#JIT In Supply Chain

Text

Mastering Logistics Management: A Comprehensive Guide to Streamlining Supply Chains and Boosting Efficiency

Logistics management refers to the process of planning, implementing, and controlling the flow of goods, services, and information from the point of origin to the point of consumption. It involves the coordination of various activities such as procurement, transportation, warehousing, inventory management, and customer service to ensure smooth and efficient operations. Logistics management plays…

View On WordPress

#advanced technologies#collaboration and communication#cost reduction#customer satisfaction#data analytics#demand planning#efficient operations#international trade#inventory management#just-in-time (JIT) inventory#last-mile delivery#lean management#logistics management#reverse logistics#risk management#supply chain optimization#sustainability practices#third-party logistics#transportation optimization#warehouse automation

0 notes

Text

0 notes

Text

Supply-Chain Term of the Day: Just-in-Time JIT

Supply-Chain Term of the Day: Just-in-Time JIT

A dependent demand inventory control philosophy which views production as a system in which all operations, including the delivery of materials needed for production, occur just at the time they are needed. Thus, stocks of material are virtually eliminated.

We send out a new terms every morning during the workday.

Be sure to click on the (Schedule Classes on Demand) tab above if you are…

View On WordPress

0 notes

Photo

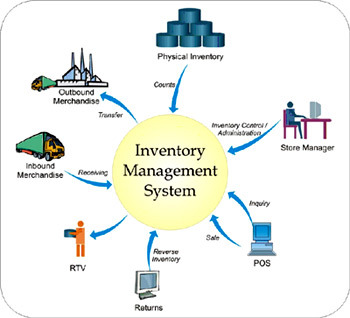

Managing Inventory for Logistic: Strategies for Effective Supply Chain Management

Introduction

Good inventory management is vital for logistic firms to guarantee on-time and efficient supply chain management. This entails the careful monitoring, control, and optimization of stock levels to decrease expenses while fulfilling customer needs. The Best Logistic Company in India in this blog, discuss some techniques for successful inventory management that logistics companies can use to bolster their supply chain management.

Important techniques

1. Adopt a Just-in-Time (JIT) approach:

A Just-in-Time (JIT) method involves ordering products right when they are needed to meet customer orders, thereby eliminating the need for excessive stockpiling. This way, companies can minimize their inventory while still meeting consumer demands, thus cutting down on inventory carrying costs and freeing up space.

2. Use Forecasting Techniques:

Logistics companies can use forecasting techniques to predict customer demand and adjust inventory levels accordingly. This approach ensures that inventory levels are optimized to meet customer demand, reducing the risk of stockouts or excess inventory.

3. Utilize Technology:

Technology can help logistics companies manage their inventory more efficiently. Inventory management software can track inventory levels, forecast demand, and automate the reordering process.

4. Implement an ABC Analysis:

An ABC analysis categorizes inventory into three categories based on it’s value and usage.

Class A inventory is high-value and fast-moving,

Class B inventory is medium-value and medium-moving,

Class C inventory is low-value and slow-moving.

By categorizing inventory, logistics companies can prioritize inventory management efforts and allocate resources more effectively.

5. Adopt a Continuous Improvement Approach:

Continuous improvement involves constantly monitoring and optimizing inventory management processes. Logistics companies can use data analytics to track inventory performance, identify inefficiencies, and make data-driven decisions to improve inventory management.

Logistic companies can benefit greatly from implementing effective inventory management strategies. By adopting a JIT approach, using forecasting techniques, utilizing technology, implementing an ABC analysis, and adopting a continuous improvement approach, logistics companies can improve their supply chain management and provide better service to their customers.

#Inventory Management Strategies For Logistic And Supply Chain#Effective Inventory Control Methods For Supply Chain Management#3pl in India#Top logistic company in India#Best logistic company in India#3pl service provider

4 notes

·

View notes

Text

Well, it's a good thing that there aren't any disastrous side effects which could come about from having a lean production system.

Yeah, this textbook was written before the pandemic/Evergiven incident, but that kind of supply chain issue should have been obvious to anyone who thought about it.

Of course, even if a financial manager at one company had noticed and cared, they couldn't do anything about it. One company using less efficient but more resilient business practices wouldn't meaningfully affect the greater economy—it would just put that company in a disadvantageous short-term position, letting it be outcompeted by another company which used JIT inventory management.

If everyone came together and agreed to not use JIT, the economy would be more resilient. Sure, every company would have more current assets tied up in inventory instead of being reinvested (generally into various types of market securities), but we wouldn't suffer catastrophic production chain shutdowns from comparatively minor disasters.

2 notes

·

View notes

Text

What skills are essential for success in a medical scribing course, and how do they bring success via logistic management?

Individuals interested in the fields of transportation and supply chain management might benefit greatly from taking shipping and logistics management courses. An outline of what to anticipate from a course like this is provided below:

Introduction to Shipping and Logistics: An introduction to the ideas and principles of shipping and logistics management usually occurs at the start of a course. An outline of the supply chain, different forms of transportation, and the function of logistics in company operations are all included in this.

Transportation Modes: You'll learn about different transportation modes used in logistics, including:

Maritime shipping

Air freight

Rail transportation

Trucking and road transportation

Multimodal transportation

Logistics Operations and Processes: Courses cover the various aspects of logistics operations, such as:

Inventory management

Warehousing and distribution

Order processing and fulfillment

Transportation planning and scheduling

Freight forwarding and brokerage

Supply Chain Management: You'll gain an understanding of supply chain management principles and practices, including:

Supplier management

Demand forecasting

Inventory optimization

Lean and just-in-time (JIT) principles

Risk management in the supply chain

International Trade and Customs Compliance:Topics include international trade, customs laws, and the documentation needed to import and export commodities across international boundaries may be covered in courses.

Logistics Technology and Systems: You'll learn about the use of technology and software systems in logistics management, such as:

Transportation management systems (TMS)

Warehouse management systems (WMS)

Enterprise resource planning (ERP) systems

Track and trace systems

Electronic data interchange (EDI)

Sustainability and Green Logistics: The ideas of sustainability and eco-friendly logistics techniques, such as carbon footprint reduction, green transportation programs, and sustainable packaging options, may be covered in some courses.

Supply Chain Analytics and Optimization: To increase productivity and cut expenses in logistics operations, you could get training in data-driven decision-making, supply chain analytics, and optimization approaches.

Case Studies and Industry Insights: Courses often include real-world case studies, industry examples, and guest lectures from professionals in the field to provide practical insights and perspectives.

Professional Skills Development: Depending on the course, you may receive training in professional skills such as communication, teamwork, problem-solving, and project management, which are essential for success in logistics management roles.

When selecting a shipping and logistics management school, seek for those that are associated with respectable universities or accredited by pertinent industry associations. In addition, take into account elements like the length of the course, the mode of delivery (online, in-person), the industry contacts, faculty knowledge, and chances for internships or real-world experience.

Upon completion of a shipping and logistics management course, you'll be equipped with the knowledge and skills needed to pursue various career opportunities in logistics, supply chain management, transportation, warehousing, and related fields.

#shipping issue#logistics#fictional characters#education#coding#marketing#marketingcourse#careergoals#transorzesolutions#jobs#jobsearch#jobseekers#online jobs#employment#job search#workplace#opportunity#inside job#work#careerdevelopment#management#business#insights#career

0 notes

Text

Tips for Managing Your Logistics More Effectively - MVLOAD

Effective logistics management is critical for the success of any business, as it directly impacts cost, efficiency, and customer satisfaction. Here are some practical tips from MVLOAD to help you manage your logistics more effectively.

Invest in Technology

Embrace technology to automate and optimize your logistics operations. Use software for inventory management, route planning, and tracking shipments in real-time. This not only improves efficiency but also reduces human error.

Optimize Inventory Management

Maintain a balanced inventory to prevent overstocking or understocking. Implement just-in-time (JIT) practices to minimize excess stock while ensuring you have enough products to meet customer demand.

Streamline Your Supply Chain

Work closely with your suppliers and distributors to improve communication and coordination. Establish clear expectations, timelines, and regular reviews to ensure smooth operations across the supply chain.

Focus on Transportation Efficiency

Plan your transportation routes to minimize time and fuel costs. Use technology to identify the most efficient routes and track deliveries in real-time. This will help reduce delays and improve customer satisfaction.

Prioritize Customer Service

Customer satisfaction should be at the heart of your logistics strategy. Provide clear and accurate delivery information, offer tracking services, and respond promptly to customer inquiries. Excellent customer service helps build trust and loyalty.

Develop a Strong Logistics Team

Your logistics team is essential to the success of your operations. Provide training and development opportunities to ensure your team is skilled and up-to-date with industry trends. Encourage collaboration and open communication to foster a positive work environment.

Monitor and Analyze Performance

Track key performance indicators (KPIs) to assess the effectiveness of your logistics operations. Regularly review your data to identify areas for improvement and implement changes to enhance efficiency.

Implement Safety Protocols

Safety is paramount in logistics. Ensure that all employees are trained in safety procedures and that your facilities and equipment meet safety standards. This reduces the risk of accidents and keeps your workforce safe.

Prepare for Contingencies

Unexpected events can disrupt logistics operations. Develop contingency plans for situations like natural disasters, supply chain disruptions, or transportation delays. Being prepared can help minimize the impact of these events.

Continuously Improve

Logistics is a dynamic field, so always look for ways to improve. Stay informed about industry trends and new technologies, and be open to experimenting with new approaches. Continuous improvement helps you stay ahead in the competitive logistics landscape.

By following these tips from MVLOAD, you can effectively manage your logistics operations, leading to increased efficiency, reduced costs, and enhanced customer satisfaction.

#logistics service provider#best logistics company in delhi#logistics company in delhi ncr#logistics services in delhi#logistics in delhi ncr

0 notes

Text

Metal Supply

Navigating the Metal Supply Chain: From Ore to Industry

Introduction: Metal is the backbone of modern civilization, indispensable in industries ranging from construction to electronics. However, the journey of metal from its source to its final application is a complex and multifaceted process. In this article, we will delve into the intricacies of the metal supply chain, exploring the journey of metals from extraction to distribution and their significance in various sectors of the economy.

The Extraction Process: The journey of metal begins with its extraction from the earth's crust. Mining, the primary method of extraction, involves various techniques depending on the type of metal and its geological location. Traditional methods such as open-pit mining and underground mining are still widely used, while advancements in technology have led to innovations like in-situ leaching and seabed mining.

Once extracted, the raw ore undergoes a series of processes to concentrate the metal content and remove impurities. This beneficiation process often involves crushing, grinding, and chemical treatments to separate the valuable metal from the surrounding rock. The concentrated metal is then smelted to produce pure metal ingots ready for further processing.

Refinement and Processing: After smelting, the metal undergoes further refinement to meet specific quality standards and desired characteristics. This refinement process varies depending on the metal and its intended applications. For example, steel, the most widely used metal, undergoes additional alloying to enhance its strength, durability, and corrosion resistance.

Advanced metallurgical processes such as heat treatment, casting, and forging transform raw metal into various forms such as sheets, rods, and wires, catering to diverse industrial requirements. Moreover, technological advancements have enabled the development of specialty metals with tailored properties, opening new avenues for innovation in sectors like aerospace and healthcare.

Distribution and Supply Chain Management: Once processed, metals are distributed through a complex supply chain involving manufacturers, wholesalers, and retailers. Efficient supply chain management is crucial to ensuring a steady flow of metals to end-users while minimizing costs and optimizing inventory levels.

Just-in-time (JIT) inventory systems and advanced logistics technologies play a vital role in streamlining the metal supply chain, enabling manufacturers to respond quickly to changing demand and market fluctuations. Moreover, digitalization and data analytics are revolutionizing supply chain management, providing real-time insights into inventory levels, demand forecasts, and supply chain performance.

The Role of Metals in Industry: Metals are ubiquitous in modern industry, serving as essential components in countless products and infrastructure. From the steel beams supporting skyscrapers to the silicon chips powering smartphones, metals form the foundation of our technological society.

In the automotive sector, lightweight metals like aluminum and titanium are increasingly replacing traditional steel components, enabling fuel efficiency and reducing emissions. In the renewable energy industry, metals such as copper and rare earth elements are essential for the production of solar panels, wind turbines, and electric vehicle batteries, driving the transition to a low-carbon economy.

Challenges and Opportunities: Despite their indispensable role, the metal industry faces several challenges, including environmental concerns, resource depletion, and geopolitical tensions. The extraction and processing of metals often have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

To address these challenges, the industry is embracing sustainable practices such as recycling, energy efficiency improvements, and responsible sourcing initiatives. Recycling, in particular, plays a crucial role in reducing the demand for virgin materials and minimizing waste, thereby conserving resources and reducing environmental footprint.

Moreover, advances in technology, such as additive manufacturing (3D printing), are opening new possibilities for metal fabrication, allowing for the production of complex geometries with minimal material waste. Additionally, developments in materials science and nanotechnology hold the promise of creating new lightweight, high-strength materials with enhanced performance and durability.

Conclusion: The metal supply chain is a complex and dynamic ecosystem that underpins modern industrial civilization. From extraction to distribution, metals undergo a journey of transformation, shaping the world around us and driving technological innovation. As we navigate the challenges of sustainability and resource management, the metal industry continues to evolve, embracing new technologies and practices to meet the needs of a changing world.

1 note

·

View note

Text

How to Develop a Robust Production Planning and Control Strategy: 6 Proven Tips

Production planning and control (PPC) plays a vital role in any manufacturing organization's success. It involves creating a production plan that outlines how resources will be allocated, schedules when tasks need to be completed and monitors progress along the way. A robust production planning and control strategy can help you optimize your operations, reduce costs, improve quality, and increase customer satisfaction. Here are six proven tips to develop an effective production planning and control strategy for your business.

1. Understand Your Business Requirements:

The first step in developing a robust PPC strategy is understanding your business requirements. You should consider factors such as demand forecasting, inventory management, lead times, capacity constraints, and resource availability. By analyzing these factors, you can create a realistic production schedule that aligns with your overall business goals. Make sure you involve all relevant stakeholders, including production managers, engineers, and suppliers, to ensure everyone understands their roles and responsibilities.

2. Implement Lean Manufacturing Techniques:

Lean manufacturing techniques focus on eliminating waste and maximizing efficiency. These methods include just-in-time (JIT) delivery, continuous improvement, total productive maintenance (TPM), and cellular manufacturing. By implementing lean principles into your PPC strategy, you can streamline processes, reduce lead times, lower costs, and enhance product quality. Additionally, lean manufacturing encourages cross-functional collaboration, which can foster innovation and problem-solving skills among team members.

3. Utilize Advanced Technology:

Advanced technology has transformed modern manufacturing by providing real-time data analytics, automation, and artificial intelligence (AI). Tools like enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and supply chain management software can significantly improve your PPC capabilities. For instance, ERP systems enable centralized visibility over all aspects of your operation, from raw materials procurement to finished goods distribution. Meanwhile, MES provides detailed insights into machine performance and downtime, allowing you to proactively address potential issues before they become major problems.

4. Establish Key Performance Indicators (KPIs):

To measure the effectiveness of your PPC strategy, establish KPIs that align with your business objectives. Common KPIs include on-time delivery rate, inventory turnover ratio, cycle time reduction percentage, and return on investment (ROI). Regularly monitoring these metrics allows you to identify areas for improvement and adjust your strategy accordingly. Moreover, sharing KPI results with employees fosters accountability and motivates them to contribute towards achieving organizational goals.

5. Foster a Culture of Continuous Improvement:

Continuous improvement is essential for maintaining a competitive edge in today's fast-paced marketplace. Encourage open communication and feedback within your organization, promoting employee involvement in identifying opportunities for process optimization. Consider establishing suggestion programs or Kaizen events, where teams collaborate to brainstorm ideas for improving specific workflows. Remember, even small improvements can yield significant long-term benefits.

6. Train and Empower Employees:

Finally, invest in training and development programs to empower your employees to excel in their roles. Ensure they understand your PPC strategy and its importance to the company's success. By equipping them with the necessary knowledge and skills, you can build a capable workforce committed to delivering high-quality products efficiently. Furthermore, involving employees in decision-making processes increases job satisfaction and reduces turnover rates, leading to a more stable and productive work environment.

Conclusion

A well-designed production planning and control strategy can greatly benefit any manufacturing business seeking operational excellence. By following these six proven tips – understanding business requirements, implementing lean techniques, utilizing advanced technology, setting KPIs, fostering continuous improvement, and training/empowering employees – you can develop a robust PPC strategy tailored to your unique needs. Keep in mind that successful implementation requires ongoing effort and commitment; however, the rewards of improved productivity, reduced costs, enhanced quality, and increased customer satisfaction make it worthwhile.

0 notes

Text

Steel Supply Chain Management: Challenges and Best Practices

The steel industry operates within complex supply chains that must be effectively managed to ensure seamless production, distribution and delivery of steel products. From raw materials to finished goods, successful supply chain management is vital for optimizing operations and meeting customer demands. In this article we explore some of the challenges encountered by steel supply chain management as well as best practices that may improve its efficiencies.

Management Challenges of Steel Supply Chain

1. Raw Material Acquisition Steel production

relies on various raw materials, such as iron ore, coal and alloys. However, maintaining an affordable supply can be challenging due to fluctuating prices, geopolitical risks and transportation constraints partner with the best lime steel manufacturers in jodhpur .

2. Production Planning For efficient steel manufacturing,

matching production capacity with demand forecasts is paramount. However, unexpected disruptions such as equipment failure or labor shortages may wreak havoc with production schedules, leading to inefficiency.

3. Inventory Management Maintaining

optimal inventory levels in the steel industry is of utmost importance in order to avoid stockouts and minimize carrying costs. Inadequate management could lead to excess or obsolete inventories tying up capital and warehouse space.

4. Transportation and Logistics

Due to their size and weight, steel products often require special handling during their delivery process. Finding reliable logistics partners and optimizing transportation routes are two major hurdles within the steel supply chain.

5. Quality Control and Compliance

Ensuring product quality and compliance with industry standards throughout the supply chain are critical to customer satisfaction and regulatory compliance, whereas any inadequacies in quality control measures could result in product defects and recalls that could harm both customer relationships as well as regulatory enforcement efforts.

1. Strategic Partnerships

To improve supply chain visibility and responsiveness, build strategic relationships with dependable suppliers and logistics providers to form collaborative relationships for enhanced supply chain visibility and responsiveness. Cooperative relationships may allow for improved negotiation terms as well as faster issue resolution.

2. Digital Transformation

Implementing cutting-edge technologies like IoT sensors, predictive analytics, and blockchain can enhance supply chain transparency and real-time monitoring enabling proactive decision-making and risk management.

3. Lean Manufacturing

Whilst lean principles aim to streamline production processes and eliminate waste, continuous improvement methodologies such as Six Sigma and Kaizen can optimize resource usage while increasing productivity.

4. Inventory Optimization

Make the most out of inventory optimization tools to accurately anticipate demand and maintain optimal stock levels. Implement just-in-time (JIT) inventory practices to lower carrying costs and enhance cash flow.

5. Risk Mitigation Strategies

Develop contingency plans for potential supply chain disruptions such as supplier failure or natural disaster. Diversify sourcing options and increase resilience through sound risk mitigation strategies.

Conclusion

Effective supply chain management is vital to the success of top lime manufacturers for steel industry in Rajasthan operations. By addressing challenges and implementing best practices, steel companies can increase operational efficiency, lower costs and deliver superior products to customers. Attracting innovation while forging collaborative partnerships is key to building resilient supply chains within this dynamic industry.

#top lime manufacturers for steel industry in Rajasthan#best lime steel manufacturers in jodhpur#best lime steel manufacturers in rajasthan

0 notes

Text

3+3 Inventory Management Strategies

There’s no arguing that inventory management is critical for any modern organization. Without proper inventory management, your firm risks upsetting its consumers, losing important sales, or investing in products that will not sell. As you can expect, any of these scenarios will be counterproductive to your growth and can be highly damaging to your bottom line.

Inventory management tactics are used by both large corporations and small enterprises to maintain their operations effective and profitable. In this blog post, we’ll discuss three key inventory management approaches, as well as how inventory management software can help you manage your inventory more effectively.

3 must-know inventory management strategies

The push technique, pull technique, and just-in-time approach are the three most common inventory management strategies. These methodologies provide firms with various options for addressing client demand.

Continue reading to find out more about these three inventory management strategies:

The Push Strategy for Inventory Management

The push strategy is a type of inventory control in which things are “pushed” down from the manufacturer to the store, warehouse, or business. A consumer or employee will then purchase or use the item from the inventory on hand.

In order to successfully use the push approach, a company must accurately estimate product demand. Understanding how much of a product is required and at what time of year is critical. Using inventory management software lets organizations evaluate how inventory has been used over time, providing crucial insights into how much inventory they may need to acquire during the calendar year.

For example, an electronic store may stock dozens and dozens of air conditioners and coolers in the spring and summer, but only a few in the winter. These retailers decide how many air conditioners and coolers to purchase based on how many they’ve sold previously and when. The push method is ideal for companies that can precisely estimate client demand.

Hint: Push Strategy works far better only and only if the prediction of requirement is better and more accurate based on previous data. This Inventory Management style helps organizations to fetch the best of the best rate.

The Pull Strategy for Inventory Management

The pull strategy is an inventory management system in which a store, warehouse, or corporation only “pulls” an item when a customer or employee orders it. Instead of moving down the supply chain, an item climbs up which can take a long time!

Many furniture-making shops, for example, are “pulled” only after consumers have handed over their payment cards. These people choose their furniture from a reference or a website, and the final furniture is either created or procured for them at the time of purchase. Customers are usually fine with it taking months because it is an industry standard.

However, the pull method is not for every firm, especially if clients can get identical goods from another source right away in a short time

Hint: The pull technique is typically used for specialty items, costly items, or items with little or unpredictable demand.

The Just-in-Time Strategy (JIT) for Inventory Management

The pull strategy is related to the just-in-time inventory strategy in that organization’s order inventory “just in time” to fulfil a customer’s order or a company necessity. Of course, adopting a just-in-time inventory management plan successfully necessitates dependable suppliers, vendors, and third-party logistics partners. Without them, a company may be unable to meet customer demand, which is almost always a prescription for disaster.

Just-in-time inventory saves firms money by reducing inventory carrying costs, reducing headstock, and improving cash flow. Companies that rely on JIT inventory, on the other hand, are not always able to satisfy demand and may have to overpay for a product to deliver it to their consumers promptly.

Apart from that, there are 3 More Inventory Management Techniques which are prevalent in the Market:

ABC Analysis:

This method works by identifying the most and least popular types of Inventory. This method of inventory is segregated based on Consumption and Investment and then given the classification of A, B, and C which will define the focus area on inventory which is highly consumed and has a high cost.

Batch Tracking:

Particularly, Pharma and FMCG manufacturers use this Inventory Management Technique where the focus is to build groups of similar items to track expiration dates and trace defective items.

Cross-Docking:

This technique focus on eliminating the warehouse by unloading the Inventory directly from a supplier truck to the delivery truck.

What Next?

No matter what method of inventory management your business practices, experts can help you practice better, faster, and less stressful inventory management and control. Stratefix consulting, a top-rated firm specializing in business growth consulting and strategy consulting firm can help you get organized fast, even if you’re in over your head.

#Business growth consulting#consulting firms in india#strategy consulting firm#management consulting surat

0 notes

Text

Optimizing the Supply Chain with Javier Daniel Salcido_ Strategies for Timely Resource Management in Oilfields

Javier Daniel Salcido Odessa Texas

Optimizing the Supply Chain with Javier Daniel Salcido: Strategies for Timely Resource Management in Oilfields

In the fast-paced world of oilfield operations management, effective supply chain management is crucial for ensuring the timely delivery of resources and materials needed to keep operations running smoothly. From drilling equipment and machinery to personnel and consumables, the oilfield supply chain encompasses a wide range of components that must be carefully managed to minimize downtime and maximize efficiency. In this blog, we explore strategies for optimizing the supply chain in oilfield operations, highlighting key principles and best practices for timely resource management.

Understanding the Oilfield Supply Chain

The oilfield supply chain is a complex network of interconnected processes and stakeholders involved in the procurement, transportation, and delivery of resources and materials to support drilling and production activities. This includes everything from sourcing raw materials and components from suppliers to managing inventory, logistics, and distribution to remote drilling sites. Effective supply chain management is essential for ensuring that the right resources are available at the right time and place to meet the demands of drilling operations and maximize productivity and profitability.

At the heart of the oilfield supply chain is the concept of just-in-time (JIT) inventory management, which aims to minimize inventory holding costs and reduce waste by ensuring that resources are delivered precisely when they are needed. By maintaining lean inventories with the help of experts like Javier Daniel Salcido and relying on real-time data and forecasting tools, oilfield operators can optimize resource allocation and minimize the risk of stockouts or excess inventory. Additionally, establishing strategic partnerships and collaborations with suppliers and logistics providers can help streamline procurement processes and enhance the efficiency and reliability of the supply chain.

Utilizing Advanced Technology and Data Analytics

In today's digital age, advanced technology and data analytics play a crucial role in optimizing the oilfield supply chain. From cloud-based inventory management systems and IoT-enabled sensors to predictive analytics and artificial intelligence (AI), technology offers powerful tools for tracking, monitoring, and optimizing supply chain operations in real-time. These tools provide oilfield operators with valuable insights into inventory levels, demand patterns, and supplier performance, allowing them to make informed decisions and proactively address potential bottlenecks or disruptions.

By leveraging data analytics and predictive modeling with the help of experts like Javier Daniel Salcido, oilfield operators can anticipate changes in demand, identify opportunities for process improvement, and optimize resource allocation to minimize downtime and maximize efficiency. For example, predictive maintenance algorithms can analyze equipment performance data to forecast potential failures and schedule maintenance activities proactively, reducing the risk of unplanned downtime and costly repairs. Similarly, AI-powered demand forecasting tools can analyze historical data and market trends to predict future demand for resources and materials, enabling more accurate inventory planning and procurement decisions.

Implementing Lean Manufacturing Principles

In addition to leveraging advanced technology, oilfield operators can optimize the supply chain by adopting lean manufacturing principles and practices. Lean principles, such as continuous improvement, waste reduction, and value stream mapping, focus on identifying and eliminating inefficiencies and bottlenecks in the production process to streamline operations and improve overall performance. By applying lean principles to the oilfield supply chain with the help of experts like Javier Daniel Salcido, operators can reduce lead times, improve resource utilization, and enhance productivity and profitability.

One key aspect of lean manufacturing in the oilfield context is optimizing transportation and logistics processes to minimize delays and reduce costs. This may involve consolidating shipments, optimizing routing, and implementing just-in-time delivery schedules to ensure that resources are delivered to drilling sites in a timely and cost-effective manner. Additionally, implementing visual management techniques, such as kanban systems and standardized work instructions, can help streamline workflows and improve communication and coordination among supply chain stakeholders.

Ensuring Regulatory Compliance and Risk Management

In the highly regulated oil and gas industry, ensuring compliance with regulatory requirements and managing risks are critical aspects of supply chain management. From safety and environmental regulations to import/export controls and tax compliance, oilfield operators must navigate a complex web of regulations and requirements to avoid costly fines, penalties, and reputational damage. Additionally, managing risks such as supply chain disruptions, geopolitical instability, and natural disasters requires proactive planning and contingency measures to safeguard operations and mitigate potential impacts.

Effective risk management in the oilfield supply chain involves identifying potential threats and vulnerabilities, assessing their likelihood and potential impact, and implementing strategies to mitigate or avoid them altogether. This may include diversifying suppliers and sourcing locations, implementing redundant systems and backup plans, and maintaining adequate insurance coverage to protect against unforeseen events. By taking a proactive and holistic approach to compliance and risk management with the help of experts like Javier Daniel Salcido, oilfield operators can ensure the reliability, resilience, and sustainability of their supply chain operations.

Fostering Collaboration and Communication

Effective supply chain management in the oilfield industry relies on strong collaboration and communication among all stakeholders, including suppliers, logistics providers, contractors, and internal departments. By fostering open lines of communication and collaboration, oilfield operators can enhance transparency, responsiveness, and agility in the supply chain, enabling faster decision-making and problem-solving. This may involve regular meetings, performance reviews, and joint planning sessions to align objectives, address challenges, and identify opportunities for improvement.

Furthermore, leveraging digital collaboration tools and platforms can facilitate real-time communication and information sharing among supply chain partners, regardless of their location or time zone. Cloud-based collaboration platforms, project management software, and communication apps enable stakeholders to share documents, track progress, and communicate in real-time, enhancing visibility and coordination across the supply chain. By fostering a culture of collaboration and communication with the help of experts like Javier Daniel Salcido, oilfield operators can build stronger relationships with suppliers and partners and drive continuous improvement and innovation in the supply chain.

Optimizing the supply chain is essential for ensuring timely resource management and maximizing efficiency in oilfield operations. By understanding the complexities of the oilfield supply chain and implementing strategies such as leveraging advanced technology, adopting lean manufacturing principles, ensuring regulatory compliance and risk management, and fostering collaboration and communication, oilfield operators can streamline operations, minimize downtime, and enhance profitability. With careful planning, proactive management, and continuous improvement, oilfield operators can optimize their supply chain operations to meet the evolving demands of the industry and drive sustainable growth and success.

0 notes

Text

Strategic Warehouse Solutions: Maximizing Space Utilization in Dubai

In Dubai, a bustling hub of global commerce and logistics, efficient utilization of warehouse space is crucial for businesses looking to optimize their operations. The city's strategic location as a crossroads of international trade elevates the importance of effective logistics strategies, involving freight forwarding companies in Dubai, warehouse for storage in Dubai, and local courier service in Dubai. These elements work in tandem to ensure the seamless flow of goods through Dubai's logistics network. This article explores the significance of strategic warehouse solutions in maximizing space utilization, highlighting the roles played by freight forwarding companies, warehousing solutions, and local courier services in enhancing logistics efficiency in Dubai.

The Role of Warehouse for Storage in Dubai

A warehouse for storage in Dubai is more than just a storage facility; it's a critical component of the supply chain that impacts everything from inventory management to order fulfillment speeds. Modern warehousing solutions in Dubai are designed to accommodate the diverse needs of various industries, incorporating advanced technologies for inventory tracking, climate control, and security. Effective space utilization within these warehouses can significantly reduce operational costs, improve order processing times, and increase overall efficiency.

Partnering with Freight Forwarding Companies in Dubai

Freight forwarding companies in Dubai are integral to the logistics ecosystem, managing the complexities of shipping international freight and ensuring goods are transported efficiently across borders. These companies often collaborate closely with warehouses to streamline the transition from international transportation to local storage and distribution. By optimizing logistics operations, freight forwarding companies in Dubai play a pivotal role in enhancing warehouse space utilization, ensuring goods are stored strategically for easy access and quick turnover.

Leveraging Local Courier Service in Dubai

Once goods are optimally stored and ready for distribution, the local courier service in Dubai becomes crucial in executing the last mile of delivery. Ensuring efficient pick-up from the warehouse and prompt delivery to the final destination, local courier service in Dubai is essential for maintaining the flow of goods to customers. The synergy between warehousing solutions and local couriers is vital for minimizing storage time and maximizing warehouse space utilization.

Strategies for Maximizing Warehouse Space Utilization

Implement Advanced Inventory Management Systems: Utilizing RFID tags, barcodes, and warehouse management software can enhance inventory visibility, allowing for more effective use of space.

Adopt Flexible Storage Solutions: Modular shelving and mobile racking systems can adapt to changing inventory levels and product sizes, optimizing storage density.

Utilize Vertical Space: High-rise storage systems can significantly increase warehouse capacity, making the most of available vertical space.

Integrate Order Fulfillment Strategies: Implementing just-in-time (JIT) fulfillment or cross-docking can reduce the need for long-term storage, freeing up space for more inventory turnover.

Outsource to Specialized Warehouses: For businesses with specific storage needs, such as temperature control or high-value security, partnering with specialized warehouse for storage in Dubai can provide tailored solutions without the need for extensive internal infrastructure.

Conclusion

In the dynamic and competitive landscape of Dubai's logistics sector, maximizing warehouse space utilization is key to achieving operational efficiency and cost-effectiveness. Through strategic partnerships with freight forwarding companies in Dubai and leveraging the capabilities of local courier service in Dubai, businesses can enhance their warehouse operations, ensuring goods are stored, managed, and distributed with optimal efficiency. As Dubai continues to grow as a global logistics hub, the adoption of innovative warehouse solutions and strategic space utilization practices will remain essential for businesses aiming to thrive in the international market.

#freight forwarding companies in dubai#warehouse for storage in dubai#local courier service in dubai

0 notes

Text

PP Production Planning

Production Planning: The Heartbeat of Manufacturing

Production planning (PP) is the cornerstone of efficient manufacturing operations. It involves strategically aligning your company’s capacity with customer demand to ensure products are manufactured on time and to the highest quality standards. A well-executed production plan translates into happy customers, reduced costs, and increased profitability for your business.

What is Production Planning?

Production planning defines the how, what, and when of the manufacturing process. It encompasses a wide range of activities, including:

Demand forecasting: Predicting future customer demand to ensure you produce adequate quantities.

Master Production Scheduling (MPS): Creating a high-level plan for the types and quantities of finished goods to be produced within specific time periods.

Material Requirements Planning (MRP): Calculating the raw materials and components needed for production and ensuring their timely availability.

Capacity Planning: Evaluating your available resources (workforce, machinery, time) and determining if they can meet the production schedule demands.

Shop floor scheduling: Detailed planning for the sequence and timing of manufacturing activities on the factory floor.

The Importance of Production Planning

Effective production planning offers a host of benefits:

Meeting customer demand: Aligning production with demand forecasts ensures you have enough inventory to fulfill orders promptly without producing excessive quantities.

Optimized resource utilization: Efficient capacity planning helps you make the most of your workforce, equipment, and facilities.

Inventory control: MRP aids in maintaining balanced inventory levels, lowering holding costs while avoiding stockouts.

Reduced waste: Efficient planning minimizes production downtime, material overages, and bottlenecks.

Improved on-time delivery: Meeting deadlines fosters greater customer satisfaction and loyalty.

Tools and Techniques in Production Planning

Various tools and techniques can support a robust production planning process:

Software solutions: Enterprise Resource Planning (ERP) systems, often with dedicated Production Planning (PP) modules like SAP PP, streamline planning processes, centralize data and support complex decision-making.

Gantt Charts: These visual tools illustrate the production schedule, helping track progress and identify potential delays.

Kanban: A system that signals the need for material replenishment, maintaining a smooth flow of production.

Just-In-Time (JIT): A philosophy focused on producing only what is needed, when it is needed, reducing inventory costs.

Key Considerations for Production Planning

Data Accuracy: Reliable input data on demand forecasts, lead times, and inventory levels is crucial.

Flexibility: Plans should be adaptable to changes in customer demand or supply chain disruptions.

Communication: Collaboration between sales, production, and procurement teams is vital for a successful plan.

Continuous improvement: Regularly review and adjust your production planning processes to address any inefficiencies.

Conclusion

Production planning is a dynamic, continuous process—far from being a static one-time plan. Successful manufacturing enterprises invest in establishing and refining their PP strategies. Employing the techniques and tools described above will help your organization achieve the holy grail: delivering the right products to the right place at the right time, all while maximizing efficiency and profitability.

youtube

You can find more information about SAP PP in this SAP PP Link

Conclusion:

Unogeeks is the No.1 IT Training Institute for SAP PP Training. Anyone Disagree? Please drop in a comment

You can check out our other latest blogs on SAP PP here – SAP PP Blogs

You can check out our Best In Class SAP PP Details here – SAP PP Training

Follow & Connect with us:

———————————-

For Training inquiries:

Call/Whatsapp: +91 73960 33555

Mail us at: [email protected]

Our Website ➜ https://unogeeks.com

Follow us:

Instagram: https://www.instagram.com/unogeeks

Facebook:https://www.facebook.com/UnogeeksSoftwareTrainingInstitute

Twitter: https://twitter.com/unogeek

#Unogeeks #training #Unogeekstraining

1 note

·

View note

Text

Enhancing Supply Chain Efficiency: The Role of Warehouses in VKI Jaipur

In the bustling industrial landscape of Jaipur, the VKI (Vishwakarma Industrial Area) stands as a cornerstone of economic activity. With its strategic location and robust infrastructure, VKI has become a nucleus for various industries, ranging from textiles to automotive components. Among the critical elements contributing to VKI's success is its network of warehouses, facilitating seamless storage and distribution operations for businesses operating within the area and beyond.

Warehouse in VKI Jaipur:

Warehousing plays a pivotal role in the supply chain management of any industry. In VKI Jaipur, warehouses serve as the backbone of logistics operations for numerous businesses. warehouse in vki jaipur These warehouses come equipped with state-of-the-art facilities, including advanced inventory management systems, temperature-controlled storage units, and efficient material handling equipment.

The strategic location of warehouses in VKI Jaipur ensures easy access to major transportation routes, such as highways and railways, facilitating the smooth movement of goods to and from the area. This proximity to transportation hubs significantly reduces transit times and transportation costs, thereby enhancing overall supply chain efficiency.

Furthermore, warehouses in VKI Jaipur offer customizable storage solutions tailored to the specific needs of different industries. Whether it's storing raw materials, semi-finished goods, or finished products, these warehouses provide ample space and flexibility to accommodate varying inventory requirements.

Warehouse in Jaipur:

Beyond VKI, Jaipur boasts a diverse array of warehouses catering to the needs of businesses across different sectors. From small-scale enterprises to large corporations, companies rely on warehouses in Jaipur to streamline their logistics operations and ensure timely delivery of goods to customers.

The warehouse infrastructure in Jaipur is continuously evolving to keep pace with the growing demands of modern supply chains. New technologies, such as RFID (Radio Frequency Identification) and automation, are being integrated into warehouse operations to enhance efficiency and accuracy in inventory management.

Moreover, the emergence of third-party logistics providers offering warehousing services has further expanded the options available to businesses in Jaipur. These specialized logistics firms offer comprehensive warehousing solutions, allowing companies to focus on their core competencies while outsourcing their storage and distribution needs.

Medical Garment Manufacturer in Jaipur:

Among the industries benefiting from the warehousing infrastructure in Jaipur is the medical garment manufacturing sector. Jaipur has emerged as a prominent hub for medical garment production, with several manufacturers operating within the city.

These manufacturers rely on warehouses in Jaipur to store raw materials such as fabrics, elastic bands, and accessories, as well as finished garments ready for distribution. The availability of specialized warehouses equipped with cleanroom facilities ensures the hygiene and quality standards required for medical garment production are met.

Furthermore, warehouses in Jaipur play a crucial role in the Just-in-Time (JIT) inventory management strategy adopted by many medical garment manufacturers. By maintaining optimal inventory levels and minimizing storage costs, warehouses enable manufacturers to respond swiftly to fluctuating demand while keeping production costs in check.

In conclusion, warehouses in VKI Jaipur and across the city play a vital role in enhancing supply chain efficiency for businesses operating in various industries. From providing storage solutions to facilitating distribution logistics, these warehouses form the cornerstone of Jaipur's thriving industrial ecosystem. As industries continue to evolve and expand, the significance of warehouses in Jaipur is poised to grow, further solidifying the city's position as a key player in India's logistics landscape.

medical garment manufacturer in Jaipur

#warehouse in sikar road jaipur#warehouse in vki jaipur#warehouse in jaipur#safety uniform manufacturer#womenswear manufacturer in india

0 notes