#Carbon Engineering

Text

Inside Charm Industrial's big bet on corn stalks for carbon removal

Inside Charm Industrial’s big bet on corn stalks for carbon removal

Good News Notes:

“In recent weeks, a crew of staffers from a company called Charm Industrial have been working on the edge of Kansas corn fields, moving rolled bales of stalks, leaves, husks, and tassels up to a white semi-trailer.

Inside, a contraption called a pyrolyzer uses high temperatures in the absence of oxygen to break down the plant material into a mix of biochar and bio-oil. The former…

View On WordPress

#absence of oxygen#agricultural crops#back into the fields#bales#bio-oil#biochar#capture the carbon#carbon#Carbon Engineering#Charm Industrial#climate change#Climeworks#economical#EPA#good news#greenhouse gas#happy#help#high temperatures#husks#joy#Kansas corn fields#kindness#leaves#Microsoft#need#nutrients#offset their own emissions#Peter Reinhardt#positive

3 notes

·

View notes

Text

Carbon Engineering receives millions in investment from

Carbon Engineering receives millions in investment from

SQUAMISH, British Columbia, Nov. 17, 2022 (GLOBE NEWSWIRE) — Climate solutions company, Carbon Engineering (CE), has received millions in investments from Aviation industry leaders Airbus and Air Canada. These investments support the advancement of CE’s Direct Air Capture (DAC) technology that pulls carbon dioxide (CO2) directly out of the air at large, industrial scale.

This funding will…

View On WordPress

#Air Canada#Airbus#Carbon Engineering#clean tech#Climate#decarbonization#Direct Air Capture#Environment#Investment#Technology

1 note

·

View note

Text

Porsche 911 reimagined by Singer, DLS – Turbo, 2023. Singer have presented 2 new cars in their Dynamics & Lightweighting Study series based on 964 air-cooled 911 models made between 1989 and 1994. The car in Blood Orange has been specified by its owner to emphasize track performance, featuring a high-downforce rear wing with adjustable upper element and a track-oriented front fascia with larger splitter. The car in Moet Blanc has been specified by its owner to be road-focused, including an aero-optimized rear ducktail spoiler and road-oriented front fascia which reduce drag. Both are powered by 3.8 litre, 4-valves per cylinder flat-six engines with twin turbochargers, electric wastegates, air-to-water intercooling and a horizontally mounted, electrically powered fan. This evolution of the engine developed for DLS restorations enables power outputs over 700 HP at more than 9000 rpm.

#Singer#Singer DLS Turbo#2023#turbocharged#rear engine#Porsche 911 reimagined by Singer#restomod#carbon fibre#boxer engine#flat 6#Porsche 911 964

484 notes

·

View notes

Text

Just found out the OceanGate sub hull was made with Carbon Fiber???? Can fail under compression with one poorly manufactured air bubble carbon fiber??? Subjective to failure inducing embrittlement at low temperatures carbon fiber???? That carbon fiber????

I am in absolute horrified Awe. Like. I don’t know much about submarines, but I know rockets and we use carbon fiber for hobby rockets and. You can’t?? Make a pressurized vessel out of carbon fiber?? And expect it to survive cyclical loads?? Especially one experiencing temperatures as low as the waters by the Titanic!! Like the polymer matrix would DEFFO experience embrittlement and at MINIMUM crack but more likely would fail catastrophically!! Your threasbold for acceptable cracking would be MINISCULE at that pressure; you couldn’t afford brittle cracking almost at all!!

This article goes into some detail about the safety concerns with the material used and how they were literally brought up and ignored! like. This is the literal scenario they train us for ethics wise in college! Legit the definition! Of when you should put human life before the company!!

Idk it’s just. There’s so much wrong with the situation, but like. To not perform nondestructive testing on the hull?? To ignore visible defects on a supplied material??

So many red flags, so many things that should Never have happened.

#oceangate#titanic#submarine#carbon fiber#materials engineering#engineering ethics#death#i legit gasped when i heard the hull was cf#a break from fandom content for a horrified engineering rant#dont get me started on the titanium in the cf that it sounds like they used

89 notes

·

View notes

Text

This is nuts and it’s horrifying how cavalier he was with the lives of others but also I can’t help but laugh at this. Like yeah you got your wish sort of. You WILL be remembered for the rules you broke, just not fondly, and not as an innovator.

#are u serious#I know nothing abt engineering or whatever and even I know metal + carbon fibre is a no go ????!#ID in alt#oceangate#oceangategate#ceci says stuff

128 notes

·

View notes

Text

we need a fast, safe, low-level, and c-interoperable language because it can exist

i feel like there should be a version of c++ that is safer, has better syntax, and is just easier to develop in

like a fast, safe, low-level, c-interoperable language can definitely exist

c++ is not safe. a language where you can run *(int*)0=0; without any warnings, error

and before you come after me saying thats a strawman argument, there are a lot of cases where that sort of null dereference is hidden, and it can be excruciating to figure out where it happens, and god forbid it happens in production

and the syntax that comes with c++ gets super esoteric, move semantics for example can get really confusing, there are pure virtuals as opposed to abstracts, and if you get a type error, god help you

and i know go exists, but that uses a gc, so it loses speed and low-level points

and i know rust exists, and while it is great, it is so fundamentally different from c++ and other languages that it requires lots of weird bindings, and its often better to rewrite libraries in the language itself, which not as many people are willing to do, so it loses c-interpoerability points

i would KILL for Carbon to be mainstream, because it seems like such an improvement to c++ but literally no one uses it

11 notes

·

View notes

Text

#good news#environmentalism#science#engineering#co2 emissions#carbon sequestration#carbon dioxide#co2

13 notes

·

View notes

Text

ZO

#ferrari#italia#enzo#carbon#photoshoot#car lovers#fast cars#bigboytoys#ferrari enzo#carbon fiber#super cars#master piece#porsche#porsche 911#german engineering#911#bloodbath99

36 notes

·

View notes

Text

More I learn about the history of Thomas the Tank Engine the more I do, in fact, want to gatekeep All Engines Go. The original author would've hated it at any rate.

#I appreciate it doing things like#not having characters be inherently evil just because they aren't steam powered#like we do gotta care about the island of sodor's carbon footprint at some point#and I feel like the characters get along better and make up with each other instead of 'learning their lesson' or whatever#which tbh I appreciate as a parent lol#but like#I'm just not a fan of engines that can jump from track to track and move their wheels around like hands and all that#it's kinda uncanny valley tbh#like if they're Actual Trains that still need a driver and all that I can go#'oh if this wasn't a kids series its really no different than ancillary justice'#but if they're fully autonomous like the pixar cars then what is even the worldbuilding#'ellen you think too much about your toddler's fandoms' listen. listen. I wrote a curious george mdzs au.

23 notes

·

View notes

Text

i could cry just thinking about geology and paleontology like how lovely is it that we want to know what our home planet was like millions or billions of years ago we are curious about who and what inhabited this little rock in space before we came along we want to sit in the lap of mother earth and listen to her story of how she began and how she changed and how she came to be what she is now

#pls im not even a geology student im just studying about carbon capture technology in Engineering but i got way too hooked on an intro chap#ter about plant life in the carboniferous era#science is so beautiful#what do i tag this as#science#geology#paleontology#earth#planet earth#i said that?

132 notes

·

View notes

Text

Thank you school for the random lectures about basic safety. Now I'm sure I won't die by carbon monoxide.

#a group of young people died in a car because of carbon monoxide leak#they were showing the same symptoms at the same time inside the car#and absolutely none of them pieced together that maybe it had something to do with being inside the car#they were all feeling nauseous so they parked and stayed inside the car with the engine on#if you're in a closed place feeling nauseous or dizzy with other people feeling the same#then you have to fucking leave immediately#don't die for stupid reasons please

7 notes

·

View notes

Text

Lights last longer thanks to Mr. Lewis Howard Latimer 💡👏🏿

#black history#black history month#lightbulb moment#carbon filament#yamnbananas#trillnoir#digital art#glitché#art#lightbulb#incandescent#black inventors#national inventors hall of fame#engineering#thomas edison#Lewis Harold Latimer#american history

10 notes

·

View notes

Text

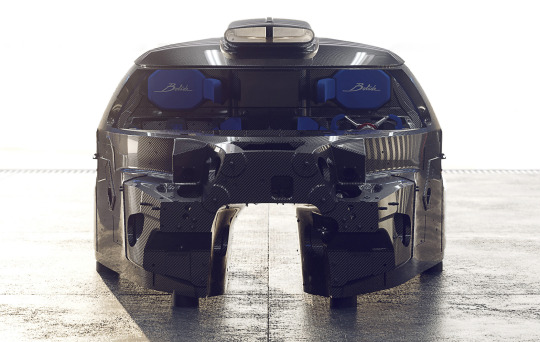

Bugatti Bolide Monocoque, 2023. Looking like Batman's next ride, Bugatti have revealed the high-grade carbon fibre structure than hides beneath the bodywork of their track-only Bolide hypercar. The Bolide’s monocoque mirrors the proportions of a catamaran, placing the driver and passenger perfectly balanced inside the car. This arrangement enables the W16 powertrain to be positioned 60mm further forward than in the Chiron, ensuring ideal packaging for track use. The carbon fibre monocoque has been developed to meet the same Fédération Internationale de l’Automobile LMH and LMDh requirements as Le Mans race cars. Powered by the 8.0 litre W16 engine, the Bolide generates 1,600PS while the car has a dry weight of just 1,450 kg. First customers will receive their cars in 2024

#Bugatti#Bugatti Bolide#Monocoque#carbon fibre monocoque#track car#race car#W16#mid-engine#hypercar#lightweight#what lies beneath#catamaran

233 notes

·

View notes

Text

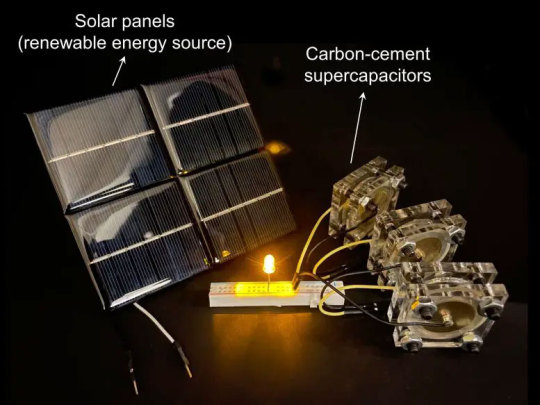

New Breakthrough in Energy Storage – MIT Engineers Create Supercapacitor out of Ancient Materials

MIT engineers have created a “supercapacitor” made of ancient, abundant materials, that can store large amounts of energy. Made of just cement, water, and carbon black (which resembles powdered charcoal), the device could form the basis for inexpensive systems that store intermittently renewable energy, such as solar or wind energy. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

Constructed from cement, carbon black, and water, the device holds the potential to offer affordable and scalable energy storage for renewable energy sources.

Two of humanity’s most ubiquitous historical materials, cement and carbon black (which resembles very fine charcoal), may form the basis for a novel, low-cost energy storage system, according to a new study. The technology could facilitate the use of renewable energy sources such as solar, wind, and tidal power by allowing energy networks to remain stable despite fluctuations in renewable energy supply.

The two materials, the researchers found, can be combined with water to make a supercapacitor — an alternative to batteries — that could provide storage of electrical energy. As an example, the MIT researchers who developed the system say that their supercapacitor could eventually be incorporated into the concrete foundation of a house, where it could store a full day’s worth of energy while adding little (or no) to the cost of the foundation and still providing the needed structural strength. The researchers also envision a concrete roadway that could provide contactless recharging for electric cars as they travel over that road.

The simple but innovative technology is described in a recent paper published in the journal PNAS, in a paper by MIT professors Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn, and four others at MIT and at the Wyss Institute.

Capacitors are in principle very simple devices, consisting of two electrically conductive plates immersed in an electrolyte and separated by a membrane. When a voltage is applied across the capacitor, positively charged ions from the electrolyte accumulate on the negatively charged plate, while the positively charged plate accumulates negatively charged ions. Since the membrane in between the plates blocks charged ions from migrating across, this separation of charges creates an electric field between the plates, and the capacitor becomes charged. The two plates can maintain this pair of charges for a long time and then deliver them very quickly when needed. Supercapacitors are simply capacitors that can store exceptionally large charges.

The amount of power a capacitor can store depends on the total surface area of its conductive plates. The key to the new supercapacitors developed by this team comes from a method of producing a cement-based material with an extremely high internal surface area due to a dense, interconnected network of conductive material within its bulk volume. The researchers achieved this by introducing carbon black — which is highly conductive — into a concrete mixture along with cement powder and water, and letting it cure. The water naturally forms a branching network of openings within the structure as it reacts with cement, and the carbon migrates into these spaces to make wire-like structures within the hardened cement.

These structures have a fractal-like structure, with larger branches sprouting smaller branches, and those sprouting even smaller branchlets, and so on, ending up with an extremely large surface area within the confines of a relatively small volume. The material is then soaked in a standard electrolyte material, such as potassium chloride, a kind of salt, which provides the charged particles that accumulate on the carbon structures. Two electrodes made of this material, separated by a thin space or an insulating layer, form a very powerful supercapacitor, the researchers found.

Since the new “supercapacitor” concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills, and allow it to be used whenever it’s needed. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

The two plates of the capacitor function just like the two poles of a rechargeable battery of equivalent voltage: When connected to a source of electricity, as with a battery, energy gets stored in the plates, and then when connected to a load, the electrical current flows back out to provide power.

“The material is fascinating,” Masic says, “because you have the most-used manmade material in the world, cement, that is combined with carbon black, that is a well-known historical material — the Dead Sea Scrolls were written with it. You have these at least two-millennia-old materials that when you combine them in a specific manner you come up with a conductive nanocomposite, and that’s when things get really interesting.”

As the mixture sets and cures, he says, “The water is systematically consumed through cement hydration reactions, and this hydration fundamentally affects nanoparticles of carbon because they are hydrophobic (water repelling).” As the mixture evolves, “the carbon black is self-assembling into a connected conductive wire,” he says. The process is easily reproducible, with materials that are inexpensive and readily available anywhere in the world. And the amount of carbon needed is very small — as little as 3 percent by volume of the mix — to achieve a percolated carbon network, Masic says.

Supercapacitors made of this material have great potential to aid in the world’s transition to renewable energy, Ulm says. The principal sources of emissions-free energy, wind, solar, and tidal power, all produce their output at variable times that often do not correspond to the peaks in electricity usage, so ways of storing that power are essential. “There is a huge need for big energy storage,” he says, and existing batteries are too expensive and mostly rely on materials such as lithium, whose supply is limited, so cheaper alternatives are badly needed. “That’s where our technology is extremely promising, because cement is ubiquitous,” Ulm says.

The team calculated that a block of nanocarbon-black-doped concrete that is 45 cubic meters (or yards) in size — equivalent to a cube about 3.5 meters across — would have enough capacity to store about 10 kilowatt-hours of energy, which is considered the average daily electricity usage for a household. Since the concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills and allow it to be used whenever it’s needed. And, supercapacitors can be charged and discharged much more rapidly than batteries.

After a series of tests used to determine the most effective ratios of cement, carbon black, and water, the team demonstrated the process by making small supercapacitors, about the size of some button-cell batteries, about 1 centimeter across and 1 millimeter thick, that could each be charged to 1 volt, comparable to a 1-volt battery. They then connected three of these to demonstrate their ability to light up a 3-volt light-emitting diode (LED). Having proved the principle, they now plan to build a series of larger versions, starting with ones about the size of a typical 12-volt car battery, then working up to a 45-cubic-meter version to demonstrate its ability to store a house-worth of power.

There is a tradeoff between the storage capacity of the material and its structural strength, they found. By adding more carbon black, the resulting supercapacitor can store more energy, but the concrete is slightly weaker, and this could be useful for applications where the concrete is not playing a structural role or where the full strength-potential of concrete is not required. For applications such as a foundation, or structural elements of the base of a wind turbine, the “sweet spot” is around 10 percent carbon black in the mix, they found.

Another potential application for carbon-cement supercapacitors is for building concrete roadways that could store energy produced by solar panels alongside the road and then deliver that energy to electric vehicles traveling along the road using the same kind of technology used for wirelessly rechargeable phones. A related type of car-recharging system is already being developed by companies in Germany and the Netherlands, but using standard batteries for storage.

Initial uses of the technology might be for isolated homes or buildings or shelters far from grid power, which could be powered by solar panels attached to the cement supercapacitors, the researchers say.

Ulm says that the system is very scalable, as the energy-storage capacity is a direct function of the volume of the electrodes. “You can go from 1-millimeter-thick electrodes to 1-meter-thick electrodes, and by doing so basically you can scale the energy storage capacity from lighting an LED for a few seconds, to powering a whole house,” he says.

Depending on the properties desired for a given application, the system could be tuned by adjusting the mixture. For a vehicle-charging road, very fast charging and discharging rates would be needed, while for powering a home “you have the whole day to charge it up,” so slower-charging material could be used, Ulm says.

“So, it’s really a multifunctional material,” he adds. Besides its ability to store energy in the form of supercapacitors, the same kind of concrete mixture can be used as a heating system, by simply applying electricity to the carbon-laced concrete.

Ulm sees this as “a new way of looking toward the future of concrete as part of the energy transition.”

Reference: “Carbon–cement supercapacitors as a scalable bulk energy storage solution” by Nicolas Chanut, Damian Stefaniuk, James C. Weaver, Yunguang Zhu, Yang Shao-Horn, Admir Masic and Franz-Josef Ulm, 31 July 2023, Proceedings of the National Academy of Sciences.

DOI: 10.1073/pnas.2304318120

The research team also included postdocs Nicolas Chanut and Damian Stefaniuk at MIT’s Department of Civil and Environmental Engineering, James Weaver at the Wyss Institute for Biologically Inspired Engineering, and Yunguang Zhu in MIT’s Department of Mechanical Engineering. The work was supported by the MIT Concrete Sustainability Hub, with sponsorship by the Concrete Advancement Foundation.

Source: scitechdaily.com

#Carbon Emissions#Civil Engineering#Engineering#MIT#Renewable Energy#Energy Storage#Ancient Materials#Tech News#good news

10 notes

·

View notes

Link

Rice University scientists have figured out a way to engineer wood to trap carbon dioxide through a potentially scalable, energy-efficient process that also makes the material stronger for use in construction.

Structural materials like steel or cement come at a high cost both in dollars and carbon dioxide emissions; building construction and use accounts for an estimated 40% of emissions. Developing sustainable alternatives to existing materials could help mitigate climate change and reduce carbon dioxide emissions.

Working to address both issues at once, materials scientist Muhammad Rahman and collaborators found a way to incorporate molecules of a carbon dioxide-trapping crystalline porous material into wood, according to a study published in Cell Reports Physical Science.

"Wood is a sustainable, renewable structural material that we already use extensively," Rahman said. "Our engineered wood did exhibit greater strength than normal, untreated wood."

To achieve the feat, the network of cellulose fibers that gives wood its strength is first cleared out through a process known as delignification.

Read more.

#Materials Science#Science#Engineered wood#Biomaterials#Carbon dioxide capture#Cellulose#Metal organic framework#Wood#Rice University

24 notes

·

View notes

Text

So Pelia is an extremely long-lived Lanthanite, a race that lived among humans on Earth for who knows how long. Pelia also seems to have a long acquaintance with human-Vulcan relationships/hybrids, to judge from her interest in Spock and association with Amanda. This suggests the possibility that Pelia's involvement might go way back. Was Pelia at Carbon Creek? Could she have known T'Pol's ancestor, T'mir, and later, T'Pol herself? Could this be setting up a T'Pol appearance in SNW? I know all the objections, not least, Jolene Blalock's disinterest in Star Trek. But a girl can dream.

17 notes

·

View notes