#rubber technology

Text

Unlocking the Secrets of Rubber Lining: A Comprehensive Overview

Rubber lining is a critical process in various industries, providing protection against corrosion, abrasion, and chemical damage. In this comprehensive guide, we delve into the intricacies of rubber lining, exploring its applications, benefits, and best practices for optimal performance.

Understanding Rubber Lining

What is Rubber Lining?

Rubber lining involves the application of a protective layer of rubber to surfaces exposed to harsh environments, such as tanks, pipelines, and industrial equipment. This layer acts as a barrier, shielding the underlying material from corrosive substances and abrasive elements.

How Does Rubber Lining Work?

During the rubber lining process, specially formulated rubber compounds are applied to the surface of the substrate using techniques such as spraying or vulcanization. The rubber material bonds securely to the substrate, forming a durable and resilient protective barrier.

Applications of Rubber Lining

1. Corrosion Protection

One of the primary applications of rubber lining is corrosion protection. Rubber-lined surfaces are resistant to a wide range of corrosive substances, including acids, alkalis, and salts, making them ideal for use in chemical processing plants, wastewater treatment facilities, and mining operations.

2. Abrasion Resistance

Rubber lining provides excellent resistance to abrasion, making it suitable for equipment and structures exposed to abrasive materials such as sand, gravel, and ore. It helps prolong the lifespan of assets by minimizing wear and tear caused by friction and impact.

3. Chemical Containment

Rubber lining is also used for chemical containment applications, where it prevents leaks and spills of hazardous substances. Rubber-lined tanks, vessels, and containment structures ensure the safe storage and handling of corrosive chemicals, protecting workers and the environment.

Benefits of Rubber Lining

(i) Enhanced Durability

Rubber lining enhances the durability of industrial equipment and structures by providing an additional layer of protection against corrosion, abrasion, and chemical damage. This extends the lifespan of assets, reducing the need for frequent repairs and replacements.

(ii) Cost Savings

By reducing maintenance requirements and minimizing the risk of equipment failure, rubber lining helps organizations save on operational costs in the long term. Investing in high-quality rubber lining can lead to significant savings over the life of industrial assets.

(iii) Versatility

Rubber lining is highly versatile and can be customized to suit the specific requirements of different applications and industries. From standard rubber compounds to specialized formulations, there are options available to meet a wide range of needs.

Best Practices for Rubber Lining

(a) Proper Surface Preparation

Before applying rubber lining, it is essential to prepare the substrate properly. This may involve cleaning the surface, removing rust or existing coatings, and roughening the surface to promote adhesion.

(b) Selection of Suitable Rubber Compounds

Choosing the right rubber compound is crucial to the success of the lining application. Factors to consider include the type of chemicals present, operating temperatures, and the level of abrasion resistance required.

(c) Quality Installation

Ensure that rubber lining is installed by trained professionals using proper techniques and equipment. Quality control measures should be in place to verify adhesion, thickness, and overall integrity of the lining.

Conclusion

Rubber lining is a versatile and effective solution for protecting industrial equipment and structures from a variety of hazards. By understanding its applications, benefits, and best practices, organizations can optimize the performance and longevity of their assets, leading to improved safety, efficiency, and cost savings.

Unlock the secrets of rubber lining and elevate your industrial protection measures today!

#industry#technology#manufacturing#materials#rubber products#rubber industry#rubber lining#rubber sheets#rubber sheet mixing#rubber lining industry#rubber lining solution#rubber lining process#rubber technology#rubber process#corrosion#abrasive coatings#protective equipment#rubber material#manufacturing industry#rubber lining techniques

0 notes

Text

EVERYONE SHUT UP AND LOOK AT MY NEW AQUA MOUSE

#GUYS LOOK HOW FFUCKING CUTE IT IS AEUGH#ITS GOT A RUBBER DUCK N EVERYTHIGN#cameo from my mettaton figurine hal 9000 pencil holder and my model commodore pet 2001 <3#Clay Posts#aqua mouse#technology#computer mouse#water mouse#frutiger aero#webcore#2000s web#early internet#web aesthetic#objectum

328 notes

·

View notes

Photo

Preparing a renewable route to rubber material

A key ingredient in the manufacture of car tires and sneaker soles could be made sustainably, following new analysis of an old catalytic process. Butadiene, an essential component of synthetic rubber, is currently produced by the petrochemical industry from fossil reserves.

But it could be efficiently made in a one-step reaction from renewable ethanol using a modernized version of an unusual old catalyst. "Butadiene is currently produced as a byproduct of the petrochemical industry, which can lead to shortages in its supply," explains Sang-Ho Chung, a research scientist in the labs of Javier Ruiz-Martinez, with whom he co-led the work. "Also, these routes are clearly not sustainable," he adds.

These challenges in butadiene production have sparked renewed interest in the Lebedev process, first developed in the 1930s, that converts ethanol to butadiene in a single catalytic reactor. "Sustainable butadiene could be made by using bioethanol in the Lebedev process or even ethanol made using cutting-edge CO -to-ethanol processes," Chung says.

Read more.

#Materials Science#Science#Rubber#Environment#Catalysts#Reactions#Manufacturing#Butadiene#King Abdullah University of Science and Technology

15 notes

·

View notes

Text

My dad got me really nice airpods for christmas so I can finally retire the earbuds that came bundled with my iPhone 5s over 40 lifetimes ago. Absolutely mystified that the noise cancelling on these is something that can be toggled off and on. How do they do that...

#textpost#I will use a piece of technology until it breaks and then I will fix it and force it to hobble along in-#-a zombie-like state until it crumbles apart or I can't fix it anymore#Which is how I've managed to trick Apple brand earbuds with their shitty rubber cords to last almost 9 years hah!#Most of the 'retro' tech I have laying around my room is legit just stuff I got in the <90s or my parents had that I keep fixing rofl#Wish I could fix the damn CD player on my Sony stereo but whatevs I like cassettes more anyway

22 notes

·

View notes

Photo

Rubber’s Lover (1996, dir. Shozin Fukui)

29 notes

·

View notes

Text

Self-Destructing Military Robots Can Carry Out Recon And Then Dissolve Into Nothing

Engineers have developed soft, rubbery robots that carry out functions as usual but then liquefy on demand when exposed to ultraviolet (UV) light. This new technology enables flexible machines with programmable lifespans and could lead to self-destructing robots that protect sensitive data.

The researchers, as per the paper published in the journal Science Advances, fabricated stretchable robots…

View On WordPress

#fluoride ions#military technology#reconnaissance#robot liquefaction#robot security#Robotics#self-destructing robots#self-dissolving robots#silicone rubber#soft robotics#transient robotics#UV light

2 notes

·

View notes

Photo

Conveyor Belt Technology by ConTech Rubber ( Conveyor Technology)

4 notes

·

View notes

Photo

5 notes

·

View notes

Text

Well that’s one less up arrow key :/

#That's not great#Considerably less than ideal#It's been stuck and only half-functional for about a week now so I decided to look up how to remove and replace#Figured it'd be a fairly easy one and done - there was in fact gunk underneath and for a moment I was like#''Hella I'm such a handy repairperson'' lol#And then I snapped one of the Extremely Small and Delicate connectors and felt a whole lot less handy and repair-y#Still can't figure out how tf it's supposed to go together it's three fucking pieces and it's confusing as all hell#It's like playing the world's worst game of Operation except rather than getting zapped (thank goodness) you just can't go up a page - ever#That's not entirely true the little rubber nub does still work but it's not a /key/ y'feel#Which is especially not great since that's how I have Mother 3 mapped currently#Yeah roast me w/e I played all of Earthbound with the arrow keys and I'm not about to stop now#Also Mother 3 and Deltarune??? The UI tho#Which makes sense for Earthbound and Undertale's relationship I guess lol#Oh yeah and more technology frustration - my computer decided to restart without telling me and didn't save my Mother 3 session#So I got to replay for like a half hour to get back to where I was /when I had last saved/ ////game////#I'm fine I'm not frustrated at all#At least I use the up arrow with my middle finger and I've gotten into the habit of pressing down with my nail#Basically turning my finger over to use the arrow - it's like a home-grown key replacement lol#I will look up how to replace this mechanism but not tonight I'm too mad

2 notes

·

View notes

Text

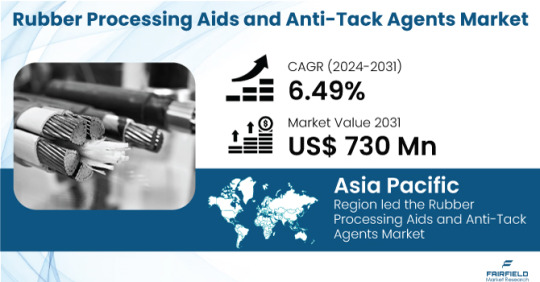

Rubber Processing Aids and Anti-Tack Agents Market - Global Growth, Share, Trends, Demand and Analysis Report Forecast 2031

Global rubber processing aids and anti-tack agents market is poised for significant expansion, with projections indicating a surge to US$730 million by 2031 from the US$470 million recorded in 2024. This impressive growth trajectory, characterized by a forecasted Compound Annual Growth Rate (CAGR) of 6.49% during 2024-2031, underscores the resilience and potential of the industry despite recent challenges.

For more information: https://www.fairfieldmarketresearch.com/report/rubber-processing-aids-anti-tack-agents-market

Mixed Performance from 2019 to 2023

The market's performance between 2019 and 2023 was a blend of growth spurred by burgeoning demand in automotive and construction sectors, offset by intermittent slowdowns attributed to economic conditions and supply chain disruptions. Despite these challenges, the industry remained steadfast, laying the groundwork for future expansion.

Cautiously Optimistic Outlook for 2024-2031

Looking ahead, the forecast for 2024-2031 maintains a cautiously optimistic outlook, anticipating short-term fluctuations before a rebound fueled by global economic improvements and eased supply chain issues. Anti-tack agents may experience minor turbulence due to economic uncertainties, but a resurgence is expected in the latter half of 2024.

Key Growth Determinants

The growth of the rubber processing aids and anti-tack agents market is underpinned by several key factors:

Increasing Demand in Automotive and Construction Industries: The rising demand for rubber products in automotive and construction sectors is a primary driver of market growth. These additives play a vital role in enhancing the processing efficiency of rubber compounds, thereby improving the properties of various products such as tires, hoses, and seals.

Technological Advancements: Continuous innovations in rubber processing aid formulations and anti-tack agent solutions are driving market expansion. Advanced technologies, including eco-friendly additives and nanotechnology-based solutions, are attracting manufacturers and end-users alike, addressing both performance and environmental concerns.

Growing Focus on Cost Reduction and Operational Efficiency: In a competitive landscape, manufacturers are increasingly focused on reducing production costs and enhancing operational efficiency. Rubber processing aids and anti-tack agents contribute significantly to achieving these objectives by optimizing processing parameters and minimizing waste.

Major Growth Barriers

Despite the promising outlook, the industry faces several challenges:

Regulatory Compliance: Stringent regulations pertaining to environmental and health safety measures can pose significant growth restraints, necessitating investments in research and development for eco-friendly products.

Volatility in Raw Material Prices: Fluctuations in raw material prices, such as petroleum-based chemicals and natural rubber, can adversely affect manufacturing costs and hinder market growth.

Substitution Threats: The emergence of alternative materials or technologies poses a threat to the market, necessitating continuous innovation to stay competitive.

Key Trends and Opportunities

The industry is witnessing notable trends and opportunities:

Sustainability Focus: Increasing emphasis on sustainability drives the demand for eco-friendly additives, presenting opportunities for innovation and market expansion.

Technological Advancements: Integration of advanced technologies into rubber processing aids enhances efficiency and product performance.

Development of Eco-Friendly Solutions: Investment in research and development for bio-based additives and environmentally benign formulations offers competitive advantages.

Expansion in Emerging Markets: Rapid industrialization in emerging economies presents growth opportunities for market players.

Regional Frontrunners

Asia Pacific: Dominates the market landscape due to flourishing automotive and manufacturing sectors.

North America: Thrives on technological advancements and sustainability focus.

Europe: Pioneering sustainable practices in the rubber industry.

Competitive Landscape

Key players such as Hallstar Innovations Corp., Lion Specialty Chemicals Co., Ltd., and McGee Industries, Inc., dominate the market. These companies employ strategies like product innovation and strategic partnerships to maintain market dominance.

0 notes

Text

I specialize in immersion heater distributor and silicone rubber heater supplier Canada. I offer a diverse range of high-quality products tailored to various heating needs, ensuring reliability and efficiency. Whether for industrial applications or water heating systems, my immersion heaters are designed to deliver optimal performance. Additionally, as a trusted supplier of silicone rubber heaters in Canada, I provide solutions that can withstand extreme temperatures and harsh environments, catering to industries such as automotive, aerospace, and medical devices. With a commitment to quality and prompt delivery, I strive to meet the heating requirements of my customers effectively, ensuring satisfaction and convenience in every purchase.

#Immersion Heaters Distributors#Silicone Rubber Heater Supplier#Canada#Heating Technologies#Industrial Heating#Electrical Heating#Manufacturing Technology

0 notes

Text

dear whoever is reading this: i am BEGGING you to watch Blackberry

#i have not the brain power to elaborate much#it's atmospheric mostly but also it's essentially learning the history of the smartphone and the rapid evolution of technology in the early#2000s#watch these dudes snap like rubber bands#also#glenn howerton

1 note

·

View note

Text

Denmark to Upgrade Its CV90 Infantry Fighting Vehicles - Technology Org

New Post has been published on https://thedigitalinsider.com/denmark-to-upgrade-its-cv90-infantry-fighting-vehicles-technology-org/

Denmark to Upgrade Its CV90 Infantry Fighting Vehicles - Technology Org

Denmark has ordered the defence contractor BAE Systems to upgrade its fleet of CV9035DK infantry fighting vehicles. These vehicles will receive many important upgrades, designed to help them to keep up with the demands of modern warfare.

CV9035DK infantry fighting vehicles are great weapons in the arsenal of the Royal Danish Army and they should continue serving for a couple of decades more.

CV9035DK is a Danish version of the Swedish infantry fighting vehicle CV90. Image credit: Pfc. Shardesia Washington via Wikimedia

The Royal Danish Army uses infantry fighting vehicles CV90. The CV90 ( Combat Vehicle 90 or strf 90) was designed in the late 1980s and entered service in 1994. Although it is technically a Swedish weapon, it is produced by BAE Systems AB, which will upgrade the Danish machines. Denmark is using the CV9035DK, which is an export version of the CV90 with a 35mm Bushmaster III autocannon.

Similar infantry fighting vehicles are used in the Netherlands, where they are designated CV9035NL, but are essentially the same thing. However, the CV9035NL already has a new turret and now the CV9035DK will get it too.

The Bushmaster III is a serious autocannon that fires 200 rounds per minute. The armour of Russian BMPs can be pierced through with no problem whatsoever, and if they hit well (that is, from the side) these rounds can even go through main battle tanks. But still, it’s time to upgrade its turret.

The Danish defence procurement organization DALO commissioned BAE Systems to modernize the fleet of CV9035DK infantry fighting vehicles. Denmark has been using 44 CV9035DKs for about 20 years now and would now like to upgrade them from the ground up. This will be a mid-life update, which could mean that these infantry fighting vehicles will be good for another two decades. War machines last a long time when there is no war.

The main upgrade for the CV9035DKs will be new turrets, but they will also receive lighter and quieter rubber composite tracks, better protection and mobility. The first upgraded infantry fighting vehicles will return to Denmark in 2026, the rest until 2029.

What’s so special about those new turrets? BAE Systems developed them some time ago and Dutch machines already use them. They have many improvements. For example, the position of the main gun has been adjusted to better balance the vehicle and to provide new opportunities to integrate other weapon systems (for example, anti-tank missiles).

According to the manufacturer, the new turret is also more ergonomic for the crew. This should not be overlooked, because soldiers can be more efficient when they are more comfortable.

It is good to remind people that while main battle tanks are great, it is infantry fighting vehicles that perform the majority of the tasks in today’s combat. Denmark has 44 CV9035DKs and 44 Leopard 2A7DK main battle tanks.

Written by Povilas M.

Sources: Tech.wp.pl, Wikipedia

#1980s#anti-tank#armored vehicles#Authored post#BAE Systems#battle tanks#Denmark#ergonomic#Featured Military news#infantry fighting vehicles#it#life#Military technology#missiles#Mobility#Netherlands#organization#Other#REST#royal#rubber#Special post#Spotlight news#tanks#Tech#technology#time#vehicles#Version#War

0 notes

Text

Rubber Lining Solutions: Enhancing Operational Efficiency

In today's industrial landscape, maintaining operational efficiency is paramount for organizations striving to remain competitive. Amidst the myriad of challenges faced by industrial sectors, ensuring the integrity and longevity of equipment and infrastructure is crucial. This is where rubber lining solutions come into play, offering a versatile and effective method for protecting assets and enhancing operational efficiency.

Understanding Rubber Lining

Rubber lining involves the application of specialized coatings to various surfaces, providing protection against corrosion, abrasion, and chemical exposure. These coatings, typically made from synthetic rubber compounds, create a durable barrier that shields equipment and infrastructure from damage, thereby extending their lifespan and reducing maintenance costs.

Key Benefits of Rubber Lining

Rubber lining solutions offer a multitude of benefits for industrial applications:

1. Corrosion Resistance

One of the primary advantages of rubber lining is its exceptional resistance to corrosion. By creating a protective barrier between metal surfaces and corrosive substances, rubber lining helps prevent degradation and prolongs the lifespan of equipment and infrastructure.

2. Abrasion Protection

In environments where equipment is subjected to abrasive materials or high levels of wear, rubber lining serves as a critical line of defense. The resilient nature of rubber coatings absorbs impact and minimizes abrasion, preserving the integrity of surfaces and components.

3. Chemical Compatibility

Rubber lining solutions are engineered to withstand exposure to a wide range of chemicals, making them suitable for applications where chemical resistance is essential. Whether dealing with acids, alkalis, or solvents, rubber linings provide reliable protection against chemical damage.

4. Flexibility and Adaptability

Rubber linings are highly flexible and adaptable, allowing them to conform to complex shapes and contours. This versatility makes them ideal for lining tanks, pipes, valves, and other equipment, ensuring comprehensive protection across various industrial applications.

Applications of Rubber Lining

Rubber lining finds extensive use across diverse industries, including:

Mining and Mineral Processing: Rubber lining is commonly used to protect equipment such as chutes, hoppers, and conveyor systems in mining operations, where abrasive materials and harsh conditions are prevalent.

Chemical Processing: In chemical plants and refineries, rubber lining provides essential protection for vessels, tanks, and piping systems that handle corrosive chemicals and aggressive fluids.

Oil and Gas Production: Rubber lining plays a vital role in offshore platforms, pipelines, and storage facilities within the oil and gas industry, safeguarding critical infrastructure against corrosion and erosion.

Water and Wastewater Treatment: Rubber linings are utilized in water treatment plants and wastewater facilities to protect tanks, basins, and pipes from corrosion and chemical attack, ensuring reliable operation and compliance with environmental regulations.

Conclusion

In conclusion, rubber lining solutions offer a versatile and effective means of enhancing operational efficiency across a wide range of industrial applications. From protecting equipment against corrosion and abrasion to ensuring chemical compatibility and adaptability, rubber linings provide invaluable benefits for organizations seeking to optimize performance and reduce maintenance costs. By leveraging the advantages of rubber lining technology, industries can enhance asset integrity, prolong equipment lifespan, and achieve greater operational efficiency in today's competitive marketplace.

#industry#technology#manufacturing#rubber products#materials#rubber process#rubber sheets#rubber lining#rubber industry#rubber sheet mixing#rubber lining solution#protective equipment#chemical resistance

0 notes

Text

Looking for precision in rubber hardness testing? Multitek Technologies, your trusted partner in quality control! We specialize in manufacturing and supplying top-notch Rubber Hardness Testers that ensure accurate results every time.

Our cutting-edge technology guarantees reliability, efficiency, and durability. 🌟 Choose Multitek for unparalleled quality in rubber hardness testing equipment.

Explore our range today: https://www.multitek.in/rubber-hardness-tester

MultitekTechnologies #RubberHardnessTester #QualityControl #Manufacturing #Innovation #Reliability #PrecisionTesting #MadeInIndia #calibration #engineering #instrumentation #iso #metrology #automation #flowmeter #technology #tuning #engineer #sensors #environmentalmonitoring #inspection #processcontrol #testequipment #controlsystem #testing #repair #fieldinstruments #datalogging #toolsofthetrade #fieldwork #protools #remotemonitoring #electrical #technicianlife #sparkylife #toolporn #cleanenvironment #laboratory @multitektechnologies

#hardness tester#micro vicker#multitek technologies#rockwell hardness tester#Rubber Hardness Tester#Rubber#Rubber Hardness Tester Machine

0 notes

Text

Revolutionizing Tire Manufacturing

Introducing our cutting-edge Microwave Preheater – the key to efficient tire production. Say hello to uniform heating and superior quality.

http://www.microwaverubberheating.com/microwave-preheater-for-tyre/

#Twinengineers#Microwaverubberheating#technology#process#rubber#rubberindustries#greentechnology#manufacturer#suppliers#exporters#Vadodara#gujarat#india#Microwavepreheater#Continuousvulcanizingovens#vulcanizingovens#Preheater#tyre#tyreindustries

0 notes