtration, ultraviolet light, and chlorine, and then send it back upstairs to be used again for nonpotable uses.

And again. And again."

#Yale 360#Yale E360#Yale Climate Connections#Extreme Water Recycling#Grey Water#Graywater#water recycling

0 notes

Text

Water Recycling in Sun Valley

Jose Mier Takes a Look at Conservation Efforts

Jose Mier is concerned about his hometown, Sun Valley, CA when it comes to water usage and recovery. Cities like Sun Valley are implementing various methods to recycle water. Here are some common approaches:

Greywater Recycling: Greywater, which is wastewater generated from activities like bathing, laundry, and dishwashing, can be treated and…

View On WordPress

0 notes

Text

With Ecostill, TMW wants to decarbonise the treatment of industrial effluents

Located in Maine-et-Loire, TMW is raising one million euros to accelerate the development of its Ecostill technology. A process that makes it possible to recycle 90% of the water from hazardous industrial liquid effluents.

The specialist in the treatment of industrial effluents TMW[1] completes a fundraising of one million euros, carried out with the investment fund management company Go Capital[2]. This round table should support the Maine-et-Loire company in the technological and commercial development of Ecostill[3], a solution dedicated to reducing CO2 emissions linked to transport and the elimination of the most harmful water from industrial processes.

“This process developed by TMW is in fact able to concentrate the most dangerous liquid effluents and to recycle 90% of the water they contain, thus making it possible to reduce the volumes of industrial water to be transported to regain control on their liquid effluents (liquid waste or sewage discharged into a river or the sea). By internalizing the management of their effluents, manufacturers can enter the era of the circular economy, by closing the cycles of water and energy”, emphasizes Guillaume Bourtourault, President of TMW.

At TMW, MHD technology is decreasing in power and increasing in volume!…

Since 2012, TMW has marketed evaporation plants, under the ECOSTILL brand, based on the principle of evaporation at atmospheric pressure and low temperature (principle of the natural water cycle).

The company has focused its commercial action on industrial customers generating effluents that are often aggressive, even toxic and dangerous. By evaporation, ECOSTILL enables them to reduce their volume of effluent to be treated, and thus to be consistent with the European "Zero Liquid Waste"[4] directive, while providing them with a significant reduction in the costs associated with it, which can reach 90 to 95%. Thus, since the beginning of the marketing of its technology in 2012, companies such as CANON, SPI AERO[5], SPAMA[6], ALFA LAVAL[7], to name a few, have equipped themselves with ECOSTILL equipment.

Less energy consumed, more gain for the customer...

To be truly "environmentally friendly" and more competitive, the process had to be further improved: TMW thus endeavoured to optimise the entire energy chain and to recover all the calories dispersed, both in the air and in the effluent: work on the air loop, development of a new plastic heat exchanger (GEPPI project also supported by ADEME[8]), everything was

With the ECOSTILL 18000, the technology is now suitable for larger volumes (greater than 15 or 18 M3/day). This last model was developed on own funds, and integrating all the improvements developed internally.

Market recognition!

Imposing an innovative and patented technology is not easy in France. For an SME such as TMW, the support of shareholders has been fundamental. Today, without being satisfied with the existing situation, they are rewarded with the trust of known and recognized industrial customers such as OBERTHUR FIDUCIAIRE[9], SIKA[10], REHAU[11], GEA[12], etc.

“We must not stop there, however,” asserts Thierry SATGE, Managing Director of TMW. “We must continue our deployment at the international level. We are lucky that the SIKA group (world leader in waterproofing, this Swiss company produces construction materials) has trusted us in Algeria. In China, in Huizhou, TMW had the opportunity to implement ECOSTILL equipment on the site of a major waste treatment operator. With the Ecostill 18000, we want to expand our offer, to be THE effluent partner of our customers by opening up to a market for which we are not yet identified. This new module will allow us to position ourselves in a higher processed volume niche than what we have been offering until now (from 20m3 to 100m3 now). Do our customers have an effluent problem? It's up to TMW to solve it! »

Source

Cédric Menuet, Avec Ecostill, TMW veut décarboner le traitement des effluents industriels, Les Echios, le 18-04-2023 ; https://www.lesechos.fr/pme-regions/pays-de-la-loire/avec-ecostill-tmw-veut-decarboner-le-traitement-des-effluents-industriels-1935907

[1] Founded in 2000, TMW is a French “cleantech” driven by investors. It focuses on water innovation, more specifically water treatment solutions using evapo-concentration. After 10 years of research and development, TMW today meets global demands for water treatment, with its own products, which are easy to use and whose technology is patented. Established in Paris, Angers and China, TMW is becoming a key player in the water treatment and pure water production sectors. http://www.tmw-technologies.com/wp-tmw/a-propos/

[2] Go Capital is preparing two new funds for a total of 130 million. The first fund of 60 million euros is being finalized with the support of the regions of the Great West, banks and entrepreneurs. Named “Go Blue Fund” and endowed with 70 million euros, the second will be dedicated exclusively to innovative companies in the maritime sector.

[3] The ECOSTILL™ module is made up of an evaporation unit and a condensation unit, a fan for air circulation and a device for superheating the liquid to be treated. The whole is covered with thermal insulation in EPP (expanded polypropylene) or textile. It recycles effluents by concentration and generation of distillate (demineralised water). The water contained in the effluent evaporates and is recovered after condensation. This results in a concentration of polluted effluent close to 95%. MHD technology is a patented process that combines the following characteristics (1) Evaporation at atmospheric pressure, at low temperature (85°C), (2) All-plastic design (PP, HDPE). http://www.tmw-technologies.com/ecostill_produits/evapo_concentration_ecostill/#1479134804480-44f95e9b-c1f0

[4] https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001

[5] For over 20 years, Spi Aéro has been specialising in Aerospace surface treatment and industrial painting. We now offer a broader range of services to support you with all your end-of-line operations. Hand us over your parts, either metallic or composite, and we shall deliver a finished product that is treated, tested and compliant, ready to be assembled. https://www.lopitz.com/en/companies/spi-aero

[6] SPAMA’s main specialty is offering healthcare tools and sports equipment. Its leading tasks are delivering tools as well as training users for appropriate implementation and regular use, along with their accompanying relatives. These services represent an extension of further healthcare provided in hospitals. SPAMA works in partnership with official bodies and institutions in the field of healthcare. These include various private sectors, government and charity associations. We aim at achieving a full coverage of services throughout towns and villages across the Kingdom of Saudi Arabia.

[7] Alfa Laval AB is a Swedish company, founded in 1883 by Gustaf de Laval and Oscar Lamm. The company, which started in providing centrifugal separation solutions for dairy (see Separator (milk)), now deals in the production of specialised products and solutions for heavy industry. The products are used to heat, cool, separate and transport such products as oil, water, chemicals, beverages, foodstuffs, starch and pharmaceuticals. Alfa Laval is headquartered in Lund, Sweden and has subsidiary companies in over 100 countries around the world

[8] The Agence de la Transition Écologique (Ecological Transition Agency) - ADEME is a public institution under the joint supervision of the Ministry of Ecological and Inclusive Transition and the Ministry of Higher Education, Research and Innovation.It participates in the implementation of public policies in the fields of the environment, energy and sustainable development. It makes its expertise and advice available to companies, local authorities, public authorities and the general public, in order to enable them to progress in their environmental approach. The Agency also helps finance projects, from research to implementation, in the following areas: waste management, soil preservation, energy efficiency and renewable energies, material savings raw materials, air quality, the fight against noise, the transition to the circular economy and the fight against food waste. ADEME is a public institution under the joint supervision of the Ministry of Ecological and Inclusive Transition and the Ministry of Higher Education, Research and Innovation.

[9] Oberthur Fiduciaire, formerly François-Charles Oberthur (FCO) is a French group specializing in the printing of secure documents and banknotes. It was created in 1984 by Jean-Pierre Savare when he bought for a symbolic franc the fiduciary activity of the Oberthur printing works, closed in 1983.

[10] Sika is an international specialty chemical company with a leading position in the development and production of systems and products for bonding, sealing, waterproofing, damping, reinforcement and protection in the construction and automotive industries. Sika has subsidiaries in 101 countries around the world and manufactures in more than 300 factories. Sika employs more than 27,000 people.

[11] The REHAU Group is a family-owned polymer business, which develops, manufactures and markets products for the automotive, construction, furniture, materials, medical and industrial sectors. Rehau employs more than 20,000 people in over 190 locations. The headquarters for the car and industry business is in Rehau and for Commercial Construction is in Erlangen. The administrative headquarters of the REHAU Group is located in Muri bei Bern, Switzerland. The turnover of the whole group amounts to approximately €3.4 billion

[12] GEA is one of the world’s largest systems suppliers for the food, beverage and pharmaceutical sectors. Our portfolio includes machinery and plants as well as advanced process technology, components and comprehensive services. Used across diverse industries, they enhance the sustainability and efficiency of production processes globally. With a head office based in Germany, its five business divisions are supported by more than 18,000 dedicated employees located in 62 countries.

0 notes

Text

Water recycling

Implementing Water Recycling to Create a Sustainable Future

The world is facing a water crisis and it is quickly becoming the biggest environmental issue of our time. As the demand for fresh water increases and the supply runs low, it is essential that we look for new ways to protect, maintain and increase our water supply. Water recycling offers a key solution to this problem and provides an opportunity for us to create a sustainable future.

The need for sustainable water recycling

Water is a vital resource that not only sustains human life, but also the environment. As the global population increases, the demand for water is rising. With finite resources, water conservation and re-use is becoming increasingly important for the long-term sustainability of our planet.

Water recycling is one way to maintain a healthy water supply. By reusing treated wastewater, we can reduce pressure on freshwater sources and provide a reliable, sustainable supply. It also has the added benefit of reducing pollution and reducing the amount of water that needs to be treated.

Water recycling is an important tool for creating a sustainable future. It promotes conservation, minimizes environmental impact, and ensures a reliable water supply. With the right policies in place, water recycling can be an invaluable resource for generations to come.

Challenges posed by water scarcity

Water scarcity is an increasingly severe problem across the globe. In many places, water is becoming a scarce commodity, leading to water shortages and increasing competition for resources. This is posing a severe challenge to global economic, social, and environmental stability.

Water scarcity can lead to a decrease in agricultural production, leading to food insecurity and malnutrition. It can also lead to shortages of clean drinking water, causing waterborne diseases to rise. Furthermore, water scarcity can lead to an increase in the number of conflicts between communities over access to limited resources.

However, in many places, the cause of water scarcity is often human-induced. This can be due to over-exploitation of water resources, pollution, or poor water management. Therefore, it is essential to implement sustainable water-management strategies in order to reduce the challenges posed by water scarcity. These strategies involve water recycling and conservation, as well as policies and regulations that promote water-use efficiency.

Implementing Water Recycling

We live in an increasingly water-stressed world, and the need to conserve and recycle water has never been more important. Water recycling is a critical part of a sustainable future, and there are many ways to make it happen.

One of the most common ways of implementing water recycling is through rainwater harvesting. This involves collecting rainwater in a tank or cistern and using it for irrigation or other non-potable uses. It’s an effective way to reduce water waste and use a renewable source of water.

Other water recycling options include wastewater reuse, desalination, and stormwater harvesting. Wastewater reuse involves treating wastewater and using it for industrial, agricultural, or landscape purposes. Desalination is the process of removing salt from seawater to create fresh water.

1 note

·

View note

Text

0 notes

Link

Triveni Group is one of the leading Water Recycling solutions. Our Water business offers efficient wastewater treatment solutions to address the growing problem of water scarcity. Today, we have more than 100 successfully operating water and sewage treatment installations.

Read More : https://www.trivenigroup.com/water-solutions

0 notes

Text

an then he fucken exploded !!!!!

#verms stuff#shadowgast#critical role#critical role fanart#proportions are All whack hoever i donot care#queue emoji with shades#also the background is like#2 images i took of water and a tree#and the grass is a recycled drawing#HAHA i love collaging#and the flower is just some thingy from my sketchbook#this is inspired by the lens flare on my digital camera#verms cr

636 notes

·

View notes

Text

Scientists from the University of Rochester have developed new electrochemical approaches to clean up pollution from "forever chemicals" found in clothing, food packaging, firefighting foams, and a wide array of other products. A new Journal of Catalysis study describes nanocatalysts developed to remediate per- and polyfluoroalkyl substances known as PFAS.

The researchers, led by assistant professor of chemical engineering Astrid Müller, focused on a specific type of PFAS called Perfluorooctane sulfonate (PFOS), which was once widely used for stain-resistant products but is now banned in much of the world for its harm to human and animal health. PFOS is still widespread and persistent in the environment despite being phased out by US manufacturers in the early 2000s, continuing to show up in water supplies.

Continue Reading.

170 notes

·

View notes

Text

Just got my waterproof and personalized 'scrunkled' Blu sticker from @stinkybrowndogs !

It looks awesome on my work bottle and now more people will see my cutie pie as I carry this around my store! 🥰

#blu❤️#dogs#i was using plastic water bottles until last week#the recyclable kind#but that news story about the tiny plastic particles actually being in your water scared me#plus those bottles litter the planet#it was time to stop

83 notes

·

View notes