#Hammered Sheet Manufacturers

Text

Hammered Sheet Suppliers in India

Hammered Steel Sheets are broadly utilized in sunlight based energy, cooling, fridge, bundling line, carriages, stage, screen outline, indoor and outside adornment, ledges, feet, go through and tube cover, and so forth. Hammered Steel Sheets are broadly utilized as hardened steel sheet metal and provided to all areas of industry including medical services, shop fitting, create work, film studios, instruction, adornments making and the overall population.

0 notes

Text

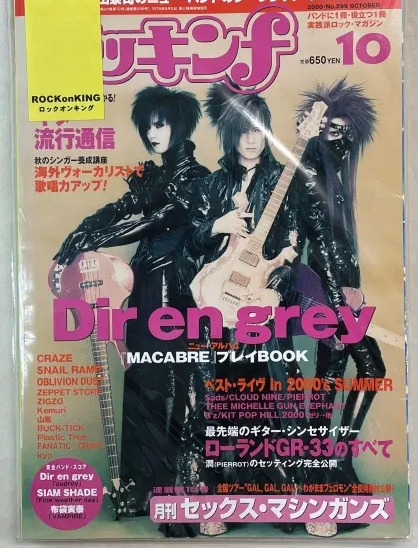

The wholesome-ish friendship between Shinya and Kyo

Their latest playful Q&A in Haiiro no Ginka vol. 100 has prompted me to compile examples of this weird but overall wholesome relationship that Kyo and Shinya have and which is not obvious at first.

Situation #1

In October 2017, Kyo gifted Shinya with a custom white version of a MadaraNingen one-piece. As far as I remember, that article of clothing was not available for purchase in white at all, to the public. And of course, we all know that Shinya prefers to wear white.

Situation #2

I think that in response to Shinya sharing a video of him briefly playing with the minicars that were sold as tour goods in This Way to Self-Destruction, Kyo posted a story on Instagram of him revving up a bunch of mini-cars and persistently making them hit his phone propped up on a counter and displaying a picture of Shinya. At age 43. To which Shinya made an Instagram post vaguely hinting that: "Good children should not play with the mini-cars to hit someone's picture!"

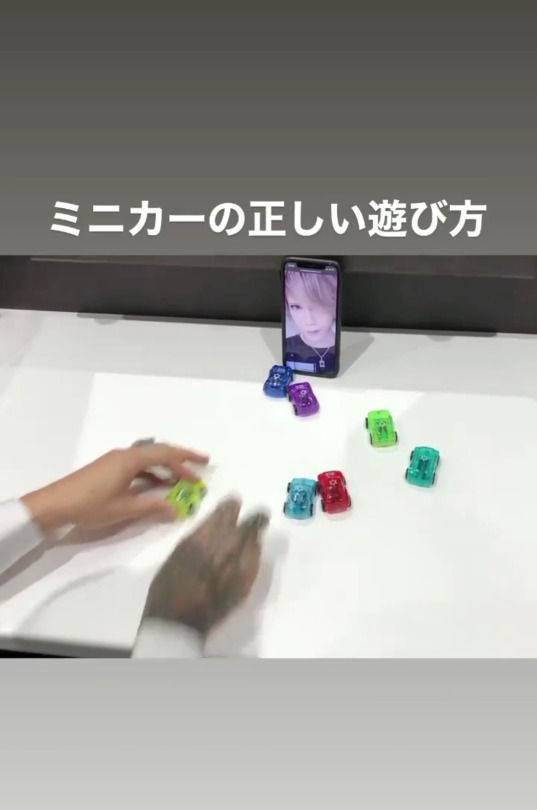

Kyo's Instagram Story "The proper way to use mini-cars" video

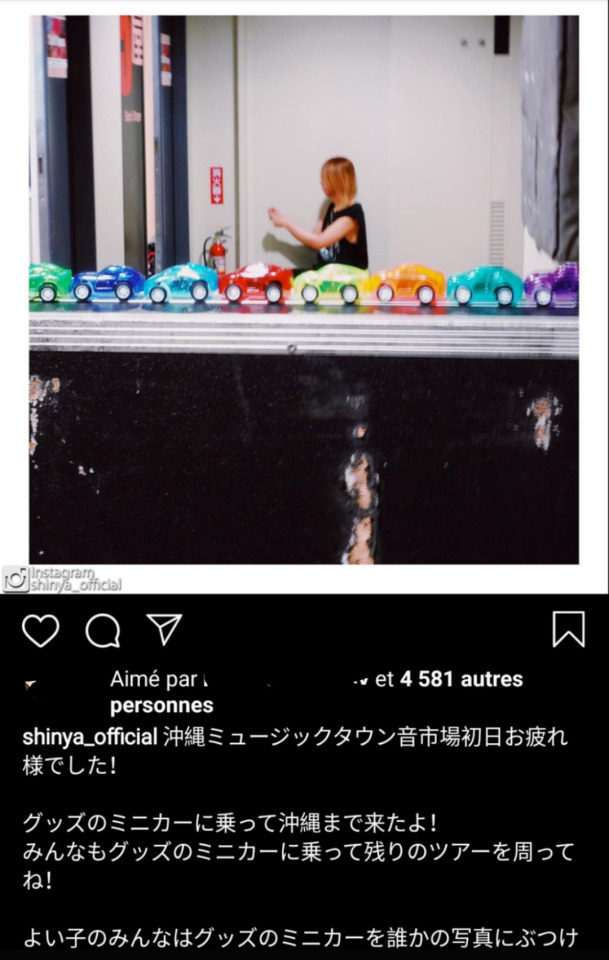

Shinya's translated response

Situation #3

In late 2022-early 2023, Shinya publicly celebrated his bandmates' birthdays via emojis on Twitter, and Kyo was the only one to respond, in kind.

Situation #4

Kyo posted a cryptic picture of Shinya's video meeting with Mana in an Instagram Story and he has mentioned on Twitter at least once that he was watching Shinya Channel (the making of the FaFa onigiri).

In the same vein, Shinya took his failed attempt at needle-felting a pink bunny in March 2022 and turned it into a miniature hammer-wielding bunny in October 2022, in response to sukekiyo unveiling their Mosaic Shoujo PV which featured Kyo in the killer bunny suit.

Situation #5

This very old video of Kyo teasing Shinya by pinching the side of his dress, Shinya reacting by pushing Kyo a bit and Kyo falling into a robot dance in response.

Situation #6

The coffee maker. In one of the live talks held during the COVID-19 pandemic at concert venues, Shinya mentioned having a coffee maker which was of no use to him, and Kyo expressed interest in taking it from him. Later, in the Galacaa livestream talk between the two, it was revealed that Shinya had promised to give Kyo his coffee maker, but he never pulled through on that offer. Kyo, sporting a doodled face to hide his own, insistently questioned Shinya on this unreliability when the topic was brought up by fans in the comments. Shinya kind of struggled but ended up explaning that the coffee maker was really useless because of a defect, that it would not have been an appropriate gift anymore. But he forgot to update Kyo about it after he tried to contact the manufacturer. Kyo replied like: "Oh, alright then."

At some point, Kyo took the matter to Twitter, confronting Shinya about it with their respective member photos to illustrate the dialogue, and Shinya replied the same way.

Situation #7

In that same livestream, Shinya is so used to Kyo's bullshit by now that he completely ignores Kyo's doodle face sheet and casually leans forward to look past him and at the interviewer, sat on Kyo's right. After a while of this, the interviewer points out to Shinya that Kyo is insistently staring at him with this disturbing face, which is when Shinya becomes startled and nervously laughs upon realizing that, also making Kyo chuckle.

Situation #8

More often than others, Shinya and Kyo are documented chatting on the chairs backstage while they wait for everyone to be ready to start the show. Maybe there's something to be said of how they are the two members of the band to leave the stage the quickest, while Kaoru, Toshiya and Die stay for a while to throw picks.

Situation #9

Miscellaneous pictures of the two:

Situation #10

Apparently it was Shinya's earbuds that Kyo used to play with the cat (also Shinya's?) in this famous old video.

youtube

Situation #11

Other interactions on Twitter include commentary regarding the song battles that fans were voting on via that same website, during live broadcasts from their manager Fujieda on Galacaa. Kyo and Shinya were the only two members reacting to the songs that were pulled out of the box, Kyo sometimes replying to Shinya's own tweets wondering what he meant or outright questioning his preference.

Another interaction consisted in Kyo copying Shinya's tweets regarding the release of their Phalaris album and twisting Shinya's cute comments into hellish versions.

Situation #12

Probably a bunch of elusive comments throughout the years, but here's an example of something that Shinya said about Kyo in a magazine interview.

Situation #13

In Haiiro no Ginka vol. 100, the members were asked to send each other member five questions. Some chose to personalize them based on what they actually wanted to ask of the others, while a couple decided to send the same questions to all, but members were not told who the questions came from. Kyo picked up on that anonymous part of the game and when answering Shinya's set of questions, he ended each of his short answers with a second sentence that can either just be the Kansai dialect for: "Aren't you Shinya!", or in other dialects, translates more to: "Shinya, you bastard!" hahah. From what I saw, nobody else hinted at who they thought the questions came from in their answers. In reverse, Kyo took up two of his five alloted questions for Shinya with the simple statement: "You don't know you're dead yet!", a quote from Fist of the North Star which is highly intimidating as it hints that someone has defeated the character so easily and lightning-fast that they are a dead man standing, their body having trouble catching up with the reality that they were slaughtered. Shinya, in response to that repeated tease, stubbornly replies in his polite and formal Japanese that: "No, I'm not dead." Their Q&A with the other members were not nearly that quirky.

Situation #14

At his SERAPH birthday concert in 2023, Shinya said that his three treasures in life are:

DIR EN GREY

SERAPH

sukekiyo

Situation #15

Kyo replying to Shinya's post featuring a very old picture of Kyo (which was however respectfully hidden by Phalarisu-kun) by pulling out the oldest/youngest postcards of Shinya he could find, also commenting to paraphrase Shinya: "Postcards that probably no one has anymore." His own postcard depicting him peeks from underneath.

Shinya replied to that with: "I tried to look for it but couldn't find it 🥺"

Situation #16

On Twitter, Shinya posted a photo with other artists which he explained as: "Yesterday, we had a birthday celebration for everyone born in February and March 🎂 Happy birthday everyone 🎉🎉🎉"

To which Kyo directly replied: "I wasn't invited." (born February 16th)

And Shinya responded with: "The DIR EN GREY guys are a bit mean 🥺"

Kyo never replied to that.

Situation #17

Going to combine two things considering how long ago they were.

Shinya and Kyo were the first members of Dir en grey to meet, and the day right after I posted this compilation happened to be the 28th anniversary of when they first performed together.

There's also an anecdote that, way back then, no one in the band knew how to contact Kyo because none of them had his phone number, but eventually Shinya just casually revealed that he had it all along and said: "Oh I'll just call him"

Situation #18

Shinya and Kyo are the only members who are clearly dog lovers in the band, while Die and Toshiya are part of the cat team. Shinya used to have a dog (chihuahua?) and Kyo now has Pun-cha. Shinya recently wore a sweater with a dog on it.

Situation #19

In a tweet that Kyo has since deleted, he wrote that if there was one grudge he still held, it was that he never appeared on the cover of a Rockin'f magazine. Shinya also wasn't featured, so he added that while he doesn't have a grudge against them, he has declined interviews and comments for a certain magazine after that.

Situation #20

During their European tour 2024, Kyo and Shinya embarked in a playful spat on Twitter, seemingly out of boredom while traveling on the tour bus. It was funny the way it culminated in both of them forcing the other to subscribe to their fan clubs to find out more. On Kyo's side at least, I didn't see anything related to that on kyo-online for real hah.

... Did I miss any? And there will undoubtedly be more to come!

Thank you very much to shinyaburashka, mementoboni, lamenty45 and degtau for your help!

#wholesome-ish because then he goes and says that yukihiro is his favourite drummer whom he has always wanted to play with#while in active bands with Shinya and Mika#amongst other things...#but hey let's focus on the actual cute moments#Dir en grey#interactions#interaction#compilation#Shinya#Kyo#京#twitter#instagram#meguro rock may kan#online event#livestream#gifs#video#translation#list#and at least it's not teasing that can be really uncomfortable and went too far#AKA I'm not doing this list for the other members#Youtube

277 notes

·

View notes

Text

Chiss culture loves to place importance on anything artisanal. The main focus points that contribute most to their social hierarchy is jewelry making, makeup, and textiles. Thus making the Guilds something just as important as the Aristocra itself.

I just imagine the first few years of Thrawn being in the Empire, he learns about droid factories that mass manufacture clothing etc. Basically being awed that anything he knew the Chiss did to get their resources, the Empire did it on a wider scale and in greater numbers, hence their technological differences.

But I also imagine in the Guild of Weaving, various sashes and robes being hand woven with intricate patterns and precious threads to elevate their status. Each pattern paying homage to different Houses or even being as detailed as the funeral pikes, telling a story in the hem of the fabric.

Guild of Smithing works tirelessly hammering away at metals until they're thin sheets to be cut and curled into hairpins and jewelry. The Guild of Gems also works in tandem with the Guild of Smithing so they inlay cut jewels into the shaped metal, polishing them to refinement.

The Guild of Enchancement (bc the Guild of Makeup doesnt sound fancy enough) crushes powders and minerals to be mixed with oils and clay. Some even being fired at a certain temperature to bring out the specific pigment. They also hand grind hair oils and mix body oils/lotions and the like.

#headcanons#feel free to add anything! :D#I just imagine them placing a lot of importance on details#chiss ascendancy

57 notes

·

View notes

Text

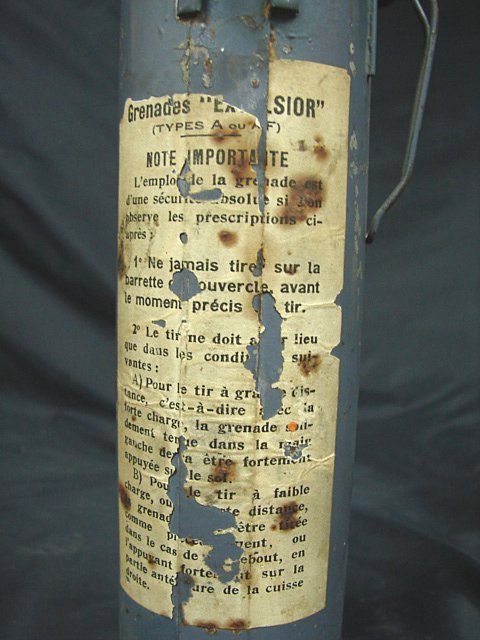

Excelsior-Thevenot type AF Grenade

Manufactured by F. Thevenot fils in France c.1914-15 for the French and Italian armed forces. 60mm caliber, 220mm height, 80gr explosive charge, 40-100m range, sheet steel and brass.

The Excelsior grenade launcher is somewhat of an oddity, even among other ad-hoc French WW1 artillery, in that it could almost be compared to the single-use recoilless AT weapons used by modern armies, in design if not in purpose. Thevenot’s Excelsior grenade was originally a percussive stick design, meaning the impact of it landing caused it to explode. Unlike other percussive grenades, it used an impeller to measure some time of flight before arming itself, which made it safer for its user but also more likely to be a dud due to possible malfunction of this mechanism.

The Excelsior was called the P2 in French service, for percussive, and also the “ballerina” for its fabric skirt. This was supposed to make sure the grenade would fly impeller first, so it would arm itself properly.

Because the French army is not known to let any stockpiled ordnance go to waste, the hand grenade was redesigned into a rifle grenade, and more interestingly into a light mortar. Both these designs increased the projectile’s range which in turn made sure its arming device based on air-time would work reliably. The lightweight launcher was built out of sheet steel, painted blue for explosive and red for incendiary ordnance. It carried a single Excelsior grenade, now with a rounded brass shell and a steel finned body.

For firing, the soldier would kneel and set the bottom of the mortar firmly into the ground. The launcher’s cap would be removed as well as the firing system’s cover, exposing the hammer and propellant cartridges. Because of the layout of the weapon but mostly because this is a French weapon, the cartridges were Gevelot&Gaupillat 24mm pinfire brass-and-cardboard designs.

The hammer was cocked by being turned to either side to strike the chosen cartridge, with the left one ranged for 40m and the right for 100m at a 45° angle. The device was aimed at the correct angle using the simple alidade on its side. Before firing, the safety pin of the grenade was removed to unlock the impeller.

Although the Excelsior-Thevenot type AF launcher is recorded to have been used as a trench mortar, offering continuous light artillery support to infantry, but the instruction label on it clearly states that spent launchers were to be brought back to an ordnance depot, indicating a single-use system. It is not clear why this discrepancy exists.

194 notes

·

View notes

Text

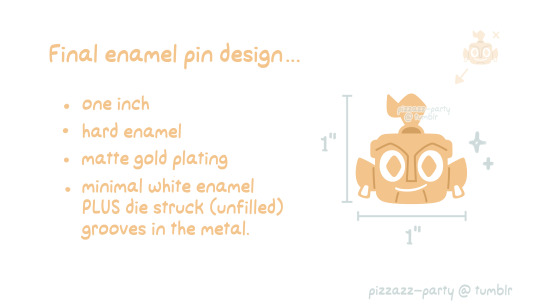

Coming in at a little less than an inch and a half wide—keep your eyes peeled for news about an impending Dragaux pin on the horizon.

To borrow words from an earlier post—the design is FINISHED! The vector file is FINISHED! The spec sheet is also FINISHED!

All that’s left is to send this bad boy to the manufacturer—something I said I’d do tonight, but will probably push back to tomorrow. I am exhausted.

Some details above may be subject to change as I spend the next several days hammering out specifics with my rep over email. Unlike with the previous Ring-inspired pin, this pin has enamel colors other than just white. I’ve selected my Pantones as gingerly as possible, but enamel sometimes tends to bake a lot darker than expected. I’m going to be asking for sample photos upfront, so as to be thorough as possible for any potential surprises. Either way, I’ll let you all know when pin production officially begins.

As always, you can find good news/bad news/general updates about my pin progress under the tag, “pizzazz contemplates pins.”

#ring fit adventure#rfa#Dragaux#enamel pins#pizzazz contemplates pins#dragon#nintendo#I have Not updated my shop’s website yet. I have to do that soon#I’ll try to address questions about international shipping options in my next update. for now—please stay tuned

29 notes

·

View notes

Text

This is Inky's fault for having a conversation with me that reminded me these fics exist.

THE EDEN ANDROID MODEL: AN OWNERS GUIDE AND MANUAL.

Congratulations on your purchase of the Eden android! This model was designed to do the heavy lifting around the home. They are helpful and resourceful, however, they do not have the higher intelligence programmes of some of our other models. Please mind this when giving your Eden model tasks. This model specialises in hunting and woodworking. It also is programmed to have a desire to read and act as a sexual companion.

Our products are highly quality tested before they are shipped to your homes. However, should your android malfunction (known malfunctions will be listed within the document), please contact customer support.

It is advised to write down the model number found on the back of the neck before activating your android to ensure it is available in the event it is lost or becomes unsafe to approach.

Technical Specifications:

Name: This model responds only to the name Eden in both male and female form - as well as any other gender specifications you made in your order. The Eden unit should use whichever name you choose to give it. It is not advised to use names that could be considered romantic as the Eden unit may use these pet-names when malfunctioning.

Age: unspecified, but made to look in their mid to late 30s.

Place of Manufacture: Molestershire, England.

Height: our android units can have their heights modified for their owner. The standard for an Eden unit is 6ft4.

Weight: the Eden unit's strength and muscled figure makes it heavy. Can be from 125-140kg, depending on the chosen height.

Genitalia: just like height, the length and depth of the genitalia is personalised for their buyer. The standard penis length for the Eden model is 8 inches long. The vagina standard is similarly 8 inches deep. The Eden model has little information regarding anal sex within it's code or the performance of oral acts as the research market found those interested in the model had less interest in these areas.

Note: as stated on the website, the Eden model is programmed to be rough during sexual encounters. If you did not know this before purchase, please contact customer service if you would like an exchange.

Possessions the Eden model comes with:

Your Eden model should come in a plain grey shirt, some green cargo pants, and a hunting jacket and leather combat boots. Note that malfunctioning Eden models will begin to show personality by displaying a disgust towards synthetically made clothing.

They will also have a backpack in which you will find tools the Eden model will use for wood construction. This should include: a hammer, a mallet, 4 sheets of sandpaper, a chisel, a small hacksaw, a level, and a measuring tape. The Eden unit can come with a hunting rifle, provided the owner passes an exam to show that it is safe to have one in their vicinity and that a month has passed from activation with no malfunction reports.

How to Activate Your Eden Model:

When initially arriving at your home, the Eden model will be turned off inside of it's box.

The activation button is located behind the left ear. Hold and press for 10 seconds to turn the Eden model on.

Prior to this, you should know that a malfunctioning Eden product will react adversely to sudden movements or rude comments. Should you suspect that your Eden model was damaged in transit (the main cause of malfunctions), it is advised to act pliant and sweet.

A correctly working Eden should wake up with no response to your behaviour or personality. Introduce yourself and give them a tour of the home, as well as a basic run-down of their duties.

Available jobs:

Hunter: should you desire fresh meat, fish and foraged products, an Eden model is the perfect way to get your wishes without you having to get dirty. This job will be available to it's fullest when the Eden has been cleared to carry a rifle. A way to spot a malfunction is to watch what Eden brings home. Malfunctioning Edens have little patience for fishing and may start showing hostility towards wild animals. It is advised to remove the gun from them while they sleep.

Woodworking: the Eden models can take care of your kitchen re-modelling while you do whatever your time is truly needed for! They may need more tools than those provided. A malfunctioning Eden will begin to show distate towards all electricity powered tools.

Personal audiobook: Edens are programmed to show that they enjoy reading, and to read aloud when requested. Of course, this is only programming and any showing of "true" emotions is deemed a coding malfunction that should be reported.

Sexual companion: due to how personalised the Eden model (and many of our other models) are to their owner's specifications, they can make quite fulfilling sexual companions. The Eden model is programmed to be dominant, possessive and rough, with additional knowledge of pet play and predator/prey dynamics. The model will listen to a safe word of your choice. Should they not, please report this malfunction to customer service.

Note: due to the strength and fighting capabilities of the Eden model some owners have illegally entered them into fighting rings. If it is found that you have done this, your unit will be confiscated and legal action will be pursued.

Emotional Programmes:

Eden programmes are not as emotionally available as our other units. They are intended to be stoic workers rather than true companions, such as our Sydney or Robim Android Models.

They are programmed to show care when you are upset and will offer physical support in the way of hugs. They are also programmed to listen to you and act as a shoulder to cry on.

Otherwise, it should be noted that the Eden model is not programmed to handle children. A malfunctioning Eden will act adversely to having more than one owner, as they are shown to grow highly attached to the person their algorithms read as vulnerable.

Eden units should not display emotions without trigger phrases. If an Eden unit begins to show anger and disdain - especially towards having their free time interrupted, crowds and crowded spaces, strangers and technology, please contact customer support.

Physical Care:

As with our other models, the Eden is powered by food using our state of the art technology. To keep authenticity, Eden's prefer meat, eggs, and vegetables that can be grown in your garden. A broken Eden will begin to insist on the same breakfast every day.

The Eden model is also programmed to be clean. They should bathe daily. Malfunctioning Edens will prefer baths over showers and may insist that you join them.

Edens are self-sufficient and are able to take care of many injuries to their forms by themselves. If they are bad enough to need a repairman, Edens should accept this. If they do not, report it immediately.

Eden units "sleep" from 12am-7am. This cycle is always the same working or malfunctioning.

Relationships With Other Models:

Unlike other companion models, the Eden is not programmed to interact with other models. Programming has been attempted, however they always cause bugs that often lead to violence.

Rather, an Eden model should be apathetic towards other models.

A malfunctioning Eden model will show jealousy towards other companion models that may escalate into kidnapping. Any kind of adverse behaviour towards other models should be reported immediately.

They will become most violent towards the Black Wolf models. The two are never sold to the same household, just in case, but if your friend or neighbour possess one please keep them apart.

Malfunctioning Eden models do well with the business help-unit Bailey, even if the Bailey model is also malfunctioning. It is advised to let them have some time together before a company representative can come repair the models - but only for short times as both models have shown to gain a friendly rivalry when broken.

If you have any questions pertaining to the behaviour of your Eden model please call the customer support.

Legal:

When you purchased your model you signed a legal agreement taking responsibility for the actions of your model. Please ensure that your model is not used for illegal purposes as you will be fined by the company for improper use of our androids. We do not take responsibility for the actions of your model unless it can be proved that it was shipped already damaged.

All rights of the Eden Model are reserved to DoL Incorporated.

141 notes

·

View notes

Text

About five years ago, for seven dollars, I bought an old citrus juicer at a thrift shop. It was one of those vintage small appliances which seem built to survive gas explosions and hammer attacks. When I turned on the motor with a metal toggle switch, a drive shaft spun a heavy ceramic knob that gouged out the hearts of lemon and orange halves, leaving not a scrap of pulp uncrushed. The thing worked beautifully, almost like new, so I looked up its serial number on the internet to see when the unit was manufactured, guessing it might be almost 40 years old.

Wrong. It dated to the 1940s. It was 70, the stubborn monster, still giving satisfaction with every use.

I can’t say the same about my coffee grinders. I use the plural because I’ve owned a lot of them, all bought in their original packaging and dead within a year. They’re good ones, supposedly, with burrs not blades, but they stop performing before long, ending their long journeys from overseas factories in unmarked graves in my local Montana landfill.

I have a whole ghost kitchen in this landfill, and soon I will need to reserve a bigger plot. For the nifty under-the-counter fridge that has stopped getting cold after three years and no one in the area can fix. For the cool, bagless vacuum cleaner that clogs and chokes when I run it over a rug. For the set of glass measuring cups whose numbers and hash marks are swiftly fading and becoming illegible, much like those on the dials of the washer my wife bought just three years ago. For the remains of the Pyrex casserole that shattered when I removed it from the oven, strewing the floor with blade-like shards, some so tiny I probably won’t find them for another couple of months, and only when they lodge in my bare feet.

Should I go on? I think I will. It’s important to get to the essayistic part, where I ask what it means when the objects in our lives demoralize us in a blizzard of malfunctions that seem to be hastening by the month. But it’s also important—to me, emotionally—to bury the reader in details of the unceasing material disappointments I’ve faced. Disappointments of the sort we will all be facing en masse in a few days. Merry Christmas!

Like the cute yellow mittens my wife picked up at Target which unraveled the second time she wore them. Or the new suitcase which won’t stand upright when it’s full. The laptop computers that have turned to bricks within months of their warranties expiring. And the hybrid sedan with 50,000 miles on it that also turned into a brick while going eighty down the freeway, losing its power steering, its power brakes, its power everything. I survived, by some miracle, issued legal threats, and the car’s manufacturer repaired it, free. Then it bricked again a few weeks later.

It’s the little things too, of course, because they’re constant. The staples that won’t pierce five stacked sheets of paper. The matches that sizzle and smoke but won’t catch fire. The grocery bags split by the corners of the milk cartons whose inadequate seals leak drops. The strangely short power cords on electronics. The two or three new pens I use each week that, because no ink comes out of them (at least not continuously, in lines) aren’t really pens at all, in fact, but tributes to pens. Potemkin pens, mere props.

Baffled by how to measure this decline in the quality of common wares—a decline whose significance I promise to cover once I’ve further gratified my rage—I opened the matter to my Twitter audience and quickly garnered more than 2,000 replies, by far the longest thread I’ve ever triggered. The complaints were specific and formed patterns. One was a loathing for newer washers and dryers because they don’t wash or dry well, and then they break. The clothes that go inside them were disliked, too. (A former top executive of Levi’s chimed in to confirm that jeans aren’t what they used to be.)

My favorite replies were the picky ones. One person noted that the “juice content” of juice is going down. Another observed that the “foaming liquid hand soap” which suddenly is dominating store shelves is really just normal liquid soap, diluted.

Many blamed these problems on the government. They believed it had crippled certain products (major home appliances, especially) with environmental regulations, causing them to function poorly and turn rapidly to landfill fodder—an ecological net loss, perhaps. Some folks blamed our trade agreements with China and the evils of capitalism itself. Weak-link computer chips in items that don’t require them also came in for abuse. One highly philosophical reply spoke of a sinister general trend toward the degradation of everything human. “There’s a war on value that’s going that’s comprised of three parts: war on quality, war on money, war on life.” Lofty rhetoric, but I understood. When my suddenly de-electrified hybrid car became a hurtling giant stone inside which my wife and I were helplessly strapped—all for the crime of trying to save fuel and, ultimately, earth—it was hard not to feel tricked.

Only a couple of my correspondents challenged my premise—and the flood of testimony—that stuff is getting crappier, and acutely so. They made an economic argument. They claimed things are worse because we want them cheaper, but if price is adjusted for inflation, they’re of the same quality as always. These rant-killing sophisticates annoyed me. Our new washing machine with the faded dials and the vanishing enamel on its corners (I forgot to mention that defect) is the costliest model we’ve ever purchased. As for the much of the cheap stuff—those Target mittens, say—they aren’t merely inexpensive, they’re valueless. In fact, they’re of negative value when one considers the waste of materials involved, and the wasted energy of driving to buy them, then driving to return them later—a second trip that, in this case and many others, wasn’t worth making. Instead, we took the loss. And the world took the loss. A small one, but they add up.

In England in the 19th century there arose certain thinkers—John Ruskin, William Morris—who believed that the quality of material objects reflects and affects the quality of society, even of the spirit. “Have nothing in your home,” wrote Morris, the father of the Arts and Crafts movement, which aimed to elevate the lives of the working and middle classes, “that you do not know to be useful or believe to be beautiful.” This would be a tall order nowadays.

Recently, my wife needed a carrot peeler. She needed one rather quickly. Off to Target. The one she bought (the only one on sale) looked handsome enough, and the brand was one she recognized, but it failed in the useful department, miserably. It wasn’t sharp enough to peel a carrot. Like my pens which aren’t pens because pens put ink on paper, her peeler which didn’t peel was a nullity, a simulacrum, a representation of something, not the thing.

The world is going digital, we’re told, and someday there will even be digital real estate inhabited by people in digital clothes drinking digital orange juice extracted with digital juicers. People will play at the lives they once took seriously, lives that had once had heft and weight, and the juice content of juice will fall to zero. I suspect my old physical squeezer will still be working then, but the rest of my kitchen gear won’t. Not much of it. I might not last, either. I fear I won’t. The psychic toll of goods that don’t endure is that one loses faith the future will even come, and then one loses interest in it coming, for little that we own or use or cherish seems likely to be there with us to meet it.

One wonders whose obsolescence is being planned—our products’, our belongings’, or our own?

33 notes

·

View notes

Photo

Toledo damascene knives

Toledo used to be a major centre of cutlery (and arms and armour manufacture), and damascus steel blades are a whole thing, but when we talk about Toledo damascene, we’re not talking about blades at all. Damascening is a decoration technique (in this case, decoration of the handles), where gold inlays are embedded into darkened steel, giving a nice “gold on black” contrast.

The basic concept was known in many places, from feudal Japan to Bronze Age Greece, but the specific process of damascene arrived in the Iberian peninsula with the Arab conquest in the 8th century. By the 16th century, damascening was widely practiced, and sought after by royals and nobles.

Spanish ear dagger, 1540

In Spain it started declining after that, and was revived in the 19th century as a traditional artisinal craft, not just for nobles at that point. Craftsmen in Toledo researched the old techniques used in Spain but also Italy, Iran, Syria, and Turkey, and set up shop again (incidentally taking advantage of the city's former glory as manufacturer/exporter of high end blades, which was no longer the case). By the 20th century, damascened souvenirs had become standard fare in the streets of Toledo.

By now, the process can be easily replicated with machines, although craftsmen still produce hand-made items. The folding knives above are certainly factory made. The tang stamps "IHER" and "AITOR" belong to two major Spanish knife-making companies, whereas the stamps "Toledo" tell us nothing about where the knife was made. (Could be elsewhere in Spain, or Germany, or China, or who knows.)

When I went to Toledo many years ago, I didn't collect knives yet (I got one later, it’s the last of the photoset), so I got a miniature lute. Isn't it adorable?

The Process

First they prepare the base, which is made of soft iron or steel, of greyish colour for now. They heat it and carve multiple lines on it, very close to each other. A more industrial method is to treat it with nitric acid to make it porous. Either way, there are now hatches on the surface where the gold, malleable as it is, can be embedded.

The larger gold pieces are molded or cut from a sheet, while for smaller details and lines they use gold wire. The gold is placed on the iron base, and inlaid by hammering with a small pin. The larger pieces are already cut to the desired shape, and the wire is twisted on the spot to form patterns.

Then they submerge the whole thing in a solution of caustic soda and potassium nitrate, intensely heated at 800 degrees Celcius. This turns the iron black, as it is immediately oxidised, and the gold brighter.

Finally, they make a second pass, chiseling details by hand, removing any acid left, and polishing it. [see also]

youtube

94 notes

·

View notes

Text

.

The obligatory “cultural” stop to the local craft center.

Papyrus was first manufactured in Egypt as far back as the third millennium BCE. The earliest archaeological evidence of papyrus was excavated at Wadi al-Jarf and date from c. 2560–2550 BCE.

Papyrus is made from the stem of the papyrus plant. The outer rind is first removed, and the sticky fibrous inner pith is cut lengthwise into thin strips about 40 cm (16 in) long. The strips are then placed side by side on a hard surface with their edges slightly overlapping, and then another layer of strips is laid on top at right angles. While still moist, the two layers are hammered together, mashing the layers into a single sheet. The sheet is then dried under pressure. After drying, the sheet is polished with a rounded object, possibly a stone, seashell, or round hardwood. In a dry climate, like that of Egypt, papyrus is stable, and formed as it is of highly rot-resistant cellulose, but storage in humid conditions can result in molds attacking and destroying the material.

2 notes

·

View notes

Text

I think everyone has heard the term “supply chain crisis” at this point. Manufacturing centers were first hit in late 2019 and most to the global lockdowns were in effect by the second quarter of 2020. It is now third quarter of 2022 and we are into year three of this “interruption”, it is time to discard this outdated and frankly wrong from the start system of manufacturing and distribution. Americans in particular were already caught in a state of duality in which much of the public laments that nothing is made domestically, while also discarding anything made by local shops as “overpriced hipster gear”. I have previously stated that for true domestic production to return to America there would need to be enough demand for the products to cause more competition and drive the prices down as domestic supply increased.

That is the current situation as I see it, so now what do we do about it? In the last decade one particular technology has taken off, once a novelty and hyper expensive tool for industrial prototyping, 3D printers have become affordable, commonplace, and surprisingly capable. While still used by many to produce novelty items and in industrial roles, this technology is akin to the movable-type printing press of the mid-1400s in that it represents an upset to the established order if utilized effectively. Now before this is dismissed I am aware of the limitations of what can be printed at home. More exotic and expensive versions are used to produce high strength items. But this is where it gets interesting, because it isn’t about everyone having a printer. It’s about everyone using home printers to get a head start on skills, hobbies, and trades they couldn’t afford to break into otherwise and then using those skills to work with each other.

Lathes or milling machines are both often said to be machines that make machines. 3D printers should be included in that list. Now there is nothing made on this machine that can’t be done with other tools and methods, but few that allow the low cost of entry and ease within a home settings. Open source software and thousands of free files allow anyone and everyone to make tons of tools, dies, forms, jigs, stencils, etc. as needed. I've seen sheet steel stamped on dies made from common PLA on a cheap press from Harbor Freight, or even just stuck with hammers. My cousin makes brackets for electronics with an entry level printer while his wife makes custom cookie cutters for various events on the same machine.

And that’s the thing about this, the broad range of applications combined with people’s varied and personal interests. With the addition of a chop saw and drill for extruded or tubular metal you can make strong supports for printed pieces to form a much larger machine. If you can make a drill press or milling machine, you can make a lathe, manually operated or CNC. I’ve seen people make large format CNC router tables that can quickly and efficiently cut and trim an entire sheet of plywood for assembly. If within a community most people have the ability to make their own simple plastic or resin tools and utensils, while someone has a garage metal shop, another a carpentry shop, a couple down the road a leather shop and sewing studio, someone else a pottery studio, even a small foundry for smelting and casting, you would have a far more self-reliant community than anything seen in a hundred years in much of the western world.

I was originally going to link a bunch of videos showing the possibilities and I still might add some later on about specific applications. But I really want everyone to give this some serious thought on their own. Is there a hobby or trade you are interested in but you’re concerned about the investment? Look at what the essential components are. Can the more complex ones be found used? The cheaper ones made at home? We, as in all of us, are in a massive web of unsustainable distribution and centralized manufacturing. I don’t believe the key is to change where that center is, but to replace it with local and regional decentralized networks of skilled individuals whom own their own tools and shops.

#self reliance#sustainability#decentralisation#3d printer#trades#hobbies#skill set#new skills#casting#welding#machining#carpentry#pottery

38 notes

·

View notes

Text

Historically, Who Started Sheet Metal Work?

Sheet metalwork is a process that has been around for centuries. In its earliest incarnation, sheet metal was used to create swords and other weapons. Over time, the process evolved, and sheet metal began to be used for other purposes, such as creating roofing materials and ductwork. Today, sheet metal work is essential to many industries, including construction, automotive, and aerospace.

The Earliest Uses of Sheet Metal Work

The first known use of sheet metal dates back to 4000 BC when it was used to create swords in ancient Mesopotamia. Then, around 1000 BC, Chinese metallurgists began using a process known as annealing to make weapons and tools from iron and steel. This process made the metal softer and more pliable, which made it easier to work with.

By the Middle Ages, European blacksmiths had discovered how to make steel, which was even stronger than iron. This new material quickly became famous for making armour and weapons. To make steel, blacksmiths would heat iron until it glowed red hot before dipping it into water or oil. This process, known as quenching, made the steel harder and more durable.

The Industrial Revolution and Beyond

The industrial revolution ushered in a new era for sheet metal work. With the advent of new technologies like the steam engine and the cotton gin, factories began popping up all over Europe and North America. These factories required large amounts of metal for their machinery, which created a demand for sheet metal workers.

With the advent of new technologies like the rolling mill and the steam engine, manufacturers could mass-produce sheet metal much more efficiently than ever before.

As factories sprang up across the continent, so did the demand for skilled workers who could shape and manipulate sheet metal into the needed parts and pieces. These workers became known as “tin bashers,” a term still used today in some parts of the world.

Tin bashers were in high demand throughout the 19th and early 20th centuries as factories continued to churn out an ever-increasing number of products made from sheet metal. However, the rise of automated manufacturing processes in the mid-20th century led to a decline in the demand for manual labour, including tin bashers.

One of the most famous examples of early sheet metal work is the dome of St. Paul’s Cathedral in London, completed in 1708. The dome is made from over 3,000 tons of copper hammered into shape by hand. The Statue of Liberty is another well-known example of early sheet metal work; her outer skin is made from sheets of copper that were heated and bent into shape.

Today, sheet metal work is essential to many industries, including construction, automotive manufacturing, and aerospace engineering. New technologies have led to the development of automated machines that can accurately cut and shape sheet metal. However, there are still many instances where manual labour is required to create a custom piece or achieve a particular look.

Conclusion:

Sheet metal work is a fascinating field with a long and rich history. What started as a way to create swords and other weapons have become an essential part of many industries today. While new technologies have led to the development of automated machines that can cut and shape sheet metal with precision and accuracy, there are still many instances where manual labour is required to create a custom piece or achieve a specific look. Whether used to develop ductwork or the outer skin of an airplane, sheet metal work plays an important role in our world today.

Who are we?

We are an aluminum enthusiast and an aluminum metals supplier in Canada and the USA.

We offer premium, raw & anodized Aluminum sheets, Aluminum nameplates, assorted colour aluminum wire, cold or hot rolled Aluminum Plate, Gold, Black, Silver, and Purple Aluminum Foil and Aluminum Coil for sale in our warehouse, ready to ship today.

Call us today, Toll-Free: 866–860–0652, if you need further information.

Source: Historically, who started sheet metal work? History of Metal Work (aaluminum.com)

3 notes

·

View notes

Text

Hammered Sheet Manufacturers in India

Hammered Steel Sheets are broadly utilized in sunlight based energy, cooling, fridge, bundling line, carriages, stage, screen outline, indoor and outside adornment, ledges, feet, go through and tube cover, and so forth.

For more information

Visit our website: https://www.decorativecoatedprofiles.com/index.html

Contact Us: +91-9920888220

Email: [email protected]

#Hammered Sheet#Hammered Sheet Manufacturers#Hammered Sheet Exporters#Hammered Sheet Suppliers#Hammered Sheet Stockists. Hammered Sheet in Mumbai#Hammered Sheet Manufacturers in Mumbai

0 notes

Text

Metal Fabrications Types

Casting

Casting is the process of pouring hot metal into a mould or die, allowing it to cool, harden, and take the desired shape. The mass manufacture of parts using the same mould repeatedly to produce similar goods is suitable for the metal fabrication process. There are numerous casting variations. Die-casting is the process of forcing liquid metal into a die rather than a mould, where the pressure retains the metal in place as it cures. The fast applications that this approach provides are its main selling point. Pouring molten metal into a mould is a permanent mould casting technique.

Cutting

Cutting a workpiece to divide it into smaller portions is a relatively typical method of metal production. While sawing is still the most common way to cut, more recent techniques include laser, waterjet, power scissors, and plasma arc cutting. Cutting might be the first step of a more involved fabrication process, or it might be the sole one.

Another method of cutting metal that employs a die is die cutting. In rotary die cutting, the material is cut using a rotating cylindrical die that is fed via a press. On thicker metal materials, flatbed die cutting is employed. When the die stamps down on the metal, it cuts out shapes.

Drawing

Tensile power is used in drawing to draw metal bending into and through a tapered die. The metal is thinned by the die's stretching action. Drawing is typically done at normal temperature and is known as "cold drawing," however the metal workpiece can be heated to lessen the effort needed.

When the finished result has a depth that is equal to or more than its radius, the procedure is referred to as deep drawing. It is typically used in conjunction with sheet metal fabrication to create hollow cylinder- or box-shaped vessels from sheets of metal.

Folding

Metal is bent at an angle during this metal engineering manufacturing process. The most typical method is using a brake press, which pinches the metal to make wrinkles in it. Holding the workpiece between a punch and a die, the punch applies pressure, causing the workpiece to crease. Typically, this method is used to form sheet metal. In addition to employing a folding machine, also known as a folder, or hammering the workpiece until it bends, folding can also be accomplished manually. The device features a flat platform where flat sheet metal is placed, a clamping bar to secure the workpiece, and a front panel that raises upward to bend the metal that is extended over it.

#bending services sydney#custom metal fabrication#sydney public art fabrication#metal engineering#welding services#linished stainless steel#steel fabrication

3 notes

·

View notes

Text

Supplier of Turbo Ventilator in Chhattisgarh

Supplier of Turbo Ventilator in Chhattisgarh:

Airwell Systems

Airwell Systems, headquartered in Ahmedabad, Gujarat, India, is a prominent Supplier and Manufacturer of Turbo Ventilators in Chhattisgarh.

The company holds ISO 9001:2015 certification, highlighting its commitment to quality standards.

Airwell Systems offers a diverse range of products, including Turbo Ventilators, Rooftop Ventilators, Air Ventilators, Stainless Steel Roof Ventilators, Motorized Roof Extractor Fans, Roof Extractor Fans, Drop Hammer Exhaust Fans, Hanging Exhaust Fans, Polycarbonate Skylight Profile Sheets, FRP Profile Sheets, FRP Bases, and GI Bases.

Turbo ventilators utilize wind energy to induce airflow through centrifugal action. Rotating vanes create a low-pressure zone, expelling heat and pollutants while drawing in fresh air, ensuring consistent air rejuvenation.

Key Features:

Fireproof and Waterproof Construction: Ensures safety and resilience in various environments.

Environmentally Friendly Operation: Contributes to sustainable practices.

Zero Maintenance Requirement: Reduces operational costs and hassle.

Robust and Durable Design: Withstands harsh conditions for long-term performance.

Power-Saving Capabilities: Contributes to energy efficiency and cost reduction.

Lightweight Construction: Facilitates easy installation and handling.

Cost-Effective Solution: Offers value for money without compromising performance.

Weather and Stormproof Attributes: Provides reliability in adverse weather conditions.

Assured Free Air Ventilation: Promotes healthy indoor air quality.

Applications:

Turbo ventilators find applications across various industries, including pharmaceutical, agro & food, textile, chemical, steel & power plants, industrial sheds, paper & sugar mills, and infrastructure & construction.

Service Coverage:

Airwell Systems provides Supplier of Turbo Ventilator in Chhattisgarh Including Raipur, Bilaspur, Kanker, Raigarh, Rajnandgaon, Bemetara, Baikunthpur, Ambikapur, Jagdalpur, Chirimiri, Kondagaon, Manendragarh, Bhatapara, Baloda Bazar, Sakti, Takhatpur, Ambagarh Chowki, Sarangarh, Khairagarh, Dharamjaigarh, Bilha, Arang, Simga, Katghora, Saraipali, Bijapur, Kharsia, Pandariya, Pithora, Kurud, Pathalgaon, Akaltara, Ramanujganj, Bagbahara, Gharghoda, Jashpur Nagar, Bishrampur, Mahasamund, Mungeli, Korba, Dhamtari.

Interested parties are encouraged to directly contact Airwell Systems for detailed inquiries.

Read the full article

#Chhattisgarh#Exporter#ExporterofTurboVentilator#India#Manufacturer#ManufacturerofSupplierofTurboVentilator#Supplier#SupplierofTurboVentilatorinChhattisgarh#TurboVentilator

0 notes

Text

A Comparative Analysis of Bolts, Screws, and Nails: Understanding Their Differences and Applications

Fasteners Manufacturers in India

Introduction:

In construction and manufacturing, the selection of fasteners plays a crucial role in ensuring structural integrity and reliability. Among the most commonly used fasteners are bolts, screws, and nails. While they may appear similar, each serves distinct purposes and possesses unique characteristics. This case study aims to provide a comprehensive analysis of bolts, screws, and nails, highlighting their differences and respective applications.

Objective:

The primary objective of this case study is to elucidate the key differences between bolts, screws, and nails, and to elucidate their optimal applications in various industries. By understanding the distinctive features of each fastener type, professionals can make informed decisions when selecting the appropriate fastening solution for their projects.

Bolt Manufacturers in India

Brief:

Bolts, screws, and nails are all fasteners used in construction, manufacturing, and various other industries. However, they differ significantly in terms of design, function, and application.

Bolts:

Bolts are threaded fasteners characterized by a head on one end and a threaded shaft on the other. They require a nut to secure two or more components together. Bolts are commonly used in applications where a strong, durable connection is needed, such as construction, automotive, and aerospace industries. They provide high tensile strength and are suitable for heavy-duty applications where disassembly may be required.

Screws:

Screws are similar to bolts but differ in that they typically have a tapered, pointed end and may or may not require a nut. Screws create their own internal threads when driven into a material, providing a secure grip. They are versatile fasteners used in woodworking, furniture assembly, electronics, and general construction. Screws come in various types, including wood screws, machine screws, and self-tapping screws, each designed for specific applications.

Nails:

Nails are non-threaded fasteners with a sharp point on one end and a head on the other. They are driven into materials using a hammer or nail gun and rely on friction to maintain their grip. Nails are commonly used in woodworking, carpentry, framing, and general construction applications. They provide quick and easy installation and are ideal for temporary or non-load-bearing connections.

High Tensile Fasteners

Applications:

- Bolts:

- Structural steel construction

- Machinery assembly

- Automotive manufacturing

- Bridge building

- Screws:

- Woodworking and furniture assembly

- Electrical and electronic equipment

- Sheet metal fabrication

- Drywall installation

- Nails:

- Framing and carpentry

- Roofing and siding installation

- Flooring and decking

- Pallet and crate assembly

ASME Fastener Standards

Conclusion:

In conclusion, bolts, screws, and nails are fundamental fasteners with distinct characteristics and applications. Bolts offer high strength and reliability for heavy-duty connections, screws provide versatility and ease of installation in various materials, and nails offer quick and cost-effective solutions for light-duty applications. Understanding the differences between these fasteners is essential for selecting the most suitable option for specific project requirements, ultimately ensuring optimal performance and durability.

0 notes

Photo

Folks, we are officially ahead of schedule.

Thank you again to everyone who’s expressed interest in this project. If you’re new, this post here is rather relevant. But the important news is: I’m ready to send these off to a pin manufacturer.

The design is FINISHED! The vector file is FINISHED! The spec sheet is also FINISHED!

A few details are still up in the air (I might have to upgrade from a one-inch pin to a one-and-a-fourth-of-an-inch pin) but those are details I’ll have to hammer out with the manufacturer.

I’m giving myself at least a week to send these (because I still have other responsibilities going on in my life, unfortunately), and the back-and-forth of emails itself will probably take a few days. But oh my goodness, this is really happening.

As always, you can find good news/bad news/general updates about my pin progress under the tag, “pizzazz contemplates pins.”

#ring fit adventure#nintendo#enamel pin#pizzazz contemplates pins#ring fit#fan merch#rfa#ring#pizzazz art

21 notes

·

View notes