#Printing efficiency

Text

Maximize Your Printing Potential with the HP PageWide XL Pro 5200

Maximize Your Printing Potential with the HP PageWide XL Pro 5200

The ultimate solution, is for the fastest print machine in Singapore.

http://www.uscsolns.com

http://www.largeformatspecialist.com.sg

If you’re looking for a large format printer that can help you respond quickly to customer demands and expand your business, the HP PageWide XL Pro 5200 is an excellent choice. With its impressive speed and versatility, this printer is capable of handling a wide…

View On WordPress

#Board printing#Cardstock printing#Energy-efficient printing#FSC-certified paper#HP Eco-Carton cartridge#HP Learn#HP PageWide technology#HP SmartStream#HP-branded solution#Large format printer#LED printer comparison#Printing efficiency#Printing speed#Printing versatility#Recyclable prints#Short-term retail posters#Water-based inks

0 notes

Text

YOUCANT DO THAT.,

#sanders art tag#sanders tattag#garfield#got the mona lisa done in the Least Efficient Way Imaginable btw#printed n cut one to size then traced guidelines backlit from my laptop flipped over displaying the search results for ‘blank white screen’#on full brightness. yes I was standing leaning over the keyboard bc it stuck straight up at that angle

44 notes

·

View notes

Text

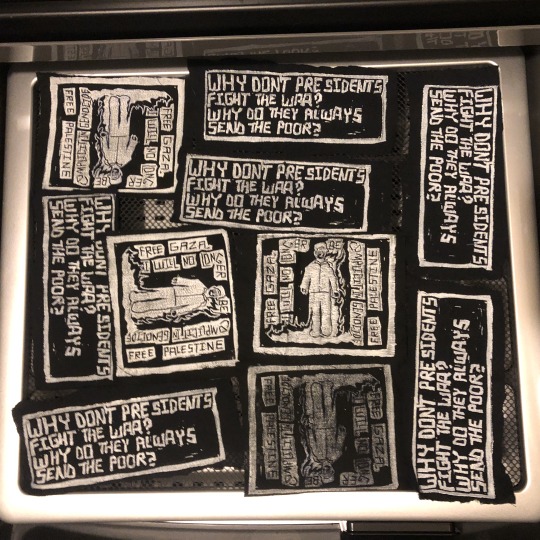

Heat setting the SOAD patches and the commemoration patches to Aaron Bushnell.

#free palestine#free gaza#keep talking about Gaza#aaron bushnell commemoration patch#these were test patches for my little Etsy shop#I still wanna work on them before officially selling them and I’m still trying to find a#proper way to efficiently donate the proceeds of the Aaron Bushnell patch to organizations dedicated to helping Palestine#aaron bushnell#soad#system of a down patch#system of a down#my stuff (patch)#my stuff (sewing)#linocut patch#linocut print#linocut#printmaking

8 notes

·

View notes

Text

listen. i bound my proof copy but i fucked up the trim so bad its absolutely embarrassing. it looks like animals have been eating it. im so sorry. i'd wanted to show off pictures but i like cannot let you all see this. im sorry.

#txt#its my first attempt bookbinding.......... i made an ugly little creature but she is mine....#need to figure out um. how to do this more efficiently. the guillotine paper cutter at the community collegeis. not it.#the art looks gorgeous in print. it reads very cohesively which was a pleasant surprise!#im super pleased with all of that! just. erm. not the. um.

7 notes

·

View notes

Text

📋

#random personal stuff#personal whining feel free to ignore#why forward me an email with additional information#when you could PRINT the email and scribble your additional remarks on it and highlight what you want me to do like I can't read#and hand me the printouts#that's so much more efficient#and not at all wasteful#this man prints every dang thing whether it needs it or not#it was like pulling teeth trying to get him to email me book order requests at all#and now we're back to square one#(it's the guy with the humming & loud videos & p o l i t i c al cartoons & questionable book orders & using my printer for pointless things#& the whim vacation which of course he got permission for with no problem)#(he'll be out the rest of the week leaving just two of us here and I am struggling to exist in the same office with him right now)#(I have been putting up with the nonsense for seven years and I am losing patience & I don't know why he won't retire because he's like 80)

11 notes

·

View notes

Photo

TRYING out actually using my ink for the black sections like hair in my art like a normal cartoonist for once but i was too lazy to actually bust out ink and a brush or even just a thick marker so i scribbled it with my fine tip drawing pen instead HDJSKDHKJDS

#art#traditional art#watercolour#oc art#ocs#oc group: lia crystal darling#oc: bibi#oc: lia#i love drawing eyebrows and eyes all the way in the forehead and bangs and hairline but with black hair thats TRICKY cause u cant SEE IT#but if i am more careful with my hairline and bang placement or if i try the 2008 furry mspaint animator on youtube method of adding#white outlines in the black parts to show eyebrows etc etc it might be viable. what do they call it in the industry? filling in blacks?#filling in the blacks with actual black instead of trying a really really dark gray can be more efficient with b&w drawing for print it seem#so im fudging around with art style shenanigans. its always good to do that. test out different ways to draw to see what feels good#good way to stave off art block too. thats why ive suddenly started drawing eyelids HJKLFDSKJFDSL it might not stay in my art forever#but rn. were in eyelid world

9 notes

·

View notes

Text

never done one of these so i thought i'd try it.

my 2nd full year as an Artist.... developed a lot. looking back at stuff from a year ago is painful as usual. first half of this year was mostly takarazuka. in march i started "painting", in the summer i started doing "lineless", then i realised that's basically painting but now i understood it and was having fun.

in september i started doing tons of black and white stuff to clear my head and because i was so inspired by witch hat atelier.

i want to keep improving

#this isnt so much The Best Thing I Drew That Month as what represents the month artistically/emotionally to me.#like november was simply the persona 5 month. and december has to be lucifer.#(also i made a LOOT of comic-type stuff that isn't really represented in this image but was lots of fun.)#it's not like before 2020 i had never picked up a pen. i just Didn't Know Anything. i just doodled on paper and showed no-one#i feel like i both drew a lot in 2022 (which i DID) and still didn't draw or learn enough or at least not efficiently enough. =_=#i also finished two fics and worked on two zines. next year i want to print my own things and do more stuff. and make artist friends.#i barely socialised or did anything other than drawing. i'm glad i had so much free time but uhh i also want to Live More.#sometimes i feel like Getting Serious now and drawing Properly and sometimes i feel like stopping drawing altogether. idek.#i just dk.......#hope there were some people that enjoyed my stuff. it seems like there was. i feel like i'm at least at the beginning of the next stage#2020...we don't talk about that. 2021 ok starting to be able to draw. 2022 finally able to draw closer to what i want. i love a lot of it.#i guess that's something.#especially in sept/oct i was really inspired. i barely used the internet except to post art it was so good. my own world#i didn't use the internet basically at all in june either - but it was the total opposite. i barely drew at all. *examines myself*#onwards i guess................. *picks up my bindle*

11 notes

·

View notes

Link

This may actually work in practice: new designs for air conditioning parts are coming. They key here is that they are too complex to make by older techniques. 3-D printing the metal parts, however, can do it

2 notes

·

View notes

Text

getting praised at work for being good at my job hehehe >:3c

2 notes

·

View notes

Text

watching ascendance of a bookworm with my sis and i am very annoyed with main’s attempt at woodcutting

“it can’t be achieved with basic woodcutting techniques” YOU SIMPLY CARVED IT WRONG I’M??

#me ranting abt woodcutting in the tags —>#woodcutting is RELIEF#ITS RELIEF PRINTING MAIN#you are supposed to carve the negative space NOT the line art 😭😭😭#girl fr just put so much ink on the page because she didn’t understand the foundational principle of woodcutting#she wants to be gutenburg so bad but doesn’t understand how stamps work#girl if you know how metal letter blocks work in a printing press how did you get woodcutting so wrong???#i think she just ended up using paper stencils? or smth to that effect#but in the end if she wants to make a printing press i imagine using a relief technique would be much more efficient#main also said that wilma’s art had too much detail for the woodcutting to turn out well but that’s not true??#wilma’s art had a perfectly acceptable level of detail for a woodcutting#in fact there are many woodcuttings that have an even greater deal of detail than wilma’s drawing#but again without the proper use of woodcutting techniques they won’t get anywhere#also lutz’s brother was using a giant ass knife for detail wood carving i was surprised lol#wouldn’t a smaller knife allow for more finesse in the actual carving process?#genuine question#anyways i’m enjoying the show i promise sjfhdjs#kris rambles

3 notes

·

View notes

Text

LED hand model Stroboscope

The LED hand model stroboscope is a versatile and powerful tool designed for a wide range of applications. With its compact and lightweight design, this stroboscope is easy to handle and transport, making it ideal for both professional and personal use. The LED lights provide a bright and consistent light output, allowing for precise control over the strobe effect. Whether you are a DJ looking to add some excitement to your next event or a photographer in need of a creative lighting solution, this stroboscope is sure to impress.

#ledstroboscope#industrialequipment#forsale#LEDhandmodel#stroboscope#motionanalysis#motionmeasurement#qualitycontrol#portabledevice#efficiency#accuracy#industrialoperations#inspectionprocess#handheldstrobe#precision#technology#innovation#manufacturing#engineering#productivity#automation#printing#printingservices#printingsolutions#industrial#industry#printingindustry

0 notes

Text

last night I was so over everything I started fantasizing about marrying my printer

#she's a butch lesbian in her mid twenties who's very efficient but not too fast#it was 2 am and she had been printing for like an hour

0 notes

Text

Research Seeks to Break the Mold of Ultra-Lightweight Aerogels - Technology Org

New Post has been published on https://thedigitalinsider.com/research-seeks-to-break-the-mold-of-ultra-lightweight-aerogels-technology-org/

Research Seeks to Break the Mold of Ultra-Lightweight Aerogels - Technology Org

Producing ultra-lightweight materials that are also strong could revolutionize multiple industries. With groundbreaking work from an interdisciplinary team of chemists and 3D printing experts, that revolution could be closer.

Garrett Godshall inspects a 3D-printed piece of aerogel produced in the partnership between the labs of Robert Moore and Chris Williams. Illustration by Alex Parrish for Virginia Tech.

Aerogels are a unique class of ultra-low-density materials with a weight only about 15 times heavier than air. If an average adult were made of aerogel, they would weigh somewhere between 3 and 14 pounds.

The material has been around for a little less than 100 years, and the first aerogels were a highly porous solid containing more than 99 percent air, nicknamed “frozen smoke.” Although these aerogels made from silica glass have achieved the Guinness World Record for the lowest density solids, they are known to be very brittle and quite expensive to process.

Today, the race is on to find new materials and cost-effective methods to produce incredibly strong aerogels for advanced applications such as thermal insulation for aerospace vehicles, passive solar insulation for next generation housing, water and air filtration, lightweight packaging, controlled drug delivery, and personally tailored biomedical scaffolding.

That race has some strong Virginia Tech contenders. Robert Moore, a professor in the Department of Chemistry in the College of Science, has joined forces with Christopher Williams, the LS Randolph Professor of Mechanical Engineering in the College of Engineering. They have brought together the resources of both their groups to produce new approaches to engineered aerogels, channeled through the Macromolecules Innovation Institute. Graduate researchers Garrett F. Godshall and Daniel A. Rau have led those teams with innovations in both materials and machinery with the methods published in the journal Advanced Materials.

An infrared camera image of polyphenylene sulfide gel during the 3D printing process. Illustration by Robert Moore, Virginia Tech.

Strong, lightweight skeletons

The first step to making an aerogel involves producing a gel, a 3D solid network that entraps a liquid, like water in gelatin. The next step involves carefully removing the liquid in the gel, leaving behind an ultralight microporous sponge-like skeleton because the heavy liquid has been replaced by air and is potentially strong because of its interconnected 3D lattice.

One material that had not previously been developed as an aerogel is polyphenylene sulfide (PPS), a super strong thermoplastic often used as a substitute for metal when weight reduction and chemical resistance is required. As an aerogel, PPS could usher in a new wave of applications, particularly in lightweight high performance thermal insulation. Recently, Moore’s research group has demonstrated a simple process for creating PPS gels and aerogels using a unique nontoxic, environmentally friendly solvent.

Moore’s team brought its process to Williams, who has pioneered novel 3D printing methods.

“Bob and I have been working together for many years thanks to the interdisciplinarity fostered through the Macromolecules Innovation Institute,” said Williams. “We hosted a joint meeting between our two groups over a summer so that our students could become more aware of our labs’ capabilities and expertise and ideate ways we could collaborate. From that meeting, we identified that Bob’s novel approach for synthesizing PPS aerogels would meld well with my group’s expertise in 3D printing and prior work in printing PPS.”

“Unlike the silica aerogels or other crosslinked polymers used by NASA, our PPS gels don’t require complex chemical reactions and they can be melted and solidified over and over again,” said Moore. “All we have to do is make a hot solution of commercially available PPS and then cool it to room temperature. Using our new, safe solvent, which is actually an FDA-approved food grade additive, the PPS solutions gel in seconds. It is as simple as making Jell-O. But once we saw the super-fast solidification of these gels, we knew it was time to team up with the Williams group to see if we could print this stuff.”

The PPS aerogel barrier has been breached with Moore’s discovery of rapid PPS gelation. Using a combination of simple chemistry and 3D printing innovation, the first additive manufacturing of PPS into an aerogel is now a reality.

Breaking the mold

Like gelatin, the gels that are used to make aerogels are conventionally formed in open molds. This yields a solid form with limited size and shape. Making PPS aerogels with engineered shapes and geometries requires a combination of innovations in polymer chemistry and advanced manufacturing.

On Moore’s team, Godshall produced pellets of the PPS gel and placed them into a new, high temperature printing tool designed by Rau specifically for this task. Inside the nozzle, the gel pellets are re-liquified and extruded onto a substrate, where they cool and re-solidify.

After the print is finished, the solvent-containing gel part has the solvent removed through an exchange process and freeze drying, resulting in a PPS aerogel. This process enables the formation of microscopic pores that can be tuned by the print settings. Moreover, at the macroscale, the three-dimensional form of the PPS aerogel can be tailored by the infinite shape possibilities of 3D printing.

Creating large, lightweight shapes to the contour of an airplane wing or small insulating structures incorporated in electronic devices means a reduction of materials in manufacturing; strong aerogel frameworks could equate to a reduction of fuel with lighter vehicles, and engineered thermal insulators could advance energy efficiency in next-generation technologies.

“This publication represents a significant breakthrough in the manufacturing of complex aerogels from engineering polymers,” said Williams. “Bob’s synthesis technique can work for a number of other high-performance polymers, and the printing process can be easily modified to account for these changes. We were surprised to learn that the processing conditions have an effect over the morphology and density of the aerogel structure. We are excited to study this further and discover how to gain control and program this structure and performance into new multi-functional parts.”

Source: VirginiaTech

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#additive manufacturing#advanced materials#aerogel#aerogels#aerospace#air#applications#approach#barrier#chemical#chemical reactions#chemistry#Chemistry & materials science news#collaborate#college#devices#drug#drug delivery#efficiency#electronic#electronic devices#energy#energy efficiency#engineering#FDA#Food#form#freeze

0 notes

Text

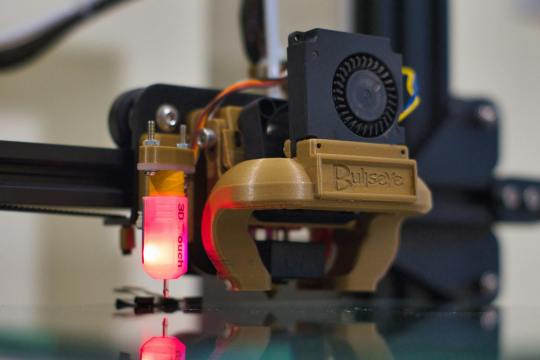

3D Printing: From Prototypes to Organ Transplants

In the last decade, the landscape of manufacturing, medical science, and even the arts have been fundamentally transformed by the advent of 3D printing technology. Once a niche tool used for the creation of simple prototypes, 3D printing has burgeoned into a revolutionary force that stands at the forefront of innovation across numerous sectors. This article delves into the journey of 3D printing,…

View On WordPress

#3D ink#3D models#3D printed organs#3D printing#3D scanners#Additive manufacturing#Aerospace#Artificial organs#Automotive#Bioengineering#Bioink#Biomaterials#Bioprinting#Biotechnology#CAD#Cellular structures#Ceramics#Creative tech#Custom-made#customization#Dental devices#Design#Design thinking#Development#Digital fabrication#Digital manufacturing#Digital models#Disruptive tech#Donor organs#efficiency

1 note

·

View note

Text

Might need to suddenly become an accompanist for this one specific thing… I’ve got until June

#can I read sheet music? yes#can I play the corresponding notes on the keyboard? also yes#but can I play chords and coordinate both hands with any sense of efficiency? not in high school when I was taking piano lessons 2x a week#… only time will tell#I forgot to print out the score before leaving work but I pulled a piece out of my vocal repertoire that includes the underscoring#so far I can play through 1.5 ish pages#the .5 ish is because it’s written for two pianos and alas I am but one person#but I’ve got the bass clef solid for 2 pages#and I got the first page of treble clef done#so far I’d say that’s pretty damn good progress for not even having looked at sheet music in 4 years#let alone played anything in 8#and only going at it for about 45 minutes#thank god for this dusty ass Yamaha keyboard#(because also we only have a piano in one of our two performance spaces. so.)#(saving us having to rent a keyboard/piano or having to move a grand across the site…)#tomorrow afternoon I’m going to print out the score and work on it on the antique grand#very excited for there to be music played in the historic house again#it hasn’t happened since pre pandemic at least#and nobody can remember when before that#5+ years if not more

1 note

·

View note

Photo

New York Roof Extensions

A large image of a backyard concrete paver patio fountain in the arts and crafts style.

0 notes