#tool making

Text

Made a handle to for this seeder tool. Got the idea from davis reproductions and the tools they made for themselves. I think I did OK for a first try.

34 notes

·

View notes

Text

Tool Making Workshop

17/01/2023

I was in the tool making workshop today with Eoin (for the painting discipline). It was a lot of creative fun - searching for found objects and then converting them into useful mark making tools.

I used one of the tools to paint a horse as my movement brief is going in the direction of horse sports.

10 notes

·

View notes

Text

Painting: Tool Making (17/1/23)

On Tuesday, I attended @eoinmclsad tool making workshop, where we were tasked to go around the campus and find items that would help us create interesting tools for painting.

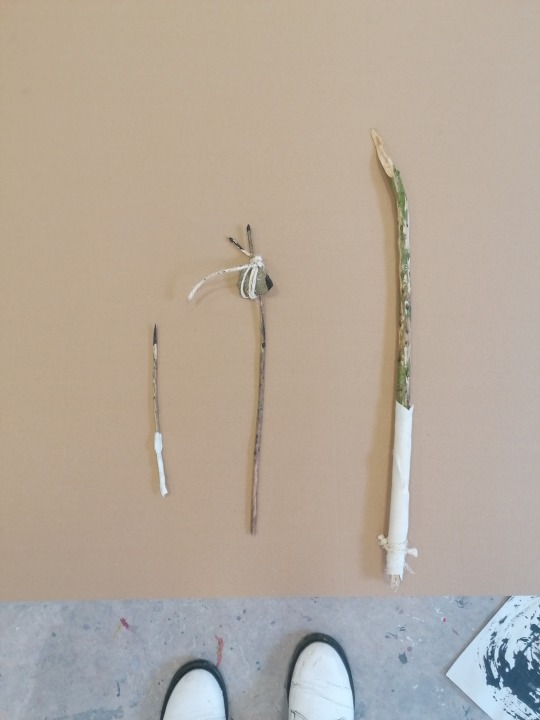

Around the campus I found multiple sticks and rocks that I thought could be turned into interesting tools. The first one I made was a stick with a piece of charcoal added to the top of it (image 1), similar to a tool that was presented to us at the beginning of the class. I recreated this tool cause I wanted to make something that would create an image with a similar technique of movement used during sword fighting, something I think that turned out well in practice (image 2).

I then changed my idea slightly to fit my theme of combat a bit more; I wanted to use this class to create small, primitive weapons, then look at what kind of marks those tools created. The first one I did was a small knife/sharpened stick, which I made using a pocket knife and sand paper (image 3). I then dipped this makeshift "knife" into paint, and used it to create sharp, quick slashes of paint across the drawing I had previously made, which created great sharp line marks on the paper. (image 4)

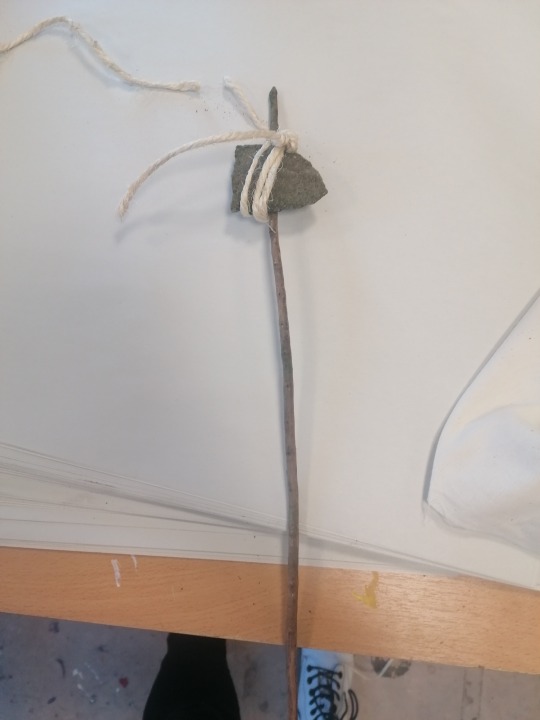

After the knifes success, I counited with my next tool, an axe/hammer. originally, I had tried to create a bigger version with a much thicker tree branch I found (image 5), but the rock I had used was too round, so I created a smaller version of the axe instead. this tool I made using a smaller branch ,and a flatter and smaller stone tied together with rope 9image 6). the axe made pointed, dotted marks onto the paper, with its only downside being that the stone spun with each hit. not as successful as the knife but still pretty good. (image 7)

The final thing I created for this workshop was made out of the previous axe handle I had created, not wanting it to go to waste. I had found a piece of crumpled paper wrapped and tied with fabric(image 8), so I had the idea of making a mace with spikes, but that idea also didn't work do to the said spikes not sticking to the fabric. In the end I created a plush mallet type tool, to resemble the markings of a punching glove. This created bigger, more rough circler marks, with I was happy with in the end, despite the top of the mallet falling apart in use. (image 9 and 10)

I enjoyed exploring this workshop because I gave me a few ideas on how I could make painting with non traditional tools, and also create images more literally connected to my projects theme of movement through combat. I also surprisingly really enjoyed the process of making the tools, especially the ones out of wood and stone materials. I would like to look further into art created by using martials such as weapons and tools usually used for combat and fighting, all the tools

I have a few videos of myself and other using this tools to create marks, all of which I will post under the tool making tag.

3 notes

·

View notes

Text

Tuesday 17th January - Movement Brief

• • •

Painting Workshop 2

Tool & Mark Making

I attended this day long workshop with @eoinmclsad .

This workshop focused on making our own tools to paint with and seeing the different types of mark each tool made.

I surprisingly found this workshop really fulfilling creatively. My art is typically very traditional so I thought I wouldn’t be able to engage creatively.

However, I found myself with an abundance of ideas which yielded great results.

• • •

My first tool was a small squid looking brush. I knotted a rough rope in a repeated pattern, looped the rope so the knots lined up and attached a handle.

The marks made with this tool were very interesting. Different amounts of paint and movements effected the marks left on the page. I created a nice piece based around my concept of travel using this brush.

• • •

My second tool was more ‘over engineered’. I found an abandoned plaster shoe and used rope to create a sort of pulley system to move the shoe around. I really wanted to incorporate this shoe as a link to travel. I intended to create a stepping mark but instead I had better results by using a circular motion.

• • •

My final tool was made using wire, masking tape and wire. This created a sort of stamp in the shape of a traditional iron. This was very enjoyable to use and created interesting marks based on the techniques used.

In the end I used this tool to create a repeated pattern of marks. The end result was just as I intended and the whole process was very creatively rewarding.

6 notes

·

View notes

Text

Mould Design in Plastic Injection Moulding

Injection Moulding is an extremely versatile procedure. It can be utilised for virtually any product. Injection moulding is the industry standard for manufacturing components for products.

There are some limitation needs to consider. Here are the rules to follow when designing your product to make sure quality and durability:

Wall Thickness

Keeping your walls thin will ensure a faster cooling rate and less materials used. Lower cooling rate and less material used will result in a shorter cycle time. This allows you more parts in a shorter amount of time, for less production cost

To strengthen parts, ribs are more effective than thicker walls. Adding ribs at right angles to a wall will add considerably to its overall strength. It is a common mistake to thicken the walls of a design to achieve this effect when ribs are a cheaper and more effective option.

Ribs should be about half the main wall thickness. There can be some leniency here, but not too much or the ribs will be completely ineffective. Half is the generally accepted standard and is more than enough to increase a wall’s strength.

Coherence

Try to make your design uniform throughout. That is, wall thickness, rib thickness and corner radii, for instance, should all be the same values. This will help the part to cool uniformly.

Corners & Edges

Corners could be an issue in a mould and will not come out flush. It is difficult to form plastic into a flawless corner. The outcome will look amateurish and messy, not to mention the power of the components can be compromised.

Corners and edges should be rounded wherever possible. Sharp edges do not always come out perfectly when the part is ejected from the mould.

Add a slight angle to the sides of your mould to allow easy release. A one- or two-degree angle should be applied to the mould on the face perpendicular to the parting line. This will allow for easy removal of the part from the mould.

Ribs

These are structural factors for your component, utilised for general stability control. Ribs are thin wall protrusions which extend vertically from a plane or wall. Adding ribs instead of thicker walls will provide greater structural support.

Bosses

These are empty, cylindrical protrusions. These are normally integrated in a style for accepting screws or other mating parts of your style. Making sure these are secured by attaching them a wall. Putting in ribs will means the bosses will stay straight as well as accommodate the part it was made for without an issue.

External Undercuts

A depression or protrusion in the exterior of the mould – the cavity half – could create issues if trying to divide parts from the mould. Adjust the parting line to lodge this.

Internal Undercuts and Overcuts

Related to external undercuts, these depressions or protrusions are within the mould – on the centre half. Adjust the parting line to lodge this.

Protrusions on the part that will snag on the mould core or cavity when it is opened can make it impossible to remove from the mould.

Threads

When your mould has a thread, always position it vertical to the parting column. This will make sure that the delicate thread isn’t damaged. It’s better, preferably, to not comprise a thread at all in the design. Making your design simple will lower the odd of something going wrong.

Injection mouldingdesign makes a superior product. The myriad possibilities far outdo the limitations. Designing for an excellent injection moulded part is the core of the design process. These restrictions are the guidelines for making a flexible end product.

Colour use

Where possible, use lighter colours for your moulds. The mould is already cool when the molten material is being injected. As such it begins the setting process immediately and will sometime leave setting patterns. Using lighter colours will help y.to hide these patterns.

Injection mouldingis the industry standard for creating lasting, quality parts. To be able to take advantage of this technology your design must meet its minimum requirements. Small considerations are all it takes and the result is a successful product that will meet all of your quality needs.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#plastic injection molding#plastic injection moulding#injectionmoulders#injection moulding#injectionmouldtooling#injection mould toolmaking#toolmaking#tool making#toolmakers#tooling#rapid prototyping#productdevelopment#product design#productdesign#made in uk#made in britain

2 notes

·

View notes

Text

Advanced Zinc Platers: Leading the Way in Electroplating Excellence

In the intricate world of metal manufacturing, electroplating stands as a vital process, enhancing the durability, appearance, and functionality of metal components. Among the myriad companies in this sector, Advanced Zinc Platers shines as a beacon of excellence, pioneering best practices and setting industry standards.

Electroplating: The Backbone of Metal Enhancement

At the core of Advanced Zinc Platers' operations lies the art of electroplating. This process involves the deposition of a thin layer of metal onto a conductive surface, typically achieved through the immersion of the substrate in an electrolyte solution containing the metal ions. Electroplating plays a crucial role in enhancing corrosion resistance, improving aesthetics, and imparting specific properties to metal parts, making them indispensable across various industries.

Specialization in Zinc Plating

While electroplating encompasses a range of metals, Advanced Zinc Platers specializes in zinc plating, leveraging its expertise to deliver superior results. Zinc plating offers excellent corrosion protection, making it ideal for applications exposed to harsh environments or prone to rusting. By meticulously controlling the plating process, Advanced Zinc Platers ensures uniform coating thickness, adherence, and surface finish, meeting the highest quality standards.

Catering to Diverse Industries

As a well-established manufacturing supplier, Advanced Zinc Platers caters to a diverse clientele spanning metal manufacturing, tool making, steel fabricators, and laser cutting industries. Its clientele relies on the company's precision-plated components to enhance the performance and longevity of their products. Whether it's automotive parts, industrial machinery, or consumer electronics, Advanced Zinc Platers' electroplated components add value across various sectors.

Commitment to Best Practices

What sets Advanced Zinc Platers apart is its unwavering commitment to best practices in the electroplating industry. The company invests in state-of-the-art equipment, employs skilled technicians, and adheres to stringent quality control measures at every stage of the plating process. From surface preparation to post-plating inspection, Advanced Zinc Platers prioritizes excellence, ensuring that each component meets or exceeds customer expectations.

Driving Innovation in Metal Finishing

Innovation is at the heart of Advanced Zinc Platers' ethos. The company continuously explores new techniques, materials, and technologies to push the boundaries of metal finishing. By staying abreast of industry trends and investing in research and development, Advanced Zinc Platers remains at the forefront of electroplating innovation, offering cutting-edge solutions to its discerning clientele.

A Vision for Sustainability

Beyond its quest for excellence, Advanced Zinc Platers is also committed to sustainability. Recognizing the environmental impact of electroplating processes, the company implements eco-friendly practices, such as wastewater treatment and recycling of plating solutions. By minimizing its carbon footprint and promoting responsible manufacturing, Advanced Zinc Platers ensures a greener, more sustainable future for generations to come.

Conclusion

In the realm of electroplating, Advanced Zinc Platers stands as a paragon of excellence, blending craftsmanship, innovation, and sustainability to deliver unparalleled results. As a trusted partner to the general industry, the company's dedication to best practices and customer satisfaction continues to propel it forward, setting new standards of quality and reliability in the electroplating industry.

Contact-

web - https://advancedplaters.com.au/

Mail - [email protected]

Ph - +61 3 8753 4626

Addresss - Advanced Zinc Platers Pty. Ltd 119, Greens Road, Dandenong, Victoria - 3175.

0 notes

Text

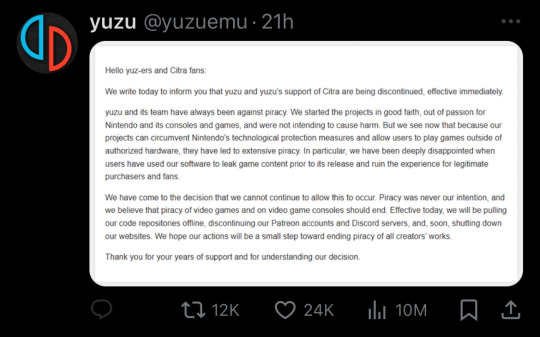

i hope everyone in nintendo’s management department dies and goes to hell no matter what and i’m not kidding

#WERE LOSING YUZU AND CITRA. I DONT KNOW IF YOU ALL UNDERSTAND HOW INSANE THIS IS#game emulation enables piracy yes but it’s also an INCREDIBLY powerful archival tool.#there are plenty of games out there that only exist in their original formats due to emulation.#this lawsuit has HORRIBLE implications for video game history. it makes it incredibly easy for companies to scorched earth their products#if they’re not profitable enough. ART IS GOING TO BE LOST BECAUSE OF THIS. GAMES PEOPLE WORKED INCREDIBLY HARD ON#it won’t just happen to bad games. it won’t just happen to old games. they will use this to keep their remake/virtual console model going#forever and you will never be able to play your favorite games in their true original forms ever again.#i am fucking INSANELY mad rn. capitalism is the death of art fr#personal

11K notes

·

View notes

Video

youtube

Cutting Operation By Fanuc Robodrill Machine

#youtube#cutting#operation#fanuc#robodrill#machine#cnc machine#metal piece#metal art#metalwork#tool making

0 notes

Text

#product development#ux design#product design#cad morphing#engineered products#product design and development#design optimization#Smart product design and development#Smart product design#Smart product development#Product Design Services#tool making#product development firm#product design firm#product design firms#medical device products#new product design

1 note

·

View note

Text

Ancient hominem ancestors making spheroids! This sounds very cool. I know it’s impossible to prove, but c’mon they look like such good throwing rocks! They’ve gotta be for hucking at things!

The Guardian article is linked and not paywalled.

1 note

·

View note

Text

A model of an idea for a transportation tool to carry stuff - and also as a frame for a mobile bed. 😅

I want to add a kind of folding chair mechanism, so that I can sit on that construction, while it holds my bags and stuff.

#Kalle mobil lite#my crafts#practical items#knottys crafts#carry#transportation tool#transport tool#carry tool#bushcrafting#bushcraft#prototyping#diy#upcycling#bamboo frame#model#crafting#craft#crafts#tools#tool making

1 note

·

View note

Text

I'd like to say a prayer, how does it go?

#setting: mez#3 hours drawing tiles 30 minutes drawing everything else. as it should be#mech pilot#'wow he must have used the symmetry tool to make it easier' - no he didn't. he did not do that.

6K notes

·

View notes

Text

painting: final piece

For my painting elective final piece, I decided to do a wall scale painting using tools based on my theme of combat, I wanted to explore movement through painting using these tools, and what type of authentic marks they would create, and how that would lend to my final image.

the background and the characters were created on separate days, for the background I used tools I had kept from my previous tool making class with @eoinmclsad. I made the marks of the background by basically hitting the sheet with the tools. each leaving a independent mark of their own. along with using a variety of colours, I got a pretty good base to work off or in the end

The image I painted was of three characters, which I brought over from my animation elective. I painted each character using a tool that corresponded with their theme, eg: a sword fighter painted by using only a pocket knife and a boxer painted using hand/fist marks. I also borrowed the corresponding colour scheme from my animation designs as well. In the end I love how the final image came out, epically the boxing character, and I'm happy that I decided to paint using unconventional tools. doing the vr based character was the hardest part of this painting, due to figuring out what type of technique to use to create the image. In the end I did this character using pointillism, to call back to pixel art and pixelated games creating images using smaller, brightly coloured dots gathered together.

I had originally created a two part time-lapse of me making this painting as well, to look at how myself moved while making the piece alongside my original idea, however both videos ended up not working out/wouldn't export for me, so I will regretfully have to leave them out of my final.

3 notes

·

View notes

Text

more of this nonsense bc im sooo normal

#adventure time#fionna and cake#prismo the wishmaster#scarab the god auditor#prohibitedwish#i couldnt decide between pre-op prismo or post-op star top surgery scars so i jus did boooth . .#been having a lot of fun coloring with that fill lasso tool as of late#also ! i feel like i should mention this ! ! this is not intended to besexual i dont see themlike that#also i literally haveno interest in that so#bleeehh they make me insane bleeehhh

3K notes

·

View notes

Text

Aluminium & Steel Mould Tooling

Aluminium Mould Tooling?

Typically we are asked to design and manufacture aluminium tooling for representative prototypes, ‘new’ pre-production parts, or low/ medium volume products.

There is a common misconception that aluminium tooling is limited to very low volumes (c 5,000 shots), however we are specialists in this field and, whilst the tools remain under our care and handling, we have historically been able to produce 100,000+ parts from aluminium tools in engineering polymers.

Many Clients who have ordered our aluminium tools for prototype development use have then been able to use the same tool for production supply.

Our aluminium tooling is used with a very wide range of high end technical and engineering polymers including Ultem, Nickel fill, Steel fill, Nanotube fill, PTFE fill, Electro-conductive, 50% glass filled PBT and Nylons, as well as the more common commercial plastics.

The alloys we use are high-grade and sourced from some of the biggest UK stockholders. We are provided with Certificates of Conformity in order to underwrite a quality tool, built to last.

Steel Mould Tooling?

Typically we are asked to design and manufacture steel tooling for Medium/ high volume production (1,000,000+).

We offer the full range of high-end traditional tool making with the benefit of using the same quality, speed of manufacture and operational systems developed by us for First Tier rapid development tooling manufacture.

If you have a new tooling project or existing product where:

Delivery is critical

Exemplary technical input, flexibility, and quality are required

In house UK design, manufacture, sampling, inspection and production is important

Confidentiality is required

You need an approved, experienced, and established Supplier

…then we are the tool making and moulding partner for you.

Please do not hesitate to contact us, if this is something you require or would like more information on.

Email: [email protected]

Tel: 01455 558825

#toolmaking#injection moulding#plastic injection moulding#tool making#uk manufacturing#made in britain#madeinbritain#ukmfg#plasticinjectionmoulding#rapidprototyping#productdesign#productdevelopment#rapid prototyping

2 notes

·

View notes

Text

Revolutionizing Metal Manufacturing: AZP's Cutting-Edge Electroplating and Coating Solutions

In the dynamic landscape of metal manufacturing, AZP stands out as a trailblazer, leading the charge in delivering innovative solutions to the general industry in Australia. With a rich history and a reputation for excellence, AZP is at the forefront of applying best practices in electroplating, particularly in zinc electroplating, corrosion protection, rust proofing, and metal parts restoration. Let's explore how AZP's expertise in electroplating and coating is reshaping the industry.

Pioneering Electroplating Excellence:

AZP has established itself as a pioneer in the electroplating industry, setting new standards of excellence in zinc plating and metal manufacturing. With a wealth of experience and cutting-edge technology, AZP offers a comprehensive range of electroplating services that ensure superior quality and durability for metal components. From sheet metal fabricating coating to corrosion protection, their electroplating solutions are trusted by businesses across various industries.

Unmatched Expertise in Coating Solutions:

When it comes to coating solutions, AZP is the name to trust. Their team of skilled professionals possesses extensive knowledge and expertise in providing a wide range of coating services, including zinc plating, silver and yellow zinc coating, and rust proofing. Whether it's metal manufacturing, tool making, or steel fabricating, AZP's coating solutions enhance the durability and longevity of metal components, ensuring optimal performance in diverse applications.

Innovative Technologies for Precision Results:

AZP leverages state-of-the-art technologies and advanced processes to deliver precision results that exceed customer expectations. From laser cutting to rumbling degreasing and stripping, their facilities are equipped with the latest equipment to handle a variety of metal fabrication needs with precision and efficiency. This commitment to innovation ensures that AZP remains at the forefront of the metal manufacturing industry, delivering superior products and services to their clients.

Tailored Solutions for Every Need:

At AZP, they understand that every project is unique, and they pride themselves on offering tailored solutions to meet the specific needs of each client. Whether it's a small-scale metal parts restoration or a large-scale sheet metal fabricating coating project, AZP works closely with clients to understand their requirements and deliver customized solutions that optimize performance and efficiency.

Commitment to Quality and Sustainability:

Quality and sustainability are core values at AZP. They are committed to upholding the highest standards of quality in every aspect of their operations, from sourcing materials to executing projects with precision and care. Additionally, AZP is dedicated to implementing sustainable practices that minimize environmental impact and promote a greener future for the industry.

Conclusion:

In the ever-evolving world of metal manufacturing, AZP stands as a beacon of innovation and excellence. With their pioneering electroplating and coating solutions, they are reshaping the industry landscape and setting new standards of quality and sustainability. For businesses seeking reliable and efficient solutions for their metal fabrication needs, AZP is the trusted partner of choice, delivering precision results and unmatched expertise every step of the way.

Contact -

Website - https://advancedplaters.com.au/

Email - [email protected]

Ph - +61 3 8753 4626

Address: Advanced Zinc Platers Pty. Ltd, 119, Greens Road, Dandenong, Victoria - 3175.

#Sheet metal fabricating coating#Electroplating#Zinc Plating#Metal manufacturing#Tool making#steel fabricators#laser cutting

1 note

·

View note