#125mm

Text

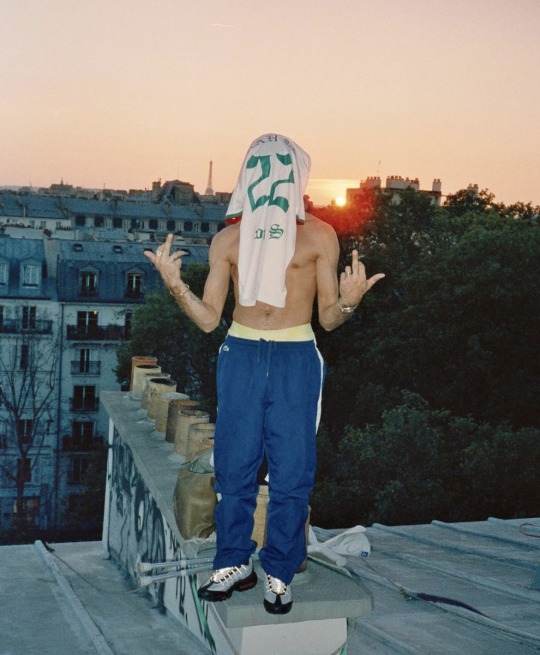

One Block Down X 125 mm, Paris pop-up

9 notes

·

View notes

Photo

#calliandra haematocephala#Jindai Botanical Garden#Tokyo#大紅合歓#神代植物公園#東京#Voigtlander Macro APO-Lanther 125mm F2.5 SL

101 notes

·

View notes

Photo

Captured Russian OF-26 125mm HE shells in Izyum, Ukraine.

#2022 russian invasion of ukraine#2022 russia-ukraine news#ukraine#russia#russian ammunition captured#Russian OF-26 125mm HE shells#tank shells#tank ammunition#war#world at war#weapons

8 notes

·

View notes

Text

Safe And Eco-friendly Piling Techniques Can Save The Environment

'Piling' means the support that is needed for any structure, and therefore is recognized as the very foundation every construction project. There are different piling strategies to make sure that foundations are deep set to the ground for stability. Because piling involves inserting considerable amounts of concrete, steel, or wood to the soil, safe and green techniques has to be considered to avoid harming the planet earth along with the environment in the end. For this reason, you will need to hire seasoned piling contractors who will be recognized for their eco-friendly and safe piling techniques.

Piling specialists are always on the lookout for eco-friendly methods and materials that may ensure a sturdy and safe solution for both the planet earth as well as your structure. Timber subfloor of an augercast or CFA pile is one eco-friendly piling technique that involves drilling into the ground using a hollow-stemmed and continuous flight auger, without casing. The cement grout mix is pumped down the auger's stem, and as the grout is pumped, the auger is slowly removed to transport the soil upward along flights. The result is a shaft of fluid cement grout that arises to ground level. Reinforcement may be placed to support any load or weight by means of tripod piles, micro piles, soldier piles, suction piles, and sheet piles, according to the architectural or infrastructure idea of the project.

Driven piles are acknowledged to be beneficial to our environment, too. They are slender and long columns that offer support for effective resistance forces. Look for a Piling and groundworks specialists that will craft them into predetermined shapes and forms, to allow them to be physically inspected before or during installation, that's possible via vibrating, impact hammering, or simply by pushing them in to the soil. Environmentally friendly driven piles are made from natural materials that conform to the standards of ASTM. When manufacturing them, their quality has to be consistent all through the first person to the last pile.

Eco friendly piling techniques will not likely merely save the surroundings. They can conserve your funds over time, too. Driven piles, for instance, usually are cost-effective since you just pay for the purpose you need-without any hidden costs and surprise expenses linked to clean-up. Installations normally do not produce spoils, and that means you do not have to concern yourself with the disposal of contaminated or hazardous materials.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes

Text

Different Installation Processes Used by Timber Floor Installers Australia

According on the experts and reputed timber floor installers, they normally use various methods and techniques for that installation process along with the method to be chosen generally is determined by the type of floor. One more thing that defines that technique of installation being chosen is the base which this installation is to be done. For example, set up . is to get done on the concrete; these experts would first assess the base and ensure who's has the required standard of moisture. In this post, we will review kinds of timber floors as well as the methods utilised by the professional for that insulation process.

The Plywood System

Experts from different companies contending with these solutions suggest that the plywood system is ideal simply for residential work, where secret nail tongue and groove floor are both a necessity.

This reason is always that using this type of method, it can be super easy to achieve that cushioned effect from the concrete floor.

This procedure for installation generally involves laying a moisture barrier in the concrete, then fixing the 15mm plywood sheeting using high tensile steel fixings.

Once done, the ground boards are then, secretly nailed and then glued very precisely for the plywood to be sure that the height of 34 mm is achieved with the finish.

According for the experts, this process is regarded as perfect for residential usage because with the solid mass of plywood subfloor that can eliminate vermin inhabitation.

One more reason cited by timber floor installers Australia is who's is a quieter floor simply to walk on compared to Batten System.

The Batten System

The next system utilized by timber floor installers will be the batten system and it is used mainly for fixing wide board Tongue & Groove flooring over concrete.

For this, they use a 70 mm x 35 mm hardwood batten that is fixed within the moisture barrier.

Once it has been done step 2 involves gluing the floor and later on, hand nailing it from the top from the board towards the battens.

The consequence of this action is always that the finished height of 54 mm is achieved very easily.

In terms of batten systems, specialists say that a 19 mm hardwood batten doubles to secret nail and fix an 80 mm x 19 mm Tongue & Groove floor board over concrete.

According in try here , this is really a much economical system compared to the one discussed above, nonetheless it features a problem with being very drummy.

Direct Glue System

The next system used by timber floor installers Australia is termed the Direct Glue System and, on this system, Tongue & Groove flooring is glued directly towards the concrete slab.

Because on this method, you will notice that the adhesion process holds importance on this system

Because of this, they have to become ensured prior to the procedure that the concrete floor is completely flat.

This flatness depends on an in depth inspection that is certainly done from the experts who'll determine whether the bottom is a great one to exercise this system.

During this inspection process, the experts also determine the volume of moisture present and whether it's depending on the required standards or not.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes

Text

What is Mini Piling and Why is It Important?

Piling helps ensure a sturdy foundation from the installation of heavy posts or stakes inside subsurface. There are various kinds of deep foundation piling, along with the micropile is one of them. Known as 'mini piling', micropiles are deep foundations developed with heavy-duty steel casings and/or threaded bars which might be small in diameter, usually three to 10 inches. The casing is installed by using a specialised drilling equipment and method. An all-thread bar serves as reinforcing steel in mini piling, which is often inserted to the casing with the micropile. The capacities can vary with respect to the profile of the subsurface and also the size in the micropile. Mini piling has been used effectively on structures with capacities exceeding 1,000 tonnes.

Mini piles used to be applied only on certain ground conditions because of factors like speed and price. Without proper equipment, mini piling is slow and tedious due to the flushing and drilling processes involved with it, resulting inside the job possibly taking hours being accomplished. However, technological advancements in equipment, machinery, and technique make mini piling popular in additional applications, particularly if the development project must conform to low vibration and no-noise regulations, which can be common in congested environments like cities.

Geotechnically speaking, mini piling is practical in ground conditions like shallow bedrock, intermediate hard strata, underpinning, cavities and boulders. Concrete piles like reinforced concrete square and spun piles can produce a large amount of noise during the driving process, so mini piles will be the better alternative because of the absence of noise and minimal vibration they generate. Hence, Deck subfloor is suitable for construction projects near or from the vicinity of residential areas, hospitals, schools, and also other places where a lot of noise might be disruptive.

Seasoned piling contractors can install mini piles. They recommend piling in the event the structure requires steady support, especially when being internal cities or on soil using a weak surface. Reputable piling contractors use suspended auger and hydraulic-driven mounted systems to push cylinders to the ground for a quick and efficient job. Be sure to work with a piling contractor that understands the floor conditions in your town.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes

Text

Different Installation Processes Used by Timber Floor Installers Australia

According towards Senton piles and reputed timber floor installers, they will use different ways and techniques for the installation process and the strategy to be chosen generally is dependent upon the type of floor. One more thing that defines that way of installation to be chosen could be the base which this installation is being done. For example, the installation is to get done on the concrete; these experts would first appraise the base and ensure it gets the required standard of moisture. In this post, we're going to review kinds of timber floors and the methods used by the professional for the insulation process.

The Plywood System

Experts from different companies casually these solutions advice that the plywood product is ideal just for residential work, where secret nail tongue and groove floor are a necessity.

This reason is the fact that using this type of method, it could be quite simple for doing that cushioned effect of the concrete floor.

This process of installation generally involves laying a moisture barrier within the concrete, then fixing the 15mm plywood sheeting using high tensile steel fixings.

Once done, the floor boards are then, secretly nailed and later glued very precisely to the plywood to be sure that the height of 34 mm is achieved with the finish.

According for the experts, this process is considered perfect for residential usage because with the solid mass of plywood subfloor that may eliminate vermin inhabitation.

One more reason cited by timber floor installers Australia is that it is a quieter floor to walk on when compared with Batten System.

The Batten System

The next system employed by timber floor installers is the batten system in fact it is used mainly for fixing wide board Tongue & Groove flooring over concrete.

For this, they'll use a 70 mm x 35 mm hardwood batten which is fixed in the moisture barrier.

Once it's been done step 2 involves gluing the bottom and later on, hand nailing it over the top in the board for the battens.

The consequence of this process is that the finished height of 54 mm is achieved very easily.

In relation to its batten systems, specialists say that a 19 mm hardwood batten doubles to secret nail and connect an 80 mm x 19 mm Tongue & Groove floor board over concrete.

According for many years, this is often a much economical system than the one discussed above, nevertheless it features a drawback of being very drummy.

Direct Glue System

The next system used by timber floor installers Australia is called the Direct Glue System and, with this system, Tongue & Groove flooring is glued directly for the concrete slab.

Because with this method, so as to the adhesion process holds importance within this system

Because on this, it has to get ensured prior to the process that the concrete floor is absolutely flat.

This flatness is determined by an end inspection that is done with the experts that will decide if the floor is good enough to exercise this product.

During this inspection process, professionals also determine the amount of moisture present and be it depending on the specified standards or not.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes

Photo

Mapping

SIGMA 18-125mm f3.8-5.6 DC OS HSM

63mm f7.1 1/200 ISO1600 EXP0

0 notes

Text

0 notes

Text

FOTD #085 : pink waxcap! (porpolomopsis calyptriformis)

the pink waxcap is a species of agaric fungus in the family hygrophoraceae. interestingly, this fungus is neither mycorrhizal nor saprophytic, but may be associated with mosses. it is found in several european countries :-)

the big question : can i bite it??

technically yes, but these mushrooms are so scarce & are threatened, so i don't recommend picking them for food.

p. calyptriformis description :

"basidiocarps are agaricoid, up to 125mm (5 in) tall, the cap narrowly conical at first, retaining an acute umbo when expanded, up to 75mm (3 in) across, often splitting when expanded, the margins turning upwards. the cap surface is smooth to fibrillose, slightly shiny or greasy, pale rose-pink to lilac-pink (rarely white). the lamellae (gills) are widely spaced, waxy, cap-coloured or whiter. the stipe (stem) is smooth, white to pale cap-coloured, lacking a ring."

[images : source & source]

[fungus description : source]

#• fungus of the day !! •#[porpolomopsis calyptiformis]#: pink waxcap :#085#||#fungi#fungus#mushroom#nature#earth#cottagecore#foraging#mycology#forestcore#mushrooms#fotd#fungus of the day#pink#pink mushroom#europe#porpolomopsis calyptiformis

249 notes

·

View notes

Photo

1 note

·

View note

Photo

68 notes

·

View notes

Text

RKF-C/09 Tagetes Fusilier

The Tagetes is the backbone of the Baronic Unified Command. Noble or not, every cadet earns their chevrons in the chair of one of these bastards. The retrofitted version you're looking at doesn't deviate much from the old standby. It's got an uparmor package with a new alloy mix that the Royal Foundry boys cooked up (top secret!). Combined with reinforced joints means that it can take a real beating and keep ticking. Just don't expect it to be doing the two-step anytime soon.

This Tagetes is a Fusilier, squad marksman version. Sensor suite's been retooled, derived from interferometry suites yanked off frigates and downscaled. Don't know what black magic the eggheads had to conjure to fit them into the chassis, but you won't find a better fire control and target acquisition system anywhere else.

Fusilier's standard issue weapon is the Hesse-Kovan Heavy Industries made HvC-125 Precision Assault Cannon. A reliable and imminently accurate system, it'll sling a 125mm through a target two kilos away, no problem. HcVs take all kinds of solid state ammo to boot, sabot, squashhead, plasma-jacketed, even loitering munitions. Won't fire energetic munitions though, barrel deforms too easily under heat stress. However, H&K is working on a version that'll accept linear accelerators mods or nuclear shaped charge ammunition, expect it by the end of next Standard year.

-Quartermaster Sergeant Emilie Levallier, inventory memo

Art by the fantastic EM Fields, catch em on twitter at: https://twitter.com/EMFields_Art

201 notes

·

View notes

Text

Safe And Eco-friendly Piling Techniques Can Save The Environment

'Piling' refers back to the support that's needed for just about any structure, and so is known as abdominal muscles first step toward every construction project. There are different piling techniques to make certain that foundations are deep set to the ground for stability. Because piling involves inserting large amounts of concrete, steel, or wood to the soil, safe and beneficial to our environment techniques should be thought to avoid harming our planet along with the environment in the end. For this reason, you should hire seasoned piling contractors that are recognized for their eco-friendly and safe piling techniques.

Piling specialists will almost always be searching for eco-friendly methods and materials that will ensure a sturdy and safe solution for both planet earth along with your structure. The use of an augercast or CFA pile is but one eco-friendly piling technique which involves drilling in the ground using a hollow-stemmed and continuous flight auger, without any casing. The cement grout mix is pumped on the auger's stem, and as the grout is pumped, the auger is slowly removed to transport the soil upward along flights. The result is a shaft of fluid cement grout that arises to walk-out. Reinforcement may be placed to compliment any load or weight by way of tripod piles, micro piles, soldier piles, suction piles, and sheet piles, with respect to the architectural or infrastructure concept of the project.

Driven look at this site are acknowledged to be beneficial to our environment, too. They are slender and long columns that supply support for effective resistance forces. Look for a Piling and groundworks specialists that may craft them into predetermined shapes and sizes, to enable them to be physically inspected before or during installation, which can be possible via vibrating, impact hammering, or simply by pushing them in to the soil. Environmentally friendly driven piles are made from natural materials that comply with the standards of ASTM. When manufacturing them, their quality has to be consistent all through the first person to the final pile.

Eco friendly piling techniques will not likely merely save the environment. They can help the bank balance ultimately, too. Driven piles, for instance, are generally cost-effective when you just pay for the purpose you need-without hidden costs and surprise expenses associated with clean-up. Installations normally do not produce spoils, which means you don't need to worry about the disposal of contaminated or hazardous materials.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes

Text

Get All Types Of Piling For Every Type Of Building

Pile foundation is done where the soil is weak. Deck subfloor could have many reasons like soil erosion, strong wind, floods, continuous rain, land slides etc. Extra moisture also feeble the soil and does not let it rest worthy enough for any project or building. But you know value of a robust infrastructure as well as in the development of the continent. For a healthy economy, a good infrastructure is utmost important and zilch should are available in between this. Not even the weak soil.

The infrastructure is not ignored because with the weak soil. So it is better to ignore the weakness. There are many locations, that are suitable for a building though the soil because weakness doesn't secure the project. But other favorable factors cannot be ignored. So here the best way round is always to make assistance of technology. Technology will not mean only software and applications, but has several faces, even just in the sector of property and infrastructure.

What the Company Does:

The company is giving the most effective piling in order to create the base in the building. A soil when weak can also be based on technology. Piling is the simplest way to bolster the soil. A long cylindrical structure consisting of concrete is deep inserted into the soil. Then the burden in the building passes for the piles rather than happening soil on a whole. The piles share the stress of the building. The company gives the very best Pile Foundation for the buildings. Pile foundation makes all the base, strong to give more strength and durability to your building. Nothing can achieve success with out a powerful base. Hence for durability, a strong base is essential. Pile foundation is completed to bolster the base of the building.

The company is a professional in every work of Ground Engineering and pile foundation is of these. Pile foundation is a flagship work in the company. The company gives both, the pre cast pile and also the bored piles. The best of the concrete is used to make the Bored Piles. Bored piles need extra labor and expertise because here environmental surroundings is uncontrollable and exceptional knowledge is required to handle such situations. The company has a team of those exceptionally genius engineers who work to offer you the most effective piles and piling services. The company because dedication and the most effective team is serving the nation for longer than 4 decades yet still could be the leader in the industry.

#House piles#Timber piles#Senton piles#Pile supports#125 x 125mm H5 piles#Timber pile supports#Deck piles#Deck subfloor#Timber subfloor#Timber pile chairs

0 notes