#semifinished

Text

For Sale Standalone villa with sea view @ Wadi Soma

Our villa is built on 1 level with built up area 255 Sq. It features 4 bedrooms, 4 bathrooms, nanny's room, driver's room, living/dining area and open plan kitchen.

Price: 38,000,000 EGP.

Pay only 10% for contractual, following a payment plan of 5 years.

Delivery in 3 years - semi-finished.

For more details, contact +201111251110

or email us [email protected]

or visit our website www.beeyoot.net

#redsea#somabayredsea#WadiSoma#villaforsale#villaforsaleinsomabay#seaview#semifinished#nannyroom#driverroom#FacilitiesManagement#beachlife#restaurants

0 notes

Text

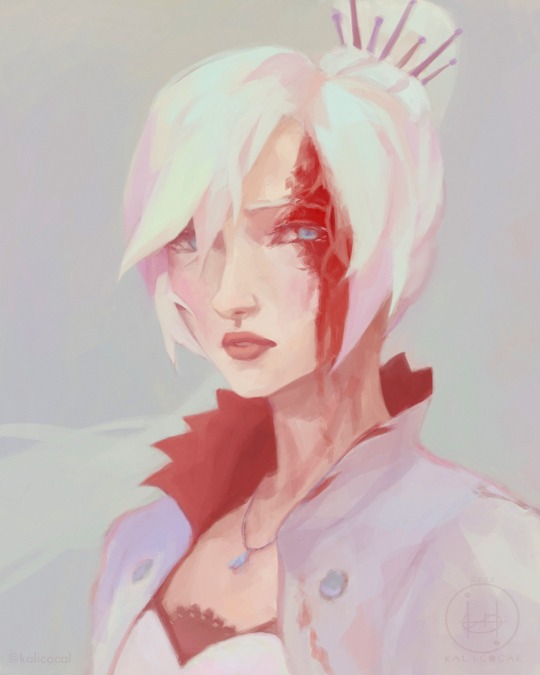

the loneliest girl

#weiss schnee#rwby#rwby fanart#team rwby#artists on tumblr#revisiting an old fandom#her trailer popped up on my yt recs around early july (?) so i made this then just cleaned it up a lil now#reminds me of my old rwby art thatre still probably floating out there somewhere lol#july2022#my rwby art#my art#clip studio paint#semifinished art

96 notes

·

View notes

Text

pinterest has an unfortunately limited amount of inspo for rustic/vintage eclectic/eco modern/maximalist styled semifinished basement studio apartments

2 notes

·

View notes

Text

Semifinished OSMP Rambo and Tubbo

4 notes

·

View notes

Text

Commonly Used Materials for Metal Injection Molding (MIM)

https://www.jlymim.com/commonly-used-materials-for-metal-injection-molding-mim.html

1. Introduction of Metal Injection Molding

Metal injection molding (MIM) is a near-net-shape process suitable for small, three-dimensional complex shape products with special performance requirements. This technology is a new near-net-shape technology in powder metallurgy, which is formed by introducing modern plastic injection molding technology into the field of powder metallurgy.

MIM process flow is as follows: all kinds of fine metal powder (generally less than 20 μ m) and the preset binder, mixed with a certain proportion, are made to the feedstock with rheological properties. By injecting the feedstock into the mold cavity through an injection machine, the semifinished products are formed. After removing the binder and sintering at a high temperature, various metal parts can be obtained.

2. What is the Ideal Mim Powder Like?

The particle size, tap density and particle shape of MIM powder are the key performance indicators to determine whether the powder can be successfully used in the MIM process. MIM process requires very fine powder (~10μm) to ensure uniform dispersion, good rheological properties and a high sintering rate.

The ideal MIM powder has the features as follows: the powder size is 2-8μm; the bulk density is 40 %~50 %; The tap density is more than 50%; the powder particles are nearly spherical with a large specific surface area.

At present, MIM metal powder raw materials include iron, nickel, titanium, stainless steel, precious metals, superalloys and other materials. At the same time, it is developing towards diversification, such as structural materials, functional materials, magnetic materials and so on.

The main production methods of MIM powder are carbonyl method, ultra-high pressure water atomization method, high pressure gas atomization method, plasma atomization method and laminar flow atomization method. Different powder preparation technologies have different effects on the grain size of powders, particle shape, microstructure, chemical properties, manufacturing cost and so on.

3. How to Choose a Binder for Metal Injection Molding?

Binder is the core technology of metal injection molding. Compared with the conventional powder metallurgy method, MIM has a significant difference of high binder content. The main function of the binder is to act as a carrier for the flow of bonded metal powder particles and to maintain the shape of the workpiece after molding.

The binder for MIM shall meet the following requirements:

Small contact angle with powder, strong adhesion and no reaction with powder;

The viscosity changes little in the range of injection temperature, but the viscosity changes fast in cooling, so it is difficult to stick the mold;

A relatively small amount of binder can make the mixture have better rheological properties.

0 notes

Text

Mega-trends Driving Chemical Industry - Success Priorities Pt.2.4

SELL BUSINESS OUTCOMES INSTEAD OF JUST PRODUCTS

In Future most chemical companies will move from B2B push models to business-to-business-to-consumer (B2B2C) models. Digital technology and concepts such as Industry 4.0 will be leveraged to deliver sustainable, co-developed applications, services, and business outcomes. Companies that have identified an experience gap will gain a competitive advantage by engaging more closely with their customers and ecosystem partners. This engagement will enable them to deliver outcome-driven services and address customer expectations. This experience, along with developing customer relationships based on trust and shared values and risks, will be the new paradigm.

They will establish searchable intellectual-property databases to access relevant scientific information to create co-innovated products and solutions. Having established this foundation, they will extend into properties prediction and performance of new formulations to significantly shorten the development process and time to market while monitoring product and formulation compliance along the entire lifecycle. Furthermore, they will extend into their customers’ value chain, monitor process parameters, and allow in site quality control in real-time through sensors at customer operations. The implementation of Industry 4.0, where all sensors, devices, machines, and other equipment are connected in one single network, will provide an unprecedented amount of insight that eventually reveals new business opportunities, such as predictive maintenance, further improving the product experience. In terms of logistics, they will track and trace material flow and product integrity along the entire value chain.

Finally, they will collaborate on open innovation platforms, turn data into value-based services, and establish transformative business outcome-driven and customer-centric revenue models to improve quality and reduce costs and risks for customers.

OUTCOME-BASED CO-INNOVATION IN CHEMICAL COMPANIES

Traditionally, chemical companies have developed products in response to market needs driven by downstream industry sectors, such as consumer products, pharmaceuticals, engineering, and construction. In the future, chemical companies will strive for unprecedented levels of customer experience by anticipating market trends and needs, rapidly developing and manufacturing corresponding formulations and selling based on business outcomes, such as first-pass-quality semifinished parts or goods, instead of selling by quantity. Innovative technologies, such as machine learning, the IoT, artificial intelligence, and blockchain, enable these processes. A cumbersome, multistep development process and a traditional revenue model based on product quantity delay time to market and time to value.

Solutions offered in New World Scenario: Chemical Company simulates property and performance of new formulation using machine learning.

Top Value Drivers

Faster time to market

Increased Quality

Higher Customer satisfaction

Reduced Costs and Waste

Increased Brand Recognition.

Summary

With growing competition, ongoing globalization, and blurring industry boundaries, companies can no longer afford to focus solely within their own four walls. Established business models and practices based on linear value chains are no longer sustainable in an era where companies are expected to be responsible for the emissions of their suppliers, customers, and other downstream business partners.

To survive and thrive in today's competitive environment, companies cannot rely solely on organic growth. Instead, more and more are turning to mergers, acquisitions, and divestitures to expedite portfolio adjustments and diversify into promising new markets or segments. The business model is being challenged by the mass commoditization of products and formulations, global competition, higher demand from consumers for sustainable products and operations, and exponentially increasing regulatory requirements. In conclusion, those who are willing to evolve will be welcomed by the market, while those who are not willing will be lost in the crowd.

To Read full article click https://www.linkedin.com/pulse/mega-trends-driving-chemical-industry-success-priorities-solulever-1f/?trackingId=%2F%2FRj8SuQSiSch4u0x4FcWg%3D%3D

Solulever, a Dutch Technology Startup, is based on the principles of Industry 4.0 and delivers top industrial connectivity platforms to help manufacturers in taking up the digital transformation of their plant. Solulever's Brabo Edge Platform® is a platform that allows seamless connectivity to different tools and equipment on the shop floor. It performs data mashups that are therefore available to the development teams on a real-time basis

0 notes

Text

Inventory Management Systems

Integrated procurement system are used to manage the flow of raw materials, semifinished, and finished products. They also equip staff with the ability to coordinate various activities in order for efficient inventory management.

Although inventory management systems don't make decisions, they help employees make them. An inventory management system that is well-designed will help you forecast the demand and supply. It will also eliminate the need for paperwork and make it easy to find information about warehouses and links to raw material suppliers, customers, wholesalers, retailers, and other relevant entities. An inventory management system consists of sales forecast, production planning and advanced planning to procure raw materials and semi-finished goods. This helps in maintaining a desired inventory level.

There are many software tools available and offline resources that can be used to assist a company in creating a successful inventory management system. Experts are often entrusted with managing inventory management systems in large companies. These companies rely on customized software.

Specialized firms can help you design your operating system. Inventory management systems are preferred by companies with large inventories. This system ensures there is no theft or wastage, that warehouses are properly managed and that customers don't lose sales due to a shortage of finished products. Regular upgrades are necessary for information systems. These systems can have many new features without spending a lot. You can learn more about inventory management systems by taking a variety of training courses. These courses are often short-term and help you to manage your inventory systems effectively.

#purchasing system in malaysia#integrated procurement system#user friendly procurement system#adam Integrated Solutions

1 note

·

View note

Text

Cold soups as beet of, okroshka, green shi enter in a few diets as on the hot weather, cold soups temperature are 10-12C.

Fruit cold soup.

400 gr ready dish are 20 gr rice, 15 gr dried fruits, sugar.

Cook fruit, berry soups of fresh, dried or canned fruits, fruit-berry juices.

In soups add rice, vermicelli, sugar. Ready soup dress with creams, or fromage.

Proteins 1.9 gr, fats 0.1 gr, carbohydrates 40.7 gr.

Energy value 162.3 kcal.

Dish use for diets nr 1, not rubbing for diets 2,3,4 a, 5 7-10, 10 c, 11, 16.

Diet nr 10 c.

Salt free cooking, are meat, fish boiling, baking, usual temperature.

First variant for diets are proteins 90 gr, fats 70 gr, animal fats 35 percent, carbohydrates 300 gr.

Second variant a diet are proteins 100 gr, fats 80 gr, carbohydrates 350 gr, salt cooking 3-5 gr, rising on 25-50 percents, calium , phosphorus, mg on 1.5-2 times as vitamin C, B,PP . Common mass ration are 2 kg, free liquid one l.

Bread salt free, of rye, millet flour, by hard grinding, yesterday baking or dried, bran, health, rusks, dry rich cookie, crunchy loaves.

Cutlets steam meat.

88 gr ready dish are beef of first category 100 gr, milk 20 gr, millet bread 10 gr, mass for semifinished 100 gr. Proteins 15,5 gr, fats 5,6 gr, carbohydrates 6.1 gr, energy value 136.0 kcal.

Dish you can use for diets nr 1, 1 b, 2, 3, 4, 4 b, 4 a, 4 b, 4 v, 5, 5 v, 5 a, 7-10, 10 i, 10 b.

Beef boiled with white sauce.

90 gr ready dish are beef first category as 100 gr, vegetable infusion 50 gr, flour 5 gr, oil, fromahe 3 gr, ready meat mass 43 gr, proteins 14.7 gr, fats 8.3 gr, carbohydrates 3.8 gr, energy value 148.3 kcal, dish use for diets nr 1,2,3, 4 a, 5,7-10, 10 c.

Diet nr 10 c. Recommending dishes.

Soups vegetarian, fruit, milk, cereal, salt free. Fish, meat of bird, inside organs without of animals, boiled, baked, non-fat fish, boiled or baked. Soft-boiled eggs 3 pieces/week, white steam omelet, non-fat fromage, doctor s sausage, salt free cheese, farrago, sea cabbage salads, soaked herring for 2 times.week. Milk natural, in dishes, sour milk, kefir, sour cream, curd fresh, in dishes. Sweets, berries, fruits of ripe, jam, honey on 50 gr/day.

Stewed cabbage with apples.

200 gr ready dish a cabbage 188 gr, apples 57 gr, vegetable infusion 30 gr, butter oil 10 gr.

Proteins 2.3 gr, fats 13.8 gr, energy value 138.3 gr, dish use for diets nr 2,3,5, 7-10, 7 a, 10 c, 11,15

Stewed cabbage sauerkraut.

200 gr ready dish are sauerkraut 300 gr, butter oil 10 gr, pasta tomato, flour 3 gr, sugar 3 gr.

Proteins 2.2 gr, fats 8.3 gr, carbohydrates 10.5 gr, energy value 101.6 gr.

Dish use for diets nr 7, 10, 11, 15, 8-9 as sugar-free.

Diet nr 10 c.

Cereal and macaronies, friable porridges, puddings, baked puddings, vegetable oils non raffinate, for dishes adding, cooking , salad as, farragos, butter oil, for cooking. Limiting flour dishes, macaronies, carrot, squashes, pumpkin, cucumbers, tomatoes, beet, cabbage, bean, potato, cauliflowers, fresh, shredding, chopping. baked, stewed, salads for, garnishes,addings , greens, and avoiding spinach, sorrel.

Sauces, spices milk, of vegetable infusion, fruit, berry , spices without.

Pilaf by Milan.

250 gr rice, 500 gr broth, 100 gr olive oil, or any other vegetable oil, 200 gr mushrooms, 200 gr tomatoes, 150 gr parmesan. Rice fry, add mushrooms boiled, shredding, fried, tomatoes chopped. Mix, and add broth. When broth boils, close pod with lid and put on warmed oven for 16 min, serve hot as hot snack. Separately serving shredding parmesan or tomato sauce.

Baked fish in marinade.

Without a harmful cholesterol.

750 gr sea fish, 1/2 glass vegetable oil, 2 tbl.sp. vinegar, salt, pepper, bay leaf, breading rusks, white wine.

Clean fish, peel clean, put in marinade of vinegar and oil, spices, in 3 hours remove fish, infuse for liquid remove, salt, roll in breading and bake in oven on form, pour over sometimes with oil, white wine. Garnish to serve rice with tomato sauce.

In prostatitis.

25 gr chopped brown peel of chestnuts horse, 250 ml. spirit and infuse in dark place for ten days, shaking everyday, use on 30 drops for 3 times/day.

Diet nr 10.

Tea with milk, inka drink with milk, hibiscus drink, black currant, fruit, vegetable juices, compotes, kvas, gas drinks limiting.

And in anti-atherosclerotic diet adding proteins with bread, cereal , vegetable products as of sea cabbage, squids, sea scallop, mussels.

Avoiding are fat meat, fish, strong broth meat, hard fats, inside organs of animals, brains, sorrel, spinach, creams, pastry, pies, cakes, spicy, salted fat snacks, chocolate, cacao, butter ice cream, alchokol.

Pancake with jam.

220 gr ready dish are milk, flour 100 gr, jam 50 gr, butter oil 10 gr, sugar, yeasts 5 gr. Proteins 13.3 gr, fats 14.1 gr, carbohydrates 117.0 gr, energy value 621.4 kcal, dish use for diets nr 2, 7-11, 15.

Ban.

70 gr ready dish a flour 40 gr, milk 20 gr, butter oil , yeast, vegetable oil 51 gr, eggs 1/4 piece, proteins 6.9 gr, fats 17.3 gr, carbohydrates 36.2 gr, energy value 260. 3 kcal.

Dish you can use for diets nr 2,3, 4 a, 5,7-10, 7 b, 11,15

Diet nr 10 c.

Approximately menu for a day, anti-atherosclerotic.

1 st breakfast oats porridge, eggs boiled, tea with milk.

2 nd breakfast. Shredding vegetables salad, with vegetable oil, hibiscus drink 150 gr.

Lunch. Vegetarian shi, tomatoes fresh, cucumbers salad, cutlets meat baked with boiled potato, fresh apples.

Afternoon snack. Fruit juice 150 gr, rusks.

Dinner. Golubtsi stuffed with vegetables, curd pudding with jam, tea with milk.

For night. Kefir 200 gr.

For all day are bran bread 150 gr, white millet bread 100 gr, sugar 35 gr.

from Valga s health news,gardening,and cooking ,and beauty . https://ift.tt/C7N6D52

via https://ift.tt/XBi9sl5

0 notes

Text

China to help stabilize global supply chain

China will play a key role in underpinning the global supply chain in the second half of the year amid government policy measures to stabilize the economy while tackling the impact of COVID-19 via targeted means, experts said. China will play a key role in underpinning the global supply chain in the second half of the year amid government policy measures to stabilize the economy while tackling the impact of COVID-19 via targeted means, experts said. Although major economies such as Germany, France, South Korea and the United States saw trade deficits in recent months, the surplus of China's foreign trade topped 2.48 trillion yuan ($367 billion) in the first half, as exports soared after the COVID-19 resurgences were brought under control in the Yangtze River Delta region in May and June, data from the General Administration of Customs showed. As China's trade surplus rose significantly to $97.94 billion in June from $78.76 billion in May, experts said the growth has helped buffer the yuan's exchange rate with other major currencies and further stabilize the domestic inflation rate, reducing the need to raise interest rates or intervene on the currency exchange rate. As the US Federal Reserve raised key interest rates steeply to curb runaway inflation in the second quarter, the euro, the pound and the Japanese yen all plunged against the US dollar. The currency depreciation in these major economies has brought stagflation and downside risks, said Xu Hongcai, deputy director of the China Association of Policy Science's economic policy committee. As many traditional manufacturing powerhouses such as Germany and South Korea must import large amounts of raw materials to meet the demand from the local manufacturing sector, the impacts of the Russia-Ukraine conflict, high inflation rate in the US, and soaring global energy and commodity prices have all pushed these countries to spend more on import of both energy and production materials since the second quarter, Xu said. Even though facing imported inflationary pressure, China, supported by its ongoing industrial transformation and upgrading, will continue to work toward stabilizing the global supply chain, said Wei Qijia, a researcher at the Economic Forecasting Department of the State Information Center. He said China's highly concentrated supply chains, efficient productivity, relatively lower domestic costs of industrial power and production materials, as well as many trade partners' heavy dependence on its industrial goods and semifinished products, will keep the growth rate of the nation's trade surplus within a reasonable range in the coming months. "China does not pursue trade surplus on purpose. The accelerated trade surplus growth in the first half of the year was mainly attributable to the epidemic-induced import volume contraction," said Wei Jianguo, vice-president of the China Center for International Economic Exchanges in Beijing. He predicted that China's trade surplus growth may slow down during the second half of the year, as the nation is expected to import large amounts of energy, minerals and machinery to speed up effective infrastructure investment in pursuit of a more vigorous economic recovery. Zhang Jianping, head of the center for regional economic cooperation at the Chinese Academy of International Trade and Economic Cooperation, said a certain amount of uncertainty shrouds China's second-half exports due to fluctuations in global market demand. But, given the better-than-expected export performance during the first half, China should accelerate effective policy implementation to promote robust growth of foreign trade. Only by encouraging and facilitating enterprises to receive new business orders could the nation expand export market space amid uncertainties, he said. Nio, China's new energy vehicle manufacturer, is one such enterprise in pursuit of more business, said Zhang Hui, vice-president of Nio Europe. In addition to exporting electric vehicles to Norway, it is building its first overseas plant in Hungary to support its expansion in Germany, the Netherlands, Sweden and Denmark later this year. Nio's Hungary factory is expected to be operational in September and serve as a production, service and R&D center for the company's power products, including battery-swapping stations in Europe, said Zhang.

submitted by /u/12345carrie

[link] [comments]

from news about electric cars https://ift.tt/q1G7BPA

0 notes

Text

How To Scrub The Plastic Extrusion Machine In China

The china plastic extrusion machine extrusion machine produces pellets, which are the uncooked materials for plastic polymers.

What is a plastic extruder?

A plastic extruder is a machine that's used to supply varied varieties of plastic products. It's composed of a quantity of different components, including a barrel, which is where the plastic pellets are melted and turned into merchandise; a feeder, which provides the pellets to the barrel; and a die, which shapes the plastic pellets into the desired form.

How does the plastic extruder work?

The plastic extruder is a machine that melts the thermoplastic pellets after which extrudes it by a die to create semifinished products. The extrusion course of happens in two phases: the feeder and the die. In the feeder, the pellets are fed into the die, the place they're melted and then pressured by a small opening at high speed. This produces the finished product, which is then ejected from the die and collected on the opposite side of the machine.

Advantages of Using a Plastic Extrusion Machine

There are a few the explanation why chances are you'll want to consider using a plastic extrusion machine. Firstly, they are dependable and efficient, making them a great alternative for small-scale manufacturing. Secondly, they can be simply cleaned, which is especially important in environments with excessive levels of contamination. Finally, they produce high-quality products that are effectively suited for many applications. If you're seeking to take your production degree up a notch, a plastic extrusion machine is a great possibility. These machines are dependable and environment friendly, making them good for small-scale manufacturing. They can be simply cleaned, ensuring that your atmosphere remains free from contamination. In addition, the merchandise that they produce are of top of the range, making them effectively suited for many applications. If you're desirous about learning more about plastic extrusion machines, or if you're already utilizing one and want to learn extra about how to keep it clean, we suggest studying our weblog put up.

Disadvantages of Using a Plastic Extrusion Machine

The plastic extrusion machine is an effective way to produce high-high quality plastic products. However, there are some disadvantages of utilizing a plastic extrusion machine that should be considered earlier than making the purchase. The first drawback is that plastic extrusion machines are very noisy. This can be a problem if the machine is utilized in an industrial setting the place sound levels are vital. Additionally, the noise can be disruptive to employees who are attempting to work on other duties. Another drawback of using a plastic extrusion machine is that the plastic produced by the machine is commonly brittle. Because of this it's troublesome to create products that are sturdy and durable. As well as, the plastic produced by a plastic extrusion machine usually has a “plastic smell” which will be unpleasant.

What's inside and out of doors of the machine?

The plastic extrusion machine is one in all the most important machines in a plastics manufacturing facility. It can be used to provide quite a lot of merchandise equivalent to bottle caps, medical tubing, and bumper caps. The machine consists of two important parts: the extruder and the die. The extruder is a large metallic body that sits on a rotating platform. The die is a small metallic field that sits on high of the extruder and melts the plastic pellets into tubes. The extruder has several openings that permit air and plastic pellets to circulate into and out of it. The plastic pellets are heated by the recent air flowing by way of the extruder, and this heat causes them to melt. The melted pellets are then pressured by means of the openings in the die, which shapes them into tubes. The extruder and die have to be clear to ensure that the plastic tubing produced by the machine is of top of the range. There are several methods to wash the extruder and die: guide cleansing, utilizing automated cleaning machines, or utilizing a mix of each strategies. Manual cleaning includes cleaning the inside and outdoors of the machine with brushes or different objects. Automatic cleansing machines use brushes, jets, or other objects to clean the machine. A combination

1 note

·

View note

Text

For sale 3 BR Villa with Shared pool @ Bay west valley - Soma bay

Our villa is built on 1 level with gross area of 158 Sq. and Land area 400 Sq.

it features 3 bedrooms, 2 bathrooms, living/dining area, Nanny's room and open plan kitchen.

Price: 14,280,000 EGP.

Pay only 10% for contractual, 10% after 1 year and the remaining quarterly installments over 5 years.

Delivery date after 3 years from contracting date - semi-finished.

For more details, call 1111251110

or email us [email protected]

or visit our website www.beeyoot.net

#redseaegypt#somabayredsea#somabay#baywest#villaforsaleinsomabay#propertyforsaleinsomabay#facilitiesmanagement#semifinished#sharedpools#sea#restaurants#beachlife#divingcenters#divinglife#Bars#3bedrooms_2bathrooms#nannyroom

0 notes

Text

[11.18.shityear]

foud out about gaussian blur. I exagerated & put it on everything.

no one’s safe

1 note

·

View note

Photo

Semifinished... @sozeroni_pizzeria #semifinished #streetartbudapest #streetart #art #artist #sozer #szinesbudapest #graffitiporn #graffiti #color #green #beautiful #ilovethiscity #cool #awesome #sozeroni_pizzeria (helyszín: Filatorigát)

#sozer#color#streetart#art#beautiful#ilovethiscity#green#sozeroni_pizzeria#graffiti#awesome#szinesbudapest#artist#semifinished#graffitiporn#streetartbudapest#cool

2 notes

·

View notes

Photo

#semifinished #afzalmiyankarchobwale #+919391081171 (at Afzal Miyan Karchob Wale) https://www.instagram.com/p/B7blID9BzM7/?igshid=c8umfqdt88jq

0 notes

Photo

drew my persona + angsty thing for no reason

0 notes

Photo

VERGA Attachments- Manufacturer of World class Excavator Attachments & Excavator Buckets, supply Attachments for Various regions across the globe.

To know more about our Attachments,

Click here- www.verga.biz/attachments

VERGA offer: Excavator Buckets | Skid Steer Attachments | Hitches | Quick Couplers | Grapples | Pallets Fork Frames | Rippers | Tree Shears | Thumbs | Snow Ploughs | Custom Built Attachments.

#VergaAttachments #Excavator #ExcavatorAttachments #ExcavatorEquipment #ExcavatorBuckets #Custombuiltattachments #SemifinishedAttachments #semifinished #Trulyinternational #Diggerbuckets #Diggingbuckets

For Product info,

E-Mail us- [email protected]

#VergaAttachments#Excavator#ExcavatorAttachments#ExcavatorEquipment#ExcavatorBuckets#Custombuiltattachments#SemifinishedAttachments#semifinished#Trulyinternational#Diggerbuckets#Diggingbuckets

0 notes