#IndustrialEngineering hashtag

Text

JIS B2220 2K FLANGES

Introduction:

In the realm of industrial piping systems, adherence to rigorous standards is paramount to ensure safety, reliability, and performance. Among these standards, JIS B2220 stands out as a crucial benchmark for flanges used in various industries worldwide. In this comprehensive guide, we delve into the significance of JIS B2220 flanges, their applications, and why they are indispensable components in modern engineering.

Unveiling JIS B2220 Flanges:

JIS B2220 is a Japanese Industrial Standard that specifies the dimensions, materials, and technical requirements for steel pipe flanges. These flanges are widely utilized in industries such as oil and gas, petrochemical, chemical processing, marine engineering, and more. JIS B2220 flanges are meticulously designed to meet the demanding needs of diverse applications, ensuring compatibility, efficiency, and safety.

Key Features of JIS B2220 Flanges:

Dimensional Accuracy: JIS B2220 flanges adhere to precise dimensional tolerances, ensuring seamless compatibility with piping systems and other components.

Material Specifications: These flanges are available in various materials such as carbon steel, stainless steel, and alloy steel, catering to a wide range of operating conditions and environments.

Pressure Ratings: JIS B2220 flanges are designed to withstand different pressure ratings, ranging from low to high-pressure applications, making them versatile solutions for diverse industrial settings.

Applications of JIS B2220 Flanges:

Oil and Gas Industry: JIS B2220 flanges play a vital role in offshore platforms, refineries, and pipelines, facilitating the safe and efficient transport of oil and gas resources.

Chemical Processing: In chemical plants and refineries, JIS B2220 flanges ensure the integrity of piping systems handling corrosive fluids and chemicals, minimizing the risk of leaks or failures.

Marine Engineering: These flanges are extensively used in shipbuilding and marine engineering applications, where reliability and durability are paramount in harsh marine environments.

Why Choose JIS B2220 Flanges?

Global Recognition: JIS B2220 is an internationally recognized standard, ensuring consistency and interoperability across different regions and markets.

Quality Assurance: JIS B2220 flanges undergo stringent quality control measures to meet industry standards, providing peace of mind regarding reliability and performance.

Versatility: With a wide range of sizes, materials, and pressure ratings available, JIS B2220 flanges offer versatile solutions for various industrial applications.

Conclusion:

In conclusion, JIS B2220 flanges are indispensable components in industrial piping systems, ensuring seamless connectivity, reliability, and safety. Whether in the oil and gas sector, chemical processing plants, or marine engineering applications, JIS B2220 flanges provide the foundation for efficient and robust infrastructure. By adhering to stringent standards and embracing quality solutions, industries can enhance operational efficiency and mitigate risks effectively. Embrace the reliability and versatility of JIS B2220 flanges for your industrial endeavors, and experience the difference in performance and longevity they offer.

#hashtag#JISB2220 hashtag#Flanges hashtag#IndustrialEngineering hashtag#OilAndGas hashtag#ChemicalProcessing hashtag#MarineEngineering hashtag#QualityAssurance

0 notes

Text

Why Is 1.2311 Plastic Mould Steel Important?

1.2311 is a type of Plastic Mold Steel that holds significance in various Industrial Applications, especially in the manufacturing of Plastic Injection Molds. Here's why it's important:

1. Good Machinability: 1.2311 Plastic Mold Steel possesses good machinability properties, which means it can be easily machined into desired shapes and forms using conventional machining techniques. This attribute is crucial in mold making where precision is key.

2. Excellent Wear Resistance: It offers excellent wear resistance properties, which is essential for Plastic Molds that undergo repeated cycles of molding and demolding. This ensures that the mold maintains its shape and functionality over a long period of time.

3. High Hardness: 1.2311 Steel can be hardened to a high level, providing the necessary hardness required for withstanding the pressures and stresses encountered during the injection molding process.

4. Good Polishability: The Steel is capable of being polished to a smooth finish, which is important for achieving high-quality surface finishes on Molded Plastic Parts.

5. Good Dimensional Stability: It exhibits good dimensional stability under high temperatures and pressures, ensuring that the molds retain their shape and dimensions throughout the molding process.

6. Cost-Effective: Compared to some other mold steels, 1.2311 Steel is relatively cost-effective while still offering good mechanical properties, making it an attractive choice for many mold-making applications.

In summary, 1.2311 Plastic Mold Steel is important due to its combination of machinability, wear resistance, hardness, polishability, dimensional stability, and cost-effectiveness, all of which are critical factors in the production of high-quality plastic components through injection molding processes.

Sandeep Enterprises reputation as a respected entity within the Steel Industry is well-earned and reflects its unwavering dedication to excellence, quality, and customer satisfaction. By consistently prioritizing these core values, Sandeep Enterprises has solidified its position as a trusted partner for clients across diverse sectors.

The company's commitment to delivering superior Products and Services is evident in its adherence to stringent quality control measures. By maintaining high standards throughout the production process, Sandeep Enterprises ensures that its steel products consistently meet or exceed industry requirements and customer expectations.

#SandeepEnterprises hashtag#Steel hashtag#PlasticMoulding hashtag#InjectionMoulding hashtag#MouldMaking hashtag#SteelAlloy hashtag#Manufacturing hashtag#IndustrialEngineering hashtag#ToolAndDie hashtag#MouldSteel hashtag#InjectionMoulds hashtag#PrecisionMachining

0 notes

Text

Serge Vessel – Level Control

S.R. Bhat (Technical Director, COMFIT)

Many times, a product produced in a process equipment is used as feed to another equipment. In these cases, it is necessary to make the feed flow to the second equipment steady, i.e. any variations in the feed should be very slow. This must be achieved even if the product out coming put of the first equipment is not steady. E.g. Naphtha coming out of the crude distillation unit of a refinery is unstable, i.e. it contains a lot of volatile components. These volatile constitute Liquefied Petroleum Gas (LPG), which is very valuable. This stream is fed to another distillation column called Naphtha Stabilizer. Purpose of the Naphtha Stabilizer are two. They are:

1. Recover the LPG, allowing minimum slippage of LPG to Naphtha.

2. Remove LPG from Naphtha with minimum slippage of Naphtha to LPG. To achieve this, a serge vessel is introduced in between the Crude Distillation Column and the Naphtha Stabilizer. Feed flow into the stabilizer is controlled by a control valve introduced between the serge tank and stabilizer. Process variable for this control loop is the liquid level in the serge tank. This level keeps varing around 50%. If this controller is well tuned, level will always mainted tightly near the 50 % mark. This would defeat the purpose of surge vessel by making the vessel outlet flow closely follow the badly varing inlet flow. On the other hand, by keeping the controller sluggish (i.e. making proportionality gain low), the surge tank serves its purpose. When the input flow to the serge vessel increses, sluggish level controller acts very slowly, resulting in the slow and steady increase of outlet flow from the vessel. This increses the level in the serge tank. On the other hand, when the inlet flow to the serge vessel reduces, exactly the reverse happens.

This is a strange case of attuned controller gives the desire result. This has been successfully done in the Naphtha Stabilizer of refinery, which resulted in substantial increase in of the production of the valuable LPG, but also improved its weathering.

#SergeVessel hashtag#LevelControl hashtag#ProcessEngineering hashtag#FeedFlowStabilization hashtag#NaphthaStabilizer hashtag#LPGRecovery hashtag#ControlSystem hashtag#ProcessOptimization hashtag#RefineryTechnology hashtag#SurgeTankSuccess hashtag#EfficientProduction hashtag#ProcessControl hashtag#SteadyFeedFlow hashtag#industrialengineering hashtag#comfit hashtag#valvemanufacturer hashtag#valves hashtag#valveindustry hashtag#valvefactory hashtag#india

0 notes

Photo

#blackandwhite #bnw #bnwphotography #metal #machining #turning #modeling #gear #gearbox #workshop #canon #eos7d #saturday #picoftoday #picsoftheday #abandonnedmachinery #oldcity #oldmachines #abandonedplaces #aude #france #southoffrance #technology #rustymachines #rustymetal #rust #dust #dustymachine #hashtag #industrial #industrialengineering #december (à Carcasonne, Languedoc-Roussillon, France) https://www.instagram.com/p/Bq1x-8ogTrk/?utm_source=ig_tumblr_share&igshid=h297xcho8czl

#blackandwhite#bnw#bnwphotography#metal#machining#turning#modeling#gear#gearbox#workshop#canon#eos7d#saturday#picoftoday#picsoftheday#abandonnedmachinery#oldcity#oldmachines#abandonedplaces#aude#france#southoffrance#technology#rustymachines#rustymetal#rust#dust#dustymachine#hashtag#industrial

0 notes

Photo

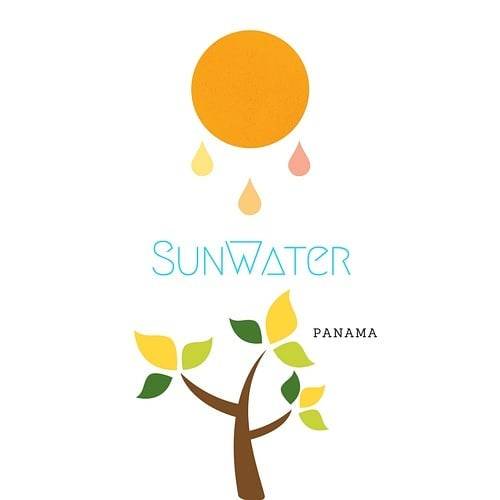

For a better Panama for a better World... Everybody with the Hashtag SunWater Panama... Representado a la USMA con mi proyecto de innovación social en el Foro de Educación para la Innovación y la Competitividad @usmapanama @industrialusma @senacyt @twcinternships #SunWaterPanama #love #magic #inlove #socialinnovation #TWCAlumni #happiness #10maprovincia #panamenian #industrialengineer #smile #workinghard #egresadosusma #Senacyt #IngenieraBernal (at Panama City, Panama)

#ingenierabernal#workinghard#love#twcalumni#socialinnovation#panamenian#magic#egresadosusma#sunwaterpanama#senacyt#10maprovincia#smile#inlove#happiness#industrialengineer

0 notes

Text

ASTM A105 Flanges: Ensuring Quality with Triton Alloy INC

Introduction:

When it comes to ensuring the integrity and reliability of piping systems, ASTM standards play a pivotal role. Among these standards, ASTM A105 stands out prominently in the realm of flanges. At Triton Alloy INC, we understand the critical importance of adhering to ASTM standards for optimal performance and safety. In this comprehensive guide, we delve into the significance of ASTM A105 flanges, their applications, and why Triton Alloy INC is your trusted partner in meeting these standards.

Understanding ASTM Standards:

The American Society for Testing and Materials (ASTM) establishes and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. These standards ensure consistency, quality, and safety across various industries. Among the myriad of ASTM standards, ASTM A105 specifically addresses carbon steel forgings for piping applications.

ASTM A105 Flanges:

ASTM A105 flanges are forged carbon steel piping components primarily used in high-pressure and high-temperature service. These flanges are commonly utilized in industries such as oil and gas, petrochemical, power generation, and more. Their superior strength, durability, and resistance to corrosion make them a preferred choice in critical environments.

Applications of ASTM A105 Flanges:

Oil and Gas Industry: ASTM A105 flanges are extensively employed in oil refineries, offshore platforms, and pipelines due to their ability to withstand harsh operating conditions.

Petrochemical Plants: Flanges manufactured in accordance with ASTM A105 standards are vital components in petrochemical processing units for connecting piping systems securely.

Power Generation: Whether in conventional power plants or renewable energy facilities, ASTM A105 flanges ensure the integrity of piping networks in various power generation applications.

Why Triton Alloy INC?

At Triton Alloy INC, we are committed to delivering excellence in every product we offer. Here's why choosing us for your ASTM A105 flange needs is the right decision:

Quality Assurance: Our ASTM A105 flanges undergo rigorous testing to meet and exceed ASTM standards, ensuring reliability and performance.

Expertise and Experience: With years of experience in the industry, our team possesses the expertise to provide tailored solutions for your specific requirements.

Customization Options: We offer customization options to meet unique project needs, ensuring seamless integration and optimal functionality.

Customer Satisfaction: At Triton Alloy INC, customer satisfaction is our top priority. We strive to provide exceptional service, timely delivery, and ongoing support to our valued clients.

Conclusion:

In conclusion, ASTM A105 flanges are indispensable components in various industries, ensuring the efficient and safe operation of piping systems. When sourcing ASTM A105 flanges, partnering with a reputable supplier like Triton Alloy INC is crucial to guaranteeing quality, compliance, and peace of mind. Trust Triton Alloy INC for all your ASTM A105 flange requirements, and experience the difference quality and expertise make in your projects.

#ASTM#hashtag#ASTMA105#ASTMFlanges#ASTMStandards#CarbonSteel#PipingComponents#OilAndGas#Petrochemical#PowerGeneration#QualityAssurance#TritonAlloyINC#FlangeApplications#IndustrialEngineering#SafetyStandards#CustomizationOptions

0 notes

Photo

#blackandwhite #bnw #bnwphotography #metal #machining #turning #modeling #gear #gearbox #workshop #canon #eos7d #saturday #picoftoday #picsoftheday #abandonnedmachinery #oldcity #oldmachines #abandonedplaces #aude #france #southoffrance #technology #rustymachines #rustymetal #rust #dust #dustymachine #hashtag #industrial #industrialengineering #december (à Carcasonne, Languedoc-Roussillon, France) https://www.instagram.com/p/Bq1xdVOg9YR/?utm_source=ig_tumblr_share&igshid=ljavcfcejlfu

#blackandwhite#bnw#bnwphotography#metal#machining#turning#modeling#gear#gearbox#workshop#canon#eos7d#saturday#picoftoday#picsoftheday#abandonnedmachinery#oldcity#oldmachines#abandonedplaces#aude#france#southoffrance#technology#rustymachines#rustymetal#rust#dust#dustymachine#hashtag#industrial

0 notes

Photo

For a better Panama for a better World... Everybody with the Hashtag SunWater Panama... Representado a la USMA con mi proyecto de innovación social en el Foro de Educación para la Innovación y la Competitividad @usmapanama @industrialusma @senacyt @twcinternships #SunWaterPanama #love #magic #inlove #socialinnovation #TWCAlumni #happiness #10maprovincia #panamenian #industrialengineer #smile #workinghard #egresadosusma #Senacyt #IngenieraBernal (at Panama City, Panama)

#magic#egresadosusma#twcalumni#sunwaterpanama#senacyt#socialinnovation#panamenian#workinghard#industrialengineer#smile#inlove#ingenierabernal#10maprovincia#love#happiness

0 notes

Photo

Lo recuerdo como si fuera ayer.... Hoy Alcanzo por fin la victoria 27/8/2012 - 27/4/2017... Compren 27 porque va a jugar.... Ahora todos con el hashtag.... Y vamos por el Master.... #mariasegradua #managementindustrialengineering #industrialengineer #engineers #femaleengineer #Thesis #27 #41/2 #happiness #3deagosto #inlove #lovely #happy #usmeña #listaparaaceptarlamision (at Usma)

#happiness#mariasegradua#thesis#managementindustrialengineering#industrialengineer#engineers#happy#listaparaaceptarlamision#27#femaleengineer#3deagosto#inlove#41#lovely#usmeña

0 notes