#sandblasting

Text

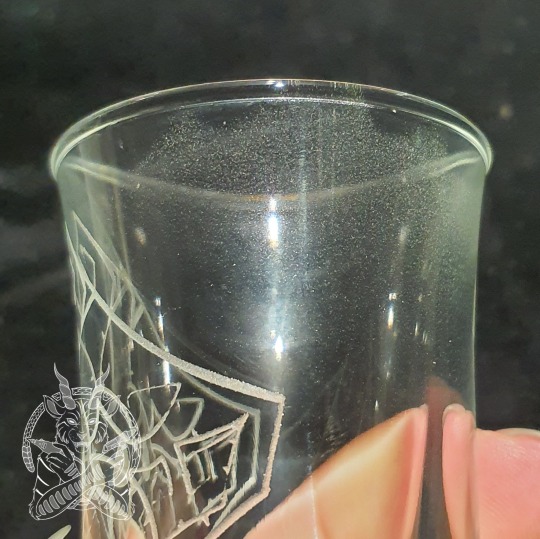

Made some shot glasses with the MSA Ghost skull emblem and spiky vines. Messed up a little and got kind of terrible overspray going on. Didn't mask off high enough nor was careful enough with the airstream direction while sandblasting, so there's some obvious frosting on the insides of three of them, and some less obvious but there-if-you-know-what-to-look-for on a fourth. One each of the big-skull-some-vines and small-skull-more-vines turned out fine.

Made these over a year ago, but didn't photograph them until today.

#msa ghost#mystery skulls animated#mystery skulls animated ghost#msa#skull#spiky vines#sandblasting#sandblasting is love sandblasting is life#shot glass#glasswork#coldworked glass#glassware#Chim made a thing#artisan crafts#artists on tumblr#fan art#fanart

42 notes

·

View notes

Text

suppository machine restoration | source

#it makes sausages. i think#talos gifs#stim gifs#stim#restoration#rust#mechanical#metal#metallic#tools#sandblaster#sandblasting#shiny#spraypaint#black#silver#screw#nuts and bolts#drill#wheel#wrench#gold#lathe#cat#irl hands#metalwork#long post

219 notes

·

View notes

Text

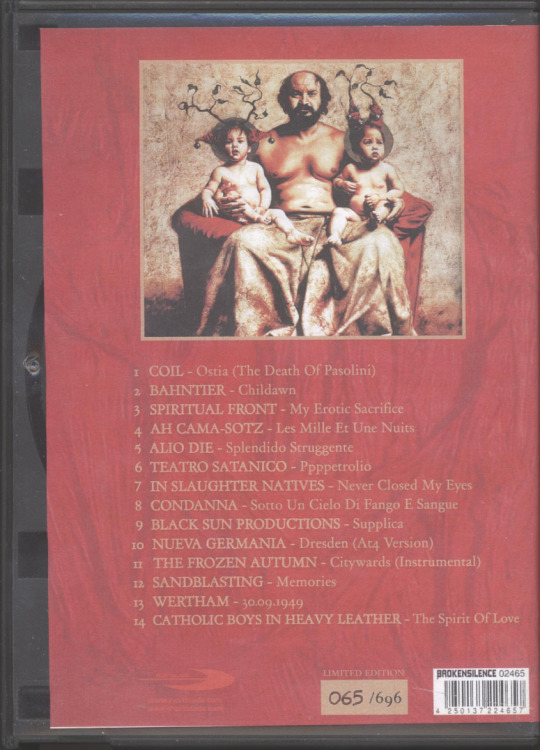

my bootleg copy of songs for a child a compilation tribute to pier paolo pasolini

#pier paolo pasolini#cds#bootleg#industrial#industrial music#coil#bahntier#spiritual front#ah cama-sotz#alo die#teatro satanico#in slaughter natives#condanna#black sun productions#nueva germania#the frozen autumn#sandblasting#wertham#catholic boys in heavy leather#goth#goth music#cultreslut

9 notes

·

View notes

Text

✨#Pregunta✨

¿Podría Gaara hacerle sandblasting a alguien hasta quitarle la piel de los huesos?

[ENG. Trans.: Could Gaara sandblast the skin out of someone until it's bare bone?]

4 notes

·

View notes

Text

Silicon carbide (SiC) and aluminum oxide (Al2O3) are two of the most commonly used abrasive materials in industrial applications. Both materials have unique properties that make them suitable for various applications. In this article, we will compare the properties of SiC and Al2O3 and highlight their differences.

2 notes

·

View notes

Audio

(sandblasting)

3 notes

·

View notes

Text

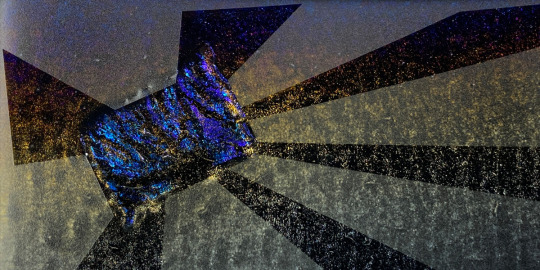

Amazing Iridised and Dichroic Platter. Fused Glass Project Tutorial

Amazing Iridised and Dichroic Platter. Fused Glass Project Tutorial

In this tutorial, we’ll be making a platter using iridised and dichroic glass. The technique is one I especially love as I’m sure you will.

The video tutorial includes the design, materials, and equipment information, as well as cutting the glass with a ring saw, and coldworking including sandblasting, fusing, fire polishing, and slumping.

(more…)

View On WordPress

#Bullseye glass#Dichroic glass#fused glass ideas#fused glass platter#fused glass project#fused glass techniques#fused glass tutorial#fusing projects#fusing techniques#glass fusing mold#glass fusing project#glass fusing tutorial#iridised glass#sandblasting#stainless steel mould

3 notes

·

View notes

Text

Sandblasting Services in NJ

Sandblasting is like a superhero for surfaces! It's all about blasting away dirt, rust, and old paint with high-speed abrasive materials. From reviving rusty cars to prepping surfaces for a fresh coat of paint, sandblasting does it all. It's the go-to choice for industries, artisans, and even DIY enthusiasts because it gets the job done right. With sandblasting, you can say goodbye to imperfections and hello to a smooth, clean surface ready for whatever comes next. So, if you're looking to give your project a fresh start, sandblasting is the way to go!

0 notes

Text

Revitalize Your Surfaces: Commercial Sandblasting Services In Melbourne

Are you looking for commercial sandblasting in Melbourne? If Yes! Then ProStrip Sandblasting is the best option for you. Our company specializes in commercial and industrial sandblasting and abrasive blasting in the automotive, trucking, marine, agricultural, road and rail, mining, and heavy industries. We have operated alongside top-tier commercial builders taking strict guidelines and following safety protocols. We are committed to delivering exceptional results and outstanding customer service, utilizing state-of-the-art equipment and techniques to achieve the desired finish. To learn more about our services, visit our website at prostripsandblasting.com.au today !

0 notes

Text

Discover the transformative power of our sandblasting services. Specializing in industrial equipment and decorative pieces, we expertly remove old coatings, rust, and grime, leaving surfaces clean and smooth. Trust our precision techniques for outstanding results. Contact us to discuss your sandblasting needs!

0 notes

Text

How to Prep Your Surface for Sandblasting: Steps for Success

Successful sandblasting relies heavily on proper surface preparation to achieve optimal results. Whether you're removing rust, paint, or corrosion, thorough surface preparation is essential to ensure adhesion, longevity, and the desired finish of the coating or substrate.

Here are the steps for prepping your surface for sandblasting:

1. Clean the Surface: Before sandblasting, remove any loose debris, dirt, grease, or contaminants from the surface using a solvent, degreaser, or pressure washer. A clean surface ensures proper adhesion and prevents contaminants from embedding into the substrate during sandblasting.

2. Assess the Surface Condition: Inspect the surface for any cracks, corrosion, or damage that may affect the sandblasting process or the integrity of the substrate. Repair any defects or imperfections before proceeding with sandblasting to ensure a smooth and uniform finish.

3. Select the Right Abrasive Material: Choose the appropriate abrasive material based on the surface material, condition, and the desired outcome of the project. Consider factors such as hardness, particle size, and aggressiveness to achieve optimal results without causing damage to the substrate.

4. Adjust Equipment Settings: Calibrate the sandblasting equipment, including the pressure, nozzle size, and abrasive flow rate, to suit the surface material and the level of material removal required. Test the equipment settings on a small inconspicuous area before proceeding with the full sandblasting process.

5. Wear Personal Protective Equipment (PPE): Ensure all operators wear appropriate PPE, including respirators, goggles, gloves, and protective clothing, to protect against airborne dust, abrasive particles, and debris generated during sandblasting.

6. Establish Containment Measures: Set up containment measures such as tarps, barriers, or enclosures to contain and collect abrasive media, dust, and debris generated during sandblasting. Proper containment prevents environmental contamination and ensures a safe working environment.

7. Sandblast in Controlled Conditions: Perform sandblasting in a controlled environment with adequate ventilation and lighting to ensure visibility and safety. Monitor weather conditions, humidity levels, and temperature to prevent moisture contamination or condensation on the surface.

8. Monitor Progress and Adjust as Needed: Regularly inspect the surface during sandblasting to assess progress and adjust equipment settings or techniques as needed. Avoid overblasting or excessive material removal, which can cause damage or surface roughness.

9. Post-Blast Surface Treatment: After sandblasting, clean the surface to remove any residual abrasive media, dust, or debris. Apply a protective coating or primer to prevent corrosion, rust, or contamination of the newly blasted surface.

In conclusion, avoiding common mistakes in sandblasting requires thorough preparation, proper equipment setup, adherence to safety protocols, and attention to detail throughout the process. By being aware of these common pitfalls and taking proactive measures to prevent them, you can ensure a successful sandblasting project with optimal results and minimal risks.

0 notes

Text

Mystery Skulls Animated glitter jar, sandblasted with the MSA skull emblem and filled with pink glitter and glow powder in mineral oil.

[Video description: Small glass jar with black plastic screw-top lid, held between thumb and index finger. Size of jar is approximately 3.5cm total height and 1.5cm in diameter. The outer surface is sandblasted with two Mystery Skulls Animated skull emblems, on opposite sides of the jar. The jar is filled with a mix of pink glitter and glow powder suspended in clear mineral oil. First part of the video is a slow turnaround of the jar, showing off the sandblasted parts. The glitter and glow powder has settled to the bottom of the jar.

Second part of the video shows the jar being flipped and twisted around to get the the glitter and glow powder cascading down and swirling around. Third part of the video is the same twirling-about thing but in the dark, to show off the pink glow. End description.]

#glitter jar#Mystery Skulls Animated#MSA#MSA Ghost#Mystery Skulls Animated Ghost#fan art#fanart#glitter#glow powder#UV reactive#glow in the dark#sandblasting#sandblasting is love sandblasting is life#glasswork#coldworked glass#glass#I will put glow powder on or in absolutely every piece of art that I can#Chim made a thing#artisan crafts#artists on tumblr

37 notes

·

View notes

Text

The Diesel Air Compressor with an After-Cooler 50-275CFM is a high-performance, heavy-duty machine designed for demanding industrial applications. The air compressor for sand blaster features a powerful diesel engine and an after-cooler system that reduces moisture and heat, enhancing the compressor’s efficiency and longevity. With a capacity of 50-275 cubic feet per minute, the air compressor needed for sandblasting delivers consistent, reliable air pressure for various tasks. This robust and versatile compressor is an ideal choice for construction, mining, and other industries requiring substantial and steady air power.

How Often Should I Service The After-Cooler 50-275CFM Diesel Air Compressors for Sand Blaster?

The frequency of servicing the after-cooler diesel air compressors 50-275CFM can depend on the usage and the environment in which it operates. However, as a general rule, it is recommended to service this diesel powered air compressor every 500-1000 hours of operation. Regular maintenance includes checking and cleaning the after-cooler, changing the oil, replacing the air filter, and inspecting for any potential issues. Always refer to the manufacturer’s guidelines for specific maintenance schedules. Remember, regular servicing not only ensures the efficient operation of the air compressor needed for sandblasting but also extends its lifespan.

Can A Diesel Air Compressor With An After-Cooler 50-275CFM Be Used In Any Environment?

A diesel air compressor for sand blaster with an after-cooler 50-275CFM can be used in a variety of environments, but not all. The sand blaster air compressor is designed to withstand harsh conditions and is often used in construction, mining, and other heavy-duty applications. However, this air compressor size for sandblasting may not be suitable for environments with extreme temperatures, high humidity, or corrosive elements. Additionally, the air compressor needed for sandblasting should not be used in enclosed spaces without proper ventilation due to the risk of diesel exhaust fumes. Therefore, while this type of compressor is highly versatile and robust, it is important to consider the specific environmental conditions before use.

0 notes

Text

Unlock Versatility and Power with Skid Steer & Track Loader Rentals: Get the Job Done with Ease

When it comes to heavy-duty construction, landscaping, or agricultural projects, having the right equipment can make all the difference. Skid steers and track loaders are versatile machines that excel in maneuverability and power. In this blog, we will explore the benefits of renting skid steers and track loaders from a reputable rental company like EZ Equipment Rental, and how they can help you accomplish your tasks with ease.

Versatility for Various Applications:

Skid steer and track loader rentals offers access to a range of attachments and configurations that allow these machines to adapt to various tasks. Whether you need to move and load materials, clear debris, grade surfaces, or excavate, these machines can handle it all. With a wide selection of attachments such as buckets, forks, grapples, and augers, skid steers and track loaders can be tailored to meet the specific requirements of your project, providing unmatched versatility and efficiency.

Power and Performance:

Skid steers and track loaders are known for their exceptional power and performance. These machines are equipped with powerful engines and robust hydraulic systems, enabling them to handle heavy loads and challenging terrain. By renting from a trusted rental company like EZ Equipment Rental, you can be assured that you'll have access to well-maintained machines that deliver optimal performance. The combination of power and performance ensures that you can complete your tasks efficiently, saving time and effort.

Enhanced Maneuverability and Accessibility:

Skid steers and track loaders are designed for exceptional maneuverability, making them ideal for projects in confined spaces or uneven terrain. Their compact size allows them to navigate through tight spaces with ease, while their tracked or wheeled configurations provide stability and traction on various surfaces. Whether you're working in construction sites, landscaping projects, or agricultural fields, these machines can reach areas that larger equipment cannot. Renting skid steers and track loaders allows you to benefit from their agility and accessibility, ensuring that you can tackle any job, no matter the environment.

Expert Guidance and Support:

Navigating the world of skid steers and track loaders can be overwhelming, especially for first-time users. EZ Equipment Rental offers expert guidance and support to assist you in selecting the right machine and attachments for your project. Their knowledgeable staff can provide operational training, safety guidelines, and recommendations, ensuring a smooth rental experience.

Conclusion:

Renting skid steers and track loaders from a reputable rental company like EZ Equipment Rental unlocks the versatility, power, and efficiency needed to accomplish a wide range of projects. With their wide selection of machines, enhanced maneuverability, and expert support, renting is the smart choice for achieving success in construction, landscaping, and agricultural endeavors.

#industrial equipment#equipment rental#manufacturing#dump trailer#trailers rental#sandblasting#forklift rental#insulation removal

0 notes

Text

A good mirror always spread the good vibes! We provide high quality mirror with any size and customization!

Contact us for your free quote right now!

WhatsApp on +971-525577392

https://www.dubaiglassmirror.com

0 notes

Text

What Are the Different Industries That Benefit from Sandblasting?

Fine particles are propelled at great speeds in this abrasive blasting technique to clean, smooth, or shape surfaces. You can hire the best sandblasting service in Dubai for a variety of purposes. Now let’s explore the various sectors that have used sandblasting to get the best outcomes possible in their particular fields. Read this blog

0 notes