#Fuel Cells

Text

Supercharging fuel cells with caffeine

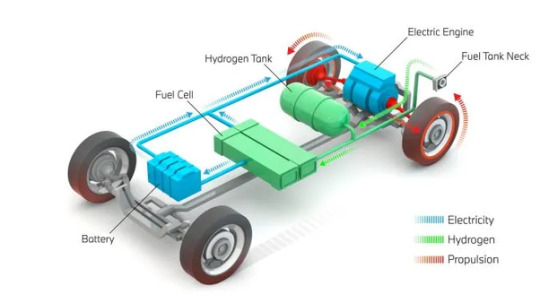

With global goals set on transitioning away from fossil fuels, fuel cells stand out as a promising carbon-free energy source. Comprising an anode and a cathode separated by an electrolyte, fuel cells convert the chemical energy of fuel directly into electricity. The anode receives the fuel, while an oxidant, typically oxygen from the air, is introduced at the cathode.

In a hydrogen fuel cell, hydrogen undergoes oxidation at the anode, producing hydrogen ions and electrons. The ions move through the electrolyte to the cathode, and electrons flow through an external circuit, generating electricity. At the cathode, oxygen combines with the hydrogen ions and electrons, resulting in water as the sole byproduct.

Read more.

#Materials Science#Science#Fuel cells#Biomaterials#Caffeine#Hydrogen#Reactions#Platinum#Chiba University

27 notes

·

View notes

Text

Powering the Future: Exploring the Hydrogen Generation Market

As the world transitions towards a low-carbon economy, hydrogen emerges as a versatile and sustainable energy carrier with the potential to revolutionize various sectors, from transportation and industry to power generation and heating. At the heart of this energy revolution lies the hydrogen generation market, which is experiencing rapid growth and innovation driven by the imperative of decarbonization and the pursuit of cleaner energy solutions.

Hydrogen generation technologies encompass a diverse range of methods, including electrolysis, steam methane reforming (SMR), biomass gasification, and solar-driven processes. Each of these methods offers unique advantages and challenges, depending on factors such as cost, efficiency, scalability, and environmental impact.

One of the key drivers of the hydrogen generation market is the increasing focus on renewable hydrogen production. Electrolysis, powered by renewable energy sources such as wind and solar, is emerging as a clean and sustainable method for generating hydrogen without greenhouse gas emissions. As renewable energy costs continue to decline and government incentives support the transition to green hydrogen, the market for renewable hydrogen is poised for significant growth.

Moreover, the expanding application of hydrogen fuel cells in transportation, stationary power, and industrial processes is driving demand for hydrogen as a clean energy carrier. Fuel cell electric vehicles (FCEVs) offer zero-emission transportation solutions with fast refueling and long-range capabilities, making hydrogen an attractive alternative to conventional internal combustion engines and battery-electric vehicles.

Another factor driving market growth is the increasing recognition of hydrogen's potential to address energy storage and grid stability challenges associated with intermittent renewable energy sources. Hydrogen storage and conversion technologies enable the storage of excess renewable energy during periods of low demand and its conversion back to electricity or heat when needed, thus enhancing grid flexibility and resilience.

Furthermore, partnerships and investments across the hydrogen value chain are accelerating the commercialization and deployment of hydrogen technologies. From electrolyzer manufacturers and hydrogen infrastructure developers to energy companies and automakers, stakeholders are collaborating to overcome technical, economic, and regulatory barriers and unlock the full potential of hydrogen as a clean and sustainable energy solution.

In conclusion, the hydrogen generation market is poised for exponential growth as the world transitions towards a low-carbon future. With advancing technologies, expanding applications, and growing investment, hydrogen is set to play a pivotal role in powering the transition to a more sustainable and resilient energy system, driving innovation, economic growth, and environmental stewardship.

#Hydrogen Generation#Renewable Energy#Fuel Cells#Green Technology#Industrial Innovation#sustainability#technology#innovation#augmented reality#environmental sustainability#immersive experiences#additive manufacturing#ai#aiincelltherapy#compliance

0 notes

Text

Molecular Weaving Makes Polymer Composites Stronger Without Compromising Function - Technology Org

New Post has been published on https://thedigitalinsider.com/molecular-weaving-makes-polymer-composites-stronger-without-compromising-function-technology-org/

Molecular Weaving Makes Polymer Composites Stronger Without Compromising Function - Technology Org

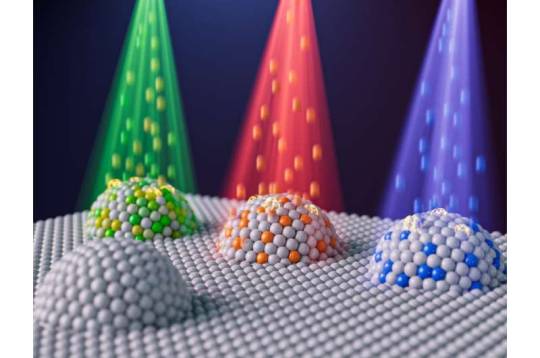

At its most basic, chemistry is a lot like working with building blocks at its most basic level, but the materials are atoms and molecules. COFs – or covalent organic frameworks, a new class of porous crystals – are a great example of a material that behaves like a molecular Lego set, where individual building blocks are connected through strong chemical bonds to form a highly open and structured network.

This intricate structure provides a scaffold for polymer chains to thread or wrap during their formation and strength. Think of a woven scarf or basket – a single piece of yarn or twine may not be much on its own, but when woven together, the pattern enhances the final product’s overall performance. Furthermore, when these chains weave together, sometimes even the chemical reactions further strengthen the material’s properties.

Schematic illustration of the COF structure, polymers, and nanofibrils courtesy of Science Magazine / UC Berkeley

In 2016, Yaghi Research Group, led by UC Berkeley’s Professor of Chemistry Omar Yaghi, realized the first molecularly woven structure by interlacing the backbone of the framework in a 3D space. These molecular woven COF crystals are tough but extremely flexible, as every atom has a high degree of freedom to move around but is also locked in place, and as a whole the woven crystals are able to dissipate energy during stress to prevent fracture.

Today, together with Ting Xu, Professor of Chemistry and Materials Science & Engineering; and Rob Ritchie, Professor of Materials Science & Engineering, the lab is now leveraging both the porosity and molecular weaving to make polymer composites stronger, tougher, and more resistant to fracture by threading polymer strands through the woven network. Their findings have been published in a paper by Science.

“This is exciting because most filler materials enhance one mechanical property at the detriment of another,” said Ephraim Neumann, a PhD candidate at the College of Chemistry working at the Yaghi Research Group. Neumann is sharing his first authorship with joint student of Xu and Ritchie, Junpyo (Patrick) Kwon, who graduated (PhD) last year from UC Berkeley.

But why are COFs themselves so useful to everyday life? One example is that due to their exceptional porosity, COFs are used extensively in storing and separating gases such as hydrogen and methane. Both hydrogen and methane are clean energy carriers that can be used in fuel cells and combustion engines. Storing them enables their use in transportation and power generation without producing harmful emissions.

Now, thanks to this new research that suggests polymer composites can be made more durable, the applications and uses have wider implications.

“When we add a small amount (1%) of these woven COF crystals to other materials such as polymer or plastic in this case, the materials become significantly tougher and can have a high tolerance for damages and fractures. This could have a huge impact on the materials industry,” said Yaghi.

For example, polyimide, found in almost every laptop and electrical wiring, was one of the investigated polymers in this study. By adding woven COF nanocrystals, the team was able to improve the mechanical performance of the polymer without compromising its thermal stability. This suggests this technique could lead to longer lifetimes for these composites. “Or if the material becomes more resilient, one could use less of it to achieve the same result,” hypothesized Neumann. Polyimide can also be found in the solar sails used by NASA, as it is often used as a support material that lends thermal and mechanical durability to many applications.

“Many properties of plastic products rely on polymer chain entanglements,” said Xu. “My favorite analogy is how an angel hair pasta and a bowtie pasta may respond to a swirl in the plate. Adding nanoparticles of these crystalline COFs can template how these long chains may arrange spatially and get the whole plate to work together. It also becomes feasible to pull out the chains, separate out polymers from COF nanoparticles and do the process again from scratch.”

When thinking about how this might affect industries beyond materials, Neumann concluded, “While this discovery focuses on specific polymers, the basic concept of using porous, molecularly woven COFs to enhance mechanical properties could be extended to many other materials.”

Source: UC Berkeley

You can offer your link to a page which is relevant to the topic of this post.

#3d#amp#applications#atom#atoms#Building#Cells#chemical#chemical bonds#chemical reactions#chemistry#clean energy#college#composites#crystalline#crystals#Emissions#energy#engineering#engines#form#framework#fuel#fuel cells#Fundamental physics news#how#hydrogen#illustration#impact#Industries

0 notes

Text

The global electrolyzers market is expected to grow from an estimated USD 1.2 billion in 2023 to USD 23.6 billion in 2028, at a CAGR of 80.3% according to a new report by MarketsandMarkets™.

#electrolyzer#electrolysis#electrolyzers#electrolyzers market#energy#power#power generation#renewable energy#renewable#renewable fuel#renewables#green hydrogen#green hydrogen production#fuel cell#fuel cells#hydrogen fuel#hydrogen fuel cells#fuel cell electric vehicles

0 notes

Text

First Hydrogen's Hydrogen-Fuel-Cell Powered Parcel Vehicle Trials

First Hydrogen's Hydrogen-Fuel-Cell Powered Parcel Vehicle Trials

Vancouver, British Columbia–(Newsfile Corp. – August 23, 2023) – First Hydrogen Corp. (TSXV: FHYD) (OTC: FHYDF) (FSE: FIT) (“FIRST HYDROGEN” or the “Company“) announces it will be opening up fleet trials to additional commercial opportunities in response to growing interest from parcel delivery companies seeking First Hydrogen’s hydrogen-fuel-cell-powered vehicle (FCEV) for express deliveries.…

View On WordPress

0 notes

Text

#Global Distributed Energy Generation Market Size#Share#Trends#Growth#Industry Analysis By Type( Solar PV#CHP#Fuel cells#Wind Power#Other )#By Applications( Rural Areas#Urban Areas )#Key Players#Revenue#Future Development & Forecast 2023-2032

0 notes

Text

Fuel Cell or Battery Electric Vehicles – The Future of Mobility

Introduction

As we already know, the depleting deposits of fossil fuels and the adverse effect of their combustion on the environment have propelled automakers to turn to alternate sources of energy to drive vehicles.

These sources need to be diverse and sustainable energy solutions, such as battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs).

Although the automotive industry has already started looking at sustainable solutions, there is a lot of debate regarding the prioritization of BEVs over FCEVs, particularly because of the limited available reserves of lithium, which is a major component in lithium-ion batteries.

Many researchers are hence advocating the use of fuel cells, which convert the chemical reaction of a redox reaction into electricity.

However, the behavior of a fuel cell in an automotive battery is still in the R&D phase, which is why most automakers are still hesitant about using it in production vehicles. This article aims to address these concerns about this BEV-FCEV debate.

FCEVs or BEVs | Dorleco

Source: What is a Fuel Cell?

The Interplay between BEVs and FCEVs

One of the popular misconceptions in this particular debate is that lithium-ion batteries and fuel cells are competing technologies. It is important to understand that batteries are here to stay in the industry for a long time into the future now as one of the primary energy sources.

What lithium-ion cells and fuel cells do is present diverse options for solving the efficiency, emissions and sustainability problems.

Both these chemistries aim to enhance the solutions for the electrification question that the industry is currently facing.

Batteries are forecasted to be the central piece of the electrified solution in the future, and fuel cells will aim at enhancing them rather than replacing them.

This will be essential in addressing the issue of recharging time for batteries, especially for heavy-duty transport.

FCEVs or BEVs | Dorleco

Source: Electric HD trucks – when will hype become a reality? | Automotive World

Challenges in Today’s Market

The first factor that always comes into question when talking about sustainable mobility is Range, especially when talking about heavy-duty transport.

Combustion engine trucks with very high payload capacity normally have a large fuel tank, in the vicinity of 200 to 300 litres (50-80 gallons).

This often allows them to drive up to 400 miles (subject to payload) before having to stop for a refueling break.

However, the development of lithium-ion cells, as well as fuel cells, is still at an early stage, and so, none of the solutions has met the range demands of heavy-duty transport yet.

Secondly, a high-capacity battery will most likely be very heavy, which increases the amount of load, which in turn demands more energy.

For instance, the weight of the battery in the Hummer EV is anticipated to be equivalent to the Honda Civic. One solution to this vicious cycle is high-energy-density batteries (or fuel cells).

FCEVs or BEVs | Dorleco

Source: Hydrogen Fuel Cells vs. Battery Electrics: Why Fuel Cells are a Major Contender

Heavy-duty transport will be an interesting challenge for automakers since there are quite a few tradeoffs that automotive designers have to work with while using Li-ion cells.

There is a relatively lower cap on the maximum allowable weights on each axle at the moment, which means designers need to reduce the battery size, thus affecting range.

Furthermore, by limiting the payload capacity, there is a decrease in the load that a vehicle can carry per trip, which doesn’t exactly make for viable logistical economics.

Finally, there is always going to be the efficiency vs performance tradeoff that automakers have to deal with.

BEVs vs FCEVs

Downtime is one of the factors where FCEVs currently outclass BEVs. The refueling time for an FCEV is almost as low as an ICEV (internal combustion engine vehicle), thus making it an attractive solution for long-distance drives.

For BEVs, the solution to this issue would be the development of megawatt-level charging stations. Reducing the charging time also allows designers to reduce the battery size (and hence weight), as it allows drivers to stop as frequently as needed for charging.

FCEVs or BEVs | Dorleco

Source: Hydrogen cars, fuel cells, etc.: what you need to know | BMW.com

Another major advantage for FCEVs is that they have the potential to utilize renewable energy solutions on a larger scale and increase the adoption of sustainable power sources faster. They also provide necessary enhancements to the operational and performance gaps found in existing batteries.

In general, FCEVs can prove to be more effective than BEVs for a driving style that mainly consists of long-distance travel, such as commercial trucks.

Furthermore, the payload-bearing capacity of an FCEV is more than a BEV on account of fuel cell powertrains being significantly lighter, thus allowing engineers to increase the energy capacity without affecting the overall weight by much.

The biggest advantage that a lithium-ion battery has over the fuel cell is the ability to meet the powertrain dynamic demands.

There may be many fuel cell configurations being developed right now for dynamic behavior, however fuel cells are inherently meant for non-dynamic/static behavior. With researchers in the lithium-ion battery industry working on solid-state cell solutions for mobility, there is hope for better dynamic behavior from batteries soon.

So, is one better than the other in all cases?

The debate of using BEVs over FCEVs, or vice versa, should be tackled from a different perspective, as it is more a question of which solution is befitting for which transportation needs.

BEVs can effectively serve a larger sector in the industry, but their shortcomings can be dealt with by sustainable FCEV solutions.

Lighter powertrains in FCEVs allow for an increase in energy capacity without affecting the overall weight, which in turn can allow for a better range.

Fuel cells also exhibit higher payload-bearing capacity and quicker charging (or refueling time), making it an attractive proposition for heavy-duty and long-distance applications.

The drawback of a fuel cell is that hydrogen is energy-intensive when it comes to production as well as storage, not to mention that the development of fuel cells is still in its early stages, making it quite costly as compared to lithium-ion batteries. Furthermore, lithium-ion batteries exhibit much better dynamic behavior than fuel cells.

BEVs and FCEVs aren’t two sides of the same coin by any means. Instead, one needs to look at them as two different paths that can be taken to solve the same problem – tackling the challenges of sustainable mobility.

BEV and FCEV Efforts at Dorle Controls

At Dorle Controls, we develop model-based software for fuel cells as well as battery chemistries. On the development side, we are working on SOC estimation algorithms using Kalman filters, cell balancing algorithms, as well as the thermal modelling and management of both these energy sources.

Integration of fuel cell controller with the BMS controller on a CAN architecture is in focus, as is the verification and validation of batteries through charging and discharging tests. We can also help you out with rapid control prototyping for battery systems using RaptorDev tools.

To know more about our software development capabilities for battery-specific requirements, write to [email protected].

Read More On

#Fuel Cell#Battery Electric Vehicles#BEVs over FCEVs#fuel cells#Advanced Driver#automotive industry#mechanical control#technology

0 notes

Link

BMW Group has started the production of its BMW iX5 Hydrogen model in the pilot plant in Munich. It is the first SAV (Sports Activity Vehicle) powered by hydrogen fuel

0 notes

Text

Researchers engineer nanoparticles using ion irradiation to advance clean energy, fuel conversion

MIT researchers and colleagues have demonstrated a way to precisely control the size, composition, and other properties of nanoparticles key to the reactions involved in a variety of clean energy and environmental technologies. They did so by leveraging ion irradiation, a technique in which beams of charged particles bombard a material.

They went on to show that nanoparticles created this way have superior performance over their conventionally made counterparts.

"The materials we have worked on could advance several technologies, from fuel cells to generate CO2-free electricity to the production of clean hydrogen feedstocks for the chemical industry [through electrolysis cells]," says Bilge Yildiz, leader of the work and a professor in MIT's Department of Nuclear Science and Engineering and Department of Materials Science and Engineering.

Read more.

#Materials Science#Science#Nanoparticles#Nanotechnology#Ions#Radiation#Energy#Fuel cells#Catalysts#MIT

25 notes

·

View notes

Text

6 Innovations in the Trucking Industry on the Road to Environmental Sustainability - Technology Org

New Post has been published on https://thedigitalinsider.com/6-innovations-in-the-trucking-industry-on-the-road-to-environmental-sustainability-technology-org/

6 Innovations in the Trucking Industry on the Road to Environmental Sustainability - Technology Org

It’s a pivotal time for the trucking industry when as environmental concerns mount on, stakeholder companies continue to shift gears towards innovations that promise a more sustainable future.

Beyond just compliance or good PR, it’s a drive toward efficiency and responsibility that benefits everyone and perhaps the very greater good of humanity.

These six groundbreaking advancements in truck technology are changing the landscape, not only curtailing emissions but also ramping up fuel efficiency.

Let’s take a closer look at these developments steering us toward eco-friendly logistics.

A truck on the road – illustrative photo. Image credit: Gabriel Santos via Unsplash, free license

1. The Rise of Electric Trucks

It’s no secret; electric vehicles are the vanguard in sustainable transportation. Now, this revolution is barrelling into the trucking industry. Pioneers like Tesla and Nikola are unveiling electric trucks that promise zero emissions without sacrificing power or range.

With giants like Daimler also entering the fray, electrification isn’t a distant dream—it’s an unfolding reality on our highways.

Transitioning from diesel to electric could cut down greenhouse gas emissions by a whopping 75 percent over time, demonstrating that the road to sustainability can be as clean as the energy propelling these innovative rigs.

2. Advancing Aerodynamics

Airflow matters. Today’s trucks such as the Peterbilt’s Model 579 are shedding the body builds of the past for sleeker designs that slice through air resistance like a knife through butter.

These advancements in aerodynamics play a crucial role in fuel economy, with manufacturers fine-tuning every curve for optimal performance.

From trailer skirts that reduce drag to futuristic cab shapes, these modifications are not just cosmetic; they’re part of a calculated strategy to burn less fuel and emit fewer pollutants — proving efficiency is as much about shape as it is about what’s under the hood.

3. Harnessing Hybrid Technology

Hybrid engines are another piece of the complex puzzle of sustainable trucking. These powertrains marry the best aspects of internal combustion engines with electric motors, creating a synergy that reduces fuel consumption and CO2 emissions.

Notably, they offer flexibility—enabling long-haul journeys without the range anxiety associated with pure electrics. What’s more, energy-recovery systems capture power typically lost during braking. It’s a smart pivot to hybrids now forming a bridge to fully electric futures, while delivering immediate environmental benefits on our roads today.

4. Alternative Fuels Take the Wheel

Beyond electrification, alternative fuels are revving up the trucking industry’s green transition. Natural gas, biodiesel, and even hydrogen fuel cells are stepping into the spotlight, challenging traditional diesel’s dominance.

These fuels burn cleaner, slashing emissions significantly. Consider liquified natural gas trucks that emit nearly 20% less greenhouse gasses than their diesel counterparts.

It’s a shift that acknowledges not one solution fits all. Rather, a diverse fuel portfolio may be key to achieving environmental sustainability on the freight routes crisscrossing our nation.

5. Smarter Trucks for a Greener Tomorrow

Integrated telematics and features like predictive cruise control are not mere add-ons; they are revolutionizing truck efficiency.

By analyzing terrain and optimizing speed, these smart systems ensure the engine runs only as hard as necessary, minimizing fuel use and emissions. This also extends the lifetime of the truck by a significant margin.

Fleet operators, noting these advantages, often upgrade to smarter trucks or seek pre-owned Peterbilt 579 trucks at fair prices to get these eco-friendly technologies without the steep cost of brand-new models. It’s clear: intelligence on the road is now measured in data points that lead to greener miles ahead.

6. Tire Innovations Rolling Out

Tires are the unsung heroes of fuel efficiency, where even small advancements can yield significant environmental gains. The latest innovations in tire technology focus on low rolling resistance, meaning trucks require less energy to keep the wheels turning.

Manufacturers are not just pumping out new rubber; they’re engineering tires that last longer and perform better under heavy loads.

This means fewer tire changes, reduced waste, and a lighter carbon footprint. For truckers, it’s an investment that pays dividends at the pump and for the planet.

Key Takeaways

Electric trucks are leading the charge in emission-free transport.

Aerodynamic designs directly translate to fuel savings and cleaner operations.

Hybrid technology offers a practical path to reducing reliance on diesel.

Diversifying into alternative fuels can cut greenhouse gas emissions markedly.

Telematics and smart cruising enhance efficiency across truck fleets.

Tire advancements play a critical role in eco-friendly driving without compromising performance.

As the trucking industry shifts into more sustainable gear, these six innovations spotlight a journey where environmental responsibility isn’t just a destination but a continuous drive. The road ahead is greener—and with every technological advance, we move closer to a cleaner horizon.

#aerodynamics#air#anxiety#bridge#Capture#carbon#carbon footprint#Cells#CO2#Companies#compliance#continuous#cosmetic#data#Developments#economy#efficiency#electric trucks#electric vehicles#electrification#emission-free#Emissions#energy#engine#engineering#engines#Environmental#Features#fuel#fuel cells

0 notes

Text

The global Fuel Cell Generator Market is projected to reach USD 2.1 billion in 2030 from USD 0.4 billion in 2023 at a CAGR of 25.4% according to a new report by MarketsandMarkets™.

#fuel cell generator market#fuel cell generator#fuel cell technology#fuel cells#fuel cell#hydrogen fuel cells#energy#power#electricity#power generation#utilities#renewable energy#renewable#energia#alternative energy#sustainable energy#hydrogen#hydrogen fuel#hydrogen economy#hydrogen generation#sustainableenergy#sustainability#renewable power#renewables#clean power#clean electricity#clean energy#energy generation

0 notes

Text

First Hydrogen's Hydrogen-Fuel-Cell Powered Vehicle Has an Unbeatable Range

Vancouver, British Columbia–(Newsfile Corp. – August 14, 2023) – First Hydrogen Corp. (TSXV: FHYD) (OTC Pink: FHYDF) (FSE: FIT) (“FIRST HYDROGEN” or the “Company“) is pleased to announce award-winning fleet management provider Rivus, which manages approximately 120,000 vehicles, has provided their positive report on the Company’s hydrogen-fuel cell powered vehicle (FCEV). The report’s overall…

View On WordPress

0 notes

Text

on the nature of void fluid . . .

We are back with another nerd post this time with speculative planetary science :0

Here, we have a cross section of the planet's crust. Ill go into more detail on each layer below ⬇️

The Surface

The "earth" in rain world was historically an ice world, with a weak sun and sheets of glaciers covering the surface. The only form of heat being from the earth itself. It doesn't take long to find large cave systems eroded by millenia of ice melt.

The erosion of the land from the great ice sheets created a jagged landscape of underground tunnels and pockets, shaped by the flow of the melting ice over time. The planet's crust is very hollow and thin thanks to this.

The Void Sea

As the water tunneled down into the earth, it collected in large underground pockets, kept as liquid by geothermal heat. These formed the planet's first true oceans, with life originating from communities around hydrothermal vents.

The Void Seas [yes, several!] are an ancient chemosynthetic ecosystem of extremophiles. The microbiome here has adapted to metabolize with as many different materials as available in this harsh environment, including inorganic substances, leading to the Void Sea's large appetite for the surface world and anything in it.

Of course, we know that microbes aren't the only denizens of the Void. The Void Worms are filter feeders supported by this microbial ecosystem! It may take tens of thousands of years for a Void Worm to reach the sizes seen—they don't stop growing.

Void Fluid Technology

As the Ancients expanded more and more into biotechnology, they discovered they could utilize many of the microbial cultures native to the Void Sea. Filtration facilities sought to isolate these species from one another, sorting for their individual uses and properties.

For example, iterators are the largest consumers of void fluid, using both domesticated and wild strains of microorganisms. The domesticated strains were repurposed into symbiotes to act as "cells," and so the blood of an iterator, or hemolymph, is a special mixture of these symbiotic void cultures.

And as living things, iterators do need to eat! In this case, nutrition comes from the underground bacterial soup. Yummy.

They have large-scale equivalents for almost every biological process, including digestion. The "stomachs" are vats of unrefined void fluid filled with symbiotic cultures that act as enzymes to prey upon native microbes and organic detritus. Or any unfortunate maintenance worker . . .

"Ascension"

The Void Sea is the origin of life, but also highly toxic to its children on the surface, eager to eat them alive. The activities of the microbiome as well as the output of the hydrothermal vents fill the caverns closest to the Seas with noxious fumes, causing hallucinations, delirium, and eventually death.

But ultimately, the Void Sea leaves no bodies. Whatever delusional creature makes it in, never returns. After all, those microorganisms evolved to consume whatever they could get.

#rain world#rainworld#rain world fanart#rw#rain world art#rain world lore#anyway it might sound far fetched but boy do real life organisms do funky things!#some bacteria can eat trash and make electricity#like you can power a light bulb with dirt#its called microbial fuel cells and theyre fascinating#sunshower lore

729 notes

·

View notes